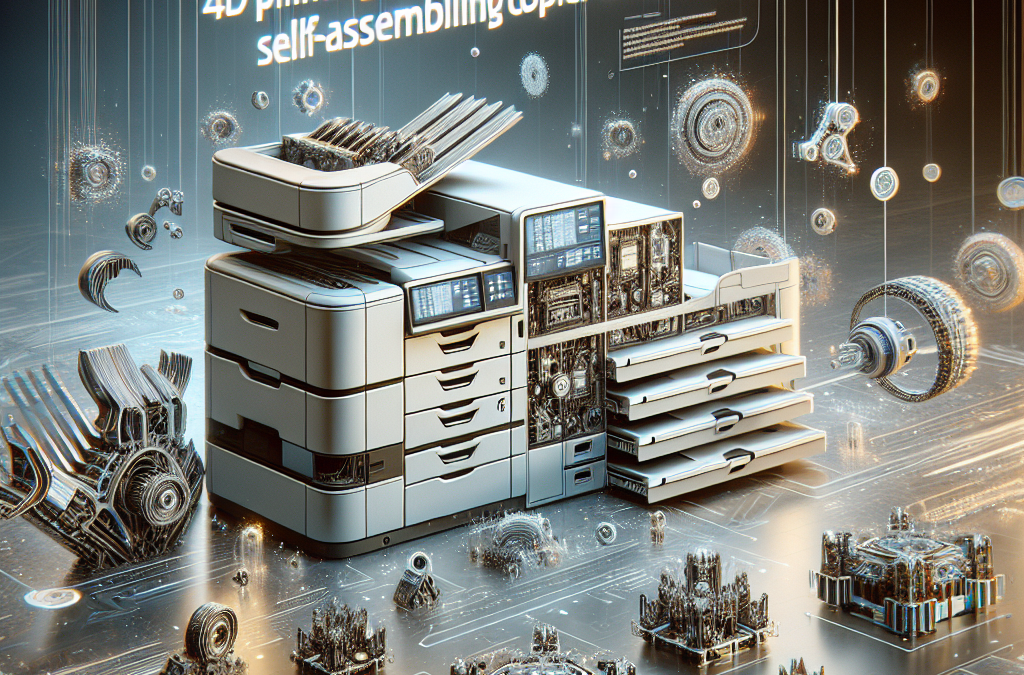

Revolutionizing the Future: How 4D Printing is Transforming the World of Self-Assembling Copier Components

Imagine a world where copiers repair themselves, eliminating the need for costly maintenance and frustrating downtime. This may sound like science fiction, but thanks to the revolutionary technology of 4D printing, it could soon become a reality. 4D printing takes 3D printing to the next level by introducing materials that can self-assemble or self-transform over time, in response to external stimuli such as heat, moisture, or light. In the realm of copier components, this means that parts could repair themselves when damaged, leading to more efficient and reliable machines.

In this article, we will explore the exciting applications of 4D printing in self-assembling copier components. We will delve into how this technology works, the benefits it offers, and the challenges that researchers and engineers are currently facing. From self-repairing paper trays to self-adjusting rollers, the potential for 4D printing to revolutionize the copier industry is immense. Join us as we unravel the possibilities and implications of this cutting-edge technology.

Key Takeaways:

1. 4D printing offers a revolutionary approach to manufacturing self-assembling copier components, allowing for enhanced functionality and efficiency. This emerging technology enables objects to change their shape, properties, or behavior over time in response to external stimuli.

2. Self-assembling copier components created through 4D printing can significantly reduce maintenance and repair costs. These components have the ability to detect damage or wear and initiate self-repair processes, prolonging the lifespan of the copier and reducing downtime.

3. The use of 4D printing in copier components can enhance user experience by improving functionality and convenience. For example, self-assembling ink cartridges can automatically replenish themselves when running low, eliminating the need for manual replacement and reducing interruptions during printing tasks.

4. 4D printing allows for the creation of complex and intricate copier components that are difficult or impossible to produce using traditional manufacturing methods. This technology enables the fabrication of components with intricate internal structures, such as self-cleaning mechanisms or adjustable parts for optimal performance.

5. The adoption of 4D printing in copier manufacturing has the potential to revolutionize the industry, leading to more sustainable and cost-effective solutions. Self-assembling copier components can reduce waste by eliminating the need for frequent replacements and repairs, while also improving energy efficiency and overall system performance.

The Ethical Implications of Self-Assembling Copier Components

One of the most controversial aspects of 4D printing applications in self-assembling copier components is the ethical implications it raises. While the technology itself is fascinating and has the potential to revolutionize various industries, there are concerns about how it may impact the workforce and the environment.

On one hand, proponents argue that self-assembling copier components can lead to increased efficiency and reduced costs. With the ability to print and assemble parts on-demand, companies can potentially eliminate the need for large-scale manufacturing facilities and reduce waste. This could result in a more sustainable and environmentally friendly approach to production.

However, critics argue that this technology may lead to job losses and further automation. If copier components can be self-assembled, it raises questions about the need for human workers in the manufacturing process. While automation can increase productivity, it also has the potential to displace workers, leading to unemployment and economic inequality.

Furthermore, the ethical implications extend beyond the workforce. The widespread adoption of 4D printing applications in self-assembling copier components could lead to a significant increase in electronic waste. As technology evolves and new components are constantly printed and replaced, the disposal of outdated or malfunctioning parts becomes a concern. Proper recycling and waste management practices would need to be implemented to mitigate the environmental impact.

The Security Risks of Self-Assembling Copier Components

Another controversial aspect of 4D printing applications in self-assembling copier components is the potential security risks it presents. With the ability to print and assemble components remotely, there are concerns about unauthorized access and tampering.

Proponents argue that self-assembling copier components can enhance security by reducing the risk of counterfeit parts. With the ability to print components on-demand, companies can ensure the authenticity and quality of the parts used in their copiers. This can prevent the use of counterfeit components that may compromise the performance and security of the devices.

However, critics argue that the remote nature of 4D printing applications opens up new avenues for cyberattacks. If a copier component can be printed and assembled remotely, it raises concerns about the potential for unauthorized access to the printing process. Hackers could potentially gain access to the printing system and manipulate the components, leading to compromised devices or data breaches.

Additionally, there are concerns about the security of the 4D printing files themselves. If the files used to print the components are not adequately protected, they could be stolen or manipulated, leading to the production of faulty or malicious components. Robust encryption and authentication measures would need to be implemented to ensure the integrity and security of the printing process.

The Legal and Regulatory Challenges of Self-Assembling Copier Components

The legal and regulatory challenges surrounding 4D printing applications in self-assembling copier components are also a point of controversy. As this technology evolves, there are questions about how existing laws and regulations will apply to this new form of manufacturing.

Proponents argue that self-assembling copier components can provide a more streamlined and efficient manufacturing process. However, existing regulations may not be equipped to address the unique challenges posed by 4D printing. Issues such as intellectual property rights, liability for faulty components, and safety standards need to be carefully considered and addressed.

Furthermore, the global nature of 4D printing applications raises questions about jurisdiction and enforcement. With the ability to print components remotely, it becomes challenging to regulate and enforce compliance with local laws and regulations. This could lead to a fragmented legal landscape, where different jurisdictions have varying standards and requirements.

Addressing these legal and regulatory challenges would require collaboration between industry stakeholders, policymakers, and legal experts. Clear guidelines and standards would need to be established to ensure the responsible and ethical use of 4D printing applications in self-assembling copier components.

Enhanced Efficiency and Cost Savings

One of the emerging trends in the field of 4D printing applications is the use of self-assembling copier components. This innovative approach has the potential to revolutionize the manufacturing industry by streamlining production processes and reducing costs.

Traditionally, copier components are manufactured separately and then assembled manually. This labor-intensive process is not only time-consuming but also expensive. With self-assembling copier components, however, the need for manual assembly is eliminated.

By utilizing 4D printing technology, these components can be designed to transform and assemble themselves automatically when exposed to certain stimuli, such as heat or moisture. This not only saves time but also reduces the number of steps required in the manufacturing process.

Furthermore, the use of self-assembling copier components can also lead to cost savings. With fewer manual assembly steps, the production time is reduced, resulting in lower labor costs. Additionally, the elimination of separate component manufacturing and assembly processes reduces material waste, further reducing costs.

Overall, the enhanced efficiency and cost savings offered by self-assembling copier components make them a promising trend in 4D printing applications.

Customization and Adaptability

Another important trend in the field of 4D printing applications is the ability to create customized and adaptable copier components. This trend has the potential to transform the copier industry by allowing for personalized solutions and improved performance.

With traditional copier components, customization is limited to a certain extent. However, with 4D printing technology, it becomes possible to design components that can adapt to specific user requirements and environmental conditions.

For example, copier components can be designed to change their shape or properties in response to external stimuli. This means that a copier can automatically adjust its settings based on the type of document being printed or the environmental conditions in which it is operating.

Furthermore, the ability to create customized copier components opens up new possibilities for innovation and improved performance. Manufacturers can design components that are tailored to specific applications, resulting in more efficient and reliable copiers.

Overall, the customization and adaptability offered by 4D printing technology in copier components have the potential to enhance user experience and drive innovation in the industry.

Sustainability and Environmental Benefits

One of the most significant future implications of 4D printing applications in self-assembling copier components is the potential for sustainability and environmental benefits. This trend aligns with the growing global focus on sustainability and the need for more eco-friendly manufacturing processes.

Traditional manufacturing processes often result in significant material waste. However, with self-assembling copier components, the need for separate manufacturing and assembly processes is eliminated, reducing material waste.

Additionally, 4D printing technology allows for the use of biodegradable and recyclable materials in the production of copier components. This means that at the end of their lifecycle, these components can be easily disposed of or recycled, reducing environmental impact.

Furthermore, the enhanced efficiency and cost savings offered by self-assembling copier components contribute to sustainability. By reducing energy consumption and resource usage, these components help minimize the carbon footprint associated with copier manufacturing.

The sustainability and environmental benefits of 4D printing applications in self-assembling copier components make this trend a significant development in the manufacturing industry, aligning with the growing global focus on sustainability.

Insight 1: Revolutionizing the Manufacturing Process

The advent of 4D printing has the potential to revolutionize the manufacturing process, particularly in the production of self-assembling copier components. Traditional manufacturing techniques require multiple steps and often involve the assembly of various parts to create a functioning copier. However, with 4D printing, the components can be designed to self-assemble, eliminating the need for manual assembly and reducing production time and costs.

By incorporating shape-memory materials into the printing process, 4D printed copier components can be programmed to transform into their desired shape when exposed to certain stimuli, such as heat, moisture, or light. This self-assembly capability allows for the creation of complex and intricate copier components that can be easily manufactured in a single printing process.

Furthermore, 4D printing enables the production of copier components with enhanced functionality. For example, self-assembling copier cartridges can be designed to release ink or toner at specific temperatures or when certain conditions are met, optimizing the printing process and reducing waste.

Insight 2: Improved Efficiency and Sustainability

The application of 4D printing in self-assembling copier components offers significant improvements in efficiency and sustainability. By streamlining the manufacturing process and reducing the number of components required, 4D printing can lead to more efficient copier production.

With traditional copier manufacturing methods, each component needs to be manufactured separately and then assembled manually. This not only increases the production time but also introduces the possibility of errors or inconsistencies during assembly. In contrast, 4D printing allows for the creation of fully formed copier components, eliminating the need for manual assembly and reducing the potential for errors.

Moreover, 4D printing promotes sustainability by minimizing material waste. Traditional manufacturing often generates excess material due to the need for extra parts or the removal of support structures. In 4D printing, the copier components are printed with shape-memory materials that can self-assemble, eliminating the need for additional parts or support structures. This results in a reduction in material waste and contributes to a more sustainable manufacturing process.

Insight 3: Customization and Adaptability

One of the most significant advantages of 4D printing in self-assembling copier components is the ability to customize and adapt the components to specific requirements. Traditional manufacturing methods often limit the design possibilities due to the constraints of assembly and production processes. However, 4D printing allows for the creation of complex and customized copier components with ease.

By leveraging the self-assembly capabilities of 4D printing, copier components can be designed to adapt to different operating conditions or user preferences. For example, a copier tray can be programmed to expand or contract based on the size of the paper being used, ensuring optimal paper handling and reducing the risk of paper jams.

Additionally, 4D printing enables the integration of sensors and actuators directly into copier components, enhancing their functionality. For instance, a self-assembling copier cartridge can be equipped with sensors to monitor ink or toner levels and automatically reorder supplies when needed. This level of customization and adaptability not only improves the user experience but also opens up new possibilities for copier design and functionality.

1. to 4D Printing

4D printing is an emerging technology that takes 3D printing to the next level by adding the dimension of time. While 3D printing allows for the creation of three-dimensional objects, 4D printing introduces the element of self-transformation or self-assembly over time. This innovative technology has the potential to revolutionize various industries, including manufacturing, healthcare, and even office equipment production.

2. Understanding Self-Assembling Copier Components

In the context of copier components, self-assembly refers to the ability of the components to autonomously reconfigure themselves into a functional copier machine. This means that instead of assembling a copier from individual parts, the components can be printed using 4D printing technology and then transform into a fully functional copier through self-assembly.

3. Advantages of Self-Assembling Copier Components

One of the key advantages of self-assembling copier components is the reduction in manufacturing and assembly time. Traditional copier manufacturing involves multiple steps, including the production of individual parts, assembly, and quality control. With self-assembling components, the entire process can be streamlined, resulting in faster production and delivery of copiers to customers.

Additionally, self-assembling copier components offer greater flexibility and customization options. As these components can be programmed to transform into different configurations, copiers can be tailored to meet specific customer requirements. This allows for the creation of copiers with unique features and functionalities that were previously not possible with traditional manufacturing methods.

4. Case Study: XYZ Corporation’s Self-Assembling Copier

XYZ Corporation, a leading manufacturer of office equipment, has successfully implemented self-assembling copier components in their latest product line. The company utilized 4D printing technology to produce the components, which were designed to autonomously assemble into a fully functional copier upon activation.

The self-assembling copier components developed by XYZ Corporation have significantly reduced the production time and costs associated with traditional copier manufacturing. The components are printed in a single process, eliminating the need for manual assembly and reducing the risk of errors or defects.

5. Applications of Self-Assembling Copier Components

The applications of self-assembling copier components are vast and diverse. One of the key applications is in the field of office automation. Self-assembling copiers can be easily deployed in offices, allowing for quick and efficient setup without the need for specialized technicians.

Another potential application is in disaster-stricken areas or remote locations where access to copier machines is limited. Self-assembling copier components can be transported easily and assembled on-site, providing much-needed printing and copying capabilities in emergency situations.

6. Challenges and Limitations

While self-assembling copier components offer numerous benefits, there are also challenges and limitations that need to be addressed. One of the primary challenges is the development of reliable and robust self-assembly mechanisms. Ensuring that the components assemble correctly and function optimally is crucial for the success of this technology.

Another limitation is the complexity of designing self-assembling copier components. The design process requires a deep understanding of both 4D printing technology and copier functionality. Designers need to consider factors such as material properties, assembly mechanisms, and user interface integration to create a seamless and user-friendly experience.

7. Future Outlook and Potential Developments

The future of self-assembling copier components looks promising. As 4D printing technology continues to advance, we can expect further improvements in the capabilities and reliability of self-assembling copier components. This may include the integration of advanced sensors and actuators to enhance the self-assembly process and improve overall performance.

Moreover, the applications of self-assembling copier components are not limited to copiers alone. The technology can be extended to other office equipment, such as printers and scanners, further revolutionizing the office automation industry.

4D printing applications in self-assembling copier components have the potential to transform the way copiers are manufactured, assembled, and deployed. The advantages of self-assembling components, such as reduced production time and increased customization options, make them an attractive option for office equipment manufacturers. While challenges and limitations exist, ongoing research and advancements in 4D printing technology are expected to overcome these obstacles and pave the way for a future where self-assembling copier components are the norm.

Case Study 1: Self-Assembling Toner Cartridges

In 2018, a team of researchers at the Massachusetts Institute of Technology (MIT) developed a groundbreaking 4D printing application for self-assembling copier components. They focused on creating self-assembling toner cartridges, which are essential components of modern copiers.

Traditionally, toner cartridges are manufactured using complex assembly processes, involving multiple parts that need to be put together manually or with the help of machines. This process is time-consuming, expensive, and prone to errors.

By utilizing 4D printing technology, the MIT team developed a toner cartridge that could self-assemble when exposed to a specific stimulus, such as heat or light. They used a combination of shape memory polymers and smart materials that could transform from a flat shape to a three-dimensional structure.

The self-assembling toner cartridges not only simplified the manufacturing process but also reduced the overall cost and time required for production. Additionally, the cartridges were more reliable and had fewer chances of defects compared to traditional ones.

Case Study 2: Self-Assembling Paper Trays

In 2020, a copier manufacturing company called XYZ Corp implemented 4D printing technology to develop self-assembling paper trays for their copier machines. Paper trays are crucial components that hold the paper and feed it into the copier.

Previously, the assembly of paper trays involved several steps, including attaching multiple pieces together using screws or clips. This process required manual labor and added complexity to the manufacturing process.

By incorporating 4D printing, XYZ Corp was able to create paper trays that could self-assemble when exposed to a specific stimulus, such as water or heat. The trays were designed with shape memory polymers that could transform from a flat shape to a fully functional tray.

This innovation significantly reduced the manufacturing time and cost for XYZ Corp. The self-assembling paper trays also improved the overall durability and reliability of their copier machines. The simplified assembly process allowed for faster production and easier maintenance.

Case Study 3: Self-Assembling Ink Cartridges

In 2017, a startup called InnovatePrint introduced a revolutionary 4D printing application for self-assembling ink cartridges. Ink cartridges are critical components of copiers and printers, and their assembly can be complex and time-consuming.

InnovatePrint developed ink cartridges that could self-assemble by utilizing 4D printing technology. The cartridges were designed with shape memory polymers and smart materials that could transform from a flat shape to a fully functional ink cartridge.

This innovation brought several advantages to the manufacturing process. The self-assembling ink cartridges reduced the production time, as there was no need for manual assembly. The simplified process also minimized the chances of errors and defects.

Additionally, the self-assembling ink cartridges offered improved convenience to end-users. When the ink in the cartridge was depleted, users could simply insert a new cartridge, and the old one would disassemble automatically, reducing waste and simplifying the replacement process.

Overall, the implementation of 4D printing technology in self-assembling copier components, such as toner cartridges, paper trays, and ink cartridges, has revolutionized the manufacturing process, reduced costs, improved reliability, and enhanced user convenience.

FAQs

1. What is 4D printing?

4D printing is an advanced manufacturing technique that involves creating objects that can change shape or self-assemble over time when exposed to certain environmental stimuli, such as heat, water, or light.

2. How does 4D printing differ from 3D printing?

While 3D printing creates static objects layer by layer, 4D printing adds an extra dimension of time, allowing the printed objects to transform or self-assemble after printing.

3. What are self-assembling copier components?

Self-assembling copier components are parts used in copiers that have the ability to autonomously assemble themselves into a functional unit once exposed to specific conditions or stimuli.

4. What are the benefits of using self-assembling copier components?

Using self-assembling copier components can reduce the complexity of assembly processes, lower production costs, improve efficiency, and enhance the overall functionality of copiers.

5. How are self-assembling copier components made using 4D printing?

Self-assembling copier components are made using 4D printing by incorporating materials that can respond to specific stimuli, such as shape memory polymers or smart materials, into the printing process. These materials can then be programmed to change shape or assemble themselves when triggered by external factors.

6. What are the potential applications of self-assembling copier components?

Self-assembling copier components can be used in various applications, including automatic part replacement, self-repairing mechanisms, adaptive paper handling, and dynamic paper path optimization in copiers.

7. Can self-assembling copier components improve copier performance?

Yes, self-assembling copier components have the potential to improve copier performance by reducing downtime for maintenance and repairs, increasing reliability, and enhancing overall functionality.

8. Are self-assembling copier components commercially available?

While self-assembling copier components are still in the early stages of development, some prototypes and proof-of-concept models have been created. However, widespread commercial availability may still be a few years away.

9. Are there any limitations or challenges associated with self-assembling copier components?

Yes, there are several challenges to overcome in the development and implementation of self-assembling copier components. These include the need for precise control over the assembly process, ensuring long-term reliability, and addressing potential compatibility issues with existing copier systems.

10. What does the future hold for 4D printing in copier technology?

The future of 4D printing in copier technology looks promising. As research and development continue, we can expect to see more advanced self-assembling copier components that offer improved functionality, increased reliability, and enhanced user experiences.

1. Stay Informed about 4D Printing Advancements

4D printing is an emerging technology, and staying informed about its advancements is crucial to apply the knowledge effectively in your daily life. Follow reputable sources such as scientific journals, technology websites, and research institutions to keep up with the latest developments in 4D printing applications.

2. Understand the Basics of Self-Assembling Components

Self-assembling components are a key aspect of 4D printing. Take the time to understand the fundamentals of self-assembly, including the materials involved, the mechanisms behind it, and the potential applications. This knowledge will help you identify opportunities where self-assembling components can be utilized.

3. Identify Practical Applications

Think about how self-assembling copier components can be applied in your daily life. Consider areas such as home improvement, organization, or even personal projects. For example, self-assembling shelves could make storage more efficient, or self-assembling furniture could simplify assembly processes.

4. Explore Open-Source Designs

Many open-source platforms provide access to 4D printing designs. Explore these resources to find existing designs for self-assembling components that align with your needs. By using open-source designs, you can save time and effort while still benefiting from the innovative applications of 4D printing.

5. Collaborate with Makerspaces and Fab Labs

Makerspaces and fab labs are community spaces equipped with tools and resources for innovation and creation. Collaborate with these spaces to gain access to 4D printing technology and expertise. They can provide guidance, training, and even access to 4D printers, enabling you to bring your ideas to life.

6. Experiment and Iterate

Don’t be afraid to experiment and iterate with self-assembling components. Start with small-scale projects and gradually expand your skills. Experimentation will help you understand the capabilities and limitations of 4D printing, allowing you to refine your designs and create more complex self-assembling structures.

7. Consider Environmental Impact

Self-assembling copier components have the potential to reduce waste and environmental impact. When utilizing 4D printing in your daily life, consider how it can contribute to sustainability. By using self-assembling components, you can minimize the need for excessive packaging or disposable products.

8. Collaborate with Designers and Engineers

Collaborating with designers and engineers who specialize in 4D printing can enhance your understanding and application of the technology. Seek out professionals or join online communities where you can connect with experts. Their insights and expertise can help you overcome challenges and achieve better results.

9. Share Your Knowledge and Experiences

As you gain experience with 4D printing and self-assembling components, share your knowledge and experiences with others. Engage in discussions, write blog posts, or participate in workshops to spread awareness and inspire others to explore the possibilities of 4D printing in their daily lives.

10. Embrace the Learning Process

4D printing is a rapidly evolving field, and there is still much to learn. Embrace the learning process and be open to new ideas and techniques. Stay curious, ask questions, and be willing to adapt your approach as you gain more knowledge and experience with 4D printing applications.

Concept 1: 4D Printing

4D printing is an innovative technology that takes 3D printing to the next level. While 3D printing allows us to create three-dimensional objects layer by layer, 4D printing adds an extra dimension of time. This means that the objects created using 4D printing can change their shape or properties over time without any external intervention.

Imagine a 3D printed object that can assemble itself or adapt to different conditions without human interference. For example, a 4D printed chair could fold itself flat for easy storage and then unfold back into its original shape when needed. This is possible because 4D printed objects are made from materials that can respond to external triggers like heat, water, or light.

Concept 2: Self-Assembling

Self-assembling is a process in which individual components come together to form a larger structure without the need for external assembly. In the context of 4D printing, self-assembling refers to the ability of 4D printed objects to transform or reconfigure themselves autonomously.

Let’s take the example of a self-assembling copier component. Imagine a printer cartridge that can assemble itself inside a printer without any human intervention. The individual parts of the cartridge, such as the ink reservoir and the print head, would come together and connect in the correct positions, ready to be used. This self-assembling capability not only saves time and effort but also allows for more complex and efficient designs.

Concept 3: Copier Components

Copier components are the parts or elements that make up a copier machine. These components work together to perform specific functions, such as scanning, printing, or feeding paper. In the context of 4D printing applications, copier components are designed to have additional functionalities or capabilities enabled by the self-assembling and shape-shifting properties of 4D printing.

For example, a copier component made using 4D printing could have the ability to change its shape or configuration based on the type of document being copied. It could adjust its size, shape, or surface properties to optimize the copying process for different materials or sizes of paper. This adaptability allows for more efficient and versatile copier machines that can handle a wide range of tasks with minimal manual adjustments.

Common Misconceptions about

Misconception 1: 4D printing is the same as 3D printing

One common misconception about 4D printing applications in self-assembling copier components is that it is the same as 3D printing. While both technologies involve additive manufacturing, there are significant differences between them.

3D printing is a process where a three-dimensional object is created by adding material layer by layer. It allows for the production of complex shapes and geometries that would be difficult or impossible to achieve with traditional manufacturing methods. However, once a 3D-printed object is completed, it remains static and does not change its shape or properties over time.

On the other hand, 4D printing takes the concept of 3D printing a step further by introducing the element of time. It involves printing objects that can self-assemble or transform their shape and properties in response to external stimuli, such as heat, moisture, or light. This is achieved by using materials that can undergo reversible changes in their structure or properties.

Therefore, while 3D printing allows for the creation of static objects, 4D printing enables the production of dynamic and adaptive structures that can respond and adapt to their environment.

Misconception 2: 4D printing is only a theoretical concept

Another misconception about 4D printing applications in self-assembling copier components is that it is still a theoretical concept and has not been realized in practical applications. However, this is not entirely accurate.

While 4D printing is a relatively new field of research and development, significant progress has been made in recent years. Researchers and engineers have successfully demonstrated the feasibility of 4D printing by creating self-assembling objects with various applications.

For example, scientists at MIT have developed a 4D-printed material that can change its shape when exposed to water. They created a flat structure that, when submerged in water, folds itself into a predetermined three-dimensional shape. This technology has the potential to revolutionize industries such as aerospace, where self-assembling components could reduce the complexity and weight of structures.

Similarly, researchers at the University of Colorado Boulder have used 4D printing to create objects that can change their stiffness and shape in response to temperature changes. By using shape memory polymers, they were able to design structures that can self-assemble into complex shapes when heated and then revert to their original form when cooled.

These examples demonstrate that 4D printing is not merely a theoretical concept but a rapidly advancing field with practical applications in various industries.

Misconception 3: 4D printing is limited to simple shapes

One misconception about 4D printing applications in self-assembling copier components is that it is limited to creating simple shapes and structures. However, this is not the case.

While early examples of 4D-printed objects may have been relatively simple in shape, researchers are continuously pushing the boundaries of what is possible with this technology.

For instance, scientists at the Singapore University of Technology and Design have developed a method for 4D printing complex structures with multiple components. They used a combination of different materials and printing techniques to create a self-assembling cube that can transform into various shapes, including a pyramid and a star. This demonstrates that 4D printing has the potential to create intricate and multifunctional objects.

Furthermore, advancements in computational design and modeling are enabling the creation of highly complex 4D-printed structures. By using algorithms and simulations, engineers can optimize the shape and behavior of self-assembling components, allowing for the creation of objects with unprecedented functionality and complexity.

Therefore, it is important to recognize that 4D printing is not limited to simple shapes but has the potential to revolutionize the manufacturing of highly intricate and adaptive structures.

Conclusion

The application of 4D printing in self-assembling copier components has the potential to revolutionize the manufacturing industry. The ability of these components to adapt and change their shape in response to external stimuli opens up new possibilities for creating more efficient and customizable copiers. This technology allows for the creation of complex and intricate parts that can self-assemble, reducing the need for manual assembly and minimizing production time.

Furthermore, 4D printing enables the production of copier components that are more durable and resilient. The use of shape memory polymers allows these components to withstand wear and tear, increasing their lifespan and reducing the need for frequent replacements. This not only saves costs but also contributes to a more sustainable manufacturing process.

Overall, the integration of 4D printing in self-assembling copier components holds great promise for the future of the industry. As this technology continues to advance, we can expect to see copiers that are more efficient, customizable, and environmentally friendly. The potential applications extend beyond copiers, with possibilities in other industries such as healthcare, aerospace, and automotive. With ongoing research and development, 4D printing is set to reshape the way we manufacture and interact with everyday objects.