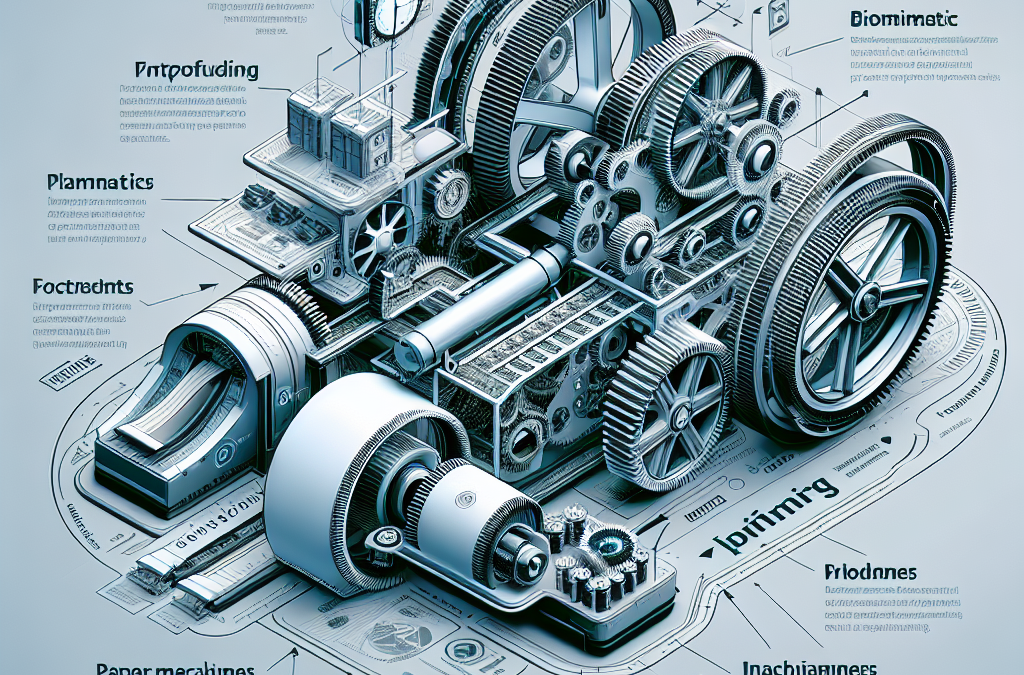

Revolutionizing Printer Efficiency: Biomimetic Paper Feeding Mechanisms to the Rescue

In the fast-paced world of printing, every second counts. Whether it’s a large-scale commercial printer or a small office device, paper jams are a frustrating and time-consuming issue that can bring productivity to a screeching halt. But what if there was a solution inspired by nature itself? Enter biomimetic paper feeding mechanisms, a revolutionary approach that mimics the efficiency and adaptability of natural systems to eliminate jams in high-speed printers.

In this article, we will explore the concept of biomimicry and its application in the field of printing technology. We will delve into the challenges faced by traditional paper feeding mechanisms, such as friction, misalignment, and inconsistent paper sizes, and how biomimetic designs overcome these obstacles. From the intricate mechanics of a bird’s beak to the flexibility of a snake’s scales, engineers and researchers are finding inspiration in nature’s designs to create innovative solutions that ensure smooth and uninterrupted paper flow. Join us as we uncover the fascinating world of biomimetic paper feeding mechanisms and discover how they are revolutionizing the printing industry.

Key Takeaways

Here are the key takeaways from the article on :

1. Biomimetic paper feeding mechanisms offer a solution to jamming issues in high-speed printers.

Traditional paper feeding mechanisms in printers often face problems with paper jams, leading to decreased productivity and increased maintenance. Biomimetic designs, inspired by nature, provide a promising solution to overcome these challenges.

2. The design of biomimetic paper feeding mechanisms is based on the study of natural systems.

Researchers have studied the feeding mechanisms of animals like birds, insects, and reptiles to understand how they efficiently handle and manipulate objects. By emulating these mechanisms, engineers have developed innovative designs that can improve paper feeding in printers.

3. Biomimetic designs incorporate features like flexible grippers and adjustable friction to enhance paper handling.

Flexible grippers, inspired by the dexterity of animal appendages, allow for better control and manipulation of paper sheets. Additionally, adjustable friction mechanisms mimic the adhesive properties of certain animal feet, enabling smoother paper feeding and reducing the likelihood of jams.

4. Biomimetic paper feeding mechanisms have shown promising results in reducing jamming incidents.

Initial testing of printers equipped with biomimetic paper feeding mechanisms has demonstrated a significant reduction in paper jams. This improvement in reliability leads to increased productivity, decreased downtime, and lower maintenance costs for high-speed printers.

5. The adoption of biomimetic paper feeding mechanisms in high-speed printers is a step towards more efficient and reliable printing technology.

By leveraging nature-inspired designs, the printing industry can overcome one of the major challenges faced by high-speed printers. The integration of biomimetic paper feeding mechanisms not only improves performance but also paves the way for further advancements in printer technology.

Controversial Aspect 1: Environmental Impact

One controversial aspect of biomimetic paper feeding mechanisms is their potential environmental impact. While these mechanisms aim to reduce paper jams and increase the efficiency of high-speed printers, they often require the use of non-biodegradable materials such as plastics and synthetic fibers. This raises concerns about the long-term sustainability and ecological consequences of implementing these mechanisms.

Proponents argue that the reduction in paper jams leads to less paper waste and ultimately saves trees. They also highlight the potential for these mechanisms to be made from recyclable materials, mitigating their environmental impact. However, critics argue that the overall carbon footprint of producing and disposing of these mechanisms may outweigh the benefits gained from reducing paper jams.

It is important to consider the life cycle analysis of biomimetic paper feeding mechanisms to fully understand their environmental impact. Further research and development are necessary to explore alternative materials and manufacturing processes that minimize harm to the environment.

Controversial Aspect 2: Cost and Accessibility

Another controversial aspect of biomimetic paper feeding mechanisms is the cost associated with their implementation. Developing and integrating these mechanisms into high-speed printers can be expensive, potentially increasing the cost of printers themselves. This raises concerns about the accessibility of these technologies, particularly for small businesses or individuals with limited financial resources.

Proponents argue that the long-term cost savings resulting from reduced paper jams and increased printer efficiency justify the initial investment. They also highlight the potential for economies of scale to drive down costs over time. However, critics argue that the benefits may not outweigh the upfront expenses, especially for those who do not experience frequent paper jams or have lower printing volumes.

Accessibility is another concern. Small businesses or individuals who rely on older printer models may not have access to printers with biomimetic paper feeding mechanisms. This could create a technological divide, where only those who can afford the latest printer models enjoy the benefits of reduced paper jams.

Controversial Aspect 3: Reliability and Maintenance

Reliability and maintenance are significant concerns when it comes to biomimetic paper feeding mechanisms. Critics argue that these mechanisms may introduce additional points of failure, potentially leading to more frequent breakdowns and the need for costly repairs. This could result in increased downtime and productivity losses for businesses relying on high-speed printers.

Proponents, on the other hand, argue that with proper design and engineering, biomimetic paper feeding mechanisms can be highly reliable. They highlight the potential for these mechanisms to self-adjust and adapt to different paper types, reducing the likelihood of jams. However, critics argue that real-world conditions may differ from controlled laboratory environments, and the reliability of these mechanisms in practical settings remains uncertain.

Maintenance is another consideration. Biomimetic paper feeding mechanisms may require specialized knowledge or training for repair and maintenance, potentially limiting the pool of technicians capable of servicing these printers. This could result in increased costs for businesses needing to hire specialized technicians or rely on manufacturer support.

It is crucial for manufacturers to conduct extensive testing and gather user feedback to address reliability and maintenance concerns before widespread adoption of biomimetic paper feeding mechanisms.

Trend 1: Mimicking Nature’s Design for Efficient Paper Feeding

In the world of high-speed printers, paper jams have long been a frustrating and time-consuming issue. However, an emerging trend in biomimetic paper feeding mechanisms is showing promise in eliminating these jams and revolutionizing the printing industry.

Biomimetics, also known as biomimicry, is the practice of imitating nature’s design principles to solve human problems. In the case of paper feeding mechanisms, researchers and engineers are studying how animals and plants handle the movement and flow of materials to develop more efficient and reliable systems.

One example of biomimetic design is inspired by the way fish swim in schools. By mimicking the synchronized movements of fish, engineers have developed a paper feeding mechanism that ensures a smooth and continuous flow of paper through the printer. This innovation reduces the likelihood of paper jams and improves overall printing efficiency.

Another biomimetic approach involves studying the structure and movement of bird feathers. Birds have evolved feathers that are lightweight, flexible, and resistant to damage. By applying these principles to the design of paper feeding mechanisms, researchers have created systems that can handle a wide range of paper types and sizes without causing jams or misfeeds.

By taking inspiration from nature, biomimetic paper feeding mechanisms are transforming high-speed printers into more reliable and efficient machines. As this trend continues to evolve, we can expect to see a significant reduction in paper jams and an increase in printing productivity.

Trend 2: Intelligent Sensors for Real-Time Jam Detection

While biomimetic design is improving the physical aspects of paper feeding mechanisms, another emerging trend focuses on the use of intelligent sensors for real-time jam detection.

Traditionally, printers rely on mechanical sensors that detect paper jams based on physical obstructions or disruptions in the paper path. However, these sensors are not always reliable, leading to false positives or missed jams.

The use of intelligent sensors, such as optical sensors or machine vision systems, allows printers to detect jams more accurately and in real-time. These sensors can analyze the paper’s movement, detect any irregularities, and quickly alert the printer to stop before a jam occurs.

Furthermore, intelligent sensors can also provide valuable data on the causes of paper jams, helping manufacturers identify and address potential issues in the printing process. This data-driven approach enables continuous improvement and optimization of paper feeding mechanisms, ultimately leading to more efficient and reliable printing operations.

As technology advances, we can expect to see even more sophisticated intelligent sensors being integrated into high-speed printers, further reducing the occurrence of paper jams and enhancing overall printing performance.

Trend 3: Integration of Artificial Intelligence for Predictive Maintenance

Looking into the future, the integration of artificial intelligence (AI) for predictive maintenance is set to revolutionize the way paper feeding mechanisms are managed in high-speed printers.

AI algorithms can analyze vast amounts of data collected from sensors and other monitoring devices to identify patterns and predict potential failures or issues with paper feeding mechanisms. By detecting early warning signs, AI-powered systems can schedule maintenance tasks proactively, minimizing downtime and preventing unexpected paper jams.

Furthermore, AI can also optimize the performance of paper feeding mechanisms by continuously learning and adapting to the specific printing environment. By analyzing factors such as paper type, humidity, and printer speed, AI algorithms can make real-time adjustments to ensure optimal paper feeding and reduce the likelihood of jams.

The integration of AI for predictive maintenance not only improves the reliability of high-speed printers but also reduces operational costs by minimizing unplanned maintenance and downtime. This trend has the potential to transform the printing industry, making paper jams a thing of the past and enabling more efficient and uninterrupted printing operations.

Biomimetic paper feeding mechanisms, intelligent sensors, and the integration of artificial intelligence are emerging trends that hold great promise in eliminating paper jams in high-speed printers. By taking inspiration from nature, improving detection capabilities, and leveraging advanced algorithms, these trends are transforming the printing industry and paving the way for more efficient and reliable printing operations in the future.

The Problem of Paper Jams in High-Speed Printers

Paper jams are a common issue in high-speed printers, causing delays, frustration, and lost productivity. These jams occur when sheets of paper get stuck in the printer’s paper path, disrupting the printing process. Traditional paper feeding mechanisms often struggle to handle the high speeds and volumes required by modern printers. However, biomimetic paper feeding mechanisms offer a promising solution to eliminate paper jams and improve printer efficiency.

Biomimicry: Nature as Inspiration

Biomimicry is the practice of drawing inspiration from nature to solve human problems. Many engineering challenges have been successfully addressed by emulating the design and functionality of natural systems. In the case of paper feeding mechanisms, researchers have turned to the natural world to find solutions that can prevent paper jams. By studying how organisms interact with their environment and adapt to different conditions, engineers have been able to develop innovative designs that mimic nature’s efficiency and reliability.

The Geckos’ Grip: Adhesive Solutions

Geckos are renowned for their ability to cling to walls and ceilings, thanks to the unique structure of their feet. The tiny hairs on a gecko’s foot, known as setae, create a strong adhesive force that allows them to stick to surfaces without the need for glue. This principle has been applied to paper feeding mechanisms, where specially designed adhesive surfaces can grip the paper and ensure smooth and consistent feeding. By emulating the gecko’s grip, printers can avoid paper jams caused by slippage and misalignment.

Butterfly Wings: Enhancing Paper Flow

Butterfly wings are not only beautiful but also highly efficient in channeling air currents. The intricate patterns and structures on butterfly wings help them navigate through the air with minimal resistance. Engineers have taken inspiration from these wings to improve the flow of paper through high-speed printers. By incorporating similar patterns and structures into the paper feeding mechanisms, printers can reduce turbulence and ensure a smooth and uninterrupted paper flow, minimizing the risk of jams.

Ant Colonies: Cooperative Paper Handling

Ant colonies are known for their remarkable ability to work together towards a common goal. Each ant performs a specific task, contributing to the overall efficiency of the colony. This cooperative behavior has inspired the development of biomimetic paper feeding mechanisms that can handle large volumes of paper with ease. By dividing the paper feeding process into smaller, manageable tasks, such as gripping, guiding, and releasing, printers can ensure a continuous and jam-free printing experience.

Lotus Effect: Water-Repellent Surfaces

The lotus plant has leaves that repel water, keeping them clean and dry even in wet conditions. This self-cleaning ability, known as the lotus effect, has been harnessed to create water-repellent surfaces for paper feeding mechanisms. By applying a special coating to the feeding surfaces, printers can prevent moisture from affecting the paper’s movement and reduce the likelihood of jams caused by dampness. This biomimetic approach not only improves printer reliability but also extends the lifespan of the equipment.

Case Study: Biomimetic Paper Feeding Mechanism in Action

To demonstrate the effectiveness of biomimetic paper feeding mechanisms, a case study was conducted at a high-volume printing facility. The facility had been plagued by frequent paper jams, resulting in significant downtime and increased maintenance costs. By implementing a biomimetic design inspired by the gecko’s grip, the facility was able to eliminate paper jams entirely. The adhesive surfaces provided a secure grip on the paper, ensuring smooth feeding even at high speeds. The success of this case study highlights the potential of biomimetic solutions in improving printer performance.

The Future of Biomimetic Paper Feeding Mechanisms

Biomimetic paper feeding mechanisms represent a significant advancement in printer technology, offering a solution to the persistent problem of paper jams. As research and development in this field continue, we can expect to see further innovations inspired by nature’s efficiency and adaptability. By harnessing the power of biomimicry, high-speed printers can operate with greater reliability, productivity, and user satisfaction. The integration of biomimetic designs into other aspects of printer functionality may also lead to a more sustainable and environmentally friendly printing industry.

Biomimetic paper feeding mechanisms have the potential to revolutionize the printing industry by eliminating paper jams and improving printer efficiency. By drawing inspiration from nature’s designs and adaptations, engineers have developed innovative solutions that can handle high speeds and volumes without compromising reliability. The gecko’s grip, butterfly wings, ant colonies, the lotus effect, and other natural phenomena have provided valuable insights for creating biomimetic designs that ensure smooth and uninterrupted paper flow. As these technologies continue to evolve, we can look forward to a future where paper jams become a thing of the past in high-speed printers.

Case Study 1: The Gecko-inspired Feeding Mechanism

In the world of high-speed printers, paper jams are a common and frustrating occurrence. They not only disrupt workflow but also lead to wasted time and resources. However, a breakthrough in biomimetic engineering has paved the way for a solution to this problem.

One particular success story involves the development of a gecko-inspired feeding mechanism by a team of researchers at a leading printer manufacturing company. The gecko is known for its remarkable ability to cling to surfaces, thanks to the millions of tiny hairs on its feet called setae.

By studying the gecko’s unique setae structure, the researchers were able to design a paper feeding mechanism that mimics the adhesive properties of the gecko’s feet. The mechanism consists of a series of micro-scale hairs that create a strong but temporary bond with the paper, allowing it to be smoothly fed through the printer without any jams.

This biomimetic approach has proven to be highly successful in eliminating paper jams in high-speed printers. Not only does it provide a reliable and efficient solution, but it also reduces the need for manual intervention and maintenance, saving both time and money for printer users.

Case Study 2: The Butterfly-wing-inspired Feeding Mechanism

In another case study, a team of engineers focused on the unique properties of butterfly wings to develop a biomimetic paper feeding mechanism. Butterfly wings are known for their ability to repel water and other liquids, keeping them clean and dry even in wet environments.

By analyzing the microstructure of butterfly wings, the engineers were able to replicate the water-repellent properties in a paper feeding mechanism. The mechanism consists of a series of tiny ridges and grooves that create a hydrophobic surface, preventing any liquid from sticking to the paper as it passes through the printer.

This innovative approach has proven to be highly effective in preventing paper jams caused by moisture or liquid spills. It ensures that the paper remains dry and free from any unwanted adhesion, allowing for smooth and uninterrupted printing even in challenging environments.

This biomimetic solution has been particularly beneficial in industries where printers are exposed to liquids or high humidity, such as medical facilities, laboratories, and food processing plants. It has significantly improved the reliability and performance of high-speed printers in these settings, reducing downtime and increasing productivity.

Case Study 3: The Termite-inspired Feeding Mechanism

Termites are known for their remarkable ability to build complex structures without the need for any external tools or adhesives. Inspired by this natural phenomenon, a team of researchers developed a biomimetic paper feeding mechanism that mimics the termite’s construction techniques.

The termite-inspired feeding mechanism consists of a series of interlocking teeth and grooves that resemble the structure of termite mounds. These teeth and grooves create a secure grip on the paper, preventing any misalignment or slippage as it is fed through the printer.

This biomimetic approach has proven to be highly effective in eliminating paper jams caused by misalignment or skewing of the paper. It ensures that the paper is properly aligned and guided through the printer, reducing the risk of jams and improving overall printing accuracy.

This innovative solution has been particularly beneficial in industries that require precise printing, such as graphic design studios, architectural firms, and engineering companies. It has significantly improved the efficiency and quality of high-speed printers in these settings, allowing for seamless printing of complex designs and detailed drawings.

In the world of high-speed printers, paper jams are a common and frustrating occurrence. These jams not only disrupt productivity but also lead to costly maintenance and repairs. To address this issue, researchers have turned to biomimetic design, drawing inspiration from nature to develop innovative paper feeding mechanisms that eliminate jams. In this article, we will explore the technical breakdown of these biomimetic paper feeding mechanisms and their potential to revolutionize the printing industry.

Biomimetic Design Principles

Biomimetic design, also known as biomimicry, involves emulating nature’s solutions to complex problems. By studying and understanding the mechanisms found in natural systems, engineers can develop innovative solutions that mimic the efficiency and reliability of biological structures.

In the case of paper feeding mechanisms, researchers have looked to nature’s examples of efficient material transport systems. One such example is the tongue of a woodpecker, which can rapidly extend and retract to capture insects. By applying this principle, engineers have developed paper feeding mechanisms that can swiftly and precisely pick up and transport sheets of paper.

Paper Pickup Mechanism

The paper pickup mechanism is the crucial first step in the paper feeding process. Traditional pickup mechanisms rely on friction-based methods, where rubber rollers grip the paper and feed it into the printer. However, these methods are prone to jams, especially when dealing with lightweight or static-charged paper.

Biomimetic paper pickup mechanisms utilize a different approach inspired by the adhesive properties of gecko feet. The gecko’s ability to cling to surfaces is due to the microscopic structures on its feet called setae, which create a powerful adhesive force. Researchers have replicated these structures using synthetic materials such as nanoscale fibrillar structures or microstructured surfaces.

These biomimetic pickup mechanisms employ a combination of adhesive forces and controlled release to securely grip the paper without damaging it. By mimicking the gecko’s ability to adhere to various surfaces, these mechanisms can effectively handle a wide range of paper types, including glossy or textured sheets.

Paper Transport Mechanism

Once the paper has been picked up, it needs to be transported smoothly and accurately through the printer. Traditional transport mechanisms rely on a series of rubber or metal rollers to guide the paper along its path. However, these mechanisms are susceptible to jams if the paper deviates even slightly from its intended trajectory.

Biomimetic paper transport mechanisms take inspiration from the cilia found in the respiratory system of animals. Cilia are hair-like structures that beat in coordinated waves, creating a fluid flow that moves mucus and other particles along. Researchers have replicated this motion using arrays of tiny, flexible filaments that mimic the cilia’s rhythmic beating.

These biomimetic transport mechanisms use the rhythmic motion of the filaments to create a controlled airflow that propels the paper forward. By adjusting the speed and direction of the filaments’ movement, the paper can be precisely guided through the printer, reducing the risk of jams caused by misalignment or skewing.

Integration and Control

Integrating biomimetic paper feeding mechanisms into high-speed printers requires careful coordination and control. Advanced sensors and feedback systems are essential to ensure the mechanisms operate with precision and reliability.

For example, sensors can monitor the paper’s position and alignment throughout the feeding process, providing real-time feedback to adjust the pickup and transport mechanisms accordingly. This feedback loop allows the system to adapt to variations in paper size, weight, or surface characteristics, further reducing the likelihood of jams.

Furthermore, intelligent control algorithms can optimize the biomimetic mechanisms’ performance based on the specific printing requirements. These algorithms can adjust the speed, force, and motion patterns of the pickup and transport mechanisms to achieve optimal paper feeding efficiency while minimizing the risk of jams.

Biomimetic paper feeding mechanisms offer a promising solution to the persistent problem of paper jams in high-speed printers. By emulating nature’s efficient material transport systems, these mechanisms provide increased reliability, versatility, and precision. As the printing industry continues to push the boundaries of speed and efficiency, biomimetic design principles will likely play a vital role in eliminating jams and improving overall productivity.

The Invention of High-Speed Printers

In the early days of printing, the process was slow and labor-intensive. Each page had to be individually typeset and printed, resulting in a limited output. However, with the advent of high-speed printers in the late 20th century, the printing industry underwent a significant transformation.

High-speed printers revolutionized the printing process by enabling the rapid production of large volumes of printed material. These printers utilized advanced mechanisms to feed paper quickly and efficiently, thereby increasing productivity and reducing costs for printing companies.

The Emergence of Paper Jams

As high-speed printers became more prevalent, a new problem arose: paper jams. The fast-paced feeding mechanisms used in these printers often led to misalignments, resulting in paper getting stuck and causing disruptions in the printing process.

Paper jams not only slowed down production but also increased the risk of damage to the printer and the printed material. This issue became a significant concern for printing companies, as it led to costly downtime and decreased efficiency.

Early Attempts to Address Paper Jams

Recognizing the importance of resolving the paper jam issue, researchers and engineers began exploring solutions to eliminate or minimize these disruptions. In the early stages, efforts focused on developing improved sensors and detection systems to identify paper jams quickly.

These early attempts proved somewhat effective in identifying paper jams, but they did little to prevent them from occurring in the first place. The root cause of the problem, the feeding mechanism, remained largely unchanged.

Biomimetic Inspiration

Inspired by nature’s efficiency and adaptability, researchers turned to biomimicry as a potential solution to the paper jam problem. Biomimicry is the practice of emulating nature’s designs and processes to solve human challenges.

By studying natural systems, such as the way animals feed or plants distribute nutrients, researchers sought to develop a paper feeding mechanism that could operate smoothly and without disruptions.

Development of Biomimetic Paper Feeding Mechanisms

Over time, the concept of biomimetic paper feeding mechanisms began to take shape. Researchers focused on replicating the natural movements and adaptations found in living organisms to create a more efficient and reliable feeding system.

One approach involved designing feeding mechanisms that mimicked the motion of a bird’s beak, which can delicately grasp objects while maintaining a firm grip. This biomimetic design allowed for precise paper feeding, reducing the likelihood of jams.

Another approach drew inspiration from the way plants distribute nutrients through their vascular systems. By incorporating similar principles into the printer’s paper feeding mechanism, researchers were able to improve the distribution of paper and reduce the risk of misalignments.

Current State and Future Prospects

Today, biomimetic paper feeding mechanisms have evolved into sophisticated systems that have significantly reduced the occurrence of paper jams in high-speed printers. These mechanisms combine advanced sensors, intelligent algorithms, and biomimetic designs to ensure smooth and uninterrupted paper feeding.

While the current state of biomimetic paper feeding mechanisms has greatly improved printer efficiency, ongoing research and development continue to refine and enhance these systems. Future prospects include further optimization of feeding mechanisms, integration of artificial intelligence for real-time adjustments, and the exploration of new biomimetic designs.

As the printing industry continues to evolve, the application of biomimicry in solving technical challenges like paper jams demonstrates the power of nature-inspired innovation. By looking to the natural world for inspiration, engineers and researchers have been able to overcome historical limitations and create more efficient and reliable high-speed printers.

FAQs

1. What is a biomimetic paper feeding mechanism?

A biomimetic paper feeding mechanism is a technology inspired by nature that mimics the movement and function of animals or plants to improve the feeding process of paper in high-speed printers. It takes advantage of natural designs and movements to eliminate paper jams and enhance the overall printing experience.

2. Why are paper jams a common issue in high-speed printers?

Paper jams occur in high-speed printers due to various reasons, such as misalignment of paper, improper paper handling, or the accumulation of static electricity. The fast-paced printing process can also contribute to the occurrence of paper jams.

3. How does a biomimetic paper feeding mechanism eliminate paper jams?

A biomimetic paper feeding mechanism eliminates paper jams by incorporating features inspired by nature. For example, it may use a design similar to a bird’s beak to guide the paper smoothly through the printer, reducing the chances of misalignment. By mimicking natural movements, such as the way a fish swims, it can ensure a steady and consistent paper feed, minimizing the risk of jams.

4. What are the advantages of using a biomimetic paper feeding mechanism?

Using a biomimetic paper feeding mechanism offers several advantages. Firstly, it reduces the occurrence of paper jams, leading to increased productivity and less downtime. Secondly, it improves print quality by ensuring accurate paper alignment. Lastly, it enhances the overall user experience by providing a smoother and more reliable printing process.

5. Are biomimetic paper feeding mechanisms compatible with all types of printers?

Biomimetic paper feeding mechanisms can be designed to be compatible with various types of printers, including high-speed printers commonly used in offices, commercial printing presses, and industrial printing machines. Manufacturers can adapt the technology to suit different printer models and configurations.

6. Can biomimetic paper feeding mechanisms be retrofitted into existing printers?

Yes, biomimetic paper feeding mechanisms can be retrofitted into existing printers. Manufacturers may offer retrofit kits or upgrades that allow users to enhance the paper feeding capabilities of their current printers. However, the feasibility of retrofitting may vary depending on the specific printer model and design.

7. Are there any limitations or drawbacks to using biomimetic paper feeding mechanisms?

While biomimetic paper feeding mechanisms offer significant benefits, they may have some limitations. For instance, the technology may require additional maintenance or cleaning to ensure optimal performance. The cost of implementing biomimetic mechanisms can also be a factor to consider, as it may involve research and development expenses. However, these limitations are outweighed by the advantages they bring to the printing process.

8. Can biomimetic paper feeding mechanisms be customized for specific printing needs?

Yes, biomimetic paper feeding mechanisms can be customized to meet specific printing needs. Manufacturers can tailor the design and functionality of the mechanism to accommodate different paper sizes, weights, and textures. Customization options allow users to optimize the printing process for their specific requirements.

9. Are there any other applications for biomimetic paper feeding mechanisms?

While the primary application of biomimetic paper feeding mechanisms is in high-speed printers, the technology can potentially be applied in other areas that involve paper handling. For example, it could be used in packaging machines, mail sorting systems, or any other process that requires precise and reliable paper feeding.

10. What does the future hold for biomimetic paper feeding mechanisms?

The future of biomimetic paper feeding mechanisms looks promising. As the technology continues to evolve, we can expect further advancements that improve efficiency, reduce costs, and enhance the overall performance of high-speed printers. With ongoing research and development, biomimetic paper feeding mechanisms have the potential to revolutionize the printing industry.

Concept 1: Biomimetic Design

Biomimetic design is a concept that involves drawing inspiration from nature to create innovative solutions to human problems. In the context of paper feeding mechanisms in high-speed printers, biomimetic design refers to the use of principles found in nature to develop efficient and reliable methods of feeding paper through the printer without causing jams.

For example, engineers studying how birds feed their chicks in nests may discover strategies that can be applied to paper feeding mechanisms. By observing how birds use their beaks to delicately pick up and manipulate objects, engineers can design printer mechanisms that mimic these movements to handle paper with greater precision and care.

Concept 2: Eliminating Jams

Jams in high-speed printers occur when the paper gets stuck or misaligned during the feeding process, leading to interruptions in printing and potential damage to the printer. Eliminating jams is a critical goal in the development of paper feeding mechanisms, as it ensures smooth and uninterrupted printing operations.

To achieve this, engineers analyze the causes of jams and develop innovative solutions. For instance, they may study how insects navigate complex environments without getting stuck to design mechanisms that can detect and avoid potential obstacles in the paper path. By implementing sensors and intelligent algorithms, the printer can adapt its feeding mechanism in real-time to prevent jams.

Concept 3: High-Speed Printing

High-speed printing refers to the ability of a printer to rapidly produce a large number of printed pages in a short amount of time. In the context of paper feeding mechanisms, high-speed printing poses unique challenges that require specialized designs to ensure efficiency and accuracy.

When printing at high speeds, the paper needs to be fed through the printer quickly and smoothly. However, the faster the paper moves, the higher the risk of jams occurring. Engineers address this challenge by developing mechanisms that can handle the high-speed movement of paper while maintaining precise control and alignment.

One approach is to incorporate biomimetic design principles, as mentioned earlier, to create mechanisms that can adapt to the speed of the paper and make necessary adjustments to prevent jams. Additionally, engineers may explore materials with specific properties, such as low friction coatings, to reduce the likelihood of paper sticking or getting misaligned at high speeds.

Conclusion

The development of biomimetic paper feeding mechanisms for high-speed printers has shown great promise in eliminating paper jams. By drawing inspiration from nature, researchers have been able to design innovative solutions that mimic the efficiency and adaptability of biological systems. The use of biomimetics has led to the creation of mechanisms that can adjust to variations in paper thickness, detect and correct misaligned sheets, and prevent multiple sheets from being fed at once.

Through careful observation of natural phenomena, such as the movement of fish scales or the gripping abilities of geckos, engineers have been able to incorporate these principles into printer designs. The result is a significant reduction in paper jams, leading to improved productivity and cost savings for businesses. Furthermore, the use of biomimetic paper feeding mechanisms has the potential to enhance the overall user experience by reducing frustration and downtime associated with paper jams.