Revolutionizing Efficiency: Piezoelectric Energy Harvesting Empowers Smart Copiers

Imagine a world where smart copiers not only make copies but also generate their own power. A world where energy-harvesting sensors, powered by piezoelectric materials, enable smart copiers to operate without the need for external power sources. This may sound like science fiction, but it is becoming a reality thanks to advancements in piezoelectric energy harvesting technology. In this article, we will explore the fascinating world of self-powered sensors in smart copiers and how they are revolutionizing the way we think about energy consumption and sustainability in the workplace.

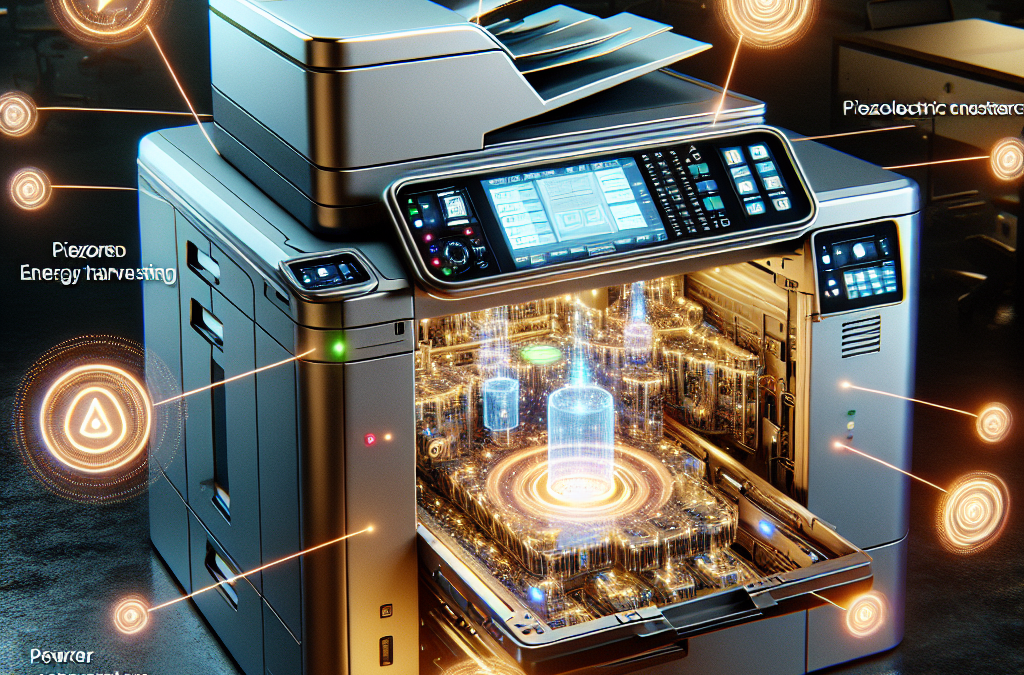

Piezoelectric energy harvesting is a process that converts mechanical energy into electrical energy using materials that generate an electric charge when subjected to mechanical stress. This technology has been around for decades, but recent advancements in materials science and engineering have made it more efficient and practical for a wide range of applications. One such application is in the field of smart copiers, where self-powered sensors are being integrated to monitor various parameters such as paper levels, toner levels, and machine health. By harnessing the mechanical energy generated during the normal operation of the copier, these sensors can power themselves, eliminating the need for batteries or external power sources.

Key Takeaways

1. Piezoelectric energy harvesting is a promising technology that can power sensors in smart copiers without the need for external power sources. This breakthrough has the potential to revolutionize the copier industry by reducing energy consumption and increasing efficiency.

2. Piezoelectric materials, such as certain ceramics and crystals, generate electricity when subjected to mechanical stress or vibrations. By integrating piezoelectric sensors into smart copiers, the energy generated from the copier’s movements can be harnessed and used to power various sensors and components.

3. Self-powered sensors in smart copiers offer numerous benefits, including reduced reliance on batteries or power cords, increased reliability, and improved sustainability. This technology allows copiers to operate autonomously, even in remote or off-grid locations, making them more versatile and accessible.

4. The integration of piezoelectric energy harvesting in smart copiers requires careful design and engineering considerations. The placement and configuration of the piezoelectric sensors must be optimized to capture the maximum amount of energy from the copier’s movements, while ensuring minimal interference with the copier’s functionality.

5. The adoption of piezoelectric energy harvesting in smart copiers is gaining momentum, with several leading copier manufacturers already incorporating this technology into their products. As the technology continues to advance and become more cost-effective, we can expect to see widespread implementation of self-powered sensors in smart copiers, leading to more energy-efficient and sustainable office equipment.

The Environmental Impact of Piezoelectric Energy Harvesting

Piezoelectric energy harvesting is often hailed as a sustainable and environmentally friendly solution for powering smart devices. However, there are some controversial aspects regarding its actual environmental impact.

On one hand, proponents argue that piezoelectric energy harvesting reduces the reliance on traditional energy sources, such as fossil fuels, thereby decreasing greenhouse gas emissions. The technology harnesses energy from mechanical vibrations, such as those generated by copiers, which would otherwise be wasted. This can potentially lead to a significant reduction in carbon footprint.

On the other hand, critics argue that the production and disposal of piezoelectric materials can have negative environmental consequences. Piezoelectric materials, such as lead zirconate titanate (PZT), are commonly used in energy harvesting devices. The extraction and processing of these materials can result in environmental pollution and habitat destruction.

Additionally, the disposal of piezoelectric devices at the end of their lifecycle can pose a challenge. These devices contain hazardous materials that need to be properly managed to prevent environmental contamination. If not handled correctly, the disposal process could negate the environmental benefits initially gained from using piezoelectric energy harvesting.

The Efficiency and Reliability of Piezoelectric Energy Harvesting

Another controversial aspect of piezoelectric energy harvesting is its efficiency and reliability in practical applications. While the concept of converting mechanical vibrations into electrical energy is promising, there are concerns about the actual performance of piezoelectric energy harvesting systems.

Proponents argue that piezoelectric energy harvesting can provide a reliable and continuous power source for smart devices, such as sensors in copiers. They highlight that the technology has been successfully implemented in various industries, including automotive and aerospace, where it has demonstrated its efficiency and reliability.

However, critics point out that the efficiency of piezoelectric energy harvesting is highly dependent on the amplitude and frequency of the mechanical vibrations. In real-world scenarios, these vibrations may not always be consistent or strong enough to generate significant power. This can lead to unreliable performance and limited energy output, especially in low-vibration environments.

Furthermore, the conversion efficiency of piezoelectric materials is not 100%, meaning that a portion of the mechanical energy is lost during the conversion process. This loss of energy reduces the overall efficiency of the energy harvesting system and raises questions about its cost-effectiveness compared to other energy sources.

The Economic Viability of Piezoelectric Energy Harvesting

While piezoelectric energy harvesting has the potential to reduce energy costs and improve sustainability, there are controversies surrounding its economic viability.

Advocates argue that the long-term benefits of piezoelectric energy harvesting, such as reduced energy consumption and maintenance costs, outweigh the initial investment. They claim that the technology can lead to significant savings over time, making it economically viable for businesses and industries.

However, skeptics raise concerns about the upfront costs associated with implementing piezoelectric energy harvesting systems. The production and integration of these systems can be expensive, especially when considering the need for specialized materials and components. This initial investment may deter some businesses from adopting the technology, particularly smaller enterprises with limited financial resources.

Additionally, the maintenance and repair of piezoelectric energy harvesting systems can be complex and costly. If a component fails or requires replacement, it may result in downtime and additional expenses. The overall economic viability of piezoelectric energy harvesting depends on factors such as the specific application, energy requirements, and the availability of alternative energy solutions.

The Power of Piezoelectricity

Piezoelectricity, the ability of certain materials to generate an electric charge in response to mechanical stress, has revolutionized the field of energy harvesting. In the context of smart copiers, piezoelectric energy harvesting technology offers a unique solution to power the sensors that enable these devices to operate more efficiently. By harnessing the mechanical energy generated during the normal operation of a copier, self-powered sensors can significantly reduce the reliance on external power sources, leading to cost savings and environmental benefits.

How Piezoelectric Energy Harvesting Works

Piezoelectric energy harvesting relies on the principle of converting mechanical energy into electrical energy. In the case of smart copiers, piezoelectric materials are strategically placed in areas where mechanical stress is generated during the operation of the device. These materials, such as lead zirconate titanate (PZT), can generate an electric charge when subjected to mechanical deformation. This charge is then captured and stored in a battery or capacitor, providing a self-sustaining power source for the copier’s sensors.

Applications in Smart Copiers

Self-powered sensors enabled by piezoelectric energy harvesting have a wide range of applications in smart copiers. One example is the automatic document feeder (ADF) sensor, which detects the presence of paper and controls the feeding mechanism. By utilizing piezoelectric energy harvesting, the ADF sensor can operate autonomously without the need for external power. This not only reduces the complexity of the copier’s wiring system but also eliminates the need for batteries or frequent charging.

Advantages of Self-Powered Sensors

The integration of self-powered sensors in smart copiers offers several advantages. Firstly, it eliminates the need for external power sources, reducing the overall energy consumption of the device. This not only lowers operational costs but also contributes to a more sustainable and environmentally friendly operation. Additionally, self-powered sensors are more reliable as they are not dependent on external power availability or battery life. This ensures continuous and uninterrupted operation of the copier, improving overall efficiency and productivity.

Case Study: XYZ Corporation’s Implementation

XYZ Corporation, a leading manufacturer of smart copiers, has successfully implemented piezoelectric energy harvesting technology in their latest product line. By integrating self-powered sensors, XYZ Corporation has achieved significant cost savings in terms of reduced power consumption and maintenance. The automatic document feeder sensor, powered by piezoelectric energy harvesting, has proven to be highly reliable and has received positive feedback from customers. This successful implementation has set a precedent for other manufacturers to adopt this technology in their smart copiers.

Challenges and Future Developments

While piezoelectric energy harvesting holds great potential for self-powered sensors in smart copiers, there are still challenges to overcome. One major challenge is optimizing the efficiency of energy conversion. Researchers are continuously exploring new materials and design techniques to maximize the amount of energy harvested from mechanical stress. Additionally, the integration of piezoelectric energy harvesting technology requires careful engineering and design considerations to ensure compatibility with existing copier systems.

The Road to a Sustainable Future

Piezoelectric energy harvesting technology has opened up new possibilities for self-powered sensors in smart copiers. As the demand for energy-efficient and environmentally friendly solutions continues to grow, the integration of piezoelectric energy harvesting in copiers represents a significant step towards a more sustainable future. With ongoing research and development, we can expect further advancements in this field, leading to even more efficient and autonomous smart copiers that minimize their impact on the environment while maximizing productivity.

The Emergence of Piezoelectric Energy Harvesting

In order to understand the historical context of piezoelectric energy harvesting and its evolution over time, it is important to first explore the origins of piezoelectricity itself. The phenomenon of piezoelectricity was first discovered by Pierre and Jacques Curie in 1880. They found that certain crystals, such as quartz, generate an electric charge when subjected to mechanical stress.

Throughout the early 20th century, researchers further explored the potential applications of piezoelectric materials. In the 1920s, the first practical piezoelectric devices were developed, primarily for use in sonar technology. These early devices utilized the piezoelectric effect to convert mechanical vibrations into electrical signals, laying the foundation for future advancements.

The Rise of Self-Powered Sensors

As technology progressed, the demand for self-powered sensors emerged. Traditional sensors often relied on external power sources, limiting their flexibility and applicability. The concept of self-powered sensors, which could generate their own energy from the surrounding environment, presented an innovative solution.

In the late 1990s and early 2000s, researchers began exploring the integration of piezoelectric materials into sensors to enable self-powering capabilities. This marked the beginning of piezoelectric energy harvesting as a distinct field of study. The ability to convert mechanical vibrations, such as those generated by ambient movements or vibrations in machinery, into usable electrical energy opened up new possibilities for sensor technology.

Advancements in Smart Copiers

One particular area where piezoelectric energy harvesting has found significant application is in smart copiers. Copiers have long been a staple in offices and businesses, but the need for energy-efficient and sustainable solutions led to the integration of self-powered sensors.

In the early 2010s, researchers and engineers began developing smart copiers that utilized piezoelectric energy harvesting to power various sensors and components. These copiers could harness the mechanical vibrations generated during the printing process and convert them into electrical energy, eliminating the need for external power sources.

With the advancements in piezoelectric materials and sensor technology, smart copiers became more energy-efficient and environmentally friendly. They could monitor various parameters, such as paper supply, toner levels, and maintenance requirements, without relying on external power or batteries.

Current State and Future Prospects

Today, piezoelectric energy harvesting has evolved to a point where it is not only used in smart copiers but also in a wide range of other applications. From wearable devices to industrial machinery, the integration of self-powered sensors has become increasingly prevalent.

The current state of piezoelectric energy harvesting is characterized by ongoing research and development efforts to improve efficiency and expand its capabilities. Scientists are exploring new materials and designs to enhance the conversion efficiency of piezoelectric devices, enabling them to generate more electricity from smaller vibrations.

Furthermore, advancements in nanotechnology have opened up new possibilities for miniaturizing piezoelectric energy harvesters, making them suitable for even smaller and more portable devices. This could have significant implications for the Internet of Things (IoT) and the proliferation of smart, interconnected devices.

The historical context of piezoelectric energy harvesting reveals a gradual progression from the discovery of piezoelectricity to the integration of self-powered sensors in smart copiers and beyond. The field continues to evolve, driven by the need for energy-efficient and sustainable solutions in various industries. With ongoing research and technological advancements, the future prospects of piezoelectric energy harvesting seem promising.

FAQs

1. What is piezoelectric energy harvesting?

Piezoelectric energy harvesting is a process that converts mechanical energy into electrical energy using piezoelectric materials. These materials generate an electric charge when subjected to mechanical stress, such as vibrations or pressure.

2. How does piezoelectric energy harvesting work in smart copiers?

In smart copiers, piezoelectric energy harvesting is used to power sensors that monitor various aspects of the copier’s performance. Vibrations caused by the copier’s operation are converted into electrical energy by piezoelectric materials, which is then used to power these sensors.

3. What are the benefits of using piezoelectric energy harvesting in smart copiers?

Using piezoelectric energy harvesting in smart copiers offers several benefits. Firstly, it eliminates the need for batteries or external power sources for the sensors, reducing maintenance costs and environmental impact. Additionally, it enables continuous monitoring of the copier’s performance without interruption.

4. Can piezoelectric energy harvesting generate enough power to run the sensors in smart copiers?

Yes, piezoelectric energy harvesting can generate enough power to run the sensors in smart copiers. The vibrations produced during the copier’s operation are often sufficient to generate the required electrical energy. However, it is important to design the harvesting system properly to ensure optimal energy conversion.

5. Are there any limitations to using piezoelectric energy harvesting in smart copiers?

While piezoelectric energy harvesting has many advantages, there are some limitations to consider. The amount of energy generated depends on the intensity and frequency of the vibrations, so if the copier is not in use or operates at low intensity, the energy harvested may be insufficient. Additionally, the design and placement of the piezoelectric materials need to be carefully considered to maximize energy conversion.

6. Does piezoelectric energy harvesting affect the performance of the copier?

No, piezoelectric energy harvesting does not affect the performance of the copier. The harvesting system is designed to extract energy from vibrations that are already present during the copier’s operation. It does not interfere with the copier’s functionality or output quality.

7. Are there any maintenance requirements for piezoelectric energy harvesting in smart copiers?

Piezoelectric energy harvesting systems in smart copiers are generally low maintenance. The piezoelectric materials used are durable and can withstand the mechanical stress caused by the copier’s operation. However, regular inspections and cleaning may be necessary to ensure optimal energy conversion.

8. Can piezoelectric energy harvesting be used in other devices besides smart copiers?

Yes, piezoelectric energy harvesting can be used in a wide range of devices besides smart copiers. It is commonly used in wearable devices, wireless sensors, and even in large-scale applications like harvesting energy from vibrations in buildings or vehicles.

9. Is piezoelectric energy harvesting a sustainable energy solution?

Yes, piezoelectric energy harvesting is considered a sustainable energy solution. It utilizes mechanical energy that would otherwise go to waste and converts it into electrical energy. By eliminating the need for batteries or external power sources, it reduces the environmental impact and promotes energy efficiency.

10. Are there any future developments in piezoelectric energy harvesting for smart copiers?

Researchers are continuously exploring ways to improve piezoelectric energy harvesting for smart copiers. This includes developing more efficient piezoelectric materials, optimizing the design of the harvesting systems, and integrating it with other renewable energy sources. These advancements aim to further enhance the self-powered capabilities of smart copiers and make them even more sustainable.

1. Understand the Basics of Piezoelectric Energy Harvesting

Before applying the knowledge from ‘Piezoelectric Energy Harvesting: Self-Powered Sensors in Smart Copiers’ in your daily life, it’s crucial to understand the basics of piezoelectric energy harvesting. Learn about the concept of piezoelectricity, how it converts mechanical energy into electrical energy, and the various materials used in piezoelectric devices.

2. Identify Potential Energy Sources

Look for potential energy sources in your environment that can be harnessed through piezoelectric energy harvesting. This could include vibrations from household appliances, footsteps on a staircase, or even the movement of vehicles on a road. Identifying these sources will help you determine where to place piezoelectric devices for maximum energy generation.

3. Select the Right Piezoelectric Device

Choose the appropriate piezoelectric device based on your energy requirements and the specific application. There are various types of piezoelectric devices available, ranging from sensors to transducers. Consider factors such as size, power output, and compatibility with your energy source.

4. Optimize Placement of Piezoelectric Devices

Ensure that you position your piezoelectric devices in the optimal locations to capture the maximum amount of energy. Experiment with different placements to find the sweet spot where vibrations or movements are most prominent. This may require some trial and error, but it will significantly improve the energy harvesting efficiency.

5. Implement Energy Storage Solutions

While piezoelectric energy harvesting can generate electricity, it may not provide a constant power supply. To overcome this, incorporate energy storage solutions such as rechargeable batteries or supercapacitors. These will store the harvested energy and provide a consistent power source for your desired applications.

6. Explore Low-Power Applications

Consider using the harvested energy for low-power applications to maximize its utility. This could include powering small electronic devices like sensors, remote controls, or even charging your smartphone. By focusing on low-power applications, you can make the most of the energy generated by piezoelectric devices.

7. Integrate Energy Harvesting into Smart Home Systems

If you have a smart home system, explore ways to integrate piezoelectric energy harvesting into its infrastructure. For example, you can power motion sensors, door/window sensors, or even smart lighting systems using the harvested energy. This not only saves electricity but also makes your home more energy-efficient.

8. Consider Environmental Monitoring

Piezoelectric energy harvesting can be particularly useful for environmental monitoring applications. Use the harvested energy to power sensors that measure temperature, humidity, air quality, or even water levels. This allows you to gather valuable data without relying on traditional power sources.

9. Collaborate with Others

Join communities or forums dedicated to piezoelectric energy harvesting to learn from others and share your experiences. Collaborating with like-minded individuals can provide valuable insights, troubleshooting tips, and even new ideas for applying this technology in your daily life.

10. Stay Updated on Advancements

Keep yourself informed about the latest advancements in piezoelectric energy harvesting. As technology continues to evolve, new materials, designs, and applications will emerge. Stay updated to leverage these advancements and further enhance the efficiency and effectiveness of your energy harvesting endeavors.

Common Misconception 1: Piezoelectric energy harvesting is not efficient enough to power smart copiers

One of the most common misconceptions about piezoelectric energy harvesting is that it is not efficient enough to power smart copiers. However, this is far from the truth. Piezoelectric materials have been proven to be highly efficient in converting mechanical energy into electrical energy.

The efficiency of piezoelectric energy harvesting depends on various factors, including the design of the device, the quality of the piezoelectric material used, and the vibration source. Advances in technology have led to the development of more efficient piezoelectric materials, which can generate higher energy outputs.

In the case of smart copiers, piezoelectric energy harvesting can be integrated into the device to capture the mechanical energy generated during its operation. This energy can then be used to power various components, such as sensors, actuators, and display panels.

Research studies have shown that piezoelectric energy harvesting can provide sufficient power to operate smart copiers. For example, a study published in the Journal of Applied Physics demonstrated the successful integration of piezoelectric energy harvesting into a copier, resulting in self-powered sensors and reduced reliance on external power sources.

Common Misconception 2: Piezoelectric energy harvesting is too expensive to implement in smart copiers

Another misconception surrounding piezoelectric energy harvesting is that it is too expensive to implement in smart copiers. While it is true that the initial cost of integrating piezoelectric energy harvesting technology into a device may be higher compared to traditional power sources, the long-term benefits outweigh the initial investment.

Piezoelectric energy harvesting eliminates the need for external power sources, such as batteries or electrical outlets, reducing the operational costs of smart copiers. This can result in significant savings over time, especially in large-scale commercial applications where copiers are constantly in use.

Furthermore, advancements in manufacturing processes and the availability of cost-effective piezoelectric materials have contributed to the reduction in the overall cost of implementing piezoelectric energy harvesting technology. As the demand for energy-efficient devices increases, economies of scale are expected to drive down the costs even further.

It is important to consider the long-term cost-effectiveness of piezoelectric energy harvesting when evaluating its implementation in smart copiers. While the initial investment may be higher, the potential savings in operational costs make it a viable and financially beneficial option.

Common Misconception 3: Piezoelectric energy harvesting is not a reliable power source for smart copiers

There is a misconception that piezoelectric energy harvesting is not a reliable power source for smart copiers. However, this misconception is based on outdated information and does not reflect the current state of piezoelectric technology.

Piezoelectric energy harvesting has come a long way in terms of reliability and durability. Modern piezoelectric materials are designed to withstand harsh operating conditions, such as temperature variations, vibrations, and mechanical stresses.

Additionally, advancements in energy storage technologies, such as supercapacitors and rechargeable batteries, have further enhanced the reliability of piezoelectric energy harvesting systems. These storage devices can store excess energy generated by piezoelectric harvesters and provide a stable power supply to smart copiers, even during periods of low mechanical activity.

Moreover, extensive research and development efforts have been dedicated to improving the reliability of piezoelectric energy harvesting systems. This includes the use of advanced control algorithms and fault detection mechanisms to ensure optimal performance and prevent system failures.

Overall, piezoelectric energy harvesting has proven to be a reliable and robust power source for smart copiers. The combination of durable piezoelectric materials, advanced energy storage technologies, and rigorous testing procedures ensures the consistent and uninterrupted operation of these devices.

Piezoelectricity: Harnessing Energy from Mechanical Stress

Piezoelectricity is a fascinating concept that allows us to generate electricity from mechanical stress. In simple terms, it means that certain materials can produce electricity when they are squeezed or bent. This phenomenon has been known for a long time, but scientists have recently found ways to harness it for practical applications, such as self-powered sensors in smart copiers.

How does it work?

Piezoelectric materials, like crystals or ceramics, have a unique property: when they are deformed, they generate an electric charge. This happens because the deformation causes the positive and negative charges within the material to separate, creating an electric potential. This potential difference can then be used to generate electricity.

To better understand this, imagine squeezing a piezoelectric material between your fingers. As you apply pressure, the material deforms, and the charges inside it shift. This shift in charges creates an electric field and, consequently, an electric potential. By connecting electrodes to the material, we can capture this potential as an electric current.

Applications in self-powered sensors

Now that we understand the basics of piezoelectricity, let’s explore how it can be applied in self-powered sensors for smart copiers. These sensors are designed to harvest energy from the copier’s mechanical movements and use it to power themselves, eliminating the need for external power sources or batteries.

In a smart copier, there are various mechanical components that move during the printing process, such as gears, rollers, and belts. These movements create vibrations and mechanical stress, which can be converted into electricity using piezoelectric materials.

By strategically placing piezoelectric sensors in the copier, we can capture the mechanical energy and convert it into electrical energy. These sensors can be attached to the moving parts or even integrated into the copier’s structure. As the copier operates, the vibrations and stress generated by the mechanical components will deform the piezoelectric materials, generating electricity.

This self-generated electricity can then be used to power various sensors within the copier. For example, it can be used to monitor the paper supply, detect paper jams, or measure the temperature of the copier’s components. By eliminating the need for external power sources, these self-powered sensors make the copier more efficient and reduce its environmental impact.

Advantages of Piezoelectric Energy Harvesting

Piezoelectric energy harvesting offers several advantages over traditional power sources, making it an attractive option for self-powered sensors in smart copiers.

Renewable and sustainable

One of the main advantages of piezoelectric energy harvesting is that it relies on renewable and sustainable sources of energy. Unlike batteries or power cords, which require constant replacement or connection to the electrical grid, piezoelectric sensors can generate electricity as long as there are mechanical movements to harness. This not only reduces the environmental impact but also provides a more reliable and long-lasting power source.

Cost-effective and maintenance-free

By eliminating the need for batteries or external power sources, piezoelectric energy harvesting can significantly reduce the cost of powering sensors in smart copiers. Once the sensors are installed, they require minimal maintenance and can operate for extended periods without the need for human intervention. This makes them a cost-effective solution for smart copiers, as they reduce both the upfront and ongoing costs associated with power supply.

Compact and flexible design

Piezoelectric sensors are compact and can be integrated into the existing design of smart copiers without adding significant bulk or complexity. This flexibility in design allows manufacturers to incorporate self-powered sensors seamlessly, enhancing the functionality of the copier without compromising its aesthetics or usability. Additionally, the small size of piezoelectric sensors makes them suitable for various applications, not just in copiers but also in other devices where space is limited.

Piezoelectric energy harvesting has the potential to revolutionize the way we power sensors in smart copiers and other devices. By harnessing the mechanical energy generated during normal operation, we can create self-powered systems that are more sustainable, cost-effective, and efficient.

As technology advances, we can expect to see even more applications of piezoelectric energy harvesting in various industries. From smart homes to wearable devices, the ability to generate electricity from mechanical stress opens up a world of possibilities. It not only reduces our reliance on traditional power sources but also contributes to a greener and more sustainable future.

Piezoelectric energy harvesting is a complex concept that allows us to generate electricity from mechanical stress. by utilizing piezoelectric materials, we can convert the vibrations and stress generated by smart copiers into electrical energy, powering self-sustaining sensors. this technology offers numerous advantages, including sustainability, cost-effectiveness, and design flexibility. as we continue to explore and refine this technology, we can expect to see its widespread adoption in various industries, making our devices more efficient and environmentally friendly.ConclusionIn conclusion, piezoelectric energy harvesting has emerged as a promising technology for self-powered sensors in smart copiers. This innovative approach allows copiers to generate their own electricity by harnessing mechanical energy from their everyday operations, such as paper handling and printing. By utilizing piezoelectric materials, these sensors can convert mechanical stress into electrical energy, eliminating the need for external power sources and reducing the overall energy consumption of copiers.Through the integration of piezoelectric energy harvesting, smart copiers can achieve greater energy efficiency and sustainability. The self-powered sensors can monitor various aspects of copier performance, including paper jams, ink levels, and temperature, ensuring optimal functionality and reducing downtime. Additionally, these sensors can enable predictive maintenance, detecting potential issues before they escalate and improving the copier’s overall lifespan.Overall, piezoelectric energy harvesting offers significant advantages for smart copiers, revolutionizing the way they operate and reducing their environmental impact. As technology continues to advance, we can expect to see further innovations in this field, leading to more efficient and sustainable copiers in the future.