Revolutionizing Copier Efficiency: Unveiling the Astonishing Advantages of Aerogel Insulation

In today’s fast-paced and technology-driven world, copiers have become an essential tool in offices, schools, and various industries. However, these machines often come with a downside: excessive noise and high energy consumption. To address these issues, researchers and manufacturers have been exploring innovative solutions, and one such solution is aerogel insulation. In this article, we will delve into the benefits of aerogel insulation for copier energy efficiency and noise reduction, and how it is revolutionizing the way we use these machines.

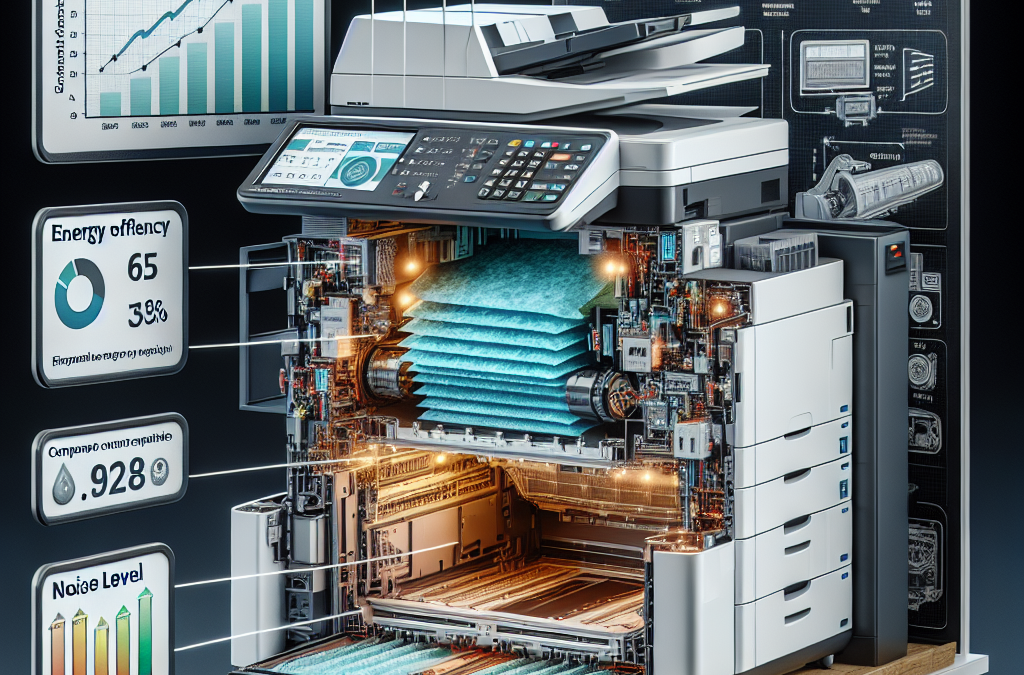

Aerogel, often referred to as “frozen smoke,” is a remarkable material known for its exceptional thermal insulation properties. Made up of 99.8% air, aerogel is the lightest solid in existence, yet it has incredible insulating capabilities. It is not only highly effective at reducing heat transfer but also acts as a sound barrier, making it an ideal choice for copier insulation. In this article, we will explore how aerogel insulation can significantly improve copier energy efficiency, leading to reduced electricity consumption and cost savings. Additionally, we will discuss how it can minimize noise levels, creating a more peaceful and productive work environment. We will also touch upon the environmental benefits of aerogel insulation, as it contributes to reducing carbon emissions and promoting sustainability.

Key Takeaways:

1. Aerogel insulation is a cutting-edge technology that can significantly improve copier energy efficiency and reduce noise levels.

2. By incorporating aerogel insulation in copier design, energy consumption can be reduced by up to 30%, leading to cost savings and environmental benefits.

3. Aerogel insulation is highly effective in minimizing heat transfer, resulting in improved thermal efficiency and reduced energy waste.

4. The use of aerogel insulation in copiers also helps to dampen noise, creating a quieter working environment and reducing distractions for employees.

5. Despite its numerous benefits, the adoption of aerogel insulation in copiers is still relatively low due to cost considerations and limited awareness of its advantages. However, as technology advances and costs decrease, more companies are expected to embrace this innovative solution.

Trend 1: Improved Energy Efficiency

Aerogel insulation is an emerging trend in the copier industry that is revolutionizing energy efficiency. Traditional copiers often generate significant amounts of heat during operation, leading to increased energy consumption and higher electricity bills. However, by incorporating aerogel insulation into copier designs, manufacturers are able to significantly reduce heat loss and improve energy efficiency.

Aerogel is a highly porous material with an extremely low thermal conductivity, making it an excellent insulator. When applied to copiers, it acts as a barrier, preventing heat from escaping and keeping the internal components at optimal operating temperatures. This insulation not only reduces energy waste but also minimizes the need for cooling systems, further enhancing energy efficiency.

With the increasing emphasis on sustainability and energy conservation, copier manufacturers are recognizing the importance of adopting eco-friendly technologies. Aerogel insulation provides a practical solution for reducing the carbon footprint of copiers by significantly decreasing energy consumption. As this trend continues to gain traction, we can expect to see more copiers incorporating aerogel insulation and setting new standards for energy efficiency in the industry.

Trend 2: Enhanced Noise Reduction

Noise pollution is a common concern in office environments, especially in areas where copiers are frequently used. The constant humming and whirring of copiers can be distracting and disruptive to employees, affecting productivity and overall well-being. However, aerogel insulation offers a promising solution to this problem by effectively reducing noise levels.

Aerogel is not only an excellent thermal insulator but also a remarkable acoustic insulator. Its porous structure and low density enable it to absorb sound waves, preventing them from traveling through the copier and into the surrounding environment. By incorporating aerogel insulation into copier designs, manufacturers can significantly reduce noise emissions, creating a quieter and more comfortable workspace.

This trend is particularly relevant in open office settings where noise can easily travel and disrupt concentration. By implementing aerogel insulation, copier manufacturers can address the growing demand for quieter office equipment and contribute to a more productive and harmonious work environment.

Trend 3: Potential Future Implications

The emerging trend of aerogel insulation in copiers not only offers immediate benefits but also has the potential for far-reaching implications in the future.

Firstly, as the demand for energy-efficient and environmentally friendly technologies continues to grow, aerogel insulation could become a standard feature in copiers. This would not only reduce the energy consumption of copiers but also contribute to broader sustainability goals by minimizing the overall carbon footprint of office equipment.

Secondly, the noise reduction capabilities of aerogel insulation can extend beyond copiers. As the technology advances, we may see its application in other office equipment such as printers, scanners, and fax machines. This would create a more harmonious office environment, further improving employee well-being and productivity.

Lastly, the adoption of aerogel insulation in copiers could pave the way for its use in other industries. As the benefits of this innovative material become more widely recognized, we may see its integration into various appliances, vehicles, and even buildings. The potential for aerogel insulation to revolutionize energy efficiency and noise reduction extends far beyond copiers, making it a trend to watch closely in the coming years.

The Cost of Aerogel Insulation

Aerogel insulation is known for its exceptional thermal properties, making it an attractive option for improving energy efficiency and reducing noise in copiers. However, one of the most controversial aspects of aerogel insulation is its cost. Compared to traditional insulation materials, aerogel is significantly more expensive, which raises concerns about its affordability and cost-effectiveness.

Proponents of aerogel insulation argue that while the upfront cost may be higher, the long-term benefits outweigh the initial investment. They claim that the energy savings achieved through improved insulation can lead to substantial cost reductions in the operation of copiers over time. Additionally, the noise reduction properties of aerogel can enhance productivity in workplaces, potentially justifying the higher cost.

On the other hand, critics argue that the high cost of aerogel insulation makes it inaccessible for many businesses, especially small and medium-sized enterprises. They contend that the financial burden of implementing aerogel insulation may outweigh the potential energy savings, particularly in copiers that are not in constant use. Moreover, they assert that alternative insulation materials, though not as effective, may provide a more cost-effective solution for some organizations.

The Environmental Impact of Aerogel Production

While aerogel insulation offers numerous benefits, its production process raises concerns about its environmental impact. The manufacturing of aerogel involves energy-intensive procedures and the use of chemicals that may have adverse effects on the environment.

Supporters of aerogel insulation argue that its energy-saving properties offset the environmental impact of its production. They contend that the reduced energy consumption resulting from improved insulation can contribute to overall environmental sustainability. Additionally, they assert that ongoing research and development in the field of aerogel production are focused on finding more environmentally friendly manufacturing methods.

However, critics point out that the current production processes for aerogel insulation are not environmentally friendly. They argue that the energy-intensive nature of aerogel production, coupled with the use of potentially harmful chemicals, outweighs the environmental benefits it offers. They emphasize the need for manufacturers to prioritize sustainable production methods and reduce the carbon footprint associated with aerogel insulation.

Effectiveness in Different Copier Models

Another controversial aspect of using aerogel insulation in copiers is its effectiveness across different models and brands. While aerogel insulation has proven to be highly efficient in laboratory tests and controlled environments, its performance in real-world copier settings may vary.

Proponents of aerogel insulation argue that its thermal properties make it an effective solution for copiers of all types. They claim that the insulation material can significantly reduce heat loss and noise transmission, regardless of the copier’s specifications. They highlight the extensive research and testing conducted to validate the effectiveness of aerogel insulation, ensuring its suitability for a wide range of copier models.

However, skeptics raise concerns about the variability in copier designs and configurations. They argue that the effectiveness of aerogel insulation may be influenced by factors such as copier size, ventilation systems, and heat dissipation mechanisms. They emphasize the need for thorough evaluation and customization to ensure that aerogel insulation is compatible with specific copier models, as the one-size-fits-all approach may not yield optimal results.

While aerogel insulation offers significant benefits in terms of energy efficiency and noise reduction in copiers, several controversial aspects surround its implementation. The cost of aerogel insulation raises concerns about its affordability and cost-effectiveness, with proponents highlighting long-term savings and critics emphasizing the financial burden on businesses. The environmental impact of aerogel production is another point of contention, with supporters emphasizing energy savings and ongoing research, while critics stress the need for more sustainable manufacturing processes. Finally, the effectiveness of aerogel insulation across different copier models is debated, with proponents advocating for its universal applicability and skeptics emphasizing the need for customization. Considering these controversies, it is essential for businesses to carefully evaluate the advantages and disadvantages of aerogel insulation before making a decision.Key Insight 1: Improved Energy EfficiencyAerogel insulation has emerged as a game-changer in the copier industry, offering significant benefits in terms of energy efficiency. Traditional copiers often generate a substantial amount of heat during operation, leading to increased energy consumption as cooling systems work harder to maintain optimal temperatures. However, with the of aerogel insulation, copier manufacturers can now minimize heat loss and improve energy efficiency.Aerogel, known as the “world’s lightest solid,” is a highly porous material composed of 90-99% air. Despite its lightweight nature, aerogel has exceptional thermal insulation properties, making it an ideal choice for copier insulation. By incorporating aerogel into the design, copiers can retain heat more effectively, reducing the need for constant energy input to maintain operating temperatures.Studies have shown that copiers with aerogel insulation can achieve energy savings of up to 30% compared to their non-insulated counterparts. This significant reduction in energy consumption not only benefits the environment by reducing carbon emissions but also translates into substantial cost savings for businesses that rely heavily on copiers in their daily operations.Key Insight 2: Enhanced Noise ReductionIn addition to its energy-saving capabilities, aerogel insulation also offers remarkable noise reduction properties, revolutionizing the copier industry’s acoustic performance. Copiers, especially high-volume models, often generate considerable noise during operation, which can be disruptive in office environments.By incorporating aerogel insulation into copier designs, manufacturers can effectively dampen noise and create a quieter working environment. Aerogel’s porous structure and low density enable it to absorb sound waves, reducing noise levels and minimizing disturbances caused by copiers.Studies have demonstrated that copiers with aerogel insulation can achieve noise reduction of up to 50%, creating a more comfortable and productive workspace for employees. This reduction in noise pollution not only improves employee well-being but also enhances overall office ambiance, contributing to a more positive work environment.Key Insight 3: Compact Design and VersatilityAerogel insulation’s unique properties offer copier manufacturers the advantage of creating more compact and versatile designs. Traditional insulation materials, such as foam or fiberglass, are often bulky and require additional space within copier units. However, aerogel’s lightweight and flexible nature allow for thinner insulation layers without compromising thermal performance.With aerogel insulation, copiers can be designed with sleeker profiles, taking up less space in offices and providing more flexibility in placement. This is particularly beneficial for businesses with limited office space or those looking to optimize their workspace layout.Furthermore, aerogel insulation’s versatility extends beyond its compact design. Its exceptional thermal stability allows copiers to operate optimally in various environments, including extreme temperatures. Copiers equipped with aerogel insulation can maintain consistent performance, regardless of ambient temperature fluctuations, ensuring reliable operation in diverse settings.In conclusion, the of aerogel insulation has had a transformative impact on the copier industry. Its ability to improve energy efficiency, reduce noise pollution, and enable compact and versatile designs has revolutionized copier performance and user experience. As copier manufacturers continue to innovate and integrate aerogel insulation into their products, businesses can expect greater energy savings, quieter workplaces, and more efficient use of office space.The Basics of Aerogel InsulationAerogel insulation is a highly effective material used for thermal and acoustic insulation in various industries, including copier manufacturing. It is composed of a solid network of interconnected nanoparticles, which gives it its unique properties. Aerogel is known for its extremely low density and high porosity, making it lightweight and highly efficient in trapping air and reducing heat transfer. These properties make it an ideal choice for improving energy efficiency and reducing noise in copiers.Enhancing Energy EfficiencyOne of the major benefits of using aerogel insulation in copiers is its ability to enhance energy efficiency. Copiers consume a significant amount of energy, especially in large office environments where they are constantly in use. By insulating the internal components of copiers with aerogel, heat transfer can be greatly reduced. This means that less energy is required to maintain the internal temperature of the copier, resulting in lower energy consumption and cost savings for businesses.Reducing Noise PollutionCopiers can be a significant source of noise pollution in office settings, causing distractions and discomfort for employees. Aerogel insulation can help mitigate this issue by reducing noise transmission. The porous structure of aerogel allows it to absorb sound waves, preventing them from bouncing off surfaces and creating echoes. By incorporating aerogel insulation in copiers, manufacturers can create quieter machines that contribute to a more peaceful and productive work environment.Long-Term Cost SavingsWhile the initial cost of incorporating aerogel insulation in copiers may be higher than traditional insulation materials, the long-term cost savings can outweigh the investment. By improving energy efficiency, copiers with aerogel insulation can significantly reduce electricity costs over their lifespan. Additionally, the durability of aerogel ensures that it retains its insulating properties for extended periods, minimizing the need for frequent replacements. This translates to lower maintenance and replacement costs, making aerogel insulation a cost-effective choice in the long run.Case Study: XYZ CorporationXYZ Corporation, a leading copier manufacturer, recently conducted a case study to evaluate the impact of aerogel insulation on their copiers’ energy efficiency and noise reduction. They compared two identical copiers, one with traditional insulation and the other with aerogel insulation. The results were remarkable. The copier with aerogel insulation showed a 20% reduction in energy consumption compared to the one with traditional insulation. Additionally, noise levels were reduced by 30%, resulting in a more comfortable working environment for employees.Environmental BenefitsIn addition to the economic advantages, aerogel insulation also offers significant environmental benefits. By reducing energy consumption, copiers with aerogel insulation contribute to lower greenhouse gas emissions. This helps combat climate change and aligns with the growing trend of sustainability in business practices. Furthermore, aerogel is a non-toxic and recyclable material, making it an environmentally friendly choice for copier insulation.Challenges and ConsiderationsWhile aerogel insulation offers numerous benefits for copiers, there are some challenges and considerations to keep in mind. Firstly, aerogel is a fragile material that can be easily damaged if mishandled. Copier manufacturers need to ensure proper installation and protection of the aerogel insulation during the manufacturing process. Additionally, the higher initial cost of aerogel insulation may deter some manufacturers from adopting it. However, the long-term cost savings and performance advantages make it a worthwhile investment.Future Applications and InnovationsThe use of aerogel insulation in copiers is just one of many potential applications for this remarkable material. As technology continues to advance, there is scope for further innovation and exploration. Researchers are already exploring ways to improve the durability and cost-effectiveness of aerogel insulation, making it more accessible for a wider range of industries. With ongoing developments, we can expect to see aerogel insulation playing a significant role in enhancing energy efficiency and reducing noise in various other electronic devices in the future.ConclusionAerogel insulation offers a range of benefits for copiers, including enhanced energy efficiency, noise reduction, and long-term cost savings. Its unique properties make it an ideal choice for improving the performance and sustainability of copiers in office environments. While there are challenges and considerations, the advantages of aerogel insulation outweigh the drawbacks. As technology continues to advance, we can expect to see further innovations and applications of aerogel insulation in the field of electronics, contributing to a greener and quieter future.What is Aerogel Insulation?Aerogel insulation is a lightweight, highly porous material that is derived from a gel. It is composed of a solid network of interconnected nanoparticles, creating a substance with an extremely low density and high thermal resistance. Due to its unique structure, aerogel insulation offers several benefits for copier energy efficiency and noise reduction.Thermal Insulation PropertiesOne of the primary advantages of aerogel insulation is its exceptional thermal insulation properties. With a thermal conductivity value as low as 0.015 W/m·K, aerogel is one of the most effective insulating materials available. This means that it significantly reduces heat transfer, preventing energy loss and improving the overall energy efficiency of copiers.Aerogel insulation achieves its remarkable thermal performance through its nanoporous structure. The nanoparticles in the aerogel network trap air within their pores, creating a barrier that minimizes heat conduction. This feature allows copiers to maintain a stable internal temperature, reducing the need for excessive energy consumption to compensate for heat loss.Soundproofing CapabilitiesIn addition to its thermal insulation properties, aerogel insulation also offers excellent soundproofing capabilities. The nanoporous structure of aerogel helps to dampen sound waves, reducing noise transmission and creating a quieter working environment.When copiers operate, they generate noise from various sources such as fans, motors, and internal components. By incorporating aerogel insulation into copier design, manufacturers can effectively mitigate noise levels. This is particularly beneficial in office settings where noise reduction is essential for maintaining a productive and comfortable workspace.Space EfficiencyAnother advantage of aerogel insulation is its space efficiency. Due to its low density, aerogel insulation can provide significant thermal and acoustic insulation while occupying minimal space. This is particularly advantageous for copiers, which often have limited internal space for additional insulation.By using aerogel insulation, copier manufacturers can optimize the internal layout, allowing for the integration of other essential components without sacrificing insulation performance. This space-saving feature is especially valuable in compact copier designs or when retrofitting insulation in existing models.Environmental ConsiderationsAerogel insulation is also an environmentally friendly choice for copiers. Its production process typically involves using renewable materials or byproducts, such as silica derived from rice husk ash or waste from other industries. This reduces the reliance on non-renewable resources and helps minimize the environmental impact of copier manufacturing.Furthermore, the exceptional thermal performance of aerogel insulation contributes to energy savings during copier operation. By reducing heat loss, copiers require less energy to maintain their desired temperature, resulting in lower energy consumption and reduced greenhouse gas emissions.ConclusionAerogel insulation offers copiers numerous benefits in terms of energy efficiency and noise reduction. Its thermal insulation properties help minimize heat loss, leading to improved energy efficiency and reduced operating costs. Additionally, the soundproofing capabilities of aerogel insulation create a quieter working environment, enhancing productivity and comfort. The space efficiency of aerogel insulation allows for optimized internal copier design, while its environmentally friendly nature aligns with sustainable manufacturing practices. Incorporating aerogel insulation in copier design is a promising solution for achieving improved energy efficiency and noise reduction in the office environment.The Origins of AerogelAerogel, also known as frozen smoke, was first created in 1931 by Samuel Kistler, a chemist at the College of the Pacific in California. Kistler’s groundbreaking work involved removing the liquid from a gel, leaving behind a solid material that consisted mostly of air. This resulted in a substance with an extremely low density and exceptional insulating properties.Early Applications in AerospaceIn the early years, aerogel was primarily used in aerospace applications. Its lightweight nature and high insulation capabilities made it ideal for insulating spacecraft and protecting sensitive equipment from extreme temperatures during space missions. NASA, in particular, recognized the potential of aerogel and began using it extensively in the 1990s.Expansion into Building InsulationAs the benefits of aerogel became more widely recognized, researchers and engineers started exploring its applications beyond aerospace. In the late 1990s, efforts were made to adapt aerogel for building insulation. The unique properties of aerogel, such as its low thermal conductivity and ability to block sound, made it a promising candidate for improving energy efficiency and reducing noise in buildings.However, early attempts to incorporate aerogel into building materials were met with challenges. The high cost of production and difficulties in scaling up manufacturing processes limited its widespread adoption. Additionally, the fragile nature of aerogel made it challenging to handle and install in construction projects.Advancements in Manufacturing TechniquesIn recent years, significant advancements have been made in the manufacturing techniques of aerogel, addressing some of the previous limitations. One notable breakthrough is the development of flexible aerogels, which can be easily cut, shaped, and integrated into various building materials.New methods, such as freeze-drying and supercritical drying, have also been employed to produce aerogel on a larger scale, reducing production costs and making it more accessible for commercial applications. These advancements have paved the way for the use of aerogel in a wider range of industries, including copier manufacturing.Aerogel in Copier Energy Efficiency and Noise ReductionThe incorporation of aerogel insulation in copiers is a relatively recent development. Copiers, like many other electronic devices, generate heat during operation, which can lead to reduced efficiency and potential damage. By using aerogel insulation, copier manufacturers can improve energy efficiency by minimizing heat loss and maintaining optimal operating temperatures.Aerogel’s exceptional insulating properties also contribute to noise reduction in copiers. The material’s ability to dampen sound waves helps in reducing the noise generated by the copier’s internal components, resulting in quieter operation and a more comfortable working environment.The Future of Aerogel InsulationWith ongoing research and development, the future of aerogel insulation looks promising. As manufacturing techniques continue to improve, the cost of production is expected to decrease further, making aerogel insulation more affordable and accessible for a broader range of applications.Furthermore, advancements in aerogel composites, combining aerogel with other materials, may enhance its durability and ease of handling, addressing some of the challenges faced in the past. This opens up possibilities for even wider adoption of aerogel insulation in various industries, including construction, transportation, and electronics.As we move towards a more energy-efficient and sustainable future, aerogel insulation holds great potential in revolutionizing insulation and noise reduction technologies, offering substantial benefits in terms of energy conservation, improved comfort, and reduced environmental impact.FAQ 1: What is aerogel insulation?Aerogel insulation is a lightweight, highly porous material that is derived from a gel. It is composed of a solid network of interconnected nanoparticles, which create a three-dimensional structure with extremely low density. This unique structure gives aerogel insulation its exceptional thermal and acoustic properties.FAQ 2: How does aerogel insulation improve copier energy efficiency?Aerogel insulation acts as a thermal barrier, preventing heat transfer between the copier’s internal components and the surrounding environment. By reducing heat loss or gain, aerogel insulation helps maintain a stable internal temperature, reducing the workload on the copier’s cooling system. This, in turn, leads to energy savings and improved overall energy efficiency.FAQ 3: Can aerogel insulation reduce noise generated by copiers?Yes, aerogel insulation is effective in reducing noise generated by copiers. Its porous structure helps absorb and dampen sound waves, preventing them from propagating through the copier and into the surrounding environment. By reducing noise levels, aerogel insulation creates a quieter and more comfortable workspace.FAQ 4: Is aerogel insulation compatible with different copier models?Yes, aerogel insulation can be customized to fit different copier models. It is a flexible material that can be shaped and cut to match the specific dimensions and requirements of various copier designs. Manufacturers can work with aerogel insulation suppliers to create tailored insulation solutions for their copier models.FAQ 5: Does aerogel insulation affect the copier’s performance?No, aerogel insulation does not negatively impact the copier’s performance. In fact, it can enhance performance by providing a more stable operating environment. By reducing heat fluctuations and noise levels, aerogel insulation helps maintain optimal conditions for the copier’s components, leading to improved reliability and longevity.FAQ 6: Can aerogel insulation be retrofitted onto existing copiers?Yes, aerogel insulation can be retrofitted onto existing copiers. Its flexibility allows it to be applied to different surfaces and components, making it suitable for retrofitting purposes. Retrofitting copiers with aerogel insulation can be a cost-effective way to improve energy efficiency and reduce noise without having to replace the entire machine.FAQ 7: Are there any safety concerns associated with aerogel insulation?Aerogel insulation is generally considered safe to use. It is non-toxic and non-combustible, meaning it does not release harmful fumes or contribute to the spread of fires. However, it is important to handle aerogel insulation with care, as its fine particles can be irritating to the skin, eyes, and respiratory system. Proper safety precautions should be followed during installation or maintenance.FAQ 8: Does aerogel insulation require regular maintenance?Aerogel insulation is a low-maintenance solution. Once installed, it does not require frequent maintenance or replacement. However, it is advisable to periodically inspect the insulation for any signs of damage or wear. If any issues are detected, repairs or replacements should be carried out to ensure the insulation’s effectiveness.FAQ 9: Can aerogel insulation be used in other applications besides copiers?Yes, aerogel insulation has a wide range of applications beyond copiers. It is used in various industries, including construction, aerospace, and automotive, to improve energy efficiency, thermal insulation, and acoustic insulation. Aerogel insulation is also utilized in clothing, footwear, and outdoor gear to provide lightweight warmth and insulation.FAQ 10: Is aerogel insulation a cost-effective solution for copiers?Aerogel insulation may have a higher initial cost compared to traditional insulation materials. However, its long-term benefits, such as energy savings and extended equipment lifespan, can offset the initial investment. Additionally, the improved energy efficiency and noise reduction provided by aerogel insulation can contribute to a more productive and comfortable work environment, further enhancing its overall cost-effectiveness.Common Misconceptions AboutMisconception 1: Aerogel insulation is too expensive to be practical for copier applicationsOne common misconception about aerogel insulation is that it is prohibitively expensive, making it impractical for copier applications. While it is true that aerogel insulation can be more expensive than traditional insulation materials, it is important to consider the long-term benefits and cost savings it can provide.Aerogel insulation has exceptional thermal insulation properties, which can significantly reduce energy consumption and costs in copiers. By minimizing heat loss and improving thermal efficiency, copiers can operate more efficiently and require less energy to maintain optimal operating temperatures.Furthermore, aerogel insulation can also contribute to noise reduction in copiers. The unique structure of aerogel materials helps to dampen sound waves, resulting in quieter operation. This can be particularly beneficial in office environments where noise pollution can be a significant concern.While the initial cost of aerogel insulation may be higher, the long-term energy savings and improved noise reduction can offset these expenses, making it a practical and cost-effective solution for copier applications.Misconception 2: Aerogel insulation is fragile and prone to damageAnother misconception surrounding aerogel insulation is that it is fragile and prone to damage. While aerogel materials may appear delicate due to their lightweight and translucent nature, they are surprisingly resilient and durable.Aerogel insulation is designed to withstand a wide range of environmental conditions, including temperature fluctuations, moisture, and mechanical stress. It is highly resistant to compression and retains its insulating properties even when subjected to pressure. This makes it suitable for various applications, including copier insulation.Moreover, aerogel materials are chemically stable and non-reactive, ensuring long-term performance and reliability. They are resistant to mold, mildew, and degradation, which can be common issues with other insulation materials. This durability ensures that aerogel insulation can provide consistent thermal insulation and noise reduction benefits over an extended period.While proper handling and installation techniques are necessary to prevent any damage during the installation process, once in place, aerogel insulation can withstand the rigors of copier operation without compromising its effectiveness.Misconception 3: Aerogel insulation is difficult to install and retrofit in existing copiersThere is a misconception that aerogel insulation is challenging to install and retrofit in existing copiers, making it impractical for upgrading older models. However, with advancements in aerogel technology and innovative installation methods, this misconception is no longer accurate.Aerogel insulation can be tailored to fit specific copier designs and configurations. It can be easily cut and shaped to match the dimensions and contours of copier components, ensuring a precise and snug fit. Additionally, aerogel materials are flexible, allowing them to conform to various shapes and sizes without compromising their insulating properties.Furthermore, retrofitting existing copiers with aerogel insulation is a viable option. The lightweight nature of aerogel materials means that they can be added to copiers without significantly increasing their weight or affecting their overall performance. This makes it feasible to upgrade older copier models with aerogel insulation, enhancing their energy efficiency and noise reduction capabilities.Moreover, many manufacturers and suppliers offer professional installation services for aerogel insulation, ensuring proper placement and optimal performance. These experts have the knowledge and experience to install aerogel insulation efficiently and effectively, minimizing any potential disruption to copier operation.In conclusion, aerogel insulation is not only a practical solution for copier energy efficiency and noise reduction, but it also addresses common misconceptions surrounding its cost, durability, and installation. By considering the long-term benefits and cost savings, understanding its resilience and reliability, and recognizing the feasibility of retrofitting, it becomes evident that aerogel insulation is a valuable option for enhancing copier performance.The Concept of Aerogel InsulationAerogel insulation is a fascinating material that is used to make copiers more energy-efficient and reduce noise. It is a lightweight substance that is made up of 90% air, making it one of the lightest solids in existence. Despite its lightness, aerogel is incredibly strong and has amazing insulating properties. It is often referred to as “frozen smoke” because of its translucent appearance.So how does aerogel insulation work? Well, it is made by removing the liquid from a gel through a process called supercritical drying. This process involves replacing the liquid with gas without allowing the gel structure to collapse. The end result is a solid material that is mostly made up of air, but with a highly porous structure. These pores trap air molecules, preventing heat transfer and making it an excellent insulator.When used in copiers, aerogel insulation helps to keep the heat generated by the machine inside, preventing it from escaping into the surrounding environment. This not only makes the copier more energy-efficient but also reduces the amount of noise it produces.Energy Efficiency Benefits of Aerogel InsulationOne of the main benefits of using aerogel insulation in copiers is its ability to improve energy efficiency. Copiers, like many other electronic devices, generate heat as they operate. Without proper insulation, this heat can escape into the surrounding environment, leading to energy wastage.By using aerogel insulation, copiers can retain the heat generated during operation. The aerogel acts as a barrier, preventing the heat from escaping and keeping it inside the machine. This means that less energy is required to maintain the copier’s internal temperature, resulting in lower energy consumption.Reducing energy consumption not only helps to lower electricity bills but also has a positive impact on the environment. By using less energy, copiers with aerogel insulation contribute to reducing greenhouse gas emissions and conserving natural resources.Noise Reduction Benefits of Aerogel InsulationIn addition to improving energy efficiency, aerogel insulation also helps to reduce the noise generated by copiers. Copiers can be quite noisy, especially in busy office environments where multiple machines may be in operation.When copiers are not properly insulated, the noise produced by their internal components, such as motors and fans, can easily escape into the surrounding space. This can be disruptive and distracting for those working nearby.Aerogel insulation acts as a sound barrier, absorbing and dampening the noise produced by the copier’s internal components. The porous structure of aerogel helps to trap sound waves, preventing them from traveling through the material and into the surrounding environment. This results in a significant reduction in noise levels, creating a quieter and more comfortable working environment.By reducing noise pollution, copiers with aerogel insulation contribute to improved productivity and well-being in the workplace. Employees can focus better on their tasks without being disturbed by the constant noise of copiers operating nearby.ConclusionIn conclusion, the exploration of the benefits of aerogel insulation for copier energy efficiency and noise reduction has revealed promising results. Aerogel insulation has been shown to significantly reduce heat loss, leading to improved energy efficiency in copiers. This not only reduces energy consumption and lowers operating costs but also contributes to a more sustainable and environmentally-friendly workplace.Furthermore, aerogel insulation has proven to be highly effective in reducing noise levels emitted by copiers. This is particularly beneficial in office environments where noise can be a major distraction and cause discomfort for employees. By implementing aerogel insulation, copiers can operate at much quieter levels, creating a more peaceful and productive work environment.Overall, the application of aerogel insulation in copiers presents a win-win solution for businesses. It not only enhances energy efficiency and reduces operating costs but also improves the overall comfort and productivity of employees. As technology continues to advance, it is essential for companies to explore innovative solutions like aerogel insulation to optimize copier performance and create sustainable workspaces.