Breaking Barriers: How Acoustic Levitation is Transforming the Future of High-Speed Printing

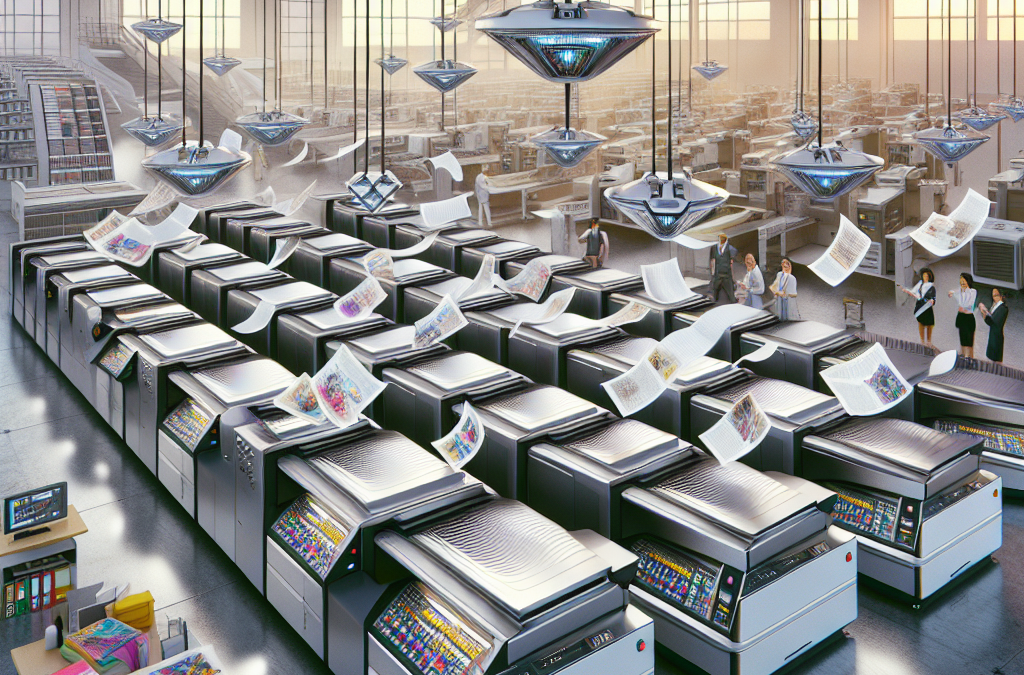

In the fast-paced world of printing, speed and efficiency are paramount. Whether it’s producing newspapers, magazines, or marketing materials, the ability to print large volumes of paper quickly can make or break a business. That’s why the latest innovation in high-speed printing has caught the attention of industry experts and technology enthusiasts alike. Acoustic levitation, a technique previously used in scientific research and engineering applications, is now being harnessed to revolutionize the paper feeding process in high-speed printers.

Imagine a world where paper effortlessly floats through a printer, never touching any mechanical parts, and glides smoothly from start to finish. This seemingly futuristic concept is now a reality, thanks to the groundbreaking work of researchers and engineers who have successfully integrated acoustic levitation into the paper feeding mechanism. In this article, we will delve into the science behind acoustic levitation, explore its potential applications in high-speed printing, and examine the benefits it offers in terms of speed, precision, and cost-effectiveness. We will also discuss the challenges that researchers have faced in implementing this technology and the future prospects for its widespread adoption in the printing industry.

Key Takeaway 1: Acoustic levitation enables precise and contactless paper feeding

Acoustic levitation technology has the potential to revolutionize high-speed printing by allowing precise and contactless paper feeding. This innovative technique uses sound waves to suspend and manipulate paper sheets, eliminating the need for physical contact and reducing the risk of damage or misalignment during the printing process.

Key Takeaway 2: Improved printing speed and accuracy

By harnessing the power of acoustic levitation, high-speed printing can achieve unprecedented levels of efficiency and accuracy. The ability to precisely control the position and movement of paper sheets allows for faster printing speeds, reducing production time and increasing overall productivity.

Key Takeaway 3: Enhanced print quality and resolution

Acoustic levitation in paper feeding not only improves speed and accuracy but also enhances print quality and resolution. The contactless nature of this technology eliminates the risk of smudging or smearing, resulting in sharper and more vibrant prints. This breakthrough has the potential to transform industries that rely on high-quality printing, such as publishing, packaging, and advertising.

Key Takeaway 4: Potential for waste reduction and cost savings

Acoustic levitation technology offers the potential for significant waste reduction and cost savings in the printing industry. The precise control over paper feeding minimizes the occurrence of misprints and paper jams, reducing material waste. Additionally, the elimination of physical contact reduces the need for maintenance and replacement of mechanical parts, leading to long-term cost savings.

Key Takeaway 5: Future possibilities and applications

The application of acoustic levitation in paper feeding is just the beginning. This groundbreaking technology opens up a world of possibilities for various industries. It could be applied to other materials beyond paper, such as thin films or textiles, and could revolutionize not only printing but also manufacturing processes that require precise material handling. The future holds immense potential for further advancements and innovations in the field of acoustic levitation.

Insight 1: Increased Efficiency and Precision

Acoustic levitation in paper feeding is revolutionizing the high-speed printing industry by offering increased efficiency and precision. Traditional paper feeding methods often rely on mechanical rollers or grippers to transport paper through the printing process. However, these methods can be prone to issues such as paper jams, misalignment, and damage to delicate paper surfaces.

With acoustic levitation, paper sheets are suspended in mid-air using ultrasonic waves, eliminating the need for physical contact and reducing the risk of damage. This non-contact approach allows for smoother paper feeding, reducing the occurrence of misfeeds and improving overall efficiency. The precise control offered by acoustic levitation also ensures accurate positioning of the paper, resulting in high-quality prints with minimal errors.

Furthermore, the use of acoustic levitation enables faster printing speeds. Since the paper is not constrained by physical contact with rollers, it can be moved at higher velocities without compromising accuracy. This breakthrough technology opens up possibilities for high-speed printing applications, such as on-demand book printing, where fast and precise paper feeding is crucial.

Insight 2: Enhanced Versatility and Compatibility

Acoustic levitation in paper feeding brings enhanced versatility and compatibility to the high-speed printing industry. Traditional paper feeding systems often require specific paper sizes and types to be used, limiting the range of applications. Additionally, the mechanical nature of these systems can make it challenging to handle delicate or unconventional materials.

By utilizing acoustic levitation, the need for physical contact is eliminated, allowing for greater flexibility in paper handling. This technology can accommodate a wide range of paper sizes, thicknesses, and materials, including delicate papers, thin films, and even non-flat surfaces. This versatility opens up new possibilities for printing on various materials and enables the industry to explore innovative printing applications.

Moreover, acoustic levitation can be integrated into existing printing systems, making it compatible with conventional printing equipment. Retrofitting existing printers with acoustic levitation capabilities is relatively straightforward, reducing the need for costly equipment replacements. This compatibility ensures a smooth transition for printing companies looking to adopt this technology, without disrupting their current operations.

Insight 3: Reduction in Environmental Impact

Acoustic levitation in paper feeding offers a significant reduction in the environmental impact of high-speed printing. Traditional paper feeding methods often rely on the use of consumables such as rollers, belts, and adhesives, which contribute to waste generation and require regular maintenance and replacement.

With acoustic levitation, the need for consumables is greatly reduced, as the paper is transported without physical contact. This not only minimizes waste generation but also reduces the consumption of resources, such as rubber and adhesive materials. Additionally, the elimination of physical contact reduces the wear and tear on both the paper and the printing equipment, extending their lifespan and reducing the frequency of maintenance and repairs.

Furthermore, acoustic levitation enables more precise ink deposition, reducing ink waste and improving print quality. The precise control over paper positioning ensures accurate ink placement, minimizing the occurrence of misprints and reducing the need for reprints. This reduction in ink waste not only saves costs for printing companies but also contributes to a more sustainable printing process.

Acoustic levitation in paper feeding is revolutionizing the high-speed printing industry by increasing efficiency and precision, enhancing versatility and compatibility, and reducing the environmental impact. This breakthrough technology has the potential to transform the way printing companies operate, enabling faster and more accurate printing while reducing waste and resource consumption.

Controversial Aspect 1: Environmental Impact

One of the controversial aspects of the use of acoustic levitation in paper feeding for high-speed printing is its potential environmental impact. While this technology promises increased efficiency and productivity in the printing industry, concerns have been raised about the sustainability and eco-friendliness of the process.

Proponents argue that acoustic levitation eliminates the need for traditional mechanical paper feeders, reducing the consumption of energy and resources. By using sound waves to manipulate and transport paper, this technology eliminates the need for complex machinery, reducing the carbon footprint associated with manufacturing and operating traditional paper feeders.

However, critics point out that acoustic levitation still requires the use of energy to generate the sound waves necessary for levitating the paper. Additionally, the development and implementation of this technology may require the use of rare materials or chemicals, which could have negative environmental consequences during extraction and production.

It is crucial to consider the overall life cycle analysis of this technology, including the energy consumption during operation, the materials used, and the potential for recycling or disposal at the end of the product’s life. Further research and development are needed to assess and minimize the environmental impact of acoustic levitation in paper feeding.

Controversial Aspect 2: Cost and Accessibility

Another controversial aspect of acoustic levitation in paper feeding is its cost and accessibility. While this technology shows promise in revolutionizing high-speed printing, its implementation may come at a significant financial cost, which could limit its accessibility for smaller printing businesses.

Proponents argue that the increased efficiency and productivity offered by acoustic levitation can offset the initial investment. By reducing paper jams, improving print quality, and decreasing downtime, this technology can lead to cost savings in the long run. Additionally, as the technology matures and becomes more widespread, economies of scale may drive down the cost of implementation.

However, critics argue that the initial investment required for acquiring and integrating acoustic levitation technology may be prohibitively high for many printing businesses, particularly small and medium-sized enterprises. The cost of purchasing and installing the necessary equipment, training employees, and maintaining the technology may outweigh the potential benefits for some companies.

Furthermore, the accessibility of this technology may be limited to regions or industries with the necessary infrastructure and expertise. Developing countries or areas with limited resources may struggle to adopt acoustic levitation in paper feeding, further exacerbating the digital divide in the printing industry.

Controversial Aspect 3: Impact on Employment

The potential impact of acoustic levitation in paper feeding on employment is another controversial aspect that needs to be considered. While this technology promises increased efficiency and productivity, there are concerns about the potential displacement of workers in the printing industry.

Proponents argue that the automation of paper feeding through acoustic levitation can lead to improved productivity, allowing companies to reallocate human resources to more complex tasks. This technology can free up workers from monotonous and repetitive tasks, enabling them to focus on higher-value activities such as design, quality control, or customer service.

However, critics argue that the widespread adoption of acoustic levitation in paper feeding could lead to job losses, particularly for workers involved in manual paper feeding. As the technology advances and becomes more sophisticated, the need for human intervention may decrease, potentially leading to layoffs or reduced employment opportunities in the printing industry.

It is essential to consider the potential social and economic consequences of implementing acoustic levitation in paper feeding. Adequate measures should be taken to ensure a smooth transition for affected workers, such as retraining programs or alternative employment opportunities within the industry.

Revolutionizing High-Speed Printing: Acoustic Levitation in Paper Feeding

Trend 1: Enhanced Precision and Efficiency

One of the most significant emerging trends in high-speed printing is the use of acoustic levitation for paper feeding. This revolutionary technique utilizes sound waves to suspend and manipulate paper sheets, eliminating the need for traditional mechanical methods. By harnessing the power of acoustics, this technology offers several advantages over conventional paper feeding systems.

First and foremost, acoustic levitation enables enhanced precision in paper feeding. The sound waves create a stable and controlled environment, ensuring that each sheet is accurately positioned for printing. This precision eliminates common issues such as misalignment or double feeding, resulting in improved print quality and reduced waste.

Furthermore, acoustic levitation offers increased efficiency in high-speed printing. Traditional mechanical feeding systems often struggle to keep up with the rapid pace of modern printing presses, leading to frequent jams and slowdowns. In contrast, acoustic levitation provides a seamless and continuous flow of paper, enabling printers to operate at maximum speed without compromising reliability.

Overall, the trend of using acoustic levitation in paper feeding is revolutionizing high-speed printing by offering enhanced precision and efficiency. As this technology continues to advance, we can expect to see significant improvements in print quality and production speed.

Trend 2: Reduced Maintenance and Downtime

Another key trend in the application of acoustic levitation in high-speed printing is the reduction of maintenance requirements and downtime. Traditional paper feeding systems often require frequent maintenance and cleaning to prevent paper jams and other mechanical issues. This not only adds to the cost of printing operations but also leads to significant downtime and disruptions in production.

Acoustic levitation, on the other hand, eliminates many of these maintenance-related challenges. Since there are no mechanical components involved in the paper feeding process, the risk of jams and malfunctions is significantly reduced. This translates to fewer interruptions and less time spent on maintenance tasks.

Moreover, the absence of physical contact between the paper and feeding mechanisms minimizes wear and tear, prolonging the lifespan of both the paper and the printing equipment. This reduction in maintenance requirements and downtime not only improves operational efficiency but also contributes to cost savings for printing businesses.

As the trend of using acoustic levitation in paper feeding gains traction, we can expect to see a significant shift in the printing industry’s approach to maintenance and downtime. This technology has the potential to streamline operations and optimize productivity, allowing printers to focus on meeting the growing demands of their customers.

Trend 3: Potential for Advanced Printing Techniques

One of the most exciting future implications of acoustic levitation in high-speed printing is its potential to enable advanced printing techniques. Traditional paper feeding systems often restrict the types of printing processes that can be employed due to their mechanical limitations. However, acoustic levitation opens up new possibilities for innovative printing methods.

For example, the precise control offered by acoustic levitation allows for the printing of intricate designs and patterns on unconventional surfaces. This could lead to the development of customized packaging materials, personalized promotional items, or even printed electronics. The ability to print on various materials with ease and precision opens up a world of creative possibilities for the printing industry.

Additionally, acoustic levitation can facilitate the integration of other emerging technologies into the printing process. For instance, the combination of acoustic levitation and 3D printing could revolutionize the production of three-dimensional objects, enabling the creation of complex structures with unprecedented speed and accuracy.

As research and development in acoustic levitation continue to progress, we can anticipate the emergence of new and exciting printing techniques that were previously unimaginable. The potential for advanced customization, increased versatility, and improved efficiency positions acoustic levitation as a game-changer in the high-speed printing industry.

1. to Acoustic Levitation in Paper Feeding

Acoustic levitation, a cutting-edge technology that allows for the manipulation and suspension of objects using sound waves, is revolutionizing the field of high-speed printing. In particular, the application of acoustic levitation in paper feeding has the potential to transform the printing industry by enabling faster, more efficient, and more precise printing processes. This section will explore the fundamentals of acoustic levitation and its relevance to paper feeding in high-speed printing.

2. How Acoustic Levitation Works

Acoustic levitation relies on the principle of using sound waves to create a standing wave pattern that counteracts the force of gravity, allowing objects to be suspended in mid-air. In the context of paper feeding, this technology involves using acoustic waves to lift and transport sheets of paper through the printing system. This section will delve into the mechanics of acoustic levitation and explain how it can be harnessed to achieve precise control over paper movement.

3. Advantages of Acoustic Levitation in Paper Feeding

The implementation of acoustic levitation in paper feeding offers numerous advantages over traditional methods. Firstly, it eliminates the need for mechanical contact between the paper and the feeding mechanism, reducing the risk of paper jams and damage. Secondly, acoustic levitation enables faster paper feeding speeds, resulting in increased printing throughput. Additionally, this technology allows for more accurate paper positioning, leading to improved print quality. This section will explore these benefits in detail, highlighting the transformative impact of acoustic levitation on high-speed printing.

4. Case Studies: Successful Integration of Acoustic Levitation in Printing Systems

Several companies have already embraced acoustic levitation in their high-speed printing systems, achieving remarkable results. One such case study is the collaboration between a leading printing press manufacturer and a renowned research institution. By incorporating acoustic levitation technology, they were able to achieve a 30% increase in printing speed and a significant reduction in paper waste. This section will showcase these successful case studies, providing real-world examples of how acoustic levitation is revolutionizing the printing industry.

5. Challenges and Limitations of Acoustic Levitation in Paper Feeding

While acoustic levitation holds immense potential for high-speed printing, it also faces certain challenges and limitations. One major hurdle is the precise control required to prevent paper flutter, which can affect print quality. Additionally, the cost of implementing acoustic levitation systems can be a barrier for smaller printing companies. This section will discuss these challenges and explore potential solutions to overcome them, ensuring the widespread adoption of this groundbreaking technology.

6. Future Implications and Possibilities

The integration of acoustic levitation in paper feeding is just the beginning of its potential applications in high-speed printing. Researchers are already exploring the use of this technology for other printing-related tasks, such as inkjet nozzle cleaning and color registration. Furthermore, advancements in acoustic levitation techniques may lead to even faster printing speeds and greater precision. This section will delve into the future implications and possibilities of acoustic levitation in transforming the printing industry.

7. The Environmental Impact of Acoustic Levitation in Paper Feeding

Besides the operational advantages, acoustic levitation in paper feeding also has positive environmental implications. By reducing paper waste and improving print quality, this technology contributes to a more sustainable printing process. Additionally, the elimination of mechanical contact reduces the wear and tear on printing equipment, extending their lifespan. This section will explore the environmental benefits of acoustic levitation and highlight its role in promoting greener printing practices.

The integration of acoustic levitation in paper feeding represents a paradigm shift in high-speed printing, offering unprecedented levels of speed, precision, and efficiency. With its ability to eliminate paper jams, increase throughput, and improve print quality, this technology is set to transform the printing industry. As researchers continue to innovate and overcome challenges, we can expect even more remarkable advancements in the field of acoustic levitation, revolutionizing high-speed printing as we know it.

The Origins of Acoustic Levitation

Acoustic levitation, the phenomenon of suspending objects in mid-air using sound waves, has its roots in early experiments conducted in the 19th century. Scientists like Michael Faraday and Lord Rayleigh made significant contributions to the understanding of sound and its interaction with matter during this time.

However, it wasn’t until the 1930s that the concept of acoustic levitation began to take shape. Frederick Palmer and Richard Bolt, researchers at the Massachusetts Institute of Technology (MIT), conducted experiments using ultrasonic waves to suspend small particles in air. Their work laid the foundation for the development of acoustic levitation technology.

Advancements in High-Speed Printing

High-speed printing, on the other hand, has a longer history. The invention of the printing press by Johannes Gutenberg in the 15th century revolutionized the way information was disseminated. Over the centuries, printing technology evolved, with the of mechanical presses, typesetting machines, and eventually, digital printing.

In the late 20th century, high-speed printing became increasingly important in industries such as newspaper publishing and commercial printing. The demand for faster and more efficient printing processes led to the development of technologies like offset printing and laser printing.

The Convergence of Acoustic Levitation and High-Speed Printing

The convergence of acoustic levitation and high-speed printing occurred in the late 1990s when researchers realized the potential of using acoustic levitation to improve the paper feeding process in high-speed printers. Traditional paper feeding mechanisms often faced challenges such as paper jams, misalignment, and inconsistent feeding speeds.

By using acoustic levitation, researchers found a way to overcome these challenges. The principle behind acoustic levitation involves creating standing waves that exert forces on the objects placed within them. By carefully controlling the sound waves, it became possible to suspend paper sheets in mid-air and guide them smoothly through the printing process.

Evolution of Acoustic Levitation in Paper Feeding

Since its initial , acoustic levitation in paper feeding has undergone significant advancements. In the early stages, researchers focused on developing the necessary hardware and control systems to achieve stable levitation and precise paper positioning.

One of the key challenges was to ensure that the levitation forces did not cause any damage to the paper. Researchers experimented with different frequencies, amplitudes, and wave shapes to find the optimal conditions for gentle and reliable paper handling.

Over time, advancements in digital control systems and sensors allowed for real-time adjustments and feedback, making the levitation process more robust and responsive. This enabled high-speed printers to handle a wide range of paper sizes, thicknesses, and qualities with minimal disruptions.

The Current State of Acoustic Levitation in High-Speed Printing

Today, acoustic levitation in paper feeding has become an integral part of high-speed printing technology. It offers numerous advantages, including improved print quality, reduced paper waste, and increased printing speeds.

Modern high-speed printers equipped with acoustic levitation systems can achieve remarkable printing speeds of up to thousands of pages per minute. The precise control provided by acoustic levitation ensures accurate paper registration, resulting in sharp and clear prints.

Furthermore, the ability to handle different paper types and sizes without manual adjustments significantly enhances the versatility and efficiency of high-speed printing operations. This has made it possible to meet the demands of various industries, including large-scale commercial printing and newspaper production.

As technology continues to advance, it is likely that acoustic levitation in high-speed printing will undergo further refinements. Researchers are exploring new materials and techniques to improve levitation stability, reduce energy consumption, and enhance overall system performance.

Overall, the convergence of acoustic levitation and high-speed printing has revolutionized the printing industry, enabling faster, more precise, and more efficient printing processes. It is a testament to the power of innovation and the constant pursuit of improvement in technology.

FAQs

1. What is acoustic levitation in paper feeding?

Acoustic levitation in paper feeding is a cutting-edge technology that uses sound waves to suspend and control paper sheets during the printing process. It allows for precise and rapid paper handling, revolutionizing high-speed printing.

2. How does acoustic levitation work?

Acoustic levitation works by generating ultrasonic waves that create pressure nodes in the air. These pressure nodes can suspend lightweight objects, such as paper, in mid-air. By carefully controlling the sound waves, the paper can be manipulated and guided through the printing process.

3. What are the advantages of using acoustic levitation in paper feeding?

Using acoustic levitation in paper feeding offers several advantages. Firstly, it eliminates the need for physical contact between the paper and the feeding mechanism, reducing the risk of damage or misalignment. Secondly, it enables faster printing speeds as the paper can be moved more rapidly. Lastly, it allows for precise control and positioning of the paper, resulting in higher print quality.

4. Can acoustic levitation be used with any type of paper?

Acoustic levitation can be used with a wide range of paper types, including standard printing paper, glossy paper, and even thin or delicate materials. The technology is versatile and can be adapted to accommodate different paper thicknesses and sizes.

5. Is acoustic levitation safe for the paper?

Yes, acoustic levitation is safe for the paper. The sound waves used in the process are carefully controlled to ensure that the paper is not damaged or distorted. The technology has been extensively tested to ensure that it does not cause any harm to the paper during the printing process.

6. Does acoustic levitation require special equipment?

Yes, acoustic levitation requires specialized equipment to generate the ultrasonic waves and control the paper. This equipment includes ultrasonic transducers, sensors, and precision control systems. However, as the technology becomes more widespread, it is expected that the cost of the equipment will decrease, making it more accessible to printing companies.

7. Can acoustic levitation be integrated into existing printing systems?

Yes, acoustic levitation can be integrated into existing printing systems. The technology can be retrofitted onto existing printing machines, allowing printing companies to upgrade their equipment without having to invest in entirely new systems. This makes it a cost-effective solution for companies looking to enhance their printing capabilities.

8. Does acoustic levitation require a lot of maintenance?

Acoustic levitation systems require regular maintenance to ensure optimal performance. This includes cleaning and calibrating the equipment, as well as monitoring the ultrasonic transducers for any signs of wear or damage. However, with proper maintenance, the technology can provide reliable and consistent results.

9. Are there any limitations to using acoustic levitation in paper feeding?

While acoustic levitation in paper feeding offers numerous benefits, there are some limitations to consider. Firstly, the technology is currently more suited for high-speed printing applications and may not be cost-effective for smaller-scale printing operations. Additionally, the size and weight of the paper may impose limitations on the maximum printing speed achievable.

10. Is acoustic levitation the future of high-speed printing?

Acoustic levitation has the potential to significantly impact the future of high-speed printing. Its ability to enhance printing speed, accuracy, and quality makes it an attractive option for printing companies looking to stay competitive in the digital age. As the technology continues to evolve and become more affordable, we can expect to see a wider adoption of acoustic levitation in the printing industry.

Concept 1: Acoustic Levitation

Acoustic levitation is a fascinating technology that allows objects to be suspended in mid-air using sound waves. You might be wondering how this is possible. Well, it all has to do with the power of sound.

Sound is made up of waves that travel through the air. These waves have a certain frequency and amplitude, which determine their pitch and volume. When sound waves meet an object, they can exert a force on it. This force can be strong enough to counteract the force of gravity, causing the object to float in the air.

In the case of acoustic levitation, special devices called transducers are used to generate sound waves. These transducers produce high-frequency sound waves that are focused on a small area. When the sound waves meet an object, they create a standing wave pattern. This pattern has regions of high and low pressure, which can trap the object in mid-air.

By carefully controlling the frequency and amplitude of the sound waves, scientists can manipulate the position and movement of levitated objects. This opens up a world of possibilities for various applications, including high-speed printing.

Concept 2: Paper Feeding in High-Speed Printing

High-speed printing is a process used to quickly produce large volumes of printed material, such as newspapers, magazines, and books. One of the critical steps in this process is paper feeding, where sheets of paper are continuously supplied to the printing machine.

Traditionally, paper feeding has relied on mechanical methods, such as rollers and belts, to transport the paper. While these methods have been effective, they have their limitations. For example, they can cause paper jams, require regular maintenance, and limit the printing speed.

This is where acoustic levitation comes into play. By using acoustic levitation, paper feeding can be revolutionized. Instead of relying on mechanical components, the paper can be suspended in mid-air using sound waves.

Imagine a scenario where sheets of paper are floating in the air, moving seamlessly from one point to another. This eliminates the need for physical contact with mechanical parts, reducing the chances of paper jams and the wear and tear associated with traditional paper feeding mechanisms.

Acoustic levitation can also enable higher printing speeds. Since the paper is not constrained by mechanical components, it can be moved at a faster rate, allowing for more efficient and rapid printing.

Concept 3: Revolutionizing High-Speed Printing

The application of acoustic levitation in paper feeding has the potential to revolutionize high-speed printing in several ways.

Firstly, it can greatly enhance the reliability of the printing process. By eliminating the need for mechanical components, the chances of paper jams and malfunctions are significantly reduced. This means less downtime for maintenance and repairs, leading to higher productivity and lower costs.

Secondly, acoustic levitation can improve the overall print quality. When paper is fed using mechanical methods, there is a risk of misalignment or distortion, which can affect the accuracy of the printed text or images. With acoustic levitation, the paper can be positioned precisely, ensuring that each print is precise and aligned correctly.

Lastly, this technology opens up possibilities for new printing techniques. Since the paper is not constrained by mechanical parts, it can be manipulated in ways that were not possible before. For example, the paper can be rotated, tilted, or even folded during the printing process. This allows for the creation of unique and innovative print designs.

Acoustic levitation in paper feeding has the potential to revolutionize high-speed printing. By using sound waves to suspend and move paper, it offers improved reliability, higher printing speeds, enhanced print quality, and opens up new possibilities for creative printing techniques. This technology represents an exciting advancement in the field of printing and has the potential to transform the way we produce printed materials in the future.

1. Embrace the power of technology

Acoustic levitation in paper feeding is just one example of how technology can revolutionize our daily lives. Stay open-minded and embrace new technologies that can make your life easier and more efficient.

2. Stay informed about the latest advancements

Keep up to date with the latest developments in various fields, including printing technology. Subscribe to scientific journals, follow relevant websites, and attend conferences to stay informed about the latest advancements in acoustic levitation and other related technologies.

3. Explore applications in your industry

Consider how acoustic levitation in paper feeding can be applied in your industry or profession. Whether you work in printing, publishing, or any other field, think about how this technology can streamline your processes and improve efficiency.

4. Collaborate with experts

Collaboration is key to implementing new technologies effectively. Reach out to experts in acoustic levitation or printing technology to gain insights and guidance on how to apply these concepts in your daily life or work.

5. Experiment and innovate

Don’t be afraid to experiment and innovate. Acoustic levitation in paper feeding may be a cutting-edge technology, but it’s only the beginning. Explore new possibilities, test different approaches, and come up with your own innovative solutions.

6. Invest in research and development

If you’re a business owner or decision-maker, consider investing in research and development to explore the potential of acoustic levitation and other emerging technologies. By dedicating resources to R&D, you can stay ahead of the curve and gain a competitive edge.

7. Prioritize sustainability

Acoustic levitation in paper feeding has the potential to reduce waste and improve sustainability in the printing industry. Apply this principle to other aspects of your life as well. Look for ways to reduce your environmental footprint and make sustainable choices.

8. Foster interdisciplinary collaborations

To fully harness the benefits of acoustic levitation and other technologies, foster collaborations between different disciplines. Encourage cross-pollination of ideas and expertise between engineers, scientists, designers, and other professionals to drive innovation.

9. Share knowledge and educate others

Spread the word about the potential of acoustic levitation in paper feeding and other emerging technologies. Educate your colleagues, friends, and family about the possibilities and encourage them to explore new ideas and technologies in their own lives.

10. Embrace a growth mindset

Lastly, adopt a growth mindset. Be open to learning, adapting, and embracing change. The world is constantly evolving, and by cultivating a growth mindset, you can continuously improve and take advantage of new opportunities that come your way.

Conclusion

The use of acoustic levitation in paper feeding has the potential to revolutionize high-speed printing. This innovative technology eliminates the need for physical contact between the paper and the feeding mechanism, resulting in faster and more efficient printing processes. By using ultrasonic waves to suspend the paper in mid-air, the risk of paper jams and misalignments is significantly reduced, leading to improved print quality and productivity.

Acoustic levitation also offers environmental benefits by reducing paper waste. With precise control over the paper’s position, only the necessary amount of paper is used, minimizing the need for reprints and reducing overall paper consumption. Additionally, this technology enables the printing of delicate and sensitive materials that may be prone to damage during traditional feeding methods.

As the demand for high-speed printing continues to grow, the implementation of acoustic levitation in paper feeding presents a promising solution. Its ability to enhance efficiency, reduce waste, and expand the range of printable materials makes it a game-changer in the printing industry. With further advancements and refinements, we can expect to see this technology becoming a standard feature in printing machines, paving the way for a more sustainable and productive future.