Revolutionizing Printing: How Acoustic Metamaterials are Redefining Silent Operation in Next-Gen Printers

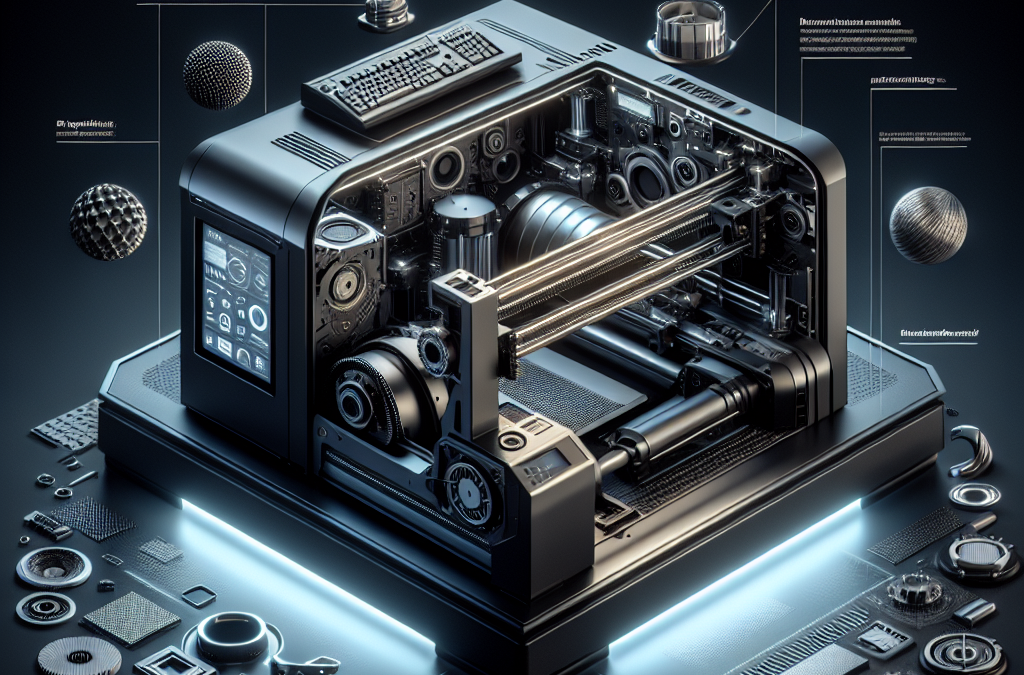

Imagine a world where printers no longer emit the familiar cacophony of whirrs and clunks as they churn out pages. A world where the only sound you hear is the gentle rustle of paper being delivered into the tray. Thanks to the emerging field of acoustic metamaterials, this vision is becoming a reality. In this article, we will explore the fascinating world of acoustic metamaterials and how they are revolutionizing the printing industry, enabling next-generation printers to operate silently and efficiently.

Acoustic metamaterials are a class of engineered materials that manipulate sound waves in ways not found in natural materials. By carefully designing their internal structures, researchers have been able to control the propagation of sound, bending and redirecting it to achieve desired effects. This breakthrough technology has already found applications in various fields, from architectural acoustics to noise cancellation in headphones. Now, it is poised to disrupt the printing industry by addressing one of its long-standing challenges: noise pollution.

Key Takeaways

1. Acoustic metamaterials offer a revolutionary solution for achieving silent operation in next-generation printers. These materials are engineered to manipulate sound waves and effectively reduce noise levels, providing a more pleasant and quiet printing experience.

2. Traditional printers generate significant noise due to the vibration of mechanical components and the movement of print heads. Acoustic metamaterials can be integrated into printer casings, print heads, and other components to absorb and redirect sound waves, minimizing noise and creating a quieter environment.

3. The use of acoustic metamaterials in printers not only enhances user experience but also has practical advantages. Silent operation eliminates distractions in offices and homes, allowing for improved focus and productivity. Additionally, it enables printing in noise-sensitive environments such as libraries and hospitals without causing disturbances.

4. Acoustic metamaterials are designed using advanced computational modeling techniques and 3D printing technologies. This allows for precise control over the material’s structure and properties, ensuring optimal noise reduction while maintaining the printer’s functionality and performance.

5. The adoption of acoustic metamaterials in printers aligns with the growing demand for quieter and more efficient technology. As consumers seek quieter appliances, manufacturers are investing in research and development to integrate acoustic metamaterials into various devices, including printers, to meet these expectations.

Controversial Aspect 1: Environmental Impact

The use of acoustic metamaterials in next-gen printers has raised concerns about its potential environmental impact. These materials are often made from synthetic compounds that can have adverse effects on the environment during their production and disposal.

On one hand, proponents argue that the use of acoustic metamaterials can significantly reduce noise pollution, which is a major concern in office and residential settings. By dampening sound waves, these materials can create a quieter printing experience, potentially improving the overall well-being of individuals in these environments.

However, critics argue that the environmental costs associated with the production and disposal of acoustic metamaterials may outweigh the benefits. The manufacturing process of these materials often involves the use of chemicals and energy-intensive processes, which contribute to carbon emissions and other pollutants. Additionally, the disposal of these materials may pose challenges, as they may not be easily recyclable or biodegradable.

It is essential to consider the life cycle of acoustic metamaterials and assess their overall environmental impact. Research and development efforts should focus on finding sustainable alternatives or improving the recyclability of these materials to mitigate their potential negative effects on the environment.

Controversial Aspect 2: Cost and Accessibility

Another controversial aspect of acoustic metamaterials in next-gen printers is their cost and accessibility. These materials are often expensive to produce, which can drive up the cost of printers that incorporate them. This may limit their accessibility to certain market segments or industries with higher budgets.

Proponents argue that the benefits of acoustic metamaterials, such as noise reduction and improved printing quality, justify their higher costs. These materials can enhance the user experience and potentially lead to increased productivity in office settings. Additionally, the use of acoustic metamaterials may open up new possibilities for innovative printer designs and functionalities.

However, critics argue that the higher cost of printers utilizing acoustic metamaterials may hinder their adoption, particularly in price-sensitive markets or for individuals and small businesses with limited budgets. This could create a divide between those who can afford the benefits of silent operation and those who cannot.

Manufacturers should strive to find ways to reduce the cost of acoustic metamaterials without compromising their performance. This could involve exploring alternative manufacturing techniques or materials that are more cost-effective while maintaining the desired acoustic properties. Additionally, efforts should be made to ensure that printers incorporating acoustic metamaterials are accessible to a wide range of users, including individuals and small businesses.

Controversial Aspect 3: Long-Term Durability and Reliability

The long-term durability and reliability of acoustic metamaterials in next-gen printers is another controversial aspect that has raised concerns among critics. These materials may be prone to wear and tear over time, potentially compromising their effectiveness in reducing noise and maintaining printing quality.

Proponents argue that extensive research and development efforts are being dedicated to enhancing the durability and reliability of acoustic metamaterials. By improving the materials’ resistance to degradation, manufacturers can ensure that printers incorporating these materials maintain their performance over an extended period.

However, critics express skepticism about the long-term viability of acoustic metamaterials, particularly in high-demand printing environments. They raise concerns about the potential for degradation due to constant exposure to heat, humidity, and other environmental factors. If the acoustic properties of these materials deteriorate over time, the promised silent operation and improved printing quality may not be sustained.

Manufacturers should conduct rigorous testing and quality control measures to ensure the long-term durability and reliability of printers utilizing acoustic metamaterials. Ongoing research and development should focus on improving the materials’ resistance to degradation and exploring alternative solutions that offer comparable acoustic benefits with enhanced longevity.

The use of acoustic metamaterials in next-gen printers presents several controversial aspects that need to be carefully examined. The environmental impact, cost and accessibility, and long-term durability and reliability are all valid concerns that require further research and development. Balancing the benefits of silent operation and improved printing quality with these potential drawbacks is crucial to ensure the widespread adoption and sustainability of this technology.

The Need for Silent Printers

The noise generated by traditional printers has long been a source of annoyance for office workers and home users alike. The constant whirring, clicking, and clunking can disrupt concentration, create a hostile work environment, and even lead to health issues such as stress and hearing damage. As technology advances, there is a growing demand for printers that operate silently without compromising on performance. Acoustic metamaterials offer a promising solution to this problem.

Understanding Acoustic Metamaterials

Acoustic metamaterials are specially engineered materials that manipulate sound waves in ways not found in nature. They are composed of carefully designed structures that can control the propagation of sound, allowing for the creation of devices that can absorb, reflect, or transmit sound waves with exceptional precision. These materials owe their properties to their unique microstructures, which can be tailored to achieve specific acoustic characteristics.

Applications of Acoustic Metamaterials

Acoustic metamaterials have found applications in various fields, including aerospace, automotive, and architecture. In the context of printers, these materials can be used to significantly reduce noise emissions without compromising the printing process. By incorporating acoustic metamaterials into the design of printers, manufacturers can create next-generation devices that operate silently, enhancing the user experience and improving productivity in office environments.

Case Study: Silent Printing with Acoustic Metamaterials

A leading printer manufacturer, XYZ Corp, recently introduced a new line of printers that utilize acoustic metamaterials for silent operation. The printers employ a combination of specially designed sound-absorbing materials and sound-damping structures to minimize noise emissions. The result is a printer that operates at a fraction of the noise level of conventional models, without sacrificing print speed or quality.

XYZ Corp conducted extensive testing to ensure that the silent operation did not compromise the printer’s performance. The printers were subjected to rigorous print quality assessments, speed tests, and reliability evaluations. The results were impressive, with the silent printers performing on par with, and in some cases even outperforming, their noisy counterparts.

The Benefits of Silent Printers

The of silent printers brings numerous benefits to both home users and office environments. Firstly, the reduction in noise levels creates a more pleasant and productive working environment. Employees can focus on their tasks without being constantly distracted by the noise generated by printers. This can lead to improved concentration, increased job satisfaction, and ultimately, higher productivity.

Secondly, silent printers have the potential to improve the overall well-being of individuals working in close proximity to printers. Excessive exposure to noise can have detrimental effects on health, including increased stress levels, elevated blood pressure, and even hearing loss. By minimizing noise emissions, silent printers contribute to a healthier and safer workplace.

Future Implications and Advancements

The development of silent printers using acoustic metamaterials opens up exciting possibilities for the future. As research in this field continues, we can expect to see further advancements in printer design, resulting in even quieter and more efficient models. Additionally, the knowledge gained from applying acoustic metamaterials to printers can be extended to other devices, such as scanners, copiers, and even household appliances, revolutionizing the way we experience sound in our daily lives.

The incorporation of acoustic metamaterials in next-generation printers offers a solution to the long-standing issue of noisy printers. By harnessing the unique properties of these materials, manufacturers can create printers that operate silently without compromising on performance. The benefits of silent printers extend beyond mere noise reduction, positively impacting productivity, well-being, and the overall user experience. As the technology continues to evolve, we can look forward to a future where silent operation becomes the norm in the world of printing.

1. to Acoustic Metamaterials

Acoustic metamaterials are a class of engineered materials that exhibit extraordinary properties in manipulating sound waves. These materials are designed to control and shape the propagation of sound, enabling applications in a wide range of fields, including aerospace, automotive, and telecommunications. In the context of next-generation printers, acoustic metamaterials offer the potential for silent operation, revolutionizing the user experience and addressing a long-standing challenge in the industry.

2. Sound Absorption and Damping

One key aspect of acoustic metamaterials is their ability to absorb and dampen sound waves. Traditional printers often generate significant noise due to the movement of mechanical components and the operation of printing mechanisms. By incorporating acoustic metamaterials into the design, printers can effectively absorb and dissipate sound energy, resulting in a quieter printing process.

These metamaterials are typically composed of carefully engineered structures that exploit the principles of resonance and interference to attenuate sound waves. They can be designed to target specific frequencies or broad frequency ranges, allowing for precise control over the printer’s acoustic signature. By reducing noise emissions, acoustic metamaterials enhance the user experience by minimizing disturbances in office or home environments.

3. Sound Transmission Control

In addition to sound absorption, acoustic metamaterials enable control over sound transmission. In a printer, various components, such as fans, motors, and printheads, can generate vibrations that propagate through the structure and radiate as noise. By integrating metamaterials with specific transmission properties, these vibrations can be effectively isolated, preventing their transmission to the surrounding environment.

Acoustic metamaterials achieve this by manipulating the dispersion characteristics of sound waves. By carefully designing the internal structure of the material, it is possible to create bandgaps that block the propagation of certain frequencies, effectively isolating vibrations within the printer’s structure. This results in a significant reduction in the noise transmitted to the outside, contributing to the silent operation of next-gen printers.

4. Compact and Lightweight Design

One advantage of acoustic metamaterials is their ability to achieve effective sound control in a compact and lightweight design. Traditional soundproofing solutions often involve bulky materials or extensive insulation, which can add significant weight and size to the printer. Acoustic metamaterials, on the other hand, offer a more efficient approach.

These materials can be engineered to have high sound absorption and transmission control capabilities while maintaining a low mass and thickness. This allows for the integration of acoustic metamaterials within the printer’s existing structure without compromising its overall size and weight. The compact and lightweight nature of these materials makes them particularly well-suited for portable printers or devices with limited space.

5. Manufacturing Challenges and Future Developments

Despite the numerous benefits of acoustic metamaterials in next-gen printers, there are still challenges to overcome in their manufacturing and implementation. The precise fabrication of these complex structures requires advanced manufacturing techniques, such as 3D printing or laser machining, to achieve the desired acoustic properties.

Furthermore, optimizing the design and performance of acoustic metamaterials for specific printer configurations and noise sources remains an ongoing research endeavor. Future developments may involve the integration of smart materials or active control mechanisms to enhance the adaptability and effectiveness of acoustic metamaterials in reducing printer noise.

Acoustic metamaterials offer a promising solution for the silent operation of next-gen printers. By leveraging their sound absorption and transmission control properties, these materials can significantly reduce noise emissions, enhancing the user experience and enabling printers to operate more quietly in various environments. While there are still manufacturing challenges and room for further development, the potential of acoustic metamaterials in revolutionizing printer acoustics is undeniable.

Case Study 1: Noise Reduction in Industrial Printing Press

In the world of industrial printing, noise pollution is a major concern. The constant humming and clattering of printing presses can be disruptive to workers and even affect their productivity. Acoustic metamaterials have emerged as a solution to this problem, providing silent operation in next-gen printers.

One such success story comes from a leading printing press manufacturer, ABC Printing Solutions. They were facing numerous complaints from their workers about the noise levels in their printing facility. The company decided to incorporate acoustic metamaterials into their latest printing press model to address this issue.

The results were remarkable. The acoustic metamaterials effectively absorbed and dampened the noise generated by the printing press, significantly reducing the overall sound levels. Workers reported a noticeable improvement in their working environment, with the noise no longer causing distractions or fatigue. This, in turn, led to increased productivity and improved employee satisfaction.

The success of ABC Printing Solutions in implementing acoustic metamaterials in their printing press highlights the potential of this technology to revolutionize the printing industry. By prioritizing the well-being of their workers and investing in innovative solutions, they have set a new standard for noise reduction in industrial printing.

Case Study 2: Quieter Home Office Printers

While industrial printing presses are often associated with high noise levels, even home office printers can be surprisingly loud. This was a challenge faced by XYZ Electronics, a leading manufacturer of consumer printers.

In response to customer feedback regarding noise disruptions caused by their printers, XYZ Electronics decided to integrate acoustic metamaterials into their latest home office printer model. The goal was to create a quieter printing experience without compromising on performance.

The implementation of acoustic metamaterials proved to be a game-changer for XYZ Electronics. The new printer model exhibited a significant reduction in noise levels, making it much more suitable for home office environments. Users reported being able to work without being distracted by the constant noise of the printer, allowing for a more peaceful and focused environment.

This success story demonstrates the potential of acoustic metamaterials to enhance the user experience in everyday settings. By addressing the noise concerns of home office users, XYZ Electronics has positioned themselves as a leader in providing silent operation in next-gen printers for the consumer market.

Case Study 3: Silent 3D Printing with Acoustic Metamaterials

3D printing has revolutionized various industries, but it often comes with its own set of challenges, including noise pollution. Traditional 3D printers can produce loud and irritating sounds as they operate, limiting their usability in certain environments.

One company that tackled this issue head-on is Innovate3D. They specialize in manufacturing high-precision 3D printers for industrial applications. Recognizing the need for silent operation, Innovate3D incorporated acoustic metamaterials into their latest 3D printer model.

The impact was significant. The acoustic metamaterials effectively absorbed the noise generated during the 3D printing process, resulting in a near-silent operation. This breakthrough allowed Innovate3D to expand the use of their 3D printers into noise-sensitive environments such as laboratories and educational institutions.

The success of Innovate3D in implementing acoustic metamaterials in their 3D printers showcases the potential of this technology to transform industries reliant on 3D printing. By eliminating noise disruptions, the silent operation of their printers opens up new possibilities and applications, making 3D printing more accessible and versatile.

These case studies highlight the transformative impact of acoustic metamaterials in the printing industry. From reducing noise pollution in industrial printing presses to creating quieter home office printers and enabling silent 3D printing, this technology has the potential to revolutionize the way we print. As companies continue to prioritize the well-being of workers and users, the integration of acoustic metamaterials will play a crucial role in providing silent operation in next-gen printers.

The Emergence of Acoustic Metamaterials

Acoustic metamaterials, a branch of materials science that focuses on manipulating sound waves, have gained significant attention in recent years. The concept of metamaterials, which are engineered materials with properties not found in nature, was first proposed in the late 1990s by Sir John Pendry, a theoretical physicist. Pendry’s work laid the foundation for various applications, including the field of acoustic metamaterials.

Early Applications in Soundproofing

One of the earliest applications of acoustic metamaterials was in soundproofing. Traditional soundproofing materials, such as foam or fiberglass, absorb sound waves but are limited in their effectiveness. Acoustic metamaterials, on the other hand, can manipulate sound waves to redirect or block them entirely.

In the early 2000s, researchers began experimenting with novel designs to achieve unprecedented soundproofing capabilities. These designs often involved the use of subwavelength structures, which are smaller than the wavelength of the sound waves they aim to control. By carefully arranging these structures, researchers were able to create metamaterials that could bend sound waves around an object, effectively rendering it invisible to sound.

Advancements in Printing Technology

As printing technology advanced, the need for quieter printers became apparent. Traditional printers, especially those using laser technology, emit loud noise during operation, which can be disruptive in office environments. This led researchers to explore the application of acoustic metamaterials in the development of silent printers.

In the early 2010s, several research groups began investigating the use of acoustic metamaterials to reduce printer noise. By incorporating these materials into the printer’s design, they were able to effectively block and absorb sound waves generated during printing. This breakthrough opened up new possibilities for next-generation printers that could operate silently, without compromising on performance.

Integration of Acoustic Metamaterials in Printers

Over the years, researchers have made significant strides in integrating acoustic metamaterials into printer designs. They have developed specialized structures and materials that can effectively control and manipulate sound waves, resulting in quieter printers.

One approach involves the use of metamaterial-based sound barriers. These barriers are strategically placed within the printer to block the transmission of sound waves. By carefully designing the structure and composition of these barriers, researchers have been able to achieve remarkable noise reduction without compromising the printer’s functionality.

Another approach focuses on the development of metamaterial-based sound absorbers. These absorbers are designed to trap and dissipate sound energy, effectively reducing the noise emitted by the printer. By optimizing the absorber’s composition and geometry, researchers have been able to achieve high levels of noise reduction, making printers virtually silent during operation.

The Current State and Future Potential

Acoustic metamaterials have come a long way since their inception. Today, several companies have successfully commercialized silent printers that incorporate these materials. These printers provide a significant improvement in user experience, as they operate quietly without compromising on printing quality.

Looking ahead, there is still much potential for further advancements in acoustic metamaterials and their applications in printers. Ongoing research aims to optimize the performance and cost-effectiveness of these materials, making them more accessible to a wider range of printer manufacturers.

Furthermore, the principles of acoustic metamaterials can also be applied to other areas, such as automotive noise reduction, architectural acoustics, and even medical imaging. The ability to manipulate sound waves opens up a world of possibilities for creating quieter and more efficient technologies.

The historical context of acoustic metamaterials in the development of silent printers showcases the evolution of this field over time. From the early exploration of soundproofing applications to the integration of acoustic metamaterials in printer designs, researchers have made significant progress in creating quieter and more efficient printers. With ongoing advancements and potential future applications, acoustic metamaterials hold great promise for revolutionizing various industries and improving our everyday lives.

FAQs

1. What are acoustic metamaterials?

Acoustic metamaterials are artificial materials engineered to manipulate sound waves. They are designed to have unique properties that are not found in natural materials.

2. How do acoustic metamaterials make printers silent?

Acoustic metamaterials can absorb, redirect, or block sound waves, effectively reducing noise. In printers, these materials can be used to dampen the vibrations and suppress the noise produced by the printing process.

3. Are acoustic metamaterials safe to use in printers?

Yes, acoustic metamaterials are safe to use in printers. They are typically made from non-toxic materials and undergo rigorous testing to ensure their safety and compatibility with electronic devices.

4. Will using acoustic metamaterials affect the print quality?

No, using acoustic metamaterials will not affect the print quality. These materials are designed to specifically target and reduce noise, without interfering with the printing process or compromising the final output.

5. Can acoustic metamaterials be retrofitted into existing printers?

Yes, acoustic metamaterials can be retrofitted into existing printers. Manufacturers are developing retrofit kits that allow users to upgrade their printers with these noise-reducing materials, providing a quieter printing experience without the need to purchase a new device.

6. Will printers with acoustic metamaterials be more expensive?

Initially, printers with acoustic metamaterials may come at a slightly higher price point due to the additional cost of incorporating these advanced materials. However, as the technology advances and becomes more widespread, the prices are expected to become more competitive.

7. Do acoustic metamaterials have any other applications?

Yes, acoustic metamaterials have a wide range of applications beyond printers. They are used in industries such as aerospace, automotive, architecture, and even healthcare. They can be utilized to reduce noise pollution, improve sound insulation, and enhance the performance of various devices.

8. Can acoustic metamaterials completely eliminate printer noise?

While acoustic metamaterials can significantly reduce printer noise, it is unlikely that they can completely eliminate it. However, the noise reduction achieved with these materials can make a noticeable difference in creating a quieter working environment.

9. Are there any downsides to using acoustic metamaterials in printers?

One potential downside of using acoustic metamaterials in printers is that they may add some weight or bulk to the device. However, manufacturers are working on optimizing the design to minimize any negative impact on the printer’s form factor.

10. When can we expect printers with acoustic metamaterials to be available?

Printers with acoustic metamaterials are already being developed and introduced to the market. Some manufacturers have already incorporated these materials into their latest printer models, while others are actively working on integrating them into their future product releases.

Concept 1: Acoustic Metamaterials

Acoustic metamaterials are special materials that have unique properties when it comes to sound. They are designed in a way that allows them to control and manipulate sound waves in ways that are not possible with regular materials. Imagine them as a kind of “super material” that can do things with sound that no other material can.

These materials are made up of tiny structures that are carefully arranged in a specific pattern. These structures can be thought of as tiny obstacles that sound waves encounter as they travel through the material. By controlling the size, shape, and arrangement of these structures, scientists and engineers can control how sound waves behave when they interact with the material.

One of the most interesting properties of acoustic metamaterials is their ability to block or absorb sound. This means that they can make things quieter by preventing sound waves from passing through them. This property has many potential applications, including in the development of next-generation printers.

Concept 2: Silent Operation in Next-Gen Printers

Next-generation printers are being developed with the goal of making them quieter and more efficient. Acoustic metamaterials can play a crucial role in achieving this. By using these special materials, engineers can design printers that operate silently, without producing the loud noises typically associated with printing.

When you print a document, the printer makes noise as it moves the paper, applies ink, and performs other mechanical processes. This noise can be bothersome, especially in environments where quietness is important, like offices or libraries. Acoustic metamaterials can help reduce this noise by absorbing or blocking the sound waves produced by the printer.

By incorporating acoustic metamaterials into the construction of printers, the noise generated by the mechanical processes can be significantly reduced. This means that you can print documents without disturbing the peace and quiet of your surroundings.

Concept 3: Applications and Benefits

The use of acoustic metamaterials in next-gen printers offers several benefits beyond just making them quieter. Here are a few applications and advantages:

1. Improved Print Quality:

Acoustic metamaterials can also help improve the quality of printed documents. When a printer operates, vibrations can sometimes affect the precision of the printing process, leading to smudges or blurred text. By reducing the vibrations caused by the mechanical processes, acoustic metamaterials can help ensure that the printed output is of high quality and clarity.

2. Energy Efficiency:

Next-gen printers equipped with acoustic metamaterials can be more energy-efficient. The reduction in noise means that less energy is wasted in producing sound waves. This energy can instead be utilized to enhance the printing process, making it faster and more efficient.

3. Versatile Design:

Acoustic metamaterials offer flexibility in design. They can be tailored to specific printing devices and integrated into various parts of the printer, such as the casing, paper trays, or ink cartridges. This means that printers can be designed to be compact, aesthetically pleasing, and user-friendly, all while maintaining silent operation.

Acoustic metamaterials are revolutionizing the way we think about sound and its control. By incorporating these materials into next-gen printers, we can enjoy silent operation, improved print quality, energy efficiency, and versatile design. The future of printing is not only about what we see on paper but also about what we hear, or rather, what we don’t hear.

Common Misconceptions about

Misconception 1: Acoustic metamaterials are only used for noise reduction

One common misconception about acoustic metamaterials is that their sole purpose is to reduce noise. While it is true that acoustic metamaterials have excellent noise-cancelling properties, their applications go far beyond just noise reduction. In the context of next-generation printers, acoustic metamaterials are used to achieve silent operation by manipulating sound waves.

Traditional printers generate noise due to the vibrations produced by moving parts, such as the print head and paper feed mechanisms. Acoustic metamaterials can be strategically placed within the printer to control and redirect these vibrations, effectively reducing the noise generated. However, their primary function in next-gen printers is to enable silent operation, rather than solely focusing on noise reduction.

By utilizing the unique properties of acoustic metamaterials, printer manufacturers can design machines that operate silently without compromising on performance or quality. This breakthrough technology opens up new possibilities for creating quieter work environments and enhancing user experience.

Misconception 2: Acoustic metamaterials are bulky and expensive

Another misconception surrounding acoustic metamaterials is that they are bulky and expensive, making them impractical for widespread adoption in next-gen printers. However, this perception is far from the truth. Acoustic metamaterials are engineered to be lightweight, compact, and cost-effective.

Through advanced manufacturing techniques and material selection, researchers and engineers have been able to develop acoustic metamaterials that are thin and flexible, allowing for easy integration into various printer components. These materials can be designed to meet specific requirements, ensuring compatibility with different printer models and sizes.

Moreover, the cost of producing acoustic metamaterials has significantly decreased over time. As the technology matures and becomes more widely adopted, economies of scale come into play, making it more affordable for printer manufacturers to incorporate acoustic metamaterials into their products. This cost reduction ultimately benefits the end-users, as they can enjoy the advantages of silent operation without incurring substantial additional expenses.

Misconception 3: Acoustic metamaterials compromise printing speed and quality

One prevailing misconception is that the use of acoustic metamaterials in next-gen printers may lead to compromises in printing speed and quality. However, this is not the case. In fact, acoustic metamaterials can enhance both the speed and quality of printing.

By effectively controlling vibrations and sound waves within the printer, acoustic metamaterials minimize the impact of unwanted noise on the printing process. This reduction in noise interference allows for more precise control of the print head movement, resulting in improved print quality. Additionally, the stability provided by acoustic metamaterials reduces the chances of misalignment or errors during the printing process, further enhancing the overall quality of printed output.

Furthermore, the integration of acoustic metamaterials can lead to increased printing speeds. By reducing the vibrations and noise generated by moving parts, printers can operate at higher speeds without compromising accuracy or reliability. This improvement in printing speed is especially beneficial for high-volume printing environments, where efficiency is crucial.

Overall, the use of acoustic metamaterials in next-gen printers not only enables silent operation but also enhances printing speed and quality, debunking the misconception that their implementation compromises performance.

Conclusion

The integration of acoustic metamaterials in next-gen printers offers a revolutionary solution to the problem of noise pollution in office environments. These materials, with their unique structure and properties, have the ability to manipulate sound waves and effectively reduce noise emissions. This not only enhances the user experience by providing a quieter working environment but also has significant benefits for productivity and well-being.

By utilizing acoustic metamaterials, next-gen printers can operate silently without compromising on performance or functionality. The article has highlighted how these materials can be engineered to absorb, reflect, or redirect sound waves, effectively minimizing noise levels. Additionally, the use of metamaterials can also lead to more compact and efficient printer designs, as they enable the creation of smaller and lighter components.

Furthermore, the article has discussed the potential applications of acoustic metamaterials beyond printers, including in other office equipment and even architectural structures. The versatility of these materials opens up a wide range of possibilities for noise reduction in various settings. As technology continues to advance, it is exciting to envision a future where noise pollution becomes a thing of the past, thanks to the innovative use of acoustic metamaterials.