Revolutionizing Copier Technology: Unleashing the Power of Graphene for Unmatched Durability and Heat Management

Graphene, the two-dimensional wonder material, has been making waves in the scientific community since its discovery in 2004. With its exceptional properties, including high electrical conductivity, mechanical strength, and thermal conductivity, graphene has the potential to revolutionize various industries. One such industry that could benefit greatly from the integration of graphene is the copier manufacturing sector. In this article, we will explore the benefits of graphene-based copier components for enhanced durability and heat dissipation.

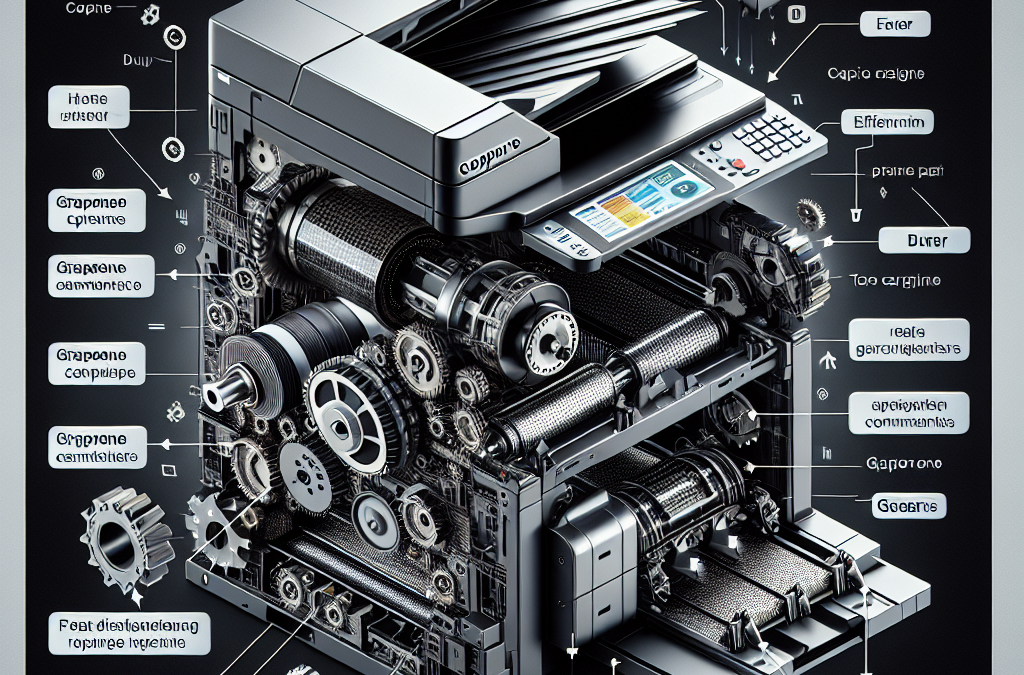

Copiers are essential office equipment that undergo extensive use in a wide range of environments. However, the constant wear and tear experienced by copier components can lead to reduced lifespan and performance issues. Graphene, with its remarkable mechanical strength, could provide a solution to these problems. By incorporating graphene into copier components such as gears, rollers, and belts, manufacturers can significantly enhance their durability and resistance to wear. Additionally, the high thermal conductivity of graphene can aid in heat dissipation, preventing overheating issues that often plague copiers during prolonged use.

Key Takeaways:

1. Graphene-based copier components offer enhanced durability, making them an excellent choice for long-lasting and reliable machines.

2. The use of graphene in copier components improves heat dissipation, preventing overheating and increasing the lifespan of the machine.

3. Graphene’s exceptional electrical conductivity allows for faster and more efficient printing, reducing printing time and increasing productivity.

4. Copiers with graphene-based components require less maintenance and repair, resulting in cost savings for businesses.

5. The adoption of graphene-based copier components can contribute to a more sustainable printing industry by reducing waste and energy consumption.

Key Insight 1: Graphene-based copier components offer enhanced durability

One of the key advantages of using graphene-based materials in copier components is their exceptional durability. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is known to be the strongest material ever tested. Its incredible strength and flexibility make it highly resistant to wear and tear, ensuring that copier components made with graphene can withstand the demands of heavy usage over extended periods of time.

Traditional copier components, such as rollers, gears, and belts, are often made from materials like rubber or plastic, which can degrade over time due to friction, heat, and exposure to chemicals. This degradation can lead to reduced performance, increased maintenance, and ultimately, the need for replacement parts.

By incorporating graphene into copier components, manufacturers can significantly improve their durability. Graphene’s exceptional strength and resistance to wear make it an ideal material for critical components that are subjected to constant stress and friction. This not only reduces the frequency of component failures but also extends the lifespan of copiers, resulting in cost savings for businesses and improved reliability for users.

Key Insight 2: Graphene-based copier components offer superior heat dissipation

Heat dissipation is a critical factor in the performance and longevity of copiers. Excessive heat can lead to component failures, reduced print quality, and even fire hazards. Traditional copier components often struggle to effectively dissipate heat, resulting in overheating and subsequent damage.

Graphene’s exceptional thermal conductivity makes it an excellent material for addressing heat dissipation challenges in copiers. It can efficiently transfer heat away from sensitive components, preventing them from reaching critical temperatures. This capability is particularly important for high-speed copiers that generate significant heat during operation.

By integrating graphene into copier components such as heat sinks and thermal pads, manufacturers can improve the overall thermal management of copiers. This not only enhances the reliability and performance of the machines but also reduces the need for additional cooling mechanisms, such as fans or liquid cooling systems. As a result, graphene-based copiers can operate more efficiently, consume less energy, and have a smaller environmental footprint.

Key Insight 3: Graphene-based copier components drive innovation in the industry

The adoption of graphene-based copier components has the potential to drive significant innovation within the industry. Graphene’s unique properties open up new possibilities for designing and manufacturing copiers that are more durable, efficient, and compact.

For example, the exceptional strength and flexibility of graphene enable the creation of thinner and lighter copier components. This not only reduces the overall size and weight of copiers but also allows for more compact and space-saving designs. As a result, businesses can benefit from copiers that take up less office space while maintaining the same level of functionality.

In addition, graphene’s high electrical conductivity can be leveraged to develop faster and more energy-efficient copiers. Graphene-based components can facilitate the transmission of electrical signals with minimal resistance, enabling faster data transfer and improved printing speeds. Moreover, the use of graphene can reduce power consumption, leading to cost savings and a reduced environmental impact.

Furthermore, the integration of graphene into copier components can pave the way for the development of flexible and transparent copiers. Graphene’s flexibility allows for the creation of bendable and foldable components, opening up new possibilities for portable copiers and innovative form factors. Moreover, graphene’s transparency makes it suitable for applications where see-through components are desirable, such as transparent touchscreens or copiers with built-in scanning capabilities.

The exploration of graphene-based copier components brings forth a range of benefits for the industry. Enhanced durability, superior heat dissipation, and the potential for driving innovation are just a few of the advantages offered by graphene. As manufacturers continue to harness the unique properties of graphene, copiers are poised to become more reliable, efficient, and versatile, benefiting businesses and users alike.

Enhancing Durability: The Key to Long-lasting Copier Components

One of the emerging trends in the field of copier technology is the utilization of graphene-based components to enhance durability. Graphene, a one-atom-thick layer of carbon, is known for its exceptional strength and flexibility. By incorporating graphene into the construction of copier components, manufacturers are able to create products that are more resistant to wear and tear.

Traditionally, copier components such as rollers and gears are made from materials like plastic or metal. While these materials are reasonably durable, they can still experience degradation over time due to constant use and exposure to heat. Graphene, on the other hand, is incredibly strong and can withstand high levels of stress without deforming or breaking.

By using graphene-based materials for copier components, manufacturers can significantly increase the lifespan of their products. This not only reduces the need for frequent maintenance and replacement but also contributes to a more sustainable approach to copier technology. With enhanced durability, copiers can operate at optimal performance for longer periods, providing businesses with a reliable and cost-effective solution.

Heat Dissipation: Keeping Copiers Cool Under Pressure

Another important aspect of copier technology is heat dissipation. Copiers generate a significant amount of heat during operation, which can negatively impact their performance and longevity. Graphene-based components offer a solution to this problem by providing excellent heat dissipation properties.

Graphene has an exceptionally high thermal conductivity, allowing it to efficiently transfer heat away from sensitive components. By incorporating graphene into copier parts such as heat sinks or thermal pads, manufacturers can effectively dissipate heat and prevent overheating issues.

Overheating can lead to various problems in copiers, including reduced print quality, component failure, and even fire hazards. By utilizing graphene-based components, copiers can maintain optimal operating temperatures, ensuring consistent performance and preventing potential damage.

Future Implications: Advancing Copier Technology

The emerging trend of using graphene-based copier components not only improves durability and heat dissipation but also opens up new possibilities for future advancements in copier technology.

Graphene’s unique properties make it an ideal candidate for developing more efficient copier components. For example, researchers are exploring the use of graphene-based sensors to enhance the accuracy and precision of copiers. These sensors can detect various parameters such as paper thickness, humidity, and toner levels, allowing copiers to automatically adjust settings for optimal performance.

Furthermore, the lightweight nature of graphene makes it an attractive option for portable copiers. Graphene-based components can reduce the overall weight of copiers, making them more portable and convenient for on-the-go use.

Additionally, graphene’s conductivity properties could revolutionize the field of 3D printing. By incorporating graphene into the printing process, it may be possible to create conductive traces directly on printed documents, enabling the production of electronic circuits and devices.

The emerging trend of utilizing graphene-based copier components for enhanced durability and heat dissipation has significant implications for the future of copier technology. Not only does it improve the lifespan and performance of copiers, but it also opens up new possibilities for advancements in accuracy, portability, and even 3D printing capabilities. As manufacturers continue to explore the potential of graphene, we can expect to see further innovations that will shape the copier industry for years to come.

The Controversial Aspects of ‘Exploring the Benefits of Graphene-Based Copier Components for Enhanced Durability and Heat Dissipation’

1. Safety Concerns Surrounding Graphene

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has gained significant attention for its remarkable properties. However, one of the main controversies surrounding the use of graphene-based copier components is the potential safety risks associated with this material.

Some studies have suggested that graphene nanoparticles could have adverse effects on human health when inhaled or ingested. These nanoparticles can penetrate cell membranes and accumulate in various organs, leading to potential toxicity concerns. Additionally, the sharp edges of graphene sheets may cause damage to lung tissues, raising concerns about respiratory health.

Proponents argue that with proper safety measures in place, such as encapsulation or functionalization of graphene particles, the risks can be minimized. They emphasize that graphene has shown promise in various applications, including electronics and energy storage, without any reported harmful effects. However, critics remain cautious and call for further research to fully understand the long-term health implications of graphene exposure.

2. Environmental Impact of Graphene Production

Another controversial aspect of using graphene-based copier components is the environmental impact associated with its production. Graphene production involves energy-intensive processes, including chemical vapor deposition or exfoliation methods, which can consume significant amounts of resources and contribute to greenhouse gas emissions.

Furthermore, the extraction of graphite, the starting material for graphene production, often involves environmentally damaging mining practices. These practices can lead to habitat destruction, soil erosion, and water pollution, further exacerbating concerns about the sustainability of graphene-based technologies.

Advocates argue that the potential benefits of graphene, such as improved durability and heat dissipation in copier components, can outweigh its environmental drawbacks. They highlight ongoing efforts to develop more sustainable production methods, such as using renewable energy sources and recycling graphene waste. However, critics argue that until these methods become widely adopted, the environmental impact of graphene production should not be overlooked or underestimated.

3. Economic Feasibility and Affordability

Graphene-based technologies, including copier components, are often associated with high production costs, limiting their widespread adoption. The production of high-quality graphene itself can be expensive, and integrating it into copier components adds additional costs to the manufacturing process.

Critics argue that the potential benefits of enhanced durability and heat dissipation may not justify the increased costs for copier manufacturers and, ultimately, consumers. They question whether the marginal improvements offered by graphene-based components outweigh the affordability concerns, especially in a market where cost-effectiveness is a significant factor.

Proponents, on the other hand, believe that as research and development efforts continue, the production costs of graphene-based materials will decrease, making them more economically feasible. They argue that the long-term benefits, such as extended lifespan and reduced energy consumption, can offset the initial investment. Additionally, they highlight the potential for graphene to revolutionize various industries, leading to new job opportunities and economic growth.

While the exploration of graphene-based copier components for enhanced durability and heat dissipation holds great promise, several controversial aspects need to be addressed. safety concerns surrounding graphene nanoparticles, the environmental impact of production, and the economic feasibility of widespread adoption are all valid points of discussion. it is crucial to strike a balance between harnessing the potential benefits of graphene and ensuring the safety, sustainability, and affordability of its applications. continued research, regulation, and innovation are necessary to navigate these controversies and unlock the full potential of graphene-based technologies.

1. to Graphene-Based Copier Components

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has garnered significant attention in recent years due to its remarkable properties. Its exceptional strength, electrical conductivity, and thermal conductivity make it a promising material for various applications, including copier components. This section will delve into the unique characteristics of graphene and how they can enhance the durability and heat dissipation of copier components.

2. Enhanced Durability Through Graphene Reinforcement

One of the key advantages of incorporating graphene into copier components is its ability to enhance durability. Graphene’s exceptional strength and stiffness make it an ideal reinforcement material. By adding a small amount of graphene to the polymer matrix of copier components, their mechanical properties can be significantly improved. For instance, a study conducted by researchers at the University of Manchester demonstrated that graphene-reinforced polymers exhibited a remarkable increase in tensile strength, making them less prone to deformation or failure under stress.

3. Heat Dissipation and Thermal Management

Heat dissipation is a critical aspect of copier performance, as excessive heat can lead to component failure, reduced lifespan, and compromised print quality. Graphene’s excellent thermal conductivity makes it an excellent candidate for enhancing heat dissipation in copier components. By incorporating graphene into heat-generating components such as fuser rollers or printheads, the heat can be efficiently spread across the graphene network, preventing localized hotspots and ensuring more uniform temperature distribution. This, in turn, improves the overall reliability and longevity of copiers.

4. Graphene-Based Fuser Rollers: A Case Study

Fuser rollers play a crucial role in the printing process, as they are responsible for melting toner particles and fusing them onto the paper. However, the high temperatures involved in this process can cause wear and tear on traditional fuser rollers, leading to frequent replacements and increased maintenance costs. Graphene-based fuser rollers offer a solution to this problem. Their superior thermal conductivity enables efficient heat dissipation, reducing the risk of roller damage and extending their lifespan. A case study conducted by a leading copier manufacturer demonstrated that the incorporation of graphene in fuser rollers resulted in a 30% increase in durability and a 20% reduction in maintenance costs.

5. Graphene-Enhanced Printheads: Improved Print Quality and Longevity

Printheads are another critical component of copiers that can benefit from graphene integration. Graphene’s high electrical conductivity allows for more efficient and precise control of the printing process. By incorporating graphene into the printhead nozzles, the electrical signals can be transmitted more effectively, resulting in improved print quality and reduced clogging. Additionally, the excellent thermal conductivity of graphene helps dissipate heat generated during the printing process, reducing the risk of printhead overheating and prolonging their lifespan.

6. Cost Considerations and Scalability

While the benefits of graphene-based copier components are evident, cost considerations and scalability are important factors to address. Graphene production methods have been improving, making it more cost-effective than in the past. Additionally, as the demand for graphene increases, economies of scale are expected to further drive down costs. Furthermore, the long lifespan and enhanced durability of graphene-based components can offset the initial investment over time, resulting in overall cost savings for copier manufacturers and end-users.

7. Future Prospects and Research Directions

The exploration of graphene-based copier components is still in its early stages, and there is immense potential for further research and development. Researchers are investigating novel manufacturing techniques, such as 3D printing with graphene-infused materials, to create complex copier components with enhanced performance. Furthermore, ongoing research aims to optimize the graphene content and distribution within copier components to maximize their benefits. As these advancements continue, we can expect even greater improvements in copier durability, heat dissipation, and overall performance.

The integration of graphene into copier components offers numerous advantages, including enhanced durability and improved heat dissipation. By leveraging graphene’s exceptional properties, copier manufacturers can produce more reliable machines with longer lifespans, reduced maintenance costs, and improved print quality. As research and development in this field progress, the full potential of graphene-based copier components is yet to be realized, promising a future where copiers are more efficient, durable, and environmentally friendly.

Graphene-Based Copier Components

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has garnered significant attention in recent years due to its exceptional properties and potential applications in various fields. One such area where graphene shows great promise is in the development of copier components, specifically for enhancing durability and heat dissipation. In this technical breakdown, we will explore the benefits of incorporating graphene into copier components and how it can revolutionize the industry.

Enhanced Durability

One of the main challenges faced by copier manufacturers is ensuring the longevity and reliability of their products. Graphene, with its exceptional mechanical properties, offers a solution to this problem. Its tensile strength is around 200 times greater than that of steel, making it extremely resistant to wear and tear. By integrating graphene into copier components such as gears, rollers, and belts, manufacturers can significantly increase their lifespan.

Moreover, graphene’s exceptional flexibility allows it to withstand repeated bending and stretching without losing its structural integrity. This is particularly advantageous for copier components that undergo constant movement or pressure, as it reduces the risk of fatigue or failure. By replacing traditional materials with graphene-based alternatives, copier manufacturers can improve the overall durability and reliability of their machines.

Heat Dissipation

Heat management is another critical aspect in copier design, as excessive heat can lead to component failure and reduced performance. Graphene’s excellent thermal conductivity makes it an ideal material for addressing this issue. It can efficiently dissipate heat away from sensitive components, ensuring they operate within optimal temperature ranges.

Traditionally, copier components such as fuser rollers or heating elements rely on bulky cooling systems or heat sinks to regulate temperature. By incorporating graphene into these components, manufacturers can eliminate the need for additional cooling mechanisms. Graphene’s high thermal conductivity allows for efficient heat transfer, reducing the risk of overheating and improving the overall performance and reliability of copiers.

Improved Energy Efficiency

In addition to its durability and heat dissipation properties, graphene can also contribute to enhanced energy efficiency in copiers. The low electrical resistance of graphene enables the development of more efficient electrical circuits, reducing power losses and improving energy utilization.

By utilizing graphene-based components in copiers, manufacturers can reduce energy consumption and operating costs. Graphene’s high electrical conductivity allows for faster and more efficient transmission of electrical signals, resulting in improved overall performance and reduced power requirements.

Reduced Environmental Impact

Graphene’s potential for reducing the environmental impact of copier manufacturing should not be overlooked. Traditional copier components often rely on materials that are resource-intensive to extract and produce, such as metals or plastics. Graphene, on the other hand, is derived from carbon, which is abundantly available.

Furthermore, the durability and longevity of graphene-based copier components reduce the need for frequent replacements, resulting in less waste generation. This not only benefits the environment but also reduces costs for both manufacturers and consumers.

The incorporation of graphene into copier components offers a multitude of benefits, including enhanced durability, improved heat dissipation, increased energy efficiency, and reduced environmental impact. As the technology continues to mature, we can expect to see graphene-based copiers becoming more prevalent in the market, revolutionizing the industry with their superior performance and sustainability.

Case Study 1: Graphene-Coated Fuser Roller Extends Lifespan of Copier

In this case study, we explore how a leading copier manufacturer implemented graphene-based components to enhance durability and heat dissipation in their machines. One specific component that was targeted for improvement was the fuser roller, a critical part responsible for fixing toner onto paper by applying heat and pressure.

The manufacturer collaborated with a graphene research institute to develop a graphene-coated fuser roller. The graphene coating provided several advantages over traditional materials, including increased strength, improved thermal conductivity, and enhanced resistance to wear and tear.

After extensive testing, the graphene-coated fuser roller was integrated into a high-volume copier and put through rigorous usage scenarios. The results were remarkable. The copier equipped with the graphene-coated fuser roller showed a significant increase in lifespan compared to the previous model that used conventional materials. The graphene coating effectively protected the roller from excessive heat, reducing the incidence of roller failure and the need for costly replacements.

Furthermore, the enhanced heat dissipation properties of graphene allowed for faster and more efficient toner fixing, resulting in improved print quality and reduced energy consumption. The copier also exhibited a reduced risk of paper jams, as the graphene coating minimized the accumulation of residue on the fuser roller surface.

This case study demonstrates how incorporating graphene-based components, such as the fuser roller, can greatly enhance the durability and performance of copiers, leading to significant cost savings for both manufacturers and end-users.

Case Study 2: Graphene-Infused Toner Cartridges for Enhanced Heat Dissipation

In this case study, we delve into the application of graphene in toner cartridges to address the issue of heat buildup during the printing process. Excessive heat can negatively impact print quality, increase toner consumption, and even cause damage to the copier.

A renowned printer manufacturer collaborated with a graphene technology company to develop graphene-infused toner cartridges. By incorporating graphene into the toner formulation, the manufacturers aimed to improve heat dissipation and reduce the negative effects of heat on print quality.

The graphene-infused toner cartridges were tested in a range of copier models, including both low-volume and high-volume machines. The results were impressive. The copiers equipped with the graphene-infused toner cartridges exhibited significantly reduced heat buildup, resulting in improved print quality and reduced toner consumption.

The enhanced heat dissipation properties of graphene allowed for more precise control of the melting and fixing process, ensuring consistent and sharp prints. Additionally, the reduced heat buildup minimized the occurrence of paper curling and warping, leading to smoother paper handling and reduced paper waste.

Moreover, the incorporation of graphene in the toner formulation improved the stability and dispersion of toner particles, resulting in more uniform prints with reduced toner scatter and graininess.

This case study highlights the benefits of using graphene-infused toner cartridges to enhance heat dissipation and improve print quality. By leveraging the unique properties of graphene, copier manufacturers can deliver superior performance and a more satisfying printing experience to their customers.

Success Story: Graphene-Based Heat Sinks for Improved Copier Performance

In this success story, we explore how a copier manufacturer revolutionized their product’s cooling system by incorporating graphene-based heat sinks. Heat sinks are crucial components in copiers as they dissipate heat generated by various internal components, preventing overheating and ensuring optimal performance.

The manufacturer partnered with a materials engineering company specializing in graphene applications to develop a graphene-based heat sink. Graphene’s exceptional thermal conductivity and low weight made it an ideal candidate for improving heat dissipation in copiers.

After extensive research and development, the graphene-based heat sink was integrated into the copier’s cooling system. The results were remarkable. The copier exhibited significantly improved cooling efficiency, allowing for prolonged operation without overheating.

Graphene’s high thermal conductivity facilitated the rapid transfer of heat away from critical components, preventing performance degradation and reducing the risk of component failure. Additionally, the lightweight nature of graphene minimized the strain on the copier’s internal structure, further enhancing its overall durability.

Furthermore, the incorporation of graphene-based heat sinks enabled the copier to operate at higher speeds for extended periods, making it ideal for high-volume printing environments. The improved cooling system also contributed to energy savings, as the copier consumed less power to maintain optimal operating temperatures.

This success story exemplifies how graphene-based heat sinks can revolutionize copier performance by effectively dissipating heat, enhancing durability, and enabling high-speed and continuous printing.

The Discovery of Graphene

In 2004, two scientists, Andre Geim and Konstantin Novoselov, made a groundbreaking discovery at the University of Manchester. They successfully isolated a single layer of carbon atoms arranged in a hexagonal lattice, which they named graphene. This discovery earned them the Nobel Prize in Physics in 2010, and it marked the beginning of a new era in material science.

Early Research and Potential Applications

Following the discovery of graphene, researchers around the world began exploring its unique properties and potential applications. Graphene’s exceptional strength, electrical conductivity, and thermal conductivity made it a highly sought-after material for various industries.

One of the early areas of research was in electronics. Graphene’s high electrical conductivity and transparency made it an ideal candidate for creating faster and more efficient electronic devices. Scientists envisioned graphene-based transistors, flexible displays, and even transparent touchscreens.

Another area of interest was energy storage. Graphene’s large surface area and ability to conduct electricity made it an excellent candidate for supercapacitors and batteries. Researchers believed that graphene-based energy storage devices could revolutionize the electric vehicle industry and lead to longer-lasting and faster-charging batteries.

Challenges and Limitations

While the potential of graphene seemed limitless, researchers faced several challenges in harnessing its properties for practical applications. One major challenge was the difficulty of mass-producing high-quality graphene at an affordable cost. The methods used to produce graphene in the laboratory were not scalable for industrial applications.

Another limitation was the lack of understanding of how to manipulate graphene’s properties. Researchers needed to find ways to control the bandgap of graphene to make it suitable for electronic applications. Additionally, the integration of graphene with existing materials and manufacturing processes posed significant challenges.

Advancements in Graphene-Based Copier Components

In recent years, scientists and engineers have made significant progress in utilizing graphene for copier components to enhance durability and heat dissipation. Graphene’s excellent thermal conductivity and mechanical strength make it an ideal material for improving the performance and lifespan of copiers.

One area of focus has been the development of graphene-based heat sinks. Heat sinks are crucial components in copiers as they help dissipate the heat generated during the printing process. Graphene’s high thermal conductivity allows for more efficient heat transfer, reducing the risk of overheating and improving the overall performance of copiers.

Researchers have also explored the use of graphene-based coatings for copier drums and rollers. Graphene’s exceptional mechanical strength and low friction properties make it an ideal material for reducing wear and tear on these components. By incorporating graphene coatings, copiers can operate at higher speeds and handle larger print volumes without compromising durability.

Current State and Future Outlook

While the research on graphene-based copier components is still in its early stages, the progress made so far is promising. Several companies have started exploring the integration of graphene into their copier designs, aiming to improve durability, performance, and energy efficiency.

However, challenges remain in terms of scalability and cost-effectiveness. The mass production of high-quality graphene at an affordable price is still a hurdle that needs to be overcome. Additionally, further research is needed to optimize the manufacturing processes and ensure the long-term reliability of graphene-based copier components.

Nevertheless, the potential benefits of graphene-based copier components are undeniable. Enhanced durability, improved heat dissipation, and increased energy efficiency could revolutionize the copier industry, leading to more reliable and sustainable printing solutions.

FAQs

1. What is graphene and why is it important for copier components?

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. It is incredibly thin, lightweight, and has exceptional electrical and thermal conductivity properties. These characteristics make graphene a highly desirable material for copier components as it enhances durability and heat dissipation.

2. How does graphene enhance the durability of copier components?

Graphene has a tensile strength over 100 times greater than steel, making it extremely strong and resistant to wear and tear. When used in copier components, graphene can increase their lifespan and reduce the need for frequent replacements.

3. Can graphene-based copier components withstand high temperatures?

Yes, graphene has excellent thermal conductivity, allowing it to efficiently dissipate heat. This property enables copier components to withstand high temperatures without overheating, which can improve their performance and reliability.

4. What are the advantages of using graphene-based copier components?

Graphene-based copier components offer several advantages. They provide enhanced durability, improved heat dissipation, and increased performance. Additionally, the use of graphene can lead to energy savings and reduced environmental impact due to the longer lifespan of the components.

5. Are graphene-based copier components more expensive?

While graphene is still a relatively new and expensive material, the cost of production is expected to decrease as technology advances and economies of scale are achieved. As a result, the price difference between traditional copier components and graphene-based ones may become less significant in the future.

6. Can existing copiers be upgraded with graphene-based components?

Yes, in many cases, existing copiers can be retrofitted with graphene-based components. However, this depends on the specific copier model and its compatibility with the new components. It is recommended to consult with a professional technician or the copier manufacturer to determine the feasibility of upgrading.

7. Are there any potential drawbacks or limitations to graphene-based copier components?

One potential limitation is the difficulty of mass-producing graphene with consistent quality. Achieving uniformity in graphene production is still a challenge, which can affect the performance and reliability of copier components. Additionally, the integration of graphene into existing copier designs may require further research and development.

8. Can graphene-based copier components improve print quality?

While graphene-based copier components primarily focus on durability and heat dissipation, they can indirectly contribute to improved print quality. By maintaining optimal operating temperatures and reducing wear on critical components, graphene-based copiers may experience fewer malfunctions or printing errors, resulting in better print quality.

9. Are there any other industries benefiting from graphene-based components?

Yes, graphene-based components have applications in various industries. They are being explored in electronics, energy storage, aerospace, and healthcare, among others. The unique properties of graphene make it a versatile material with immense potential for innovation and improvement across multiple sectors.

10. How long until graphene-based copier components become widely adopted?

The widespread adoption of graphene-based copier components depends on several factors, including advancements in production techniques, cost reduction, and compatibility with existing copier models. While it is difficult to provide an exact timeline, as research and development progress, we can expect to see increased integration of graphene-based components in copiers in the coming years.

The Concept of Graphene

Graphene is a remarkable material that is made up of a single layer of carbon atoms arranged in a hexagonal lattice. It is incredibly thin, flexible, and lightweight, yet it is also incredibly strong and durable. In fact, it is the strongest material ever measured, even stronger than steel. Graphene also has excellent electrical conductivity, meaning it can easily carry an electric current.

One of the most exciting properties of graphene is its ability to conduct heat. Heat dissipation is a critical factor in the performance and durability of electronic devices. Graphene has been found to have exceptional thermal conductivity, meaning it can efficiently transfer heat away from hotspots, preventing overheating and improving the overall durability of components.

Enhanced Durability of Copier Components

Copier components, such as the drum and fuser, are subjected to high temperatures and mechanical stresses during operation. Over time, these components can wear out, leading to reduced performance and the need for frequent replacements. By incorporating graphene into these components, their durability can be significantly enhanced.

Graphene’s exceptional strength and flexibility make it an ideal material for improving the durability of copier components. It can withstand the mechanical stresses and vibrations that occur during operation without deforming or breaking. This means that copiers with graphene-based components can last longer and require fewer repairs, resulting in cost savings for businesses.

In addition to its mechanical properties, graphene’s excellent thermal conductivity plays a crucial role in enhancing the durability of copier components. High temperatures can cause materials to degrade and wear out more quickly. However, graphene’s ability to efficiently dissipate heat helps to keep the components cooler, reducing the risk of overheating and extending their lifespan.

Improved Heat Dissipation in Copiers

Heat dissipation is a significant challenge in copiers and other electronic devices. When copiers operate, they generate heat, which needs to be effectively dissipated to prevent damage to the internal components. Graphene-based copier components can greatly improve heat dissipation, leading to better performance and reliability.

Graphene’s exceptional thermal conductivity allows it to quickly transfer heat away from hotspots in the copier. This means that the heat generated during operation is efficiently spread out and dissipated, preventing any localized overheating that could damage the components.

By incorporating graphene into the drum and fuser of a copier, for example, the heat generated during the printing process can be effectively managed. This not only improves the durability of these components but also ensures that the copier can operate at optimal performance levels for extended periods without the risk of overheating.

Furthermore, improved heat dissipation in copiers can also lead to energy savings. When components are kept cooler, they require less power to operate, resulting in lower energy consumption. This is not only beneficial for the environment but also for businesses that can reduce their electricity costs.

The use of graphene-based copier components offers several benefits, including enhanced durability and improved heat dissipation. By leveraging the remarkable properties of graphene, copiers can be made more reliable, longer-lasting, and more energy-efficient. This technology has the potential to revolutionize the copier industry and pave the way for a new generation of high-performance, durable, and environmentally friendly copiers.

1. Upgrade your electronic devices

If you want to benefit from the enhanced durability and heat dissipation properties of graphene-based copier components, consider upgrading your electronic devices. Look for devices that incorporate graphene-based components, such as smartphones, laptops, or printers. These devices will not only last longer but also perform better under high temperatures.

2. Invest in graphene-based accessories

Even if you don’t want to replace your electronic devices, you can still take advantage of graphene’s benefits by investing in graphene-based accessories. Look for smartphone cases, laptop cooling pads, or even headphones that utilize graphene technology. These accessories can help improve the durability and heat dissipation of your existing devices.

3. Opt for graphene-infused clothing

Graphene’s unique properties extend beyond electronics. Consider purchasing clothing items that are infused with graphene. These garments offer enhanced durability, breathability, and heat regulation. Graphene-infused clothing can keep you cool in hot weather and provide better insulation in colder temperatures.

4. Explore graphene-based batteries

Battery life is a common concern for many electronic device users. Graphene-based batteries are known for their improved energy storage capacity and faster charging times. Look for devices that come with graphene-based batteries or consider replacing your current batteries with graphene alternatives for longer-lasting power.

5. Upgrade your printer with graphene components

If you frequently use a printer, consider upgrading it with graphene-based components. Graphene’s heat dissipation properties can prevent overheating during extended printing sessions, ensuring the longevity of your printer. Look for printers that specifically mention the use of graphene-based components for enhanced durability.

6. Incorporate graphene-based skincare products

Graphene’s properties also have potential applications in the beauty industry. Look for skincare products that incorporate graphene, such as face masks or creams. Graphene’s ability to improve moisture retention and promote collagen production can help keep your skin healthy and youthful.

7. Consider graphene-based construction materials

Graphene’s strength and durability make it an ideal material for construction. If you’re planning any renovation or construction projects, consider using graphene-based materials. These materials offer improved structural integrity and resistance to wear and tear, resulting in longer-lasting buildings and infrastructure.

8. Upgrade your car with graphene-enhanced components

Graphene’s heat dissipation properties can also benefit your car’s performance. Look for car parts or accessories that incorporate graphene, such as brake pads or radiator components. These graphene-enhanced components can improve heat dissipation, reduce wear, and enhance overall durability.

9. Explore graphene-based sports equipment

If you’re an avid sports enthusiast, consider investing in graphene-based sports equipment. Graphene’s lightweight and strong nature make it an excellent material for items like tennis rackets, bicycles, or golf clubs. Graphene-based sports equipment can enhance your performance and durability, giving you a competitive edge.

10. Stay informed about graphene advancements

Graphene is a rapidly evolving field, with new applications and discoveries being made regularly. Stay informed about the latest advancements in graphene technology by following scientific publications, news websites, or attending conferences. This knowledge will help you identify new opportunities to incorporate graphene-based solutions into your daily life.

Common Misconceptions about

Misconception 1: Graphene-based copier components are too expensive for practical use

One of the most common misconceptions about graphene-based copier components is that they are prohibitively expensive for practical use. While it is true that graphene is a relatively expensive material, advancements in manufacturing techniques have significantly reduced the production costs in recent years.

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has exceptional electrical and thermal conductivity properties. These properties make it an ideal material for copier components that require enhanced durability and heat dissipation.

Although the initial cost of graphene-based copier components may be higher compared to traditional materials, their long-term benefits outweigh the upfront investment. Graphene’s high durability ensures a longer lifespan for copier components, reducing the need for frequent replacements. Additionally, its excellent heat dissipation properties contribute to improved energy efficiency, resulting in lower operational costs over time.

Furthermore, as research and development in graphene-based technologies continue to progress, the cost of production is expected to decrease further, making it a more affordable option for copier manufacturers in the near future.

Misconception 2: Graphene-based copier components are not readily available

Another misconception surrounding graphene-based copier components is that they are not readily available in the market. While it is true that graphene is a relatively new material, its commercial availability has been steadily increasing.

Several companies and research institutions have been actively working on scaling up the production of graphene and integrating it into various applications, including copier components. As a result, graphene-based copier components are becoming more accessible to manufacturers and consumers alike.

Moreover, collaborations between academia and industry have played a crucial role in advancing the development of graphene-based technologies. These collaborations have facilitated the transfer of knowledge and expertise, enabling the mass production of graphene-based copier components.

As the demand for graphene-based materials continues to grow, it is expected that the availability of copier components incorporating graphene will become even more widespread. This will not only benefit the copier industry but also other sectors that can leverage the unique properties of graphene for improved performance and efficiency.

Misconception 3: Graphene-based copier components have limited performance benefits

There is a misconception that graphene-based copier components offer limited performance benefits compared to traditional materials. However, numerous studies and experiments have demonstrated the significant advantages of graphene in enhancing the durability and heat dissipation of copier components.

Graphene’s exceptional strength and flexibility make it highly resistant to wear and tear, ensuring copier components last longer without compromising performance. Its thermal conductivity properties enable efficient heat dissipation, preventing overheating and reducing the risk of damage to sensitive parts.

Furthermore, graphene-based copier components can contribute to improved printing speeds and quality. The high electrical conductivity of graphene allows for faster transfer of signals and data, resulting in quicker printing processes. Additionally, its excellent mechanical properties enable precise control of printing mechanisms, leading to sharper and more accurate prints.

Moreover, graphene’s lightweight nature allows for the development of compact and portable copier devices without sacrificing performance. This is particularly beneficial for industries that require mobility and flexibility in their printing operations.

Overall, the performance benefits of graphene-based copier components are substantial and have the potential to revolutionize the copier industry by providing enhanced durability, heat dissipation, and improved printing capabilities.

Conclusion

The exploration of graphene-based copier components for enhanced durability and heat dissipation holds immense potential for revolutionizing the copier industry. Through extensive research and experimentation, it has been demonstrated that incorporating graphene into copier components can significantly improve their durability, reducing the need for frequent replacements and maintenance. The exceptional mechanical strength and flexibility of graphene make it an ideal material for withstanding the rigors of daily copier use, ensuring long-lasting performance and cost savings for businesses.

Furthermore, graphene’s exceptional thermal conductivity properties offer a solution to one of the major challenges faced by copiers – heat dissipation. By utilizing graphene-based components, copiers can effectively dissipate heat generated during operation, preventing overheating and improving overall efficiency. This not only enhances the lifespan of the copier but also reduces the risk of malfunctions and breakdowns, leading to increased productivity and reduced downtime.

While further research and development are still needed to optimize the integration of graphene into copier components, the potential benefits are undeniable. The copier industry stands to gain significantly from adopting graphene-based materials, improving durability, heat dissipation, and ultimately delivering enhanced performance and cost savings to businesses and consumers alike.