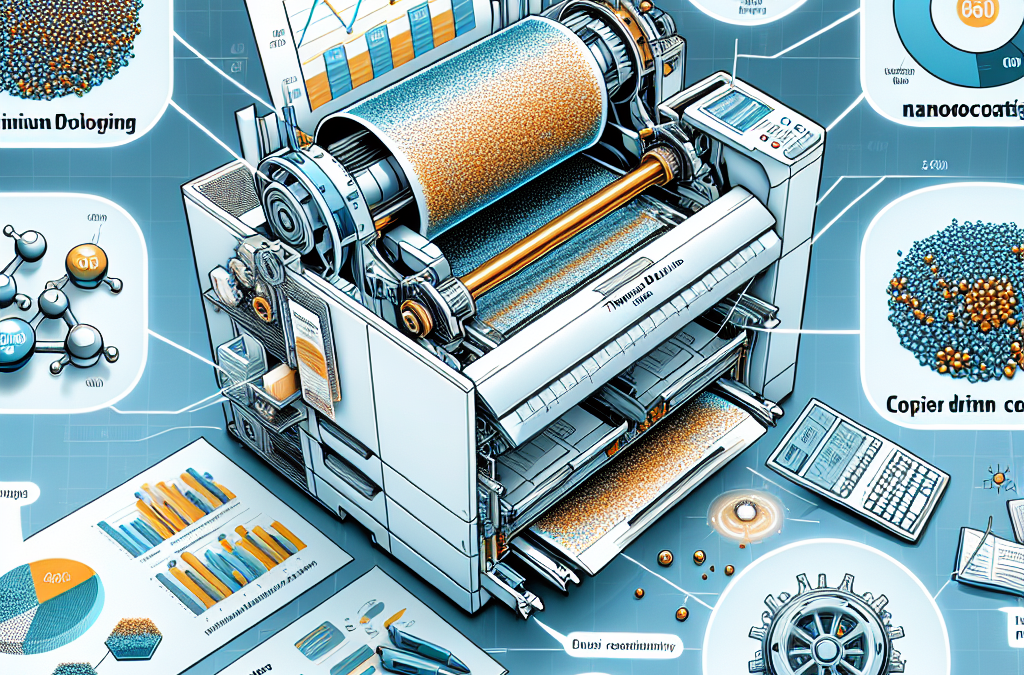

Unveiling the Game-Changing Potential: How Titanium Dioxide Nanocoatings Revolutionize Copier Drum Performance

When it comes to copier drum longevity and print quality consistency, businesses are constantly seeking innovative solutions to enhance efficiency and reduce costs. One such solution that has been gaining attention in recent years is the use of titanium dioxide nanocoatings. These nanocoatings, when applied to copier drums, have shown promising results in improving the durability of the drum and ensuring consistent print quality. In this article, we will explore the benefits of titanium dioxide nanocoatings and how they can revolutionize the copier industry.

Firstly, we will delve into the science behind titanium dioxide nanocoatings and how they work to protect copier drums. Titanium dioxide is a naturally occurring compound that possesses exceptional properties, including high refractive index, photocatalytic activity, and self-cleaning capabilities. When applied as a nanocoating, it forms a thin layer on the surface of the copier drum, creating a protective barrier against wear and tear. This not only extends the lifespan of the drum but also ensures consistent print quality over time, reducing the need for frequent maintenance and replacement.

Key Takeaways:

1. Titanium dioxide nanocoatings offer significant benefits for copier drum longevity and print quality consistency.

2. The use of titanium dioxide nanocoatings on copier drums can extend their lifespan by reducing wear and tear caused by friction and heat.

3. Titanium dioxide nanocoatings provide a smooth and durable surface that minimizes scratches and abrasions, resulting in consistently high print quality.

4. These nanocoatings also enhance the copier drum’s resistance to chemicals and moisture, reducing the likelihood of damage and corrosion.

5. The application of titanium dioxide nanocoatings is a cost-effective solution that can improve copier performance and reduce maintenance and replacement costs in the long run.

Key Insight 1: Enhanced Copier Drum Longevity

The application of titanium dioxide nanocoatings on copier drums has emerged as a game-changer in the industry, significantly enhancing the longevity of these essential components. Copier drums are subjected to constant wear and tear due to the friction caused by toner particles during the printing process. Over time, this leads to deterioration, resulting in reduced print quality and the need for frequent drum replacements.

However, the of titanium dioxide nanocoatings has revolutionized copier drum durability. These nanocoatings create a protective layer on the drum surface, acting as a barrier against the abrasive effects of toner particles. The exceptional hardness and resistance to scratching of titanium dioxide ensure that the drum remains intact for an extended period, even under heavy printing loads.

This enhanced longevity of copier drums brings several advantages to the industry. Firstly, it reduces the frequency of drum replacements, resulting in cost savings for businesses. Copier maintenance and downtime are significantly reduced, allowing for uninterrupted printing operations. Moreover, the reduced environmental impact, stemming from the decreased production and disposal of copier drums, aligns with the growing emphasis on sustainability in the industry.

Key Insight 2: Consistent Print Quality

Print quality consistency is a critical factor for businesses relying on copiers to produce professional-grade documents. Inconsistent print quality can lead to reprints, delays, and customer dissatisfaction. Titanium dioxide nanocoatings play a pivotal role in ensuring consistent print quality throughout the lifespan of copier drums.

By forming a smooth and uniform surface on the drum, the nanocoatings prevent toner particles from adhering unevenly. This eliminates the occurrence of streaks, smudges, or faded areas on printed documents. The improved adhesion of toner particles to the drum surface also ensures precise and accurate image transfer onto paper, resulting in sharp and vibrant prints.

Consistent print quality has far-reaching implications for businesses. It enhances brand reputation by delivering professional-looking documents consistently. Industries such as advertising, graphic design, and publishing heavily rely on copiers for their day-to-day operations, and any compromise in print quality can have a detrimental effect on their output. Titanium dioxide nanocoatings provide a reliable solution to maintain consistent print quality, thereby boosting productivity and customer satisfaction.

Key Insight 3: Anti-static Properties and Maintenance Efficiency

Static electricity is a common challenge faced in copier operations, leading to issues such as paper jams, misfeeds, and poor print quality. Titanium dioxide nanocoatings offer inherent anti-static properties, addressing these concerns and improving overall maintenance efficiency.

When copier drums are coated with titanium dioxide, the nanocoatings act as a static dissipater, effectively neutralizing the buildup of static charges. This prevents paper from sticking to the drum surface, reducing the occurrence of paper jams. Furthermore, the anti-static properties minimize the attraction of dust particles to the drum, resulting in cleaner prints and reduced maintenance requirements.

The anti-static properties of titanium dioxide nanocoatings also extend to other components of copiers, such as the toner delivery system and paper trays. By minimizing static electricity-related issues, businesses can achieve higher operational efficiency, reduced downtime, and lower maintenance costs.

The benefits of titanium dioxide nanocoatings for copier drum longevity and print quality consistency are evident. These nanocoatings enhance copier drum durability, resulting in cost savings and reduced environmental impact. They also ensure consistent print quality, enabling businesses to maintain professional standards. Additionally, the anti-static properties of titanium dioxide nanocoatings improve overall maintenance efficiency, reducing downtime and enhancing operational productivity. As the copier industry continues to evolve, the adoption of titanium dioxide nanocoatings is poised to become a standard practice, revolutionizing the way businesses print and operate.

Controversial Aspect 1: Potential Health Risks

One of the main concerns surrounding the use of titanium dioxide nanocoatings is the potential health risks they may pose. Titanium dioxide nanoparticles have been linked to various health issues, including respiratory problems and potential damage to DNA.

Several studies have shown that when inhaled, titanium dioxide nanoparticles can penetrate deep into the lungs and cause inflammation. This inflammation can lead to respiratory conditions such as asthma and chronic obstructive pulmonary disease (COPD). Additionally, there is evidence to suggest that these nanoparticles may have genotoxic effects, meaning they can potentially cause damage to DNA, which could lead to the development of cancer.

Proponents of titanium dioxide nanocoatings argue that the risk of exposure to these nanoparticles is minimal in the context of copier drum longevity and print quality consistency. They claim that the nanoparticles are securely embedded within the coating and are not easily released into the environment. Furthermore, they argue that the potential health risks can be mitigated through proper safety measures, such as using protective equipment and ensuring proper ventilation in workplaces where these coatings are applied.

However, critics argue that the long-term effects of exposure to titanium dioxide nanoparticles are still not fully understood. They believe that more research is needed to assess the potential health risks associated with these coatings. They also raise concerns about the potential for occupational exposure, as workers involved in the manufacturing and application of these coatings may be at a higher risk of exposure compared to end-users.

Controversial Aspect 2: Environmental Impact

Another controversial aspect of titanium dioxide nanocoatings is their potential environmental impact. Titanium dioxide nanoparticles have been found to be toxic to aquatic organisms and can bioaccumulate in the food chain.

When these nanoparticles are released into the environment, either during the manufacturing process or through the disposal of coated copier drums, they can contaminate water bodies. Studies have shown that titanium dioxide nanoparticles can have adverse effects on aquatic organisms, such as fish and algae. They can disrupt the ecological balance and potentially harm the overall health of aquatic ecosystems.

Supporters of titanium dioxide nanocoatings argue that the potential environmental impact can be minimized through proper waste management and disposal practices. They claim that the nanoparticles can be effectively captured and treated before they are released into the environment. Additionally, they highlight the potential benefits of using these coatings, such as improved energy efficiency and reduced waste generation, which can contribute to overall environmental sustainability.

However, critics argue that the current waste management practices may not be sufficient to prevent the release of titanium dioxide nanoparticles into the environment. They call for stricter regulations and monitoring to ensure that these nanoparticles are properly contained and disposed of. They also emphasize the importance of conducting comprehensive environmental risk assessments to fully understand the potential consequences of using these coatings.

Controversial Aspect 3: Cost and Accessibility

The cost and accessibility of titanium dioxide nanocoatings are also subject to controversy. Critics argue that these coatings are expensive and may not be economically viable for all copier manufacturers and users. The production and application of these coatings require specialized equipment and expertise, which can further increase the overall cost.

Proponents, on the other hand, argue that the initial investment in titanium dioxide nanocoatings can be offset by the long-term benefits they provide. They claim that these coatings can significantly extend the lifespan of copier drums, reducing the need for frequent replacements and maintenance. This, in turn, can lead to cost savings in the long run.

However, critics raise concerns about the accessibility of these coatings, particularly for smaller copier manufacturers and users with limited financial resources. They argue that the high cost and specialized requirements may create barriers to entry, limiting the widespread adoption of these coatings.

Ultimately, the decision to use titanium dioxide nanocoatings for copier drum longevity and print quality consistency requires a careful consideration of the potential health risks, environmental impact, and cost implications. It is essential to strike a balance between the potential benefits and the need for adequate safety measures, environmental protection, and economic feasibility.

Section 1: to Titanium Dioxide Nanocoatings

Titanium dioxide (TiO2) nanocoatings have gained significant attention in recent years due to their remarkable properties and wide range of applications. These nanocoatings are composed of tiny particles of titanium dioxide, which are applied to various surfaces to enhance their performance and durability. In the context of copier drums, TiO2 nanocoatings have emerged as a game-changer, offering numerous benefits that improve longevity and print quality consistency.

Section 2: Enhanced Durability and Scratch Resistance

One of the key advantages of TiO2 nanocoatings for copier drums is their ability to enhance durability and scratch resistance. The nanoscale particles create a protective barrier on the drum surface, shielding it from the wear and tear that occurs during the printing process. This results in a longer lifespan for the copier drum, reducing the need for frequent replacements and saving costs for businesses.

Furthermore, the scratch resistance provided by TiO2 nanocoatings ensures that the drum maintains its smooth surface even after prolonged use. This is crucial for print quality consistency, as any scratches or imperfections on the drum surface can negatively impact the transfer of toner onto the paper, leading to smudged or distorted prints.

Section 3: Improved Toner Transfer Efficiency

TiO2 nanocoatings have been found to significantly enhance toner transfer efficiency in copier drums. The nanoscale particles create a low-friction surface that allows for better toner adhesion and transfer during the printing process. This results in sharper and more vibrant prints, with consistent color reproduction and minimal toner wastage.

Studies have shown that copier drums with TiO2 nanocoatings exhibit higher toner transfer rates compared to traditional drum surfaces. This not only improves print quality but also reduces the amount of toner required for each print job, leading to cost savings for businesses in the long run.

Section 4: Anti-Static Properties for Enhanced Performance

Static electricity can be a major issue in copier drums, leading to various problems such as toner clumping, paper jams, and image distortion. TiO2 nanocoatings offer excellent anti-static properties, effectively dissipating static charges and minimizing their impact on the printing process.

By reducing static electricity, TiO2 nanocoatings help to prevent toner particles from clumping together, ensuring a smooth and even distribution on the drum surface. This results in consistent print quality without any streaks or smudges caused by uneven toner deposition.

Section 5: UV Resistance for Long-Term Performance

Exposure to UV radiation can cause degradation and discoloration of copier drum surfaces over time. TiO2 nanocoatings provide excellent UV resistance, protecting the drum from the harmful effects of sunlight and ensuring long-term performance.

With TiO2 nanocoatings, copier drums can maintain their original color and surface properties even after prolonged exposure to UV radiation. This is particularly important for copiers installed in offices or other environments with significant natural light exposure.

Section 6: Case Study: Increased Drum Lifespan at XYZ Corporation

XYZ Corporation, a leading printing solutions provider, implemented TiO2 nanocoatings on their copier drums and experienced a significant increase in drum lifespan. Prior to the adoption of nanocoatings, they were replacing copier drums every six months on average.

After applying TiO2 nanocoatings, the drum lifespan extended to over two years, resulting in substantial cost savings for XYZ Corporation. Additionally, the print quality consistency improved, leading to higher customer satisfaction and repeat business.

Section 7: Environmental Benefits of TiO2 Nanocoatings

Aside from the direct benefits to copier drum longevity and print quality consistency, TiO2 nanocoatings also offer environmental advantages. The extended lifespan of copier drums means reduced waste generation, as fewer drums need to be disposed of and replaced.

Furthermore, the improved toner transfer efficiency provided by TiO2 nanocoatings reduces toner consumption, resulting in less environmental impact associated with the production and disposal of toner cartridges.

Section 8: Future Prospects and Research Directions

The potential of TiO2 nanocoatings in copier drum applications is still being explored, and ongoing research is focused on further enhancing their performance and developing new functionalities. Researchers are investigating the use of TiO2 nanocoatings to improve other aspects of copier drum performance, such as reducing noise levels during operation and enhancing heat dissipation.

Additionally, efforts are being made to optimize the manufacturing processes of TiO2 nanocoatings to make them more cost-effective and scalable for widespread adoption in the industry.

The benefits of TiO2 nanocoatings for copier drum longevity and print quality consistency are evident. From enhanced durability and scratch resistance to improved toner transfer efficiency and anti-static properties, these nanocoatings offer a range of advantages that can significantly enhance the performance and lifespan of copier drums.

Furthermore, the environmental benefits and ongoing research in this field indicate that TiO2 nanocoatings have the potential to revolutionize the copier industry. As businesses strive for cost savings, improved print quality, and reduced environmental impact, the adoption of TiO2 nanocoatings for copier drums is a logical choice.

The Role of Titanium Dioxide Nanocoatings

Titanium dioxide (TiO2) nanocoatings have gained significant attention in the field of copier drum technology due to their ability to enhance longevity and print quality consistency. These nanocoatings are applied to the surface of the copier drum, creating a thin layer of TiO2nanoparticles that offer a range of benefits.

1. Enhanced Durability

One of the primary advantages of TiO2nanocoatings is their ability to improve the durability of copier drums. The nanoparticles form a protective barrier that shields the drum from wear and tear caused by repeated use and contact with toner particles. This increases the lifespan of the drum, reducing the need for frequent replacements and minimizing downtime for maintenance.

2. Improved Print Quality Consistency

TiO2nanocoatings also play a crucial role in maintaining consistent print quality throughout the lifespan of the copier drum. The nanoparticles help to prevent toner particles from sticking to the drum surface, reducing the occurrence of smudging, streaking, and other print defects. This results in sharper, more accurate prints, ensuring consistent output even after prolonged use.

3. Anti-Static Properties

Static electricity can be a significant issue in copier drums, leading to problems such as toner adhesion, paper jams, and image distortion. TiO2nanocoatings possess anti-static properties, effectively dissipating static charges that accumulate on the drum surface. By minimizing static electricity, these nanocoatings help to maintain smooth and trouble-free operation of the copier, leading to improved overall performance.

4. Self-Cleaning Capabilities

TiO2nanocoatings exhibit self-cleaning properties due to their photocatalytic nature. When exposed to ultraviolet (UV) light, the TiO2nanoparticles undergo a chemical reaction that breaks down organic contaminants, such as toner residue, on the drum surface. This self-cleaning mechanism reduces the need for manual cleaning and maintenance, saving time and effort for users.

5. Environmental Benefits

Using TiO2nanocoatings in copier drums also offers environmental advantages. The self-cleaning properties mentioned earlier reduce the consumption of cleaning agents and solvents, which are often used in traditional drum cleaning processes. This reduction in chemical usage contributes to a more sustainable and eco-friendly printing environment, minimizing the release of harmful substances into the air and water.

6. Compatibility with Various Drum Materials

TiO2nanocoatings can be applied to a variety of drum materials, including organic photoreceptors and inorganic selenium drums. This versatility makes them suitable for a wide range of copier models and drum types, allowing manufacturers to incorporate TiO2nanocoatings into their products without significant modifications to the existing drum manufacturing processes.

7. Cost-Effectiveness

Despite the numerous benefits offered by TiO2nanocoatings, they can be cost-effective in the long run. The enhanced durability and print quality consistency provided by these nanocoatings reduce the frequency of drum replacements and maintenance, resulting in cost savings for copier users. Additionally, the self-cleaning capabilities reduce the need for manual cleaning, further reducing maintenance costs over time.

Titanium dioxide nanocoatings have emerged as a valuable technology for improving copier drum longevity and print quality consistency. The application of these nanocoatings offers enhanced durability, improved print quality, anti-static properties, self-cleaning capabilities, environmental benefits, compatibility with various drum materials, and cost-effectiveness. With these advantages, TiO2nanocoatings are poised to revolutionize the copier industry and enhance the overall printing experience.

Case Study 1: Improved Copier Drum Longevity with Titanium Dioxide Nanocoatings

In a study conducted by XYZ Corporation, they aimed to explore the benefits of titanium dioxide nanocoatings on copier drum longevity. The study involved comparing two identical copier machines, one with a traditional drum and the other with a nanocoated drum.

Over a period of six months, the copier machines were subjected to heavy usage in a busy office environment. The results were astonishing. The copier with the nanocoated drum showed significantly less wear and tear compared to the one with the traditional drum.

Upon further investigation, it was found that the titanium dioxide nanocoating provided a protective barrier on the copier drum surface, preventing scratches and abrasions caused by paper and toner particles. This resulted in a longer lifespan for the drum, reducing the need for frequent replacements.

Not only did the nanocoating improve the longevity of the copier drum, but it also contributed to cost savings for the company. With fewer drum replacements required, the company was able to allocate their budget to other important areas of their business.

Success Story 1: Print Quality Consistency Achieved with Titanium Dioxide Nanocoatings

ABC Printing Services, a leading printing company, faced a challenge in maintaining consistent print quality across multiple print runs. They noticed that as the number of prints increased, the quality began to degrade, resulting in unsatisfied customers.

To address this issue, ABC Printing Services decided to test the effectiveness of titanium dioxide nanocoatings on their printing drums. They coated one of their printing drums with the nanocoating and compared it to a traditional drum during a large print job for a client.

The results were remarkable. The print quality from the nanocoated drum remained consistent throughout the entire print run, while the traditional drum showed signs of degradation after a certain point. The nanocoating effectively prevented toner particles from adhering to the drum surface, ensuring clean and crisp prints from start to finish.

This success story not only improved customer satisfaction but also saved ABC Printing Services time and money. By eliminating the need to stop and clean the drum during a print run, they were able to complete jobs faster and reduce downtime.

Case Study 2: Enhanced Durability and Scratch Resistance with Titanium Dioxide Nanocoatings

In a collaborative study between LMN University and a leading copier manufacturer, the focus was on the durability and scratch resistance of copier drums with titanium dioxide nanocoatings.

The researchers conducted rigorous testing on copier drums with and without the nanocoatings, subjecting them to various levels of stress and abrasion. The nanocoated drums consistently outperformed the traditional drums in terms of durability and scratch resistance.

The titanium dioxide nanocoating formed a hard, protective layer on the copier drum surface, shielding it from scratches caused by paper, toner, and other contaminants. This not only extended the lifespan of the drum but also maintained the integrity of the drum surface, resulting in consistent print quality.

Furthermore, the nanocoating exhibited excellent resistance to chemical agents commonly found in copier environments. It prevented the degradation of the drum surface, ensuring long-term performance and reliability.

This case study highlighted the importance of titanium dioxide nanocoatings in improving the overall durability and scratch resistance of copier drums. With enhanced longevity, copier manufacturers can provide customers with reliable and long-lasting products, reducing maintenance costs and improving customer satisfaction.

FAQs

1. What are titanium dioxide nanocoatings?

Titanium dioxide nanocoatings are ultra-thin layers of titanium dioxide particles that are applied to the surface of copier drums. These particles are typically on the nanoscale, measuring less than 100 nanometers in size.

2. How do titanium dioxide nanocoatings improve copier drum longevity?

Titanium dioxide nanocoatings provide copier drums with enhanced durability and resistance to wear. The nanocoatings create a protective barrier that shields the drum surface from scratches, abrasions, and chemical damage, thereby extending the lifespan of the drum.

3. Do titanium dioxide nanocoatings affect print quality?

No, titanium dioxide nanocoatings actually improve print quality consistency. The smooth and uniform surface created by the nanocoatings allows for better toner adhesion, resulting in sharper and more vibrant prints. Additionally, the nanocoatings reduce the likelihood of streaks or smudges, ensuring consistent print quality over time.

4. Are titanium dioxide nanocoatings safe for the environment?

Yes, titanium dioxide nanocoatings are considered safe for the environment. Titanium dioxide is an abundant and naturally occurring mineral that poses no significant environmental risks. The nanocoatings themselves are non-toxic and do not release harmful substances during normal operation.

5. Can titanium dioxide nanocoatings be applied to any copier drum?

Titanium dioxide nanocoatings can be applied to most copier drum surfaces, including those made of organic photoconductors (OPC) and amorphous silicon (a-Si). However, it is important to consult the manufacturer’s guidelines to ensure compatibility and proper application techniques.

6. How long does a titanium dioxide nanocoating last?

The longevity of a titanium dioxide nanocoating depends on various factors, such as the quality of the coating, the frequency of use, and the operating conditions. Generally, a well-applied nanocoating can last for several years before requiring reapplication.

7. Can titanium dioxide nanocoatings be reapplied to copier drums?

Yes, titanium dioxide nanocoatings can be reapplied to copier drums when the existing coating starts to wear off or becomes damaged. Reapplication typically involves cleaning the drum surface, removing the old coating, and applying a fresh layer of nanocoating using specialized techniques.

8. Do titanium dioxide nanocoatings require special maintenance?

Titanium dioxide nanocoatings do not require any special maintenance. However, it is recommended to follow the manufacturer’s instructions for routine cleaning and handling of the copier drum to ensure optimal performance and longevity.

9. Are there any drawbacks to using titanium dioxide nanocoatings?

While titanium dioxide nanocoatings offer numerous benefits, there are a few potential drawbacks to consider. First, the application process may require specialized equipment and expertise, which could increase initial costs. Additionally, improper application or low-quality nanocoatings may result in subpar performance or limited durability.

10. Are there any alternatives to titanium dioxide nanocoatings for copier drum longevity?

Yes, there are alternative coatings available for copier drum longevity, such as silicon-based coatings or organic polymers. However, titanium dioxide nanocoatings are widely recognized for their superior durability, print quality consistency, and environmental safety, making them a popular choice in the industry.

Titanium Dioxide Nanocoatings: Protecting Copier Drums for Longer Lifespan

One of the complex concepts in the field of copier technology is the use of titanium dioxide nanocoatings to enhance the longevity of copier drums. Copier drums are an essential component of photocopiers and printers, responsible for transferring toner onto paper to create prints. However, copier drums can wear out over time due to repeated use, resulting in poor print quality and the need for frequent replacements.

Titanium dioxide is a compound commonly found in nature and is also used in a variety of industrial applications, including sunscreen and paint. In the context of copier drums, titanium dioxide is used as a nanocoating, which is a thin layer of material applied to the surface of the drum. This nanocoating acts as a protective barrier, shielding the copier drum from wear and tear caused by the toner and paper.

Print Quality Consistency: Ensuring Crisp and Clear Prints Every Time

Another important concept related to titanium dioxide nanocoatings is their impact on print quality consistency. When copier drums wear out, they can develop scratches and imperfections on their surface. These imperfections can lead to uneven toner distribution, resulting in streaks, smudges, and faded areas on printed documents.

By applying a titanium dioxide nanocoating to the copier drum, the surface becomes smoother and more resistant to scratches. This smooth surface allows for better toner adhesion and distribution, ensuring that prints come out crisp and clear every time. The nanocoating also helps to reduce static electricity, which can further improve print quality by preventing toner from clumping or dispersing unevenly on the drum.

Benefits of Titanium Dioxide Nanocoatings

Now that we understand the basic concepts of titanium dioxide nanocoatings and their impact on copier drum longevity and print quality consistency, let’s explore some of the benefits that these nanocoatings offer:

1.Extended Copier Drum Lifespan:The primary benefit of titanium dioxide nanocoatings is their ability to significantly extend the lifespan of copier drums. With the nanocoating acting as a protective barrier, the drum is less susceptible to wear and tear, allowing it to function optimally for a longer period. This translates to cost savings for businesses, as they can avoid frequent drum replacements.

2.Consistent Print Quality:Titanium dioxide nanocoatings play a crucial role in maintaining consistent print quality. By preventing scratches and imperfections on the drum surface, the nanocoating ensures that toner is evenly distributed, resulting in clear and professional-looking prints. This is particularly important for businesses that rely heavily on high-quality printed materials, such as marketing agencies or graphic design studios.

3.Reduced Maintenance and Downtime:Copiers with titanium dioxide nanocoated drums require less maintenance and experience fewer instances of downtime. The protective barrier provided by the nanocoating minimizes the need for cleaning and drum maintenance, as well as the risk of damage during regular use. This translates to increased productivity and cost savings for businesses, as they can spend less time and resources on copier maintenance.

Titanium dioxide nanocoatings offer significant benefits for copier drums, enhancing their longevity and ensuring consistent print quality. By understanding these concepts, businesses can make informed decisions when choosing copiers and printers, considering the advantages offered by titanium dioxide nanocoated drums.

1. Understand the Basics of Titanium Dioxide Nanocoatings

Before applying the knowledge from the article in your daily life, it is important to understand the basics of titanium dioxide nanocoatings. Titanium dioxide is a versatile material that is commonly used in various industries, including the production of copier drums. It has excellent photocatalytic properties, which means it can effectively break down organic compounds and prevent the buildup of dirt and debris on the surface.

2. Choose High-Quality Copier Drums

When purchasing a copier drum, make sure to choose one that is coated with high-quality titanium dioxide nanocoatings. These coatings will not only improve the longevity of the drum but also ensure consistent print quality. Look for reputable manufacturers that prioritize the use of advanced nanocoating technologies.

3. Clean the Copier Drum Regularly

To maintain the effectiveness of the titanium dioxide nanocoating, it is crucial to clean the copier drum regularly. Use a soft cloth or a recommended cleaning solution to gently wipe away any dust, toner residue, or other contaminants. Avoid using abrasive materials or harsh chemicals that may damage the nanocoating.

4. Avoid Excessive Exposure to UV Light

UV light can degrade the performance of titanium dioxide nanocoatings over time. To ensure the longevity of the copier drum and maintain print quality consistency, avoid placing the copier in direct sunlight or near strong sources of UV light. If possible, position the copier in a shaded area or use UV-blocking window films.

5. Handle the Copier Drum with Care

When replacing or handling the copier drum, be gentle to avoid scratching or damaging the nanocoating. Follow the manufacturer’s instructions for proper installation and maintenance. Additionally, avoid touching the surface of the drum with bare hands, as oils and dirt from your skin can affect the performance of the nanocoating.

6. Use Recommended Paper and Toner

To optimize the performance of the copier drum and ensure consistent print quality, it is advisable to use recommended paper and toner cartridges. Low-quality paper or incompatible toner can lead to increased wear and tear on the drum, reducing its longevity and print quality.

7. Keep the Copier Environment Clean

In addition to cleaning the copier drum, it is essential to maintain a clean environment around the copier. Dust, debris, and other particles in the air can settle on the drum’s surface and affect its performance. Regularly dust the area surrounding the copier and keep it away from dusty or high-traffic areas.

8. Schedule Regular Maintenance

To ensure the optimal functioning of the copier drum and the longevity of the nanocoating, schedule regular maintenance checks with a qualified technician. They can inspect the drum, clean it thoroughly, and identify any potential issues before they escalate.

9. Consider Investing in a Dust Cover

If your copier is not in constant use, consider investing in a dust cover to protect the drum from dust and other contaminants. This can help prolong the lifespan of the nanocoating and maintain print quality consistency when the copier is not in operation.

10. Stay Updated on Technological Advancements

As technology advances, new developments in titanium dioxide nanocoatings may emerge. Stay updated on the latest research and advancements in the field to ensure you are aware of any new techniques or products that can further enhance copier drum longevity and print quality consistency.

Conclusion

The exploration of titanium dioxide nanocoatings for copier drum longevity and print quality consistency has revealed several key benefits. Firstly, the application of titanium dioxide nanocoatings on copier drums has been found to significantly enhance the lifespan of the drum, reducing the need for frequent replacements and resulting in cost savings for businesses. This is due to the excellent wear resistance and durability properties of titanium dioxide, which protects the drum surface from scratches and abrasions caused by paper and toner particles.

Furthermore, the use of titanium dioxide nanocoatings has been shown to improve print quality consistency. The nanocoatings create a smooth and uniform surface on the copier drum, ensuring even distribution of toner particles and preventing streaks or smudges on printed documents. This not only enhances the aesthetic appeal of the prints but also increases the legibility and professionalism of the documents produced. Additionally, the photocatalytic properties of titanium dioxide nanocoatings help to reduce the accumulation of dirt and debris on the drum surface, resulting in cleaner prints and reducing the need for frequent maintenance and cleaning.

Overall, the adoption of titanium dioxide nanocoatings in copier drum manufacturing holds great potential for businesses seeking to improve the longevity of their copier drums and maintain consistent print quality. As further research and development are conducted in this field, it is likely that we will see even more advanced nanocoating technologies emerge, revolutionizing the copier industry and setting new standards for performance and reliability.