Revolutionizing Copier Technology: The Power of Self-Healing Materials to Prolong Device Lifespan

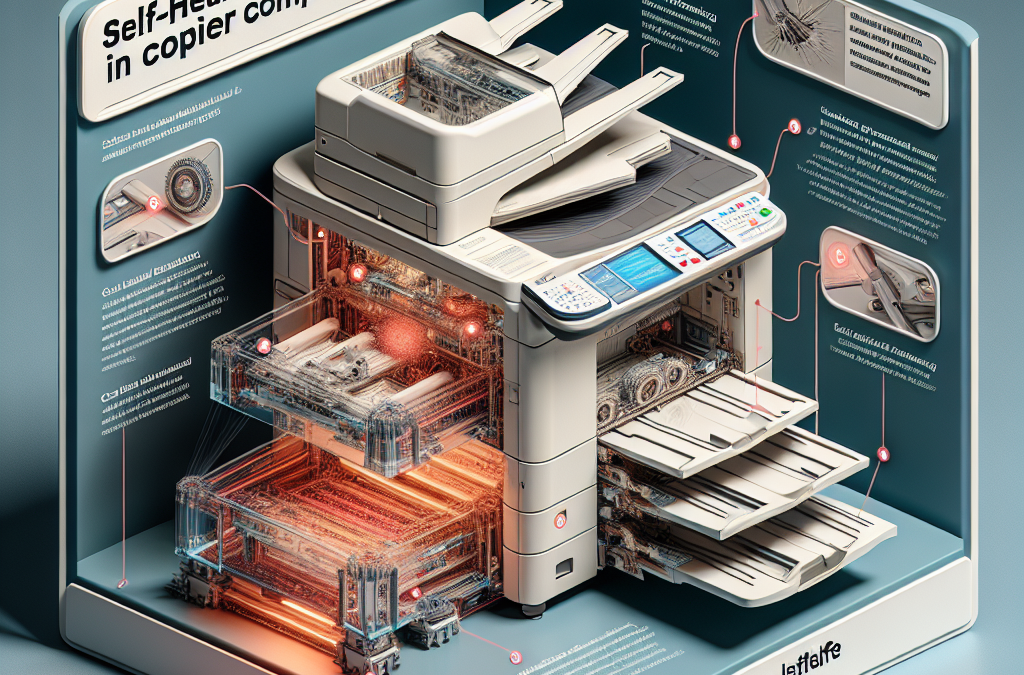

Imagine a world where your office copier never breaks down, where you never have to deal with frustrating paper jams or malfunctioning components. It may sound like a dream, but thanks to advancements in self-healing materials, this could soon become a reality. Self-healing materials have been making waves in various industries, and now they are poised to revolutionize the copier industry by extending the lifespan of these essential devices.

In this article, we will explore the concept of self-healing materials and how they can be applied to copier components. We will delve into the science behind these remarkable materials, understanding how they have the ability to repair themselves when damaged. We will also examine the potential benefits of using self-healing materials in copiers, such as reduced maintenance costs, increased device durability, and improved overall performance. Additionally, we will discuss the challenges and limitations of implementing self-healing materials in copier manufacturing, as well as the future prospects of this technology.

Key Takeaways:

1. Self-healing materials have the potential to revolutionize copier components by extending their lifespan and reducing maintenance costs.

2. Self-healing materials are capable of repairing minor damage and preventing further deterioration, resulting in longer-lasting copier components.

3. The use of self-healing materials in copier components can significantly reduce the need for frequent repairs and replacements, leading to cost savings for businesses.

4. Self-healing materials can enhance the reliability and performance of copiers, ensuring consistent output quality and minimizing downtime.

5. The development and implementation of self-healing materials in copier components require further research and testing, but the potential benefits make it a promising avenue for the industry.

Insight 1: Self-healing materials revolutionize copier components

The copier industry has witnessed a significant technological breakthrough with the of self-healing materials in copier components. This innovation has the potential to extend the lifespan of copier devices, reduce maintenance costs, and enhance overall productivity.

Traditionally, copier components are prone to wear and tear due to constant usage, resulting in frequent breakdowns and the need for costly repairs or replacements. However, self-healing materials offer a promising solution to this problem. These materials have the ability to repair themselves when damaged, thereby reducing the need for manual intervention and prolonging the lifespan of copier components.

Self-healing materials work by incorporating microcapsules or microvascular networks within the copier components. When a crack or damage occurs, the microcapsules release healing agents or the microvascular network delivers healing fluids to the affected area, effectively repairing the damage. This process can occur repeatedly, ensuring that the copier component remains functional even after multiple instances of damage.

The of self-healing materials in copier components has the potential to revolutionize the industry by minimizing downtime, reducing maintenance costs, and improving the overall user experience. Copier devices equipped with self-healing materials can operate for longer periods without requiring repairs or replacements, leading to increased productivity and cost savings for businesses.

Insight 2: Extended device lifespan leads to sustainability benefits

One of the key advantages of self-healing materials in copier components is the extended lifespan they offer to devices. By reducing the frequency of breakdowns and the need for repairs or replacements, self-healing materials contribute to the sustainability of copier devices and the environment.

Traditionally, copier devices have a limited lifespan, typically ranging from five to ten years. After this period, copiers are often discarded and replaced, resulting in significant electronic waste. However, with the integration of self-healing materials, copier devices can potentially operate for longer periods, reducing the need for premature replacements.

This extended device lifespan not only reduces electronic waste but also conserves valuable resources that would have been used in the manufacturing of new copiers. By minimizing the environmental impact associated with copier production and disposal, self-healing materials contribute to a more sustainable and eco-friendly copier industry.

Moreover, the use of self-healing materials in copier components aligns with the growing trend of circular economy principles. Instead of following a linear model of production and disposal, copier devices equipped with self-healing materials can be repaired and reused, promoting a more sustainable approach to resource utilization.

Insight 3: Challenges and future prospects for self-healing materials in copier components

While self-healing materials offer promising benefits for copier components, there are still challenges to overcome and future prospects to explore in order to fully harness their potential.

One of the primary challenges is the cost associated with implementing self-healing materials in copier components. Currently, these materials are relatively expensive compared to traditional materials, which may hinder their widespread adoption. However, as research and development in this field progress, it is expected that the cost of self-healing materials will decrease, making them more accessible to copier manufacturers.

Another challenge is the scalability of self-healing materials. While they have shown great potential in laboratory settings, their performance and durability in real-world copier devices need to be thoroughly tested and validated. Ensuring that self-healing materials can withstand the rigors of copier usage and maintain their healing properties over an extended period is crucial for their successful integration into the industry.

Despite these challenges, the future prospects for self-healing materials in copier components are promising. Continued research and development efforts are likely to lead to the discovery of new and more cost-effective self-healing materials. Additionally, advancements in manufacturing techniques and processes can further enhance the scalability and reliability of self-healing materials, making them a standard feature in copier devices.

The of self-healing materials in copier components has the potential to revolutionize the industry by extending device lifespan, reducing maintenance costs, and promoting sustainability. While challenges remain, the future prospects for self-healing materials in copier components are optimistic, paving the way for a more efficient, cost-effective, and environmentally friendly copier industry.

Section 1: to Self-Healing Materials

Self-healing materials are a revolutionary development in the field of engineering. These materials have the ability to repair themselves when damaged, thereby extending the lifespan of various components and devices. In the context of copier components, self-healing materials offer immense potential to enhance the durability and reliability of these machines. The concept of self-healing materials is inspired by biological systems, where living organisms have the ability to heal wounds and regenerate damaged tissues. By incorporating self-healing materials in copier components, manufacturers can reduce maintenance costs, increase device longevity, and improve overall customer satisfaction.

Section 2: How Self-Healing Materials Work

Self-healing materials function through the activation of embedded healing agents or the use of reversible chemical reactions. When a copier component made from self-healing materials is damaged, the healing agents are released or the chemical reactions are triggered, leading to the repair of the damaged area. For instance, microcapsules containing healing agents can rupture upon damage, releasing the healing agents that flow into the crack or fissure and solidify to restore the mechanical integrity of the component. Alternatively, reversible chemical reactions can occur, allowing the material to revert to its original state.

Section 3: Applications of Self-Healing Materials in Copier Components

Self-healing materials find numerous applications in copier components. One of the primary areas where these materials are utilized is in the development of photoreceptor drums. Photoreceptor drums are critical components in copiers, responsible for capturing and transferring images onto paper. By using self-healing materials in the construction of photoreceptor drums, manufacturers can prevent scratches and abrasions caused by repeated use, thus ensuring consistent image quality and extending the lifespan of the drum.

Section 4: Case Study: Self-Healing Rollers

A notable example of self-healing materials in copier components is the use of self-healing rollers. Rollers are essential for paper feeding and transportation within copiers. Over time, these rollers can develop cracks or become worn out, leading to paper jams and reduced performance. By incorporating self-healing materials in the construction of rollers, manufacturers can mitigate these issues. The self-healing mechanism allows the rollers to repair themselves, eliminating cracks and restoring their original smooth surface, thereby improving paper feeding efficiency and prolonging the lifespan of the copier.

Section 5: Advantages of Self-Healing Materials in Copier Components

The integration of self-healing materials in copier components offers several advantages. Firstly, it reduces the need for frequent maintenance and replacement of damaged components, resulting in cost savings for both manufacturers and end-users. Secondly, self-healing materials enhance the durability and reliability of copiers, reducing downtime and improving productivity. Additionally, the extended lifespan of copier components contributes to sustainability efforts by reducing electronic waste, making self-healing materials an environmentally friendly choice.

Section 6: Challenges and Limitations

While self-healing materials offer significant benefits, they also face certain challenges and limitations. One challenge is the cost associated with the production and integration of self-healing materials into copier components. The development of these materials often requires specialized manufacturing processes, which can increase production costs. Additionally, the effectiveness and longevity of self-healing materials may vary depending on the severity and type of damage. For instance, extensive damage or continuous stress may exceed the self-healing capabilities of the material, necessitating traditional repairs or component replacement.

Section 7: Future Outlook and Potential Innovations

The field of self-healing materials is continuously evolving, and ongoing research and development efforts aim to address the existing limitations and explore new possibilities. Future innovations may involve the integration of smart sensors that can detect and trigger the self-healing process automatically. This would further enhance the efficiency and effectiveness of self-healing materials in copier components. Moreover, advancements in material science and engineering techniques may lead to the development of self-healing materials with enhanced mechanical properties and extended lifespans, making them even more suitable for copier applications.

The utilization of self-healing materials in copier components presents a promising opportunity to extend the lifespan of these devices and enhance their performance. By incorporating self-healing mechanisms, copier manufacturers can reduce maintenance costs, improve customer satisfaction, and contribute to sustainability efforts. While challenges and limitations exist, ongoing research and innovation in the field of self-healing materials offer a bright future for copier technology. As the demand for durable and reliable copiers continues to grow, self-healing materials are poised to play a vital role in shaping the next generation of copier components.

The Emergence of Self-Healing Materials

In the early 2000s, the concept of self-healing materials began to gain traction in the scientific community. Researchers were exploring ways to create materials that could repair themselves when damaged, leading to extended lifespans for various products. The initial focus was on applications in the aerospace and automotive industries, where self-healing materials could potentially reduce maintenance costs and increase safety.

Expanding Applications in Consumer Electronics

As the technology behind self-healing materials advanced, their potential applications expanded beyond the aerospace and automotive sectors. Consumer electronics, particularly copiers, became a target for implementing these materials. Copiers are heavily used in offices and businesses, often experiencing wear and tear due to frequent use. Self-healing materials offered a promising solution to extend the lifespan of copier components and reduce the need for repairs or replacements.

Early Challenges and Limitations

When self-healing materials were first introduced in copier components, they faced several challenges and limitations. One of the main obstacles was the development of materials that could effectively heal themselves without compromising the performance of the copier. It required a delicate balance between durability and self-repair capabilities.

Another challenge was the cost of implementing self-healing materials in copier production. The manufacturing processes and materials involved in creating self-healing components were more expensive compared to traditional alternatives. This made it difficult for manufacturers to justify the adoption of self-healing technology, especially in a highly competitive market.

Advancements in Material Science

Over time, advancements in material science and engineering have addressed many of the initial challenges faced by self-healing materials in copier components. Researchers have developed innovative materials that possess both high durability and efficient self-repair properties. These materials can withstand the rigors of copier usage while autonomously healing minor damages.

Additionally, the cost of producing self-healing materials has decreased as manufacturing processes have become more streamlined. This has made it more economically viable for copier manufacturers to incorporate self-healing technology into their products.

Integration of Smart Technologies

In recent years, the evolution of self-healing materials in copier components has been further enhanced by the integration of smart technologies. Copiers are now equipped with sensors and monitoring systems that can detect and assess the extent of damage to various components. This real-time data allows the self-healing mechanisms to activate precisely where and when they are needed, optimizing the repair process.

Furthermore, the integration of smart technologies enables copiers to communicate with users and service providers. This facilitates proactive maintenance and repair, ensuring that potential issues are addressed before they become significant problems. The combination of self-healing materials and smart technologies has revolutionized the copier industry, extending device lifespans and improving overall efficiency.

The Future of Self-Healing Materials in Copier Components

Looking ahead, the future of self-healing materials in copier components appears promising. Ongoing research and development continue to push the boundaries of material science, leading to even more advanced self-healing capabilities. The integration of artificial intelligence and machine learning algorithms may further enhance the efficiency and effectiveness of self-repair processes.

As self-healing materials become more commonplace and cost-effective, their adoption in copier manufacturing is likely to increase. This will result in copiers that are more durable, reliable, and environmentally friendly, as the need for frequent repairs and replacements diminishes. Ultimately, self-healing materials have the potential to revolutionize not only copiers but also various other consumer electronics, paving the way for a more sustainable and efficient future.

FAQs

1. What are self-healing materials?

Self-healing materials are a class of materials that have the ability to repair themselves when damaged. These materials can automatically detect and repair small cracks or other types of damage, restoring their original functionality.

2. How do self-healing materials work in copier components?

In copier components, self-healing materials are integrated into the structure of the device. When the copier is in use, these materials can detect any damage or wear and tear that occurs. Once damage is detected, the self-healing materials initiate a repair process, filling in the cracks or restoring the damaged area. This helps to extend the lifespan of the copier components.

3. What are the benefits of using self-healing materials in copier components?

Using self-healing materials in copier components brings several benefits. First, it helps to increase the durability of the components, reducing the need for frequent repairs or replacements. This ultimately leads to cost savings for the users. Additionally, self-healing materials can improve the overall performance and reliability of the copier, as any damage is quickly repaired, ensuring smooth operation.

4. Are there any limitations to self-healing materials in copier components?

While self-healing materials offer significant advantages, they do have some limitations. These materials are most effective in repairing small cracks or damage. They may not be able to repair larger or more severe damage. Additionally, the repair process of self-healing materials takes time, so it may not be instantaneous. However, the benefits of increased durability and extended lifespan outweigh these limitations.

5. Can self-healing materials be applied to all copier components?

Self-healing materials can be applied to various copier components, such as rollers, gears, and belts. However, the feasibility and effectiveness of using self-healing materials may vary depending on the specific component and its function. Manufacturers need to carefully evaluate and design the integration of self-healing materials into different copier components.

6. Do self-healing materials require any special maintenance?

No, self-healing materials do not require any special maintenance. Once integrated into the copier components, they work automatically without any user intervention. Users can continue to use the copier as they normally would, without any additional maintenance tasks related to the self-healing materials.

7. Can self-healing materials prevent all copier component failures?

While self-healing materials can significantly reduce the likelihood of copier component failures, they cannot prevent all failures. Some failures may occur due to factors beyond the control of the self-healing materials, such as extreme environmental conditions or manufacturing defects. However, the use of self-healing materials can greatly minimize the occurrence of failures and extend the overall lifespan of the copier.

8. Are there any cost implications of using self-healing materials in copier components?

Integrating self-healing materials into copier components may initially incur some additional costs. However, these costs are often offset by the long-term benefits of increased durability and extended lifespan. Users can save money on frequent repairs or component replacements, making the use of self-healing materials a cost-effective solution in the long run.

9. Are self-healing materials already being used in copier manufacturing?

Yes, self-healing materials are already being used in some copier manufacturing processes. Several manufacturers have recognized the advantages of these materials in improving the reliability and durability of their products. As the technology continues to develop, we can expect to see wider adoption of self-healing materials in copier manufacturing.

10. Can self-healing materials be used in other electronic devices?

Absolutely! The concept of self-healing materials is not limited to copier components. These materials have the potential to be used in various electronic devices, such as smartphones, laptops, and printers. By integrating self-healing materials into electronic devices, manufacturers can enhance their longevity and reduce the environmental impact of frequent replacements.

1. Understand the concept of self-healing materials

Before applying the knowledge from “Self-Healing Materials in Copier Components: Extending Device Lifespan” in your daily life, it is essential to understand the concept of self-healing materials. These materials have the ability to repair themselves when damaged, which can significantly extend the lifespan of various products.

2. Identify products made with self-healing materials

Start by identifying products that incorporate self-healing materials. Many electronic devices, such as smartphones and laptops, now use self-healing technologies to prevent damage from scratches and minor impacts. Research and choose products that offer these advanced features.

3. Take proper care of your devices

Even with self-healing materials, it is important to take proper care of your devices. Avoid dropping them or subjecting them to extreme conditions. Regularly clean and maintain your devices to prevent any potential damage.

4. Use protective cases and screen protectors

Although self-healing materials can prevent minor scratches, it is still a good idea to use protective cases and screen protectors. These accessories provide an additional layer of protection and can minimize the chances of permanent damage to your devices.

5. Follow manufacturer guidelines

Always follow the manufacturer’s guidelines for using and maintaining your devices. This includes recommendations for charging, storage, and cleaning. Adhering to these guidelines will help ensure the longevity of your devices.

6. Regularly update software and firmware

Software and firmware updates often include bug fixes and performance improvements that can enhance the self-healing capabilities of your devices. Stay up to date with the latest updates provided by the manufacturer to maximize the benefits of self-healing materials.

7. Invest in high-quality products

When purchasing new devices, invest in high-quality products that utilize self-healing materials. While they may come at a higher price, the durability and extended lifespan they offer can save you money in the long run by reducing the need for frequent replacements.

8. Educate yourself about self-repair techniques

Self-healing materials are not limited to electronic devices. There are various self-repair techniques that you can learn and apply in your daily life. For example, you can learn how to repair minor damages on furniture or fix small cracks in household items using self-healing materials or techniques.

9. Be proactive in addressing damages

If you notice any damages on your devices or other belongings, be proactive in addressing them. Small scratches or cracks can worsen over time if left unattended. Utilize the self-healing properties of the materials or seek professional repair services to prevent further damage.

10. Share your knowledge

Lastly, share your knowledge about self-healing materials with others. By spreading awareness, you can encourage more people to adopt these technologies and contribute to a more sustainable and environmentally friendly future.

Common Misconceptions about

Misconception 1: Self-healing materials can completely prevent all types of damage

One common misconception about self-healing materials used in copier components is that they have the ability to completely prevent all types of damage. While self-healing materials are designed to repair minor damages, they are not invincible and cannot prevent major or catastrophic damage.

Self-healing materials work by utilizing a combination of chemical reactions and physical processes to repair small cracks or scratches. These materials typically contain microcapsules or vascular networks that release healing agents when damage occurs. The healing agents then react with the surrounding material to fill in the cracks and restore the component’s integrity.

However, self-healing materials have their limitations. They are most effective in repairing small-scale damage, such as minor scratches or cracks. They may not be able to repair large-scale or structural damage that significantly compromises the functionality of the copier component. Therefore, it is important to understand that self-healing materials are not a foolproof solution for preventing all types of damage.

Misconception 2: Self-healing materials make copier components indestructible

Another misconception about self-healing materials is that they make copier components indestructible. While self-healing materials can enhance the durability and lifespan of copier components, they do not make them immune to damage.

Self-healing materials are designed to repair minor damages, but they cannot withstand extreme or repeated stress beyond their capabilities. Copier components made from self-healing materials may still experience wear and tear over time, especially if subjected to harsh operating conditions or excessive usage.

Additionally, self-healing materials may have limitations in terms of the types of damage they can repair. For example, they may not be effective in repairing damage caused by high temperatures, chemical exposure, or mechanical stress beyond a certain threshold. It is crucial to understand that self-healing materials can improve the durability of copier components, but they do not make them invincible.

Misconception 3: Self-healing materials eliminate the need for regular maintenance

One misconception that often arises is that self-healing materials eliminate the need for regular maintenance of copier components. While self-healing materials can contribute to extending the lifespan of copier components, they do not eliminate the need for routine maintenance and servicing.

Regular maintenance is essential for ensuring optimal performance and longevity of copier components, regardless of whether they are made from self-healing materials or traditional materials. Maintenance tasks such as cleaning, lubrication, and calibration are still necessary to prevent issues and ensure smooth operation.

Moreover, self-healing materials may require specific maintenance procedures or precautions to maintain their effectiveness. For example, certain cleaning agents or abrasive materials may interfere with the self-healing properties of the material. Therefore, it is important to follow the manufacturer’s guidelines for maintenance, even when copier components incorporate self-healing materials.

While self-healing materials offer promising benefits for extending the lifespan of copier components, it is important to dispel common misconceptions surrounding their capabilities. These materials cannot completely prevent all types of damage, make copier components indestructible, or eliminate the need for regular maintenance. Understanding the limitations and proper usage of self-healing materials is crucial for maximizing their effectiveness in extending the lifespan of copier components.

Conclusion:

The use of self-healing materials in copier components has the potential to revolutionize the lifespan of these devices. By incorporating materials that can repair themselves when damaged, copiers can continue to function efficiently for longer periods, reducing the need for frequent repairs or replacements. This not only saves businesses valuable time and money but also contributes to a more sustainable approach to technology consumption.

Through advancements in material science, researchers have successfully developed self-healing polymers and metals that exhibit remarkable healing capabilities. These materials can autonomously repair cracks, scratches, and other forms of damage, ensuring the longevity of copier components and extending the overall lifespan of the device. Furthermore, the integration of self-healing materials in copiers can enhance their reliability and performance, minimizing downtime and increasing productivity for users.