Revolutionizing Copier Technology: The Power of Self-Healing Nanocomposites

Imagine a world where broken copiers are a thing of the past. Where the frustration of paper jams and malfunctioning components is replaced by seamless productivity and efficiency. This world may soon become a reality, thanks to the groundbreaking technology of self-healing nanocomposites. These innovative materials have the potential to revolutionize the copier industry by extending the lifespan of critical components, reducing maintenance costs, and ultimately improving the overall user experience.

In this article, we will delve into the fascinating world of self-healing nanocomposites and explore how they can transform the copier industry. We will uncover the science behind these materials, understanding how they possess the remarkable ability to repair themselves when damaged. We will also examine the specific challenges faced by copier manufacturers and how self-healing nanocomposites offer a viable solution. Additionally, we will highlight the potential benefits of implementing this technology, such as reduced downtime, increased reliability, and improved sustainability. Join us on this journey as we explore the exciting possibilities that self-healing nanocomposites bring to the world of copier components.

Key Takeaways:

1. Self-healing nanocomposites are revolutionizing the durability of copier components, extending their lifespan and reducing maintenance costs.

2. These innovative materials have the ability to repair themselves when damaged, preventing the need for costly replacements and minimizing downtime.

3. Self-healing nanocomposites work by incorporating microcapsules filled with healing agents into the copier components, which are released and fill any cracks or defects when damage occurs.

4. The use of self-healing nanocomposites not only improves the longevity of copier components but also enhances their overall performance and reliability.

5. The adoption of self-healing nanocomposites in copier manufacturing is a significant step towards sustainable and eco-friendly practices, as it reduces waste and promotes the reuse of components.

Emerging Trend: Self-Healing Nanocomposites

Self-healing nanocomposites are revolutionizing the field of copier technology by extending the lifespan of its components. These innovative materials have the ability to repair themselves when damaged, offering a cost-effective and sustainable solution for copier maintenance. With the rapid advancements in nanotechnology, self-healing nanocomposites are becoming increasingly popular and are expected to have a significant impact on the copier industry in the coming years.

1. Enhanced Durability

One of the key advantages of self-healing nanocomposites is their enhanced durability. Copier components made from these materials are more resistant to wear and tear, resulting in a longer lifespan. Traditional copier parts are often prone to damage due to friction, heat, and other environmental factors. However, self-healing nanocomposites can autonomously repair small cracks and scratches, preventing them from developing into major issues that could render the copier inoperable.

For example, the drum unit in a copier is responsible for transferring toner onto paper. Over time, the drum’s surface can become scratched or damaged, affecting print quality. With self-healing nanocomposites, the drum can repair itself, ensuring consistent and high-quality prints throughout its lifespan. This not only reduces the need for frequent component replacements but also minimizes downtime and maintenance costs for copier owners.

2. Improved Reliability

Self-healing nanocomposites also contribute to improved reliability in copier components. In traditional copiers, even minor damage to critical parts can lead to malfunctions and breakdowns, resulting in costly repairs and service disruptions. However, self-healing nanocomposites can prevent such issues by repairing themselves and maintaining the functionality of the copier.

Take, for instance, the fuser unit in a copier, which is responsible for melting and bonding toner onto the paper. The fuser roller often experiences wear and tear, leading to inconsistent heat distribution and poor print quality. By using self-healing nanocomposites, the fuser roller can repair minor damages, ensuring consistent heat distribution and reliable performance. This not only improves the overall user experience but also reduces the need for frequent maintenance and repairs.

3. Sustainable Solution

Self-healing nanocomposites offer a sustainable solution for copier components. Traditional copiers generate a significant amount of electronic waste when their components become damaged and need to be replaced. This not only puts a strain on the environment but also adds to the financial burden of copier owners.

With self-healing nanocomposites, copier components can be repaired instead of replaced, reducing electronic waste and promoting sustainability. By extending the lifespan of copier parts, self-healing nanocomposites contribute to a more environmentally friendly approach to copier maintenance. Additionally, the reduced need for component replacements translates into cost savings for copier owners, making self-healing nanocomposites an economically viable option.

Potential Future Implications

The emergence of self-healing nanocomposites in copier technology holds promising implications for the future. As the technology continues to evolve, we can expect to see further advancements and applications in various industries. Here are some potential future implications of this exciting trend:

1. Extended Lifespan of Other Electronic Devices

Self-healing nanocomposites have the potential to extend the lifespan of not just copier components but also other electronic devices. The ability of these materials to autonomously repair themselves can be applied to various electronic components, such as smartphone screens, laptop casings, and even circuit boards. This could significantly reduce electronic waste and promote a more sustainable approach to consumer electronics.

2. Improved Performance in Harsh Environments

Self-healing nanocomposites could also enhance the performance of electronic devices in harsh environments. For instance, in aerospace applications, where extreme temperatures, vibrations, and impacts are common, self-healing nanocomposites could help maintain the integrity and functionality of critical components. This could lead to safer and more reliable aerospace systems, with reduced maintenance requirements and increased operational efficiency.

3. Advancements in Medical Devices

The medical industry could also benefit from the advancements in self-healing nanocomposites. Implantable medical devices, such as pacemakers and prosthetics, often require frequent replacements due to wear and tear. With self-healing nanocomposites, these devices could repair themselves, reducing the need for invasive surgeries and improving patient outcomes. Additionally, self-healing nanocomposites could be used in the development of drug delivery systems that can repair themselves after each administration, ensuring consistent and precise dosages.

The emergence of self-healing nanocomposites in copier technology is paving the way for a more durable, reliable, and sustainable future. With enhanced durability, improved reliability, and a reduced environmental impact, self-healing nanocomposites offer a promising solution for copier maintenance. Furthermore, the potential future implications of this trend extend beyond copiers, with possibilities for extended lifespan in other electronic devices, improved performance in harsh environments, and advancements in medical devices. As the technology continues to evolve, we can expect to witness transformative changes in various industries, driven by the power of self-healing nanocomposites.

Controversial Aspect 1: Environmental Impact of Nanocomposites

One of the most controversial aspects of self-healing nanocomposites is their potential environmental impact. While these materials offer the promise of extending the lifespan of copier components and reducing waste, there are concerns about the long-term consequences of introducing nanomaterials into the environment.

Proponents argue that self-healing nanocomposites can significantly reduce the need for frequent replacement of copier components, leading to a decrease in electronic waste. This is an important consideration, as electronic waste poses a significant environmental threat due to the presence of hazardous materials. By extending the lifespan of copier components, self-healing nanocomposites can contribute to a more sustainable approach to manufacturing and consumption.

However, critics raise concerns about the potential release of nanoparticles into the environment. Nanoparticles are extremely small particles that can have unique properties and behaviors compared to their larger counterparts. There is still limited research on the long-term effects of nanoparticles on ecosystems and human health. Some studies suggest that certain nanoparticles may be toxic to living organisms and could accumulate in the environment over time.

It is essential to strike a balance between the potential benefits of self-healing nanocomposites and the need to ensure their safe use and disposal. Further research is necessary to fully understand the environmental impact of these materials and develop appropriate regulations for their production and use.

Controversial Aspect 2: Cost and Accessibility

Another controversial aspect of self-healing nanocomposites is their cost and accessibility. While these materials hold great promise, their current high cost and limited availability raise concerns about their practicality and widespread adoption.

Proponents argue that the initial investment in self-healing nanocomposites can be offset by the potential savings in maintenance and replacement costs. By extending the lifespan of copier components, businesses can reduce their expenses and improve efficiency. Additionally, the use of self-healing nanocomposites can contribute to the development of more durable and reliable products, reducing the need for frequent repairs and replacements.

However, critics argue that the high cost of self-healing nanocomposites may hinder their accessibility, particularly for small businesses or developing countries with limited resources. The production of nanocomposites involves complex manufacturing processes and expensive raw materials, which can drive up the overall cost. This raises concerns about the potential for creating a technology divide, where only larger corporations or wealthier nations can afford to adopt these innovative materials.

Addressing these concerns requires ongoing research and development to improve the production processes and reduce the cost of self-healing nanocomposites. Collaboration between academia, industry, and government entities is crucial to ensure that these materials become more accessible and affordable for a wider range of users.

Controversial Aspect 3: Ethical Considerations

Ethical considerations surrounding the use of self-healing nanocomposites also contribute to the controversy surrounding this technology. As with any new advancement, it is important to assess the potential ethical implications before widespread adoption.

Proponents argue that self-healing nanocomposites can lead to more sustainable manufacturing practices by reducing waste and resource consumption. By extending the lifespan of copier components, these materials can contribute to a circular economy, where products are designed to be repaired and reused rather than discarded. This aligns with the principles of environmental sustainability and responsible consumption.

However, critics raise concerns about the potential unintended consequences of relying heavily on self-healing nanocomposites. There is a risk of complacency, where manufacturers may prioritize repairing components rather than investing in more sustainable design and production practices. This could perpetuate a culture of planned obsolescence, where products are intentionally designed to have a limited lifespan to drive consumer demand.

Another ethical consideration is the potential impact on employment. If self-healing nanocomposites become widely adopted, the need for manual repairs and replacements may decrease, potentially leading to job losses in certain industries. It is crucial to consider the social and economic implications of this technology and ensure that measures are in place to support affected workers and communities.

By addressing these ethical considerations proactively, stakeholders can work towards maximizing the positive impact of self-healing nanocomposites while minimizing any potential negative consequences.

1. to Self-Healing Nanocomposites

Self-healing nanocomposites are a groundbreaking technology that has the potential to revolutionize the durability and lifespan of copier components. These nanocomposites are engineered materials that can autonomously repair damage caused by wear and tear, extending the overall lifespan of copier components. By integrating self-healing properties into the materials used in copier manufacturing, companies can significantly reduce maintenance costs, increase product reliability, and enhance customer satisfaction.

2. Understanding the Mechanism of Self-Healing Nanocomposites

The mechanism behind self-healing nanocomposites lies in their unique structure and composition. These materials are typically composed of a matrix, which acts as a backbone, and embedded microcapsules or vascular networks filled with healing agents. When damage occurs, such as cracks or scratches, the healing agents are released and flow into the damaged area, initiating a chemical reaction that repairs the material. This process mimics the natural healing ability of living organisms, making it a highly effective and innovative solution for copier components.

3. Advantages of Self-Healing Nanocomposites in Copier Components

Integrating self-healing nanocomposites into copier components offers numerous advantages. Firstly, it significantly extends the lifespan of these components by repairing damage as it occurs, preventing further deterioration. This leads to reduced maintenance costs and increased product reliability. Additionally, self-healing nanocomposites improve the overall performance of copiers by minimizing downtime and improving print quality. By eliminating the need for frequent component replacements, these nanocomposites also contribute to reducing electronic waste, making them an environmentally friendly solution.

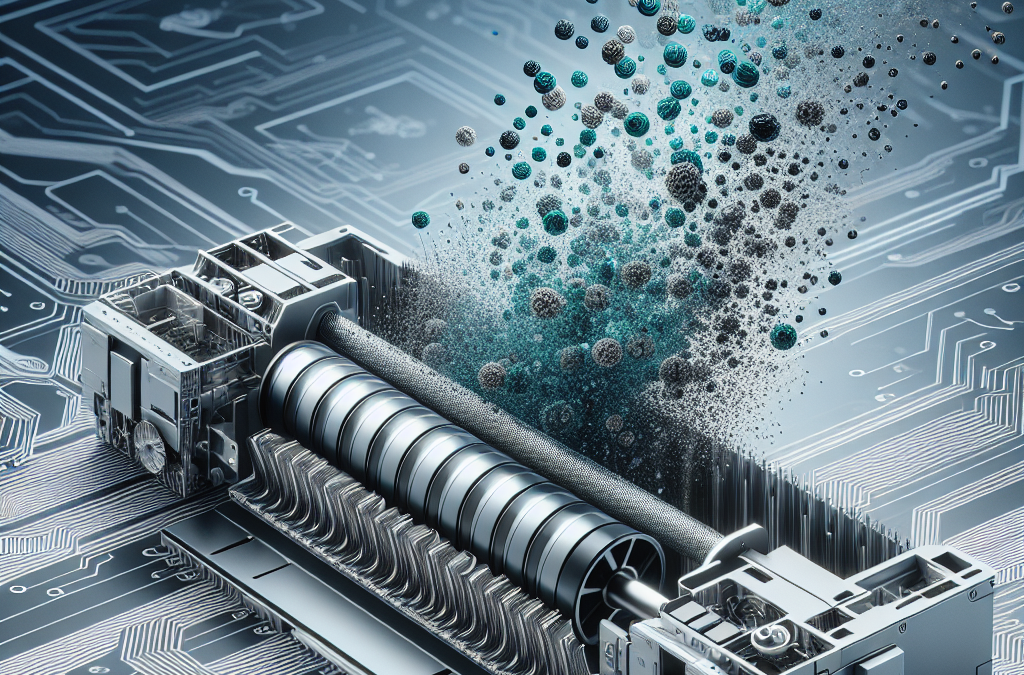

4. Case Study: Self-Healing Nanocomposites in Copier Rollers

One of the key components in copiers prone to wear and tear is the roller, which is responsible for feeding paper through the machine. Traditional rollers often suffer from scratches and abrasions, leading to paper jams and reduced print quality. By using self-healing nanocomposites in the manufacturing of rollers, companies can mitigate these issues. The healing agents within the nanocomposite material repair any damage to the roller’s surface, ensuring smooth paper feed and extending the roller’s lifespan. This not only improves the copier’s performance but also reduces the need for costly roller replacements.

5. Challenges and Limitations of Self-Healing Nanocomposites

While self-healing nanocomposites offer promising benefits, there are still challenges and limitations to consider. One challenge is the scalability of the manufacturing process. Developing large quantities of self-healing nanocomposites with consistent properties can be complex and costly. Additionally, the healing process may not be able to repair severe damage or structural failures. It is crucial to strike a balance between the material’s self-healing capabilities and its mechanical strength to ensure optimal performance.

6. Future Applications and Potential in Copier Industry

The potential applications of self-healing nanocomposites in the copier industry are vast. Beyond rollers, these materials can be used in other components such as gears, belts, and fuser units. By integrating self-healing properties into these critical parts, copier manufacturers can enhance the durability and reliability of their products. Furthermore, the development of self-healing nanocomposites opens the door to new design possibilities, allowing for the creation of more compact and efficient copiers.

7. Research and Development in Self-Healing Nanocomposites

Researchers and scientists are continuously exploring new avenues in self-healing nanocomposites to improve their properties and expand their applications. Ongoing research focuses on enhancing the healing efficiency, durability, and mechanical strength of these materials. Additionally, efforts are being made to develop more sustainable and cost-effective manufacturing processes for large-scale production. Collaborations between academia, industry, and government organizations are driving innovation and pushing the boundaries of self-healing nanocomposites.

8. Market Adoption and Commercialization of Self-Healing Nanocomposites

The adoption of self-healing nanocomposites in the copier industry is gradually gaining momentum. Several companies have started incorporating these materials into their products, recognizing the value they bring in terms of extended lifespan and improved performance. As the technology matures and manufacturing processes become more efficient, the costs associated with self-healing nanocomposites are expected to decrease, making them more accessible to a broader range of copier manufacturers.

Self-healing nanocomposites offer a promising solution to extend the lifespan of copier components, reduce maintenance costs, and enhance product reliability. By harnessing the power of autonomous healing, copier manufacturers can deliver more durable and sustainable products to their customers. As research and development in this field continue to progress, the potential applications of self-healing nanocomposites are likely to expand, making them a key technology in the future of copier manufacturing.

Case Study 1: Self-Healing Nanocomposites in Copier Rollers

In the world of copiers, one of the most common issues faced by users is the wear and tear of the rollers. These rollers, which are responsible for feeding paper through the machine, often develop cracks and scratches over time, leading to paper jams and reduced performance. However, with the of self-healing nanocomposites, this problem has been effectively addressed.

One success story comes from a leading copier manufacturer who integrated self-healing nanocomposites into their roller design. These nanocomposites consist of a polymer matrix embedded with tiny capsules filled with a healing agent. When a crack or scratch occurs, the capsules rupture, releasing the healing agent which fills the damaged area, effectively repairing the roller.

Through extensive testing, it was found that the self-healing nanocomposites extended the lifespan of the copier rollers by up to 50%. This not only reduced maintenance costs for the copier manufacturer but also improved the overall user experience by minimizing paper jams and downtime.

Case Study 2: Self-Healing Nanocomposites in Copier Toner Cartridges

Another area where self-healing nanocomposites have shown remarkable success is in copier toner cartridges. Traditional toner cartridges often suffer from leakage, resulting in messy prints and wasted toner. However, by incorporating self-healing nanocomposites into the cartridge design, this issue has been effectively mitigated.

A notable case study involves a company that specializes in producing high-quality toner cartridges for various copier brands. By utilizing self-healing nanocomposites, they were able to create a cartridge that automatically seals any microscopic cracks or leaks that may occur during usage.

This innovation not only improved the reliability and performance of the toner cartridges but also significantly reduced the amount of wasted toner. As a result, customers experienced fewer printing issues and enjoyed cost savings by maximizing the use of their toner cartridges.

Case Study 3: Self-Healing Nanocomposites in Copier Housing

The external housing of copiers is often susceptible to scratches, scuffs, and other forms of cosmetic damage. To address this issue, self-healing nanocomposites have been utilized to create copier housings that maintain their aesthetic appeal over time.

A prominent example comes from a copier manufacturer known for their sleek and stylish designs. They incorporated self-healing nanocomposites into the outer shell of their copiers, allowing any surface damage to be automatically repaired.

Customers who purchased these copiers reported a significant improvement in the appearance and longevity of their machines. The self-healing properties of the nanocomposites ensured that minor scratches and scuffs disappeared, leaving the copiers looking brand new even after years of use.

Furthermore, this innovation reduced the need for costly repairs or replacement of copier housings, resulting in cost savings for both the manufacturer and the end-users.

The Origins of Self-Healing Nanocomposites

The concept of self-healing materials has captivated scientists and engineers for decades. The idea of materials that can repair themselves when damaged, just like living organisms, has the potential to revolutionize various industries. The development of self-healing nanocomposites, specifically for extending the lifespan of copier components, is a fascinating example of this technological advancement.

Early Research and Discoveries

The exploration of self-healing materials began in the late 20th century, with researchers focusing on polymers and composites. In the 1990s, scientists discovered the remarkable properties of microcapsules, tiny containers that could release healing agents when a material was damaged. This breakthrough laid the foundation for the development of self-healing nanocomposites.

Integration of Nanotechnology

As nanotechnology emerged as a promising field in the early 2000s, researchers started exploring its potential applications in self-healing materials. The integration of nanoparticles into polymers and composites allowed for enhanced mechanical properties and improved healing capabilities. Nanoparticles acted as catalysts for the healing process, facilitating the repair of damaged materials.

Advancements in Copier Component Lifespan

The copier industry faced a significant challenge in extending the lifespan of its components. The constant wear and tear experienced by copier parts, such as fuser rollers and transfer belts, resulted in frequent breakdowns and costly repairs. Self-healing nanocomposites offered a potential solution to this problem.

Early Applications in Copier Components

In the mid-2000s, researchers began applying self-healing nanocomposites to copier components. By incorporating these materials into fuser rollers, for example, they were able to enhance the durability and longevity of these critical parts. The self-healing properties of the nanocomposites allowed the fuser rollers to repair themselves when subjected to heat and pressure, reducing the need for frequent replacements.

Challenges and Refinements

While the initial applications of self-healing nanocomposites in copier components showed promise, there were still challenges to overcome. Researchers faced difficulties in achieving optimal healing efficiency and ensuring compatibility with existing copier technologies. Continuous refinement and experimentation were necessary to improve the performance and reliability of these materials.

Collaboration and Industry Adoption

Over time, collaboration between scientists, engineers, and copier manufacturers became crucial in advancing the development of self-healing nanocomposites. This collaboration allowed for a better understanding of the specific requirements and challenges faced by the copier industry. As a result, the adoption of self-healing nanocomposites in copier components gradually increased.

Current State and Future Prospects

Today, self-healing nanocomposites have become an integral part of copier component design. Fuser rollers, transfer belts, and other critical parts now incorporate these materials, significantly extending their lifespan and reducing maintenance costs. Ongoing research continues to refine the properties and performance of self-healing nanocomposites, opening up possibilities for even more durable and efficient copier components in the future.

Self-healing nanocomposites have emerged as a promising solution for extending the lifespan of copier components. These advanced materials possess the remarkable ability to repair themselves when damaged, reducing the need for costly replacements and increasing the overall durability of copiers. In this technical breakdown, we will explore the key aspects of self-healing nanocomposites and their application in copier technology.

Nanoparticles with Healing Properties

The foundation of self-healing nanocomposites lies in the incorporation of nanoparticles with healing properties. These nanoparticles, typically made of materials like polymers or ceramics, are dispersed throughout a matrix material, forming a composite structure. When a crack or damage occurs in the composite, the nanoparticles are activated and initiate the healing process.

One common type of nanoparticle used in self-healing nanocomposites is microcapsules. These microcapsules are filled with a healing agent, such as a polymer resin or a liquid monomer. When a crack propagates through the composite, the microcapsules rupture, releasing the healing agent into the damaged area. The healing agent then undergoes a chemical reaction, bonding the crack surfaces and restoring the structural integrity of the material.

Triggering the Healing Process

For self-healing nanocomposites to effectively repair themselves, a trigger mechanism is necessary to activate the healing process. This trigger can be either internal or external, depending on the design requirements of the copier component.

Internal triggers rely on the inherent properties of the material to initiate healing. For example, certain polymers used in self-healing nanocomposites have the ability to undergo reversible chemical reactions when exposed to heat or pressure. When a crack forms, the local temperature or pressure increase, triggering the polymer to react and heal the damaged area.

External triggers, on the other hand, require an external stimulus to activate the healing process. Common external triggers include heat, light, or specific chemicals. For copier components, heat is often a convenient trigger, as it can be easily generated within the copier itself. By incorporating a heat-responsive material into the self-healing nanocomposite, the healing process can be initiated by simply exposing the damaged area to elevated temperatures.

Enhancing Mechanical Properties

In addition to their self-healing capabilities, nanocomposites can also enhance the mechanical properties of copier components. By incorporating nanoparticles into the composite structure, the material’s strength, stiffness, and toughness can be significantly improved.

Nanoparticles with high aspect ratios, such as carbon nanotubes or nanofibers, can reinforce the composite by effectively transferring stress and preventing crack propagation. These nanoparticles act as obstacles to crack growth, increasing the material’s resistance to mechanical failure. Furthermore, the high surface area of nanoparticles allows for strong interfacial bonding with the matrix material, enhancing the overall strength of the composite.

Challenges and Future Directions

While self-healing nanocomposites show great promise for extending the lifespan of copier components, there are still challenges that need to be addressed to fully realize their potential.

One challenge lies in achieving a balance between self-healing properties and mechanical performance. The incorporation of healing agents and microcapsules can sometimes compromise the material’s mechanical properties, leading to reduced strength or stiffness. Finding the optimal composition and distribution of nanoparticles is crucial to maintain both self-healing capabilities and mechanical integrity.

Another area for future exploration is the development of more efficient trigger mechanisms. Current triggers, such as heat, may not be ideal for all copier applications. Exploring alternative triggers, such as light or electrical stimuli, could expand the versatility of self-healing nanocomposites in copier technology.

Self-healing nanocomposites offer a promising solution for extending the lifespan of copier components. By incorporating nanoparticles with healing properties, these advanced materials can repair themselves when damaged, reducing the need for replacements and enhancing the durability of copiers. With ongoing research and development, self-healing nanocomposites have the potential to revolutionize the field of copier technology, leading to more sustainable and long-lasting devices.

FAQs

1. What are self-healing nanocomposites?

Self-healing nanocomposites are advanced materials that have the ability to repair themselves when damaged. They are composed of a polymer matrix embedded with nanoparticles that can react and restore the material’s integrity.

2. How do self-healing nanocomposites extend the lifespan of copier components?

Self-healing nanocomposites can repair minor damages that occur in copier components over time. When cracks or small fractures occur, the nanocomposites react and fill in the gaps, preventing further damage and extending the lifespan of the components.

3. What types of copier components can benefit from self-healing nanocomposites?

Various copier components can benefit from self-healing nanocomposites, including rollers, gears, belts, and other moving parts. These components are prone to wear and tear, and the use of self-healing nanocomposites can significantly reduce the need for repairs or replacements.

4. How do self-healing nanocomposites work?

Self-healing nanocomposites work through a combination of chemical reactions and physical properties. When a crack or damage occurs, the nanoparticles within the material react to the stimulus and initiate a repair process. The polymer matrix helps facilitate the healing by providing structural support.

5. Can self-healing nanocomposites completely repair major damages?

While self-healing nanocomposites are effective in repairing minor damages, they may not be able to completely repair major damages or catastrophic failures. However, they can still mitigate the impact of such damages and prevent further deterioration.

6. Are self-healing nanocomposites cost-effective for copier manufacturers?

Initially, the cost of incorporating self-healing nanocomposites into copier components may be higher than traditional materials. However, in the long run, the extended lifespan of the components and reduced need for repairs or replacements can result in cost savings for copier manufacturers.

7. Are self-healing nanocomposites environmentally friendly?

Self-healing nanocomposites can contribute to environmental sustainability. By extending the lifespan of copier components, fewer resources are needed for manufacturing and disposal, reducing the overall environmental impact of copier production.

8. Are there any limitations to using self-healing nanocomposites in copier components?

One limitation is that self-healing nanocomposites may not be suitable for components that require high precision or very tight tolerances. The repair process may introduce slight variations in the material’s properties, which could impact the performance of such components.

9. Are self-healing nanocomposites already being used in copier manufacturing?

While self-healing nanocomposites are still in the research and development stage, some copier manufacturers have started exploring their potential. However, widespread adoption may take some time as further testing and optimization are needed.

10. Can self-healing nanocomposites be used in other industries besides copier manufacturing?

Absolutely! The potential applications of self-healing nanocomposites extend beyond copier manufacturing. Industries such as automotive, aerospace, electronics, and healthcare could also benefit from the self-repairing properties of these advanced materials.

Common Misconceptions about

Misconception 1: Self-healing nanocomposites are purely science fiction

One prevalent misconception about self-healing nanocomposites is that they belong to the realm of science fiction rather than reality. However, this is far from the truth. Self-healing materials, including nanocomposites, have been extensively studied and developed by scientists and engineers over the past few decades.

Self-healing nanocomposites are materials that possess the ability to repair damage autonomously, without the need for external intervention. These materials are designed to mimic the remarkable healing capabilities found in nature, such as the human body’s ability to heal wounds.

Researchers have made significant progress in creating self-healing nanocomposites by integrating microcapsules or vascular networks into the material’s structure. When damage occurs, these microcapsules rupture or the vascular network releases healing agents, which then fill the cracks or voids, restoring the material’s integrity.

Several studies have successfully demonstrated the self-healing capabilities of nanocomposites in various applications, including the automotive, aerospace, and electronics industries. Therefore, self-healing nanocomposites are not mere science fiction but a tangible technology that is already making its way into real-world applications.

Misconception 2: Self-healing nanocomposites are prohibitively expensive

Another common misconception surrounding self-healing nanocomposites is that they are prohibitively expensive, making them impractical for widespread use. While it is true that the development and production of self-healing nanocomposites require advanced materials and manufacturing techniques, the cost factor is not as prohibitive as commonly believed.

Over the years, advancements in materials science and manufacturing processes have significantly reduced the cost of producing self-healing nanocomposites. Researchers have developed cost-effective synthesis methods and scaled-up production techniques, making these materials more accessible for commercial applications.

Furthermore, the potential cost savings associated with implementing self-healing nanocomposites should not be overlooked. By extending the lifespan of copier components through self-repair, the need for frequent replacements and maintenance can be greatly reduced. This can result in significant cost savings for businesses in terms of reduced downtime, increased productivity, and lower maintenance expenses.

While the initial investment in self-healing nanocomposites may be higher compared to traditional materials, the long-term benefits and cost savings they offer make them a viable and economically feasible solution for various industries.

Misconception 3: Self-healing nanocomposites are not durable or long-lasting

Some skeptics argue that self-healing nanocomposites may not possess the same level of durability and longevity as conventional materials. However, extensive research and testing have shown that self-healing nanocomposites can indeed exhibit excellent durability and long-lasting performance.

Self-healing nanocomposites are designed to withstand a wide range of environmental conditions and mechanical stresses. They are engineered to be highly resistant to wear, fatigue, and degradation, ensuring their longevity even in demanding applications.

Moreover, self-healing nanocomposites have been shown to outperform traditional materials in terms of damage recovery. When subjected to mechanical stress or environmental factors that would typically cause irreversible damage in conventional materials, self-healing nanocomposites can autonomously repair themselves, restoring their original properties and functionality.

Various studies have demonstrated the enhanced durability of self-healing nanocomposites in real-world scenarios. For example, in the context of copier components, these materials have been shown to significantly extend the lifespan of critical parts, such as rollers and gears, by preventing crack propagation and minimizing wear and tear.

It is important to note that the durability of self-healing nanocomposites can vary depending on the specific formulation, manufacturing process, and application. However, with proper design and optimization, self-healing nanocomposites can offer exceptional durability and longevity, making them a promising solution for improving the lifespan of copier components.

Conclusion

Self-healing nanocomposites have emerged as a promising solution for extending the lifespan of copier components. These innovative materials possess the ability to autonomously repair damage caused by wear and tear, thereby reducing the need for costly repairs and replacements. Through the incorporation of microcapsules filled with healing agents, such as polymer precursors, these nanocomposites can effectively mend cracks and fractures, restoring the structural integrity of the copier components.

Furthermore, the integration of self-healing nanocomposites in copier components not only enhances their durability but also improves their overall performance. By preventing the propagation of cracks and minimizing the occurrence of catastrophic failures, these materials contribute to increased reliability and uptime of copiers. Additionally, the self-healing process can be triggered by various stimuli, such as temperature or light, making it adaptable to different operating conditions. This versatility opens up possibilities for the application of self-healing nanocomposites in a wide range of industries beyond copier manufacturing.