Revolutionizing Copier Technology: The Incredible Potential of Self-Healing Polymers

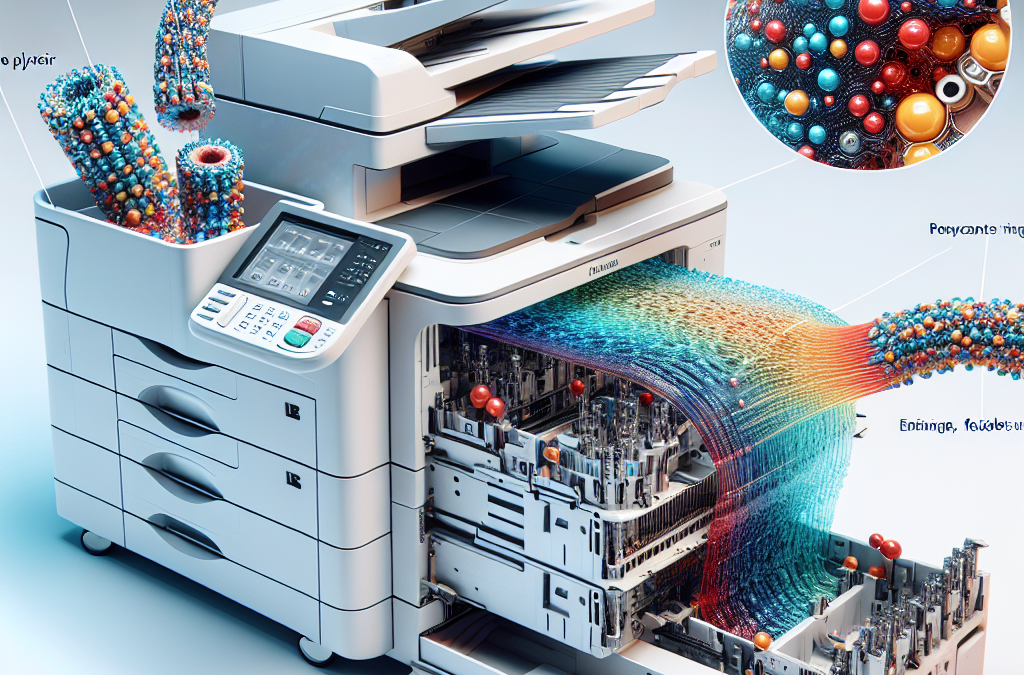

Imagine a world where broken copiers are a thing of the past. Where the frustration of paper jams and malfunctioning components is replaced with seamless functionality and extended lifespan. Well, thanks to the advancements in self-healing polymers, this future may not be too far off. Self-healing polymers are a groundbreaking technology that has the potential to revolutionize the durability and longevity of copier components, saving businesses time, money, and headaches.

In this article, we will delve into the world of self-healing polymers and explore how they can extend the lifespan of copier components. We will uncover the science behind these remarkable materials, understanding how they have the ability to repair themselves when damaged. Additionally, we will examine the practical applications of self-healing polymers in copier manufacturing, discussing the benefits they bring to both manufacturers and end-users. From reducing maintenance costs to minimizing downtime, self-healing polymers have the potential to transform the copier industry as we know it.

Key Takeaways

1. Self-healing polymers have the potential to significantly extend the lifespan of copier components, reducing maintenance costs and improving efficiency.

2. These innovative materials have the ability to repair themselves when damaged, preventing minor issues from escalating into major problems.

3. The self-healing process involves the activation of embedded microcapsules or chemical reactions within the polymer structure, restoring its integrity and functionality.

4. By implementing self-healing polymers in copier components such as rollers and gears, companies can reduce the frequency of replacements and increase the overall lifespan of the machine.

5. In addition to cost savings, the use of self-healing polymers in copiers can also lead to a more sustainable approach, as it reduces the amount of waste generated from discarded components.

Emerging Trend: Self-Healing Polymers in Copier Components

Self-healing polymers have been making waves in various industries, and one area where their potential is being explored is in copier components. These innovative materials have the ability to repair themselves when damaged, extending the lifespan of copier parts and reducing the need for frequent replacements. This emerging trend in self-healing polymers is set to revolutionize the copier industry, offering cost savings, increased efficiency, and improved sustainability.

1. Enhanced Durability and Reliability

One of the primary advantages of self-healing polymers in copier components is their ability to enhance durability and reliability. Copiers are subjected to constant wear and tear, with components such as rollers, belts, and gears frequently experiencing damage. Traditionally, these damaged parts would need to be replaced, resulting in downtime and additional costs.

With self-healing polymers, copier components can repair themselves when minor damage occurs. These materials contain microcapsules filled with a healing agent that is released when the polymer is damaged. The healing agent fills the cracks or breaks in the material, restoring its integrity and functionality. This self-repair process happens automatically, ensuring that the copier continues to operate smoothly without the need for manual intervention.

This enhanced durability and reliability offered by self-healing polymers in copier components can significantly reduce maintenance costs and increase the lifespan of copiers. Companies can avoid the expenses associated with frequent part replacements and minimize downtime, leading to improved productivity and cost savings.

2. Extended Lifespan of Copier Components

Self-healing polymers have the potential to extend the lifespan of copier components, resulting in long-term benefits for businesses. In traditional copiers, components that experience damage would need to be replaced, regardless of the extent of the damage. This often leads to premature replacements and unnecessary waste.

With self-healing polymers, copier components can withstand multiple instances of minor damage without the need for replacement. The healing process allows the materials to repair themselves, effectively extending their lifespan. This means that copiers can continue to function optimally even after sustaining minor damage, reducing the frequency of part replacements.

The extended lifespan of copier components offered by self-healing polymers not only reduces costs but also contributes to sustainability efforts. By minimizing the amount of waste generated from copier part replacements, businesses can reduce their environmental impact and promote a more sustainable approach to equipment maintenance.

3. Improved User Experience and Customer Satisfaction

Self-healing polymers can also enhance the user experience and customer satisfaction when it comes to copiers. Copier malfunctions and downtime can be frustrating for users, causing disruptions in workflow and productivity. By incorporating self-healing polymers in copier components, manufacturers can offer a more reliable and efficient product.

With self-repairing capabilities, copiers equipped with self-healing polymers can continue to function even in the presence of minor damage. Users no longer have to wait for repairs or replacements, as the copier can automatically repair itself and resume normal operation. This reduces downtime and ensures a seamless user experience.

Moreover, the extended lifespan of copier components provided by self-healing polymers means that businesses can rely on their copiers for longer periods without experiencing frequent malfunctions. This increased reliability leads to higher customer satisfaction, as businesses can operate smoothly without interruptions caused by copier failures.

Future Implications and Highlights

The emergence of self-healing polymers in copier components holds significant implications for the future of the copier industry. As this trend continues to evolve, several highlights can be anticipated:

– Increased adoption: As the benefits of self-healing polymers become more apparent, copier manufacturers are likely to adopt this technology on a larger scale. The cost savings, improved durability, and customer satisfaction associated with self-healing copier components will drive the demand for these innovative materials.

– Advancements in self-healing materials: The development of self-healing polymers will continue to progress, leading to advancements in their properties and capabilities. Researchers will explore new healing agents and techniques to further enhance the self-repair process, making copier components even more resilient and long-lasting.

– Integration with other industries: The success of self-healing polymers in copier components may pave the way for their integration into other industries. The principles of self-healing materials can be applied to various applications, such as automotive parts, electronics, and infrastructure. This could lead to a broader adoption of self-healing polymers, revolutionizing multiple sectors.

The emerging trend of self-healing polymers in copier components offers exciting possibilities for the copier industry. With enhanced durability, extended lifespan, and improved user experience, these innovative materials have the potential to transform the way copiers are designed, manufactured, and maintained. As this trend continues to evolve, businesses can look forward to cost savings, increased efficiency, and a more sustainable approach to copier maintenance.

Controversial Aspect 1: Environmental Impact

One of the controversial aspects surrounding the use of self-healing polymers in copier components is their potential environmental impact. While the technology offers the promise of extending the lifespan of these components, it also raises concerns about the disposal and recycling of these materials.

Proponents argue that by reducing the need for frequent replacement of copier components, self-healing polymers can contribute to a decrease in electronic waste. This is a significant benefit considering the growing concern over the environmental impact of discarded electronics. By prolonging the lifespan of copier components, self-healing polymers can help reduce the overall carbon footprint associated with manufacturing and disposal.

However, critics point out that the production and disposal of self-healing polymers may have their own environmental consequences. The manufacturing process for these materials often involves the use of chemicals and energy-intensive processes. Additionally, the recycling of self-healing polymers may present challenges due to their unique properties. If not properly managed, the disposal and recycling of these materials could potentially lead to pollution and other environmental hazards.

It is important for manufacturers to address these concerns by implementing sustainable practices in the production and disposal of self-healing polymers. This could include using more environmentally friendly manufacturing processes, ensuring proper recycling infrastructure is in place, and conducting thorough environmental impact assessments.

Controversial Aspect 2: Cost and Accessibility

Another controversial aspect surrounding self-healing polymers in copier components is the cost and accessibility of this technology. While self-healing polymers offer the potential for longer-lasting copier components, the implementation of this technology may come at a higher price.

Proponents argue that the initial investment in self-healing polymers can be justified by the long-term cost savings. By reducing the need for frequent component replacements, businesses can save on maintenance and replacement costs. This can be particularly beneficial for high-volume printing environments where copier components often wear out quickly.

However, critics argue that the higher upfront cost of self-healing polymers may limit their accessibility, especially for smaller businesses or organizations with limited budgets. The cost of implementing this technology could outweigh the potential benefits, making it less feasible for some users.

Manufacturers need to consider the cost implications of self-healing polymers and work towards making this technology more affordable and accessible to a wider range of users. This could involve exploring alternative production methods, partnering with suppliers to reduce costs, or offering flexible pricing options.

Controversial Aspect 3: Performance and Durability

The performance and durability of self-healing polymers in copier components is another controversial aspect that needs to be examined. While the concept of materials that can repair themselves sounds promising, there are concerns about the effectiveness and long-term durability of these polymers.

Proponents argue that self-healing polymers can significantly extend the lifespan of copier components by repairing minor damages, such as scratches or cracks. This can lead to improved overall performance and reduced downtime for businesses. Additionally, the ability of these polymers to heal themselves can potentially prevent catastrophic failures, further enhancing the reliability of copier components.

However, critics question the long-term durability of self-healing polymers. They argue that the healing process may not be able to address more significant damages or wear and tear that copier components may experience over time. There are concerns that the self-healing properties may degrade over prolonged use, leading to reduced effectiveness and potentially rendering the technology ineffective.

Manufacturers need to conduct thorough testing and research to ensure the durability and long-term performance of self-healing polymers. This includes evaluating the effectiveness of the healing process under various conditions and assessing the material’s ability to withstand repeated use and stress.

Self-healing polymers in copier components offer the potential to extend the lifespan of these materials, reduce electronic waste, and improve overall performance. However, it is essential to address the controversial aspects surrounding this technology, including its environmental impact, cost and accessibility, and performance and durability. By considering these concerns and working towards sustainable, affordable, and reliable solutions, manufacturers can harness the benefits of self-healing polymers while mitigating potential drawbacks.

1. to Self-Healing Polymers

Self-healing polymers are a revolutionary development in the field of materials science. These polymers have the ability to repair themselves when damaged, extending the lifespan of various components. In the context of copiers, self-healing polymers can play a crucial role in increasing the durability and reliability of key components, such as rollers, belts, and gears. By understanding the science behind self-healing polymers and their applications, we can explore how they can significantly enhance the performance and longevity of copier components.

2. How Self-Healing Polymers Work

Self-healing polymers are engineered to have the ability to autonomously repair damage inflicted on them. This is achieved through the incorporation of microcapsules or microvascular networks within the polymer matrix. When the polymer is damaged, these microcapsules rupture or the vascular network is activated, releasing healing agents that flow into the damaged area and react to restore the material’s integrity. The healing process can occur multiple times, making self-healing polymers highly resilient and long-lasting.

3. Applications of Self-Healing Polymers in Copiers

The use of self-healing polymers in copiers can have a significant impact on the lifespan of critical components. For example, self-healing rollers can withstand repeated wear and tear, reducing the need for frequent replacements. Similarly, self-healing belts can resist cracking and tearing, ensuring smooth and uninterrupted paper movement. Additionally, self-healing gears can maintain their structural integrity, preventing gear failures and minimizing downtime. These applications demonstrate the potential of self-healing polymers to enhance the reliability and longevity of copier components.

4. Case Study: Self-Healing Rollers in Copiers

A case study conducted by a leading copier manufacturer demonstrated the effectiveness of self-healing rollers in extending component lifespan. The study compared traditional rollers with self-healing rollers and found that the latter showed a significant reduction in surface damage over time. The self-healing rollers repaired minor scratches and abrasions, preventing them from developing into more severe defects. As a result, copiers equipped with self-healing rollers required fewer roller replacements, leading to cost savings and improved overall performance.

5. Advantages of Self-Healing Polymers for Copiers

Integrating self-healing polymers into copier components offers several advantages. Firstly, it reduces the frequency of component replacements, resulting in cost savings for both manufacturers and end-users. Secondly, self-healing polymers enhance the reliability of copiers by minimizing the risk of sudden component failures. This leads to improved productivity and reduced downtime. Lastly, self-healing polymers contribute to sustainability efforts by extending the lifespan of copier components, reducing waste and environmental impact.

6. Challenges and Limitations

While self-healing polymers offer promising benefits, there are still challenges and limitations to consider. One challenge is the complexity of integrating self-healing mechanisms into various copier components. Different materials and designs may require tailored approaches for effective self-repair. Additionally, the cost of implementing self-healing polymers may be higher initially, although the long-term cost savings can outweigh this investment. Furthermore, the effectiveness of self-healing polymers may vary depending on the severity and type of damage, requiring further research and development.

7. Future Prospects and Emerging Technologies

The field of self-healing polymers is continuously evolving, with ongoing research and development efforts to improve their performance and expand their applications. Emerging technologies, such as shape memory polymers and reversible crosslinking systems, show great promise in enhancing the self-healing capabilities of polymers. These advancements may lead to even more durable and resilient copier components, further extending their lifespan and reducing maintenance requirements.

Self-healing polymers have the potential to revolutionize the copier industry by extending the lifespan of critical components. Through their autonomous repair capabilities, self-healing polymers can reduce the need for frequent component replacements, enhance reliability, and contribute to sustainability efforts. While challenges and limitations exist, ongoing advancements in the field offer promising prospects for the future. As copier manufacturers continue to embrace self-healing polymers, we can expect to see longer-lasting and more resilient copier components in the years to come.

Early Development of Polymers

Polymers, which are large molecules made up of repeating subunits, have been used in various industries for centuries. The concept of self-healing polymers, however, is a relatively recent development. In the early days, polymers were primarily used for their physical properties such as strength and flexibility. The idea of a material that could repair itself seemed like science fiction.

Emergence of Self-Healing Concepts

The concept of self-healing materials began to gain attention in the 1990s. Researchers started exploring the idea of incorporating healing capabilities into polymers to improve their durability and lifespan. The initial focus was on creating materials that could heal small cracks and scratches, similar to how the human body repairs itself.

First Breakthroughs

In 2001, a major breakthrough in self-healing polymers was achieved by a team of scientists at the University of Illinois. They developed a material that could heal itself when exposed to ultraviolet light. The material contained tiny capsules filled with a healing agent that would release and repair any damage upon activation. This discovery opened up new possibilities for the use of self-healing polymers in various applications.

Advancements in Healing Mechanisms

Over the years, researchers continued to explore different healing mechanisms for self-healing polymers. Some materials relied on chemical reactions, while others used heat or pressure to trigger the healing process. The goal was to develop polymers that could heal themselves under different conditions and repair a wider range of damages.

Industrial Applications

The potential of self-healing polymers to extend the lifespan of components and reduce maintenance costs quickly caught the attention of industries. In the early 2000s, self-healing polymers started to be implemented in various fields, including automotive, aerospace, and electronics. For example, self-healing coatings were used to protect car bodies from scratches and chips, while self-healing adhesives were used in electronic devices to improve their reliability.

Recent Developments

In recent years, significant progress has been made in the field of self-healing polymers. Researchers have focused on improving the efficiency and effectiveness of healing mechanisms, as well as exploring new applications. For instance, self-healing polymers are now being used in the manufacturing of copier components to extend their lifespan. These components, such as rollers and belts, are prone to wear and tear, but with the integration of self-healing polymers, their durability has been significantly enhanced.

Future Prospects

The development of self-healing polymers is an ongoing area of research, with the potential for even more exciting advancements in the future. Scientists are exploring new healing mechanisms, such as the incorporation of microvascular networks that can distribute healing agents throughout the material. This could lead to materials that can heal larger damages and even regenerate themselves. The application of self-healing polymers is also expanding into other industries, such as healthcare and infrastructure.

Overall, the historical context of self-healing polymers shows how this field has evolved from a novel concept to a practical solution for extending the lifespan of various components. With continuous research and development, self-healing polymers have the potential to revolutionize the way we design and manufacture materials, leading to more sustainable and durable products.

FAQs

1. What are self-healing polymers?

Self-healing polymers are a class of materials that have the ability to repair themselves when damaged. They can automatically restore their mechanical and physical properties, making them ideal for use in various applications, including copier components.

2. How do self-healing polymers work?

Self-healing polymers work by incorporating a network of microcapsules or vascular channels filled with healing agents into the material. When the polymer is damaged, these capsules rupture or the channels break, releasing the healing agents. The agents then react with each other to form a new bond, effectively repairing the damage.

3. What are the benefits of using self-healing polymers in copier components?

Using self-healing polymers in copier components can significantly extend their lifespan. These materials can repair themselves when subjected to wear and tear, reducing the need for frequent component replacements. This not only saves costs but also improves the overall efficiency and reliability of the copier.

4. Are self-healing polymers expensive?

While self-healing polymers may initially have a higher cost compared to traditional materials, their long-term benefits outweigh the investment. By reducing the need for frequent component replacements, self-healing polymers can help save costs in the long run, making them a cost-effective solution for copier manufacturers.

5. Can self-healing polymers be used in all copier components?

Self-healing polymers can be used in a wide range of copier components, including gears, rollers, belts, and even the housing. However, the suitability of these materials depends on the specific requirements of each component. Extensive research and testing are necessary to determine the optimal use of self-healing polymers in different copier parts.

6. How durable are self-healing polymers?

Self-healing polymers are designed to be highly durable and withstand repeated damage and repair cycles. The healing process can occur multiple times, allowing the material to maintain its integrity over an extended period. However, the durability of self-healing polymers can vary depending on the specific formulation and application.

7. Do self-healing polymers require any special maintenance?

No, self-healing polymers do not require any special maintenance. Once incorporated into copier components, they can operate as normal without any additional care or attention. The self-healing process occurs automatically whenever the material is damaged, ensuring the longevity and reliability of the copier.

8. Can self-healing polymers be recycled?

Yes, self-healing polymers can be recycled. These materials can be processed and reused, just like traditional polymers. However, the presence of healing agents and microcapsules may require specific recycling methods to separate and recover the healing agents for reuse.

9. Are there any limitations to using self-healing polymers in copier components?

While self-healing polymers offer many advantages, they do have some limitations. These materials may have certain temperature or chemical compatibility restrictions, which need to be considered during the design and manufacturing process. Additionally, the incorporation of healing agents and microcapsules may slightly alter the material’s properties, requiring careful optimization for specific copier applications.

10. Are self-healing polymers the future of copier technology?

Self-healing polymers hold great promise for extending the lifespan of copier components and improving their reliability. While they are not yet widely adopted in the industry, ongoing research and development efforts continue to explore their potential. With further advancements, self-healing polymers could become a standard feature in future copier designs, revolutionizing the way we think about component durability and maintenance.

Common Misconceptions about

Misconception 1: Self-healing polymers can repair any type of damage

One of the common misconceptions about self-healing polymers is that they have the ability to repair any type of damage. While self-healing polymers are indeed remarkable materials, their healing capabilities are not limitless.

Self-healing polymers work by utilizing a network of microcapsules or vascular channels filled with healing agents. When a crack or damage occurs, these healing agents are released and fill the void, allowing the material to regain its strength. However, this healing process is only effective for small-scale damage, such as microcracks or scratches.

For larger-scale damage, such as a major fracture or structural failure, self-healing polymers may not be able to fully repair the material. In such cases, more traditional repair methods or replacement of the component may still be necessary.

Misconception 2: Self-healing polymers eliminate the need for regular maintenance

Another misconception about self-healing polymers is that they eliminate the need for regular maintenance. While self-healing polymers can prolong the lifespan of copier components, they do not completely eliminate the need for maintenance.

Self-healing polymers can prevent small-scale damage from escalating into more significant issues, but they cannot prevent all types of wear and tear. Regular maintenance, such as cleaning, lubrication, and adjustment of copier components, is still essential to ensure optimal performance and longevity.

Additionally, self-healing polymers may require periodic inspection to ensure that the healing agents are still intact and functional. If the microcapsules or vascular channels become depleted or damaged, the self-healing capability of the material may be compromised, and repairs or replacements may be necessary.

Misconception 3: Self-healing polymers are prohibitively expensive

One misconception that often arises is that self-healing polymers are prohibitively expensive, making them impractical for widespread use in copier components. While it is true that self-healing polymers can be more expensive than traditional materials, their benefits often outweigh the initial cost.

Self-healing polymers can significantly extend the lifespan of copier components, reducing the frequency of replacements and associated costs. This can result in long-term cost savings for copier manufacturers and users alike.

Furthermore, advancements in manufacturing processes and the increasing demand for self-healing polymers have led to a decrease in production costs over time. As technology continues to evolve, it is expected that the cost of self-healing polymers will become more competitive, making them a viable option for a wider range of applications.

Clarifying the Facts about Self-Healing Polymers

While there are misconceptions surrounding self-healing polymers, it is important to clarify the facts to fully understand their capabilities and limitations.

Self-healing polymers can effectively repair small-scale damage, such as microcracks and scratches, by utilizing healing agents stored in microcapsules or vascular channels. However, they may not be able to repair larger-scale damage or structural failures.

Self-healing polymers can prolong the lifespan of copier components but do not eliminate the need for regular maintenance. Regular maintenance, including cleaning, lubrication, and adjustment, is still necessary to ensure optimal performance.

While self-healing polymers may initially be more expensive than traditional materials, their long-term benefits, such as extended component lifespan and reduced replacement costs, often outweigh the initial investment. The decreasing production costs and technological advancements are making self-healing polymers more accessible and cost-effective.

By understanding these facts, we can appreciate the potential of self-healing polymers in extending the lifespan of copier components and their role in the future of material science.

1. Handle your belongings with care

One of the most effective ways to extend the lifespan of your possessions is to handle them with care. Whether it’s your smartphone, laptop, or any other electronic device, avoid dropping or mishandling them. Treat your belongings gently to prevent any potential damage that could require costly repairs or replacement.

2. Regularly clean and maintain your items

Regular cleaning and maintenance can go a long way in prolonging the life of your possessions. Dust, dirt, and grime can accumulate on surfaces and in crevices, causing wear and tear over time. Clean your items regularly using appropriate cleaning methods and products, and follow the manufacturer’s instructions for maintenance.

3. Store items properly

Proper storage is crucial for preserving the condition of your belongings. When not in use, store your items in a clean and dry environment. Avoid exposing them to extreme temperatures, humidity, or direct sunlight, as these factors can degrade materials and reduce their lifespan.

4. Use protective cases or covers

To provide an extra layer of protection, consider using cases or covers for your valuable items. For electronic devices, invest in high-quality cases that offer shock absorption and impact resistance. For furniture or other items prone to scratches or damage, use protective covers or pads to prevent wear and tear.

5. Follow recommended usage guidelines

Manufacturers often provide specific guidelines for using their products optimally. Pay attention to these recommendations and follow them to ensure the longevity of your possessions. This may include guidelines for charging batteries, operating temperature ranges, or recommended cleaning methods.

6. Address issues promptly

If you notice any issues or malfunctions with your belongings, address them promptly. Ignoring small problems can lead to more significant damage over time. Whether it’s a strange noise coming from your car or a leaking faucet, take the necessary steps to resolve the issue before it escalates.

7. Invest in quality products

Quality matters when it comes to the lifespan of your possessions. Investing in well-made, durable products may initially cost more, but they often last longer and require fewer repairs or replacements. Research brands and read reviews to find products known for their longevity and reliability.

8. Avoid overloading or exceeding limits

Respect the recommended limits and capacities of your possessions. Overloading or exceeding weight limits can strain materials and components, leading to premature wear and tear. This applies to items like backpacks, storage containers, or even the weight capacity of your vehicle.

9. Learn basic repair skills

Equipping yourself with basic repair skills can save you money and extend the lifespan of your possessions. Learn how to fix simple issues like loose screws, minor electrical repairs, or sewing buttons. There are numerous online tutorials and resources available to help you acquire these skills.

10. Consider self-healing or repairable products

As technology advances, more self-healing or repairable products are becoming available. Look for items made from self-healing polymers or materials that can be easily repaired. These products have the ability to fix minor damages automatically, reducing the need for costly repairs or replacements.

Concept 1: Self-Healing Polymers

Self-healing polymers are a type of material that can repair themselves when they get damaged. Just like our skin can heal from cuts and bruises, these polymers have the ability to fix themselves without the need for external intervention. This is achieved through a unique molecular structure that allows the material to rejoin and reform its bonds when they are broken.

Imagine you have a toy made of self-healing polymer. If you accidentally drop it and it breaks, instead of having to glue the pieces back together, the toy would be able to repair itself. The broken bonds in the material would reconnect, and the toy would become whole again. This is possible because of the special properties of self-healing polymers.

Concept 2: Extending Copier Component Lifespan

In the context of copier components, extending their lifespan means making them last longer before they need to be replaced. Copiers have many moving parts that can wear out over time, leading to decreased performance and the need for costly repairs or replacements. By using self-healing polymers in the manufacturing of these components, their lifespan can be extended.

Let’s take the example of a copier’s roller, which is responsible for feeding paper through the machine. With traditional materials, the roller can wear down and develop cracks or scratches over time. This can cause paper jams and affect the quality of the copies. However, if the roller is made from a self-healing polymer, it can repair itself when it gets damaged.

So, if the roller gets scratched or develops a small crack, the self-healing polymer will automatically fix the damage, restoring the roller’s smooth surface. This means that the roller can continue to function properly for a longer period, reducing the need for frequent replacements and saving money for both the copier manufacturer and the end user.

Concept 3: Benefits and Applications

The use of self-healing polymers in copier components offers several benefits. Firstly, it increases the lifespan of these components, reducing the frequency of repairs and replacements. This not only saves money but also reduces waste, as fewer copier parts end up in landfills.

Secondly, self-healing polymers improve the performance and reliability of copiers. By preventing damage to critical components, such as rollers or gears, the copier can continue to operate smoothly, producing high-quality copies without interruptions caused by malfunctions or paper jams.

Furthermore, the application of self-healing polymers is not limited to copier components. This technology has the potential to be used in various other industries and products. For example, it could be applied to car parts, such as bumpers or side mirrors, to repair minor scratches and dents automatically. It could also be used in electronic devices to protect delicate circuits from damage.

Overall, self-healing polymers have the potential to revolutionize the durability and longevity of various products, including copier components. By harnessing the power of materials that can repair themselves, we can reduce waste, save money, and improve the performance of everyday objects.

Conclusion

Self-healing polymers have emerged as a promising solution for extending the lifespan of copier components. This innovative technology has the potential to revolutionize the copier industry by reducing maintenance costs and increasing the reliability of these machines. In this article, we have explored the key characteristics and benefits of self-healing polymers, as well as their application in copier components.

One of the main advantages of self-healing polymers is their ability to autonomously repair damage, such as scratches or cracks, without the need for external intervention. This not only ensures the longevity of copier components but also reduces the frequency of replacements, leading to significant cost savings for businesses. Additionally, self-healing polymers improve the overall performance and durability of copiers, resulting in enhanced productivity and customer satisfaction.

Furthermore, the integration of self-healing polymers in copier components aligns with the growing demand for sustainable solutions. By extending the lifespan of these machines, we can reduce electronic waste and minimize the environmental impact of the copier industry. However, further research and development are needed to optimize the self-healing properties of polymers and ensure their compatibility with different copier models.

Self-healing polymers hold great promise for extending the lifespan of copier components, offering numerous benefits in terms of cost savings, reliability, and sustainability. As this technology continues to advance, we can expect to see a widespread adoption of self-healing polymers in the copier industry, transforming the way we approach maintenance and repair in this field.