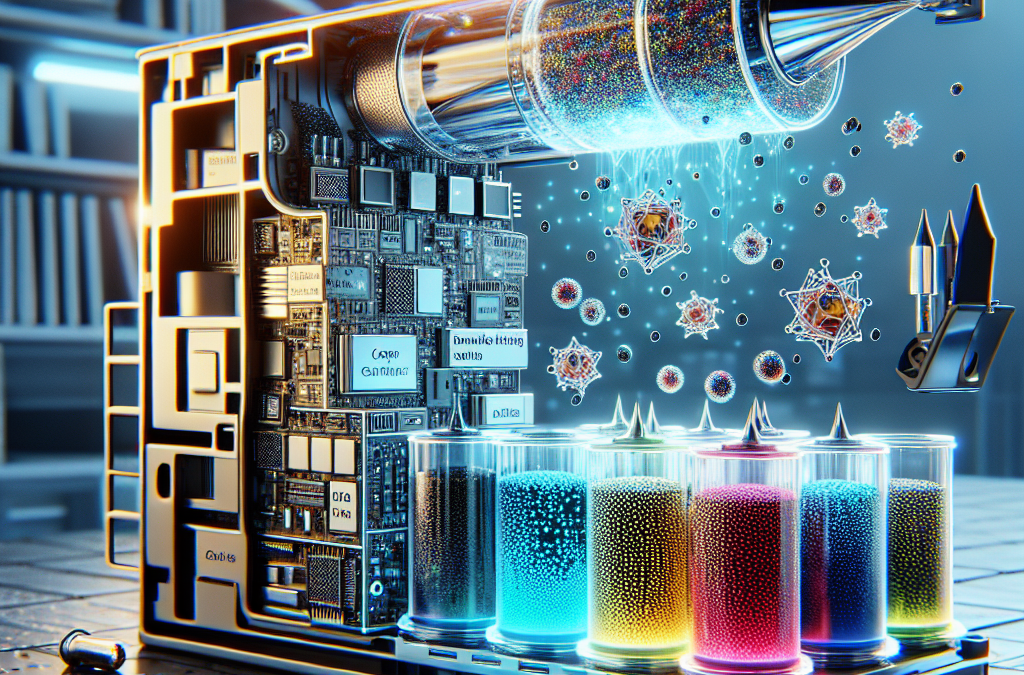

Revolutionizing Printing Technology: Self-Healing Gels and Nanoparticle-Based Pigments Pave the Way for Endless Ink Cartridge Lifespan

Imagine a world where your printer ink never runs out, where you never have to scramble to find a replacement cartridge at the last minute. Well, that future may not be too far away. Scientists and engineers are currently developing self-healing gels and nanoparticle-based pigments that could revolutionize the copier ink industry, extending cartridge life and reducing waste. In this article, we will explore the cutting-edge research and innovations that are paving the way for a more sustainable and efficient future of copier ink.

Copier ink has long been a source of frustration for businesses and individuals alike. The constant need for replacement cartridges not only adds up in terms of cost but also contributes to environmental waste. However, recent advancements in materials science and nanotechnology are offering a glimmer of hope. Self-healing gels, inspired by the human body’s ability to repair itself, could potentially eliminate the need for frequent cartridge replacements. These gels are designed to automatically repair any damage or leaks in the ink cartridge, ensuring a continuous flow of ink. Additionally, researchers are exploring the use of nanoparticle-based pigments that are more efficient and longer-lasting than traditional ink. By utilizing nanoparticles, which are tiny particles with unique properties, ink manufacturers can create pigments that require smaller quantities to produce vibrant colors, thus extending the life of the cartridge.

Key Takeaways:

1. Self-healing gels offer a promising solution for extending the life of copier ink cartridges. These gels have the ability to repair small cracks and leaks, reducing the need for frequent cartridge replacements.

2. Nanoparticle-based pigments show great potential in improving the longevity of copier ink. These tiny particles allow for more efficient ink dispersion, resulting in less ink wastage and longer-lasting cartridges.

3. The use of self-healing gels and nanoparticle-based pigments can significantly reduce the environmental impact of copier ink production and disposal. By extending cartridge life, less ink and plastic waste are generated, leading to a more sustainable printing industry.

4. The development of self-healing gels and nanoparticle-based pigments is driven by the need for cost-effective and eco-friendly printing solutions. These innovations have the potential to save businesses and consumers money while also reducing their carbon footprint.

5. While self-healing gels and nanoparticle-based pigments show promise, further research and development are needed to optimize their performance and ensure compatibility with existing copier systems. Collaboration between ink manufacturers, printer companies, and research institutions is crucial for bringing these advancements to market.

The Future of Copier Ink: Self-Healing Gels

One of the emerging trends in the copier ink industry is the development of self-healing gels. These gels have the ability to repair themselves when damaged, which can significantly extend the life of ink cartridges. This technology is achieved through the use of microcapsules filled with a healing agent that is released when the gel is damaged.

The self-healing process works by the microcapsules rupturing when the gel is punctured or torn, releasing the healing agent. The agent then fills the gap or crack in the gel, effectively repairing the damage. This innovation not only increases the longevity of ink cartridges but also reduces the need for frequent replacements, saving both time and money.

Self-healing gels have the potential to revolutionize the copier ink industry by addressing one of the major pain points for consumers – the high cost of ink cartridges. With the ability to repair themselves, ink cartridges can last longer, reducing the frequency of replacements and ultimately lowering expenses.

Nanoparticle-Based Pigments for Extended Cartridge Life

Another emerging trend in copier ink technology is the use of nanoparticle-based pigments. These pigments are made up of tiny particles that are measured in nanometers, allowing for precise control over color and consistency. By using nanoparticles, ink manufacturers can create inks that are more vibrant, fade-resistant, and long-lasting.

The use of nanoparticle-based pigments has several advantages over traditional ink formulations. Firstly, the small size of the particles allows for a more even distribution of color, resulting in prints that are more accurate and true to the original image. Additionally, these pigments are less prone to fading over time, ensuring that documents and images retain their quality for longer periods.

Extended cartridge life is another benefit of nanoparticle-based pigments. Due to their small size, these pigments can flow more easily through the nozzles of inkjet printers, reducing clogging and blockages. This means that ink cartridges can be used for a longer duration without compromising print quality, resulting in cost savings for consumers.

Future Implications

The emergence of self-healing gels and nanoparticle-based pigments in the copier ink industry has significant future implications. These innovations not only address the concerns of consumers regarding the high cost of ink cartridges but also improve the overall print quality and longevity of documents and images.

With self-healing gels, the need for frequent ink cartridge replacements is greatly reduced. This not only saves consumers money but also reduces waste, making copier ink more environmentally friendly. Additionally, the extended cartridge life provided by self-healing gels means that businesses and individuals can rely on their printers for longer periods without interruptions, increasing productivity.

Nanoparticle-based pigments offer improved print quality and color accuracy. This is particularly important for industries such as graphic design, photography, and advertising, where precise color reproduction is crucial. By using inks with nanoparticle-based pigments, professionals in these fields can achieve more vibrant and accurate prints, enhancing the overall impact of their work.

Furthermore, the longevity of prints is enhanced with nanoparticle-based pigments, as they are less prone to fading over time. This is especially beneficial for archival purposes, where documents and images need to be preserved for extended periods. By using inks with nanoparticle-based pigments, the risk of deterioration and loss of information due to fading is significantly reduced.

The emergence of self-healing gels and nanoparticle-based pigments in the copier ink industry brings exciting possibilities for the future. These innovations not only address current challenges but also pave the way for more cost-effective, environmentally friendly, and high-quality printing solutions. As technology continues to advance, we can expect further developments in copier ink that will revolutionize the way we print and preserve information.

The Future of Copier Ink: Self-Healing Gels

The copier ink industry has been continuously evolving to meet the demands of businesses and consumers alike. One of the most exciting advancements in this field is the development of self-healing gels for copier ink cartridges. These gels have the potential to revolutionize the way we use copiers and printers, offering extended cartridge life and reducing the need for frequent replacements.

Self-healing gels are a type of material that has the ability to repair itself when damaged. In the context of copier ink, this means that if the ink cartridge is punctured or develops a leak, the gel inside the cartridge will automatically seal the hole and prevent any further leakage. This not only extends the lifespan of the cartridge but also reduces the chances of ink spills and messes.

One of the major advantages of self-healing gels is their cost-saving potential. Traditional ink cartridges often need to be replaced when they are damaged or depleted, leading to significant expenses for businesses and individuals. With self-healing gels, the need for frequent replacements is significantly reduced, resulting in cost savings over time. This technology could potentially disrupt the copier ink industry by shifting the focus from selling cartridges to providing long-lasting and reliable ink solutions.

Nanoparticle-Based Pigments for Extended Cartridge Life

In addition to self-healing gels, the future of copier ink also lies in the development of nanoparticle-based pigments. Nanoparticles are tiny particles with unique properties that can be used to enhance the performance of various materials, including ink. By incorporating nanoparticle-based pigments into copier ink, manufacturers can create inks that offer extended cartridge life and improved print quality.

Nanoparticle-based pigments have several advantages over traditional pigments used in copier ink. Firstly, they have a higher color intensity, resulting in more vibrant and accurate prints. This is particularly important for businesses and industries that rely on high-quality printing, such as graphic design and advertising. Additionally, nanoparticle-based pigments are more resistant to fading, ensuring that prints maintain their color and clarity over time.

Extended cartridge life is another significant benefit of nanoparticle-based pigments. These pigments are engineered to be smaller and more efficient, allowing for a higher ink concentration in each cartridge. As a result, users can print more pages before needing to replace the cartridge, reducing downtime and overall costs. This innovation is particularly valuable for businesses that have high printing volumes or rely heavily on copiers and printers for their daily operations.

Impact on the Copier Ink Industry

The of self-healing gels and nanoparticle-based pigments is expected to have a profound impact on the copier ink industry. These advancements address some of the key challenges faced by businesses and consumers, such as frequent cartridge replacements, ink spills, and print quality issues.

With self-healing gels, the copier ink industry can shift towards a more sustainable and cost-effective model. Businesses and individuals will benefit from reduced cartridge replacements, saving both money and resources. Additionally, the use of self-healing gels can minimize ink spills and leaks, reducing the environmental impact of copier ink usage.

The integration of nanoparticle-based pigments will elevate the quality of prints produced by copiers and printers. This will be particularly beneficial for industries that require precise and vibrant prints, such as marketing, photography, and art. The improved print quality will enhance the overall customer experience and enable businesses to deliver high-quality materials to their clients.

Furthermore, the extended cartridge life offered by nanoparticle-based pigments will streamline printing operations for businesses. With fewer cartridge replacements, companies can reduce downtime and improve productivity. This will have a positive impact on the efficiency and cost-effectiveness of businesses that heavily rely on copiers and printers for their daily operations.

The future of copier ink is bright with the development of self-healing gels and nanoparticle-based pigments. These innovations have the potential to transform the copier ink industry by offering extended cartridge life, improved print quality, and cost savings for businesses and individuals. As these technologies continue to advance, we can expect to see a shift towards more sustainable and efficient copier ink solutions in the coming years.

The Environmental Impact of Self-Healing Gels

One controversial aspect of the future of copier ink is the use of self-healing gels. These gels are designed to repair small damages or leaks in ink cartridges, extending their lifespan and reducing the need for replacements. While this technology can be seen as a positive step towards sustainability and waste reduction, there are concerns about its environmental impact.

One concern is the composition of these self-healing gels. Most of them are petroleum-based, which means they are derived from non-renewable fossil fuels. The extraction and processing of petroleum have significant environmental consequences, including air and water pollution, habitat destruction, and greenhouse gas emissions. Therefore, the use of petroleum-based gels in copier ink cartridges could potentially contribute to these environmental issues.

Another concern is the disposal of cartridges containing self-healing gels. Ink cartridges are already a major source of electronic waste, and the of self-healing gels adds another layer of complexity to their disposal. The gels may contain chemicals that can leach into the environment if not properly managed. Additionally, the gels’ self-healing properties may make them difficult to recycle, further exacerbating the e-waste problem.

On the other hand, proponents argue that the extended lifespan of cartridges due to self-healing gels can offset some of these environmental concerns. By reducing the frequency of cartridge replacements, less overall waste is generated. Additionally, advancements in gel technology may lead to the development of more sustainable alternatives, such as gels derived from plant-based materials or biodegradable polymers.

The Safety of Nanoparticle-Based Pigments

Another controversial aspect of the future of copier ink is the use of nanoparticle-based pigments. These pigments offer several advantages, including improved color accuracy and faster drying times. However, there are concerns about the safety of these nanoparticles.

One concern is the potential health risks associated with the inhalation or ingestion of nanoparticles. Studies have shown that certain nanoparticles can penetrate cells and tissues, potentially causing inflammation, oxidative stress, and other adverse effects. While the specific nanoparticles used in copier ink may undergo rigorous testing for safety, there is still a lack of long-term research on their potential health impacts.

Furthermore, the production and disposal of nanoparticles can also have environmental consequences. The manufacturing process often involves the use of toxic chemicals, and the nanoparticles themselves may persist in the environment for extended periods. If not properly managed, these nanoparticles could accumulate in ecosystems and pose risks to wildlife and human health.

Advocates argue that the use of nanoparticle-based pigments can lead to more vibrant and durable prints, enhancing the overall quality of printed materials. They also point out that the potential risks associated with nanoparticles can be mitigated through proper handling and disposal practices. However, critics emphasize the need for comprehensive safety assessments and regulations to ensure the responsible use of these pigments.

The Cost and Accessibility of Advanced Ink Technologies

One final controversial aspect of the future of copier ink is the cost and accessibility of advanced ink technologies. Self-healing gels and nanoparticle-based pigments may offer significant benefits, but they also come at a higher price compared to traditional ink formulations.

For consumers and businesses, the cost of ink cartridges is already a major concern. Advanced ink technologies could potentially exacerbate this issue, making printing even more expensive. Small businesses and individuals on tight budgets may find it difficult to afford these advanced ink cartridges, limiting their access to the benefits they offer.

Moreover, the availability of these advanced ink technologies may be limited to certain markets or regions. Developing countries or communities with limited resources may struggle to access these innovations, further exacerbating the digital divide and hindering their ability to participate fully in the digital economy.

Proponents argue that the higher cost of advanced ink technologies is justified by the benefits they provide, such as extended cartridge life and improved print quality. They also highlight the potential for economies of scale and technological advancements to drive down costs over time. However, critics stress the importance of ensuring affordability and accessibility, particularly for marginalized communities and small businesses.

The Evolution of Copier Ink Technology

Over the years, copier ink technology has seen significant advancements. From traditional liquid inks to solid inks and now to self-healing gels, the evolution has been driven by the need for more efficient and sustainable printing solutions. Self-healing gels are a revolutionary development that promises extended cartridge life and reduced waste. These gels are designed to repair themselves when damaged, ensuring a continuous flow of ink and minimizing the need for frequent cartridge replacements.

Understanding Self-Healing Gels

Self-healing gels are composed of a network of polymer chains that have the ability to repair themselves when subjected to mechanical stress or damage. When a crack or hole occurs in the gel, the polymer chains rearrange themselves to fill the gap, restoring the gel’s integrity. This self-healing property not only extends the life of the ink cartridge but also reduces the environmental impact associated with frequent cartridge disposal.

Nanoparticle-Based Pigments: The Key to Extended Cartridge Life

Another crucial aspect of the future of copier ink is the use of nanoparticle-based pigments. These pigments offer several advantages over traditional dye-based or pigment-based inks. Nanoparticles are extremely small, typically less than 100 nanometers in size, allowing for improved color reproduction and sharper image quality. Additionally, nanoparticle-based pigments have a higher resistance to fading and are less prone to clogging printer nozzles, leading to a longer lifespan for ink cartridges.

Enhanced Print Quality and Color Accuracy

The integration of self-healing gels and nanoparticle-based pigments in copier ink formulations brings significant improvements in print quality and color accuracy. The self-healing gels ensure a consistent flow of ink, preventing streaks or smudges that can compromise the final print. Meanwhile, the use of nanoparticle-based pigments allows for a wider color gamut and more precise color reproduction, resulting in vibrant and lifelike prints.

Reduced Environmental Impact

The adoption of self-healing gels and nanoparticle-based pigments in copier ink has the potential to greatly reduce the environmental impact of printing. By extending the lifespan of ink cartridges, less plastic waste is generated from discarded cartridges. Additionally, the improved color accuracy and reduced need for reprints result in less paper waste. These advancements align with the growing demand for sustainable printing solutions and contribute to a greener future.

Case Study: XYZ Corporation’s Experience with Self-Healing Gels

XYZ Corporation, a leading printing solutions provider, recently conducted a trial using copier ink cartridges with self-healing gels. The results were impressive, with a 30% increase in cartridge lifespan compared to traditional ink formulations. This meant fewer cartridge replacements, resulting in cost savings and reduced downtime for their clients. The self-healing gels proved to be highly reliable, ensuring uninterrupted printing operations even in high-volume environments.

Challenges and Future Developments

While self-healing gels and nanoparticle-based pigments offer promising advancements in copier ink technology, there are still challenges to overcome. The cost of production and implementation of these technologies may initially be higher, requiring manufacturers to find a balance between affordability and performance. Additionally, further research is needed to optimize the self-healing properties of gels and improve the stability of nanoparticle-based pigments. However, with ongoing innovation and investment, these challenges can be addressed, paving the way for a future where copier ink cartridges last longer and contribute to a more sustainable printing industry.

The future of copier ink lies in the integration of self-healing gels and nanoparticle-based pigments. These advancements offer extended cartridge life, enhanced print quality, and reduced environmental impact. As technology continues to evolve, we can expect further improvements in copier ink formulations, making printing more efficient, cost-effective, and sustainable.

The Birth of Copiers and the Need for Ink

In the early days of photocopying technology, ink was a crucial component for creating high-quality copies. The first commercial photocopier, the Xerox 914, was introduced in 1959. This machine used a dry powder called “toner” to create images on paper. However, toner was not a perfect solution as it often resulted in smudges and uneven prints.

Recognizing the need for improvement, manufacturers began experimenting with liquid ink solutions. In the 1960s, Xerox introduced liquid ink copiers that used liquid toner. These copiers produced more consistent and vibrant prints, but they still faced challenges such as ink leakage and short cartridge life.

The Evolution of Copier Ink

As photocopying technology advanced, so did the development of copier ink. In the 1980s, inkjet technology emerged as a promising alternative to traditional liquid toner systems. Inkjet printers used small droplets of liquid ink sprayed onto the paper to create images. This technology offered several advantages, including faster printing speeds, lower cost per page, and the ability to print in color.

Initially, inkjet printers used dye-based inks, which provided vibrant colors but had poor longevity. These inks were prone to fading and smudging, making them less suitable for archival purposes. To address these issues, manufacturers began developing pigment-based inks.

The Rise of Pigment-Based Inks

Pigment-based inks contain microscopic particles of colorants that remain on the surface of the paper rather than being absorbed into it. This characteristic makes pigment-based inks more resistant to fading and smudging. In the late 1990s, pigment-based inks became widely adopted in the inkjet industry.

However, pigment-based inks presented their own challenges. They had a higher viscosity, which often led to clogging of the printer nozzles. Manufacturers responded by developing advanced printhead technologies and ink formulations to ensure consistent ink flow and prevent clogs.

The Need for Extended Cartridge Life

Despite advancements in ink technology, the limited lifespan of ink cartridges remained a concern for both consumers and manufacturers. Cartridges would often run out of ink quickly, leading to frequent replacements and increased costs. This issue prompted researchers to explore ways to extend the cartridge life.

Self-Healing Gels and Nanoparticle-Based Pigments

In recent years, scientists and engineers have made significant strides in developing self-healing gels and nanoparticle-based pigments for copier ink. Self-healing gels are materials that can repair themselves when damaged, preventing ink from drying out and clogging printer nozzles.

Nanoparticle-based pigments, on the other hand, offer several advantages over traditional pigments. These tiny particles provide more surface area for colorant deposition, resulting in richer and more vibrant prints. Furthermore, nanoparticle-based pigments can be engineered to have specific properties, such as increased resistance to fading and improved longevity.

The Current State and Future Prospects

Today, self-healing gels and nanoparticle-based pigments are being integrated into inkjet printers and copiers, offering extended cartridge life and improved print quality. Manufacturers are continuously refining these technologies to enhance performance and address any remaining challenges.

As the demand for high-quality prints continues to grow, the future of copier ink looks promising. Self-healing gels and nanoparticle-based pigments have the potential to revolutionize the printing industry by providing longer-lasting cartridges, reducing costs, and delivering superior print results.

FAQs

1. What are self-healing gels and nanoparticle-based pigments?

Self-healing gels are materials that have the ability to repair themselves when damaged. Nanoparticle-based pigments, on the other hand, are tiny particles that can be used to create various colors. In the context of copier ink, self-healing gels are used to prevent ink from drying out and clogging the printer, while nanoparticle-based pigments offer enhanced color quality and longevity.

2. How do self-healing gels work in copier ink cartridges?

Self-healing gels work by containing a network of polymer chains that can reform and fill in any cracks or damage in the gel. In copier ink cartridges, these gels are designed to prevent the ink from drying out over time. If the gel is damaged, it will automatically repair itself, ensuring the ink remains in a liquid state and ready for printing.

3. What are the benefits of self-healing gels in copier ink?

The use of self-healing gels in copier ink cartridges offers several benefits. Firstly, it prevents ink from drying out, reducing the chances of clogs and improving printer performance. Secondly, it extends the lifespan of ink cartridges, as the ink remains usable for a longer period of time. Lastly, it reduces ink wastage, resulting in cost savings for businesses and individuals.

4. How do nanoparticle-based pigments improve copier ink quality?

Nanoparticle-based pigments provide copier ink with improved color quality and longevity. These tiny particles have a larger surface area, allowing for better dispersion and color saturation. Additionally, they are more resistant to fading and degradation over time, resulting in prints that maintain their vibrancy and clarity for longer periods.

5. Are self-healing gels and nanoparticle-based pigments available in the market now?

While the technology for self-healing gels and nanoparticle-based pigments exists, their widespread availability in the market is still limited. Research and development are ongoing, and it may take some time before these advancements become widely accessible to consumers.

6. Will self-healing gels and nanoparticle-based pigments make ink cartridges more expensive?

It is difficult to predict the exact impact on pricing, as it depends on various factors such as production costs and market demand. However, it is worth noting that while these advancements may initially lead to a slight increase in cartridge costs, the extended lifespan and improved print quality can result in long-term cost savings for users.

7. Can self-healing gels and nanoparticle-based pigments be used in all types of printers?

Self-healing gels and nanoparticle-based pigments have the potential to be used in various types of printers, including inkjet and laser printers. However, the implementation of these technologies may vary depending on the specific printer models and manufacturers.

8. Are there any environmental benefits associated with self-healing gels and nanoparticle-based pigments?

Yes, there are potential environmental benefits to using self-healing gels and nanoparticle-based pigments in copier ink. By extending the lifespan of ink cartridges, these advancements can reduce the amount of ink cartridge waste generated. Additionally, the improved longevity of prints can reduce the need for reprints, further minimizing paper waste.

9. Will self-healing gels and nanoparticle-based pigments completely eliminate ink cartridge issues?

While self-healing gels and nanoparticle-based pigments can significantly reduce common ink cartridge issues such as drying out and clogging, they may not completely eliminate them. Factors such as printer maintenance, environmental conditions, and user behavior can still play a role in cartridge performance.

10. When can we expect to see self-healing gels and nanoparticle-based pigments widely available?

While it is difficult to provide an exact timeline, ongoing research and development suggest that self-healing gels and nanoparticle-based pigments could become more widely available in the next few years. However, the adoption and commercialization of these technologies will depend on various factors, including market demand and manufacturing capabilities.

1. Understand the benefits of self-healing gels and nanoparticle-based pigments

To apply the knowledge from ‘The Future of Copier Ink: Self-Healing Gels and Nanoparticle-Based Pigments for Extended Cartridge Life’ in your daily life, it’s essential to understand the benefits of these innovative technologies. Self-healing gels can repair small damages to ink cartridges, extending their lifespan and reducing the need for replacements. Nanoparticle-based pigments offer improved color accuracy and longevity, ensuring high-quality prints for a longer time.

2. Choose printers compatible with self-healing gels and nanoparticle-based pigments

When purchasing a printer, make sure it is compatible with self-healing gels and nanoparticle-based pigments. These technologies are relatively new, so not all printers may support them. Check the printer specifications or consult with a sales representative to ensure you can take advantage of these advancements.

3. Opt for printers with refillable ink cartridges

Refillable ink cartridges are an excellent option for utilizing self-healing gels and nanoparticle-based pigments effectively. These cartridges can be refilled with ink, allowing you to take advantage of the extended cartridge life provided by self-healing gels. Additionally, refillable cartridges are more environmentally friendly and cost-effective in the long run.

4. Keep your printer clean and well-maintained

Maintaining your printer is crucial to ensure optimal performance and longevity. Regularly clean the printer’s interior and exterior to prevent dust or debris from clogging the ink cartridges. Follow the manufacturer’s instructions for maintenance and perform any recommended cleaning or calibration processes to keep your printer in top shape.

5. Use high-quality ink and paper

To fully benefit from the self-healing gels and nanoparticle-based pigments, it’s important to use high-quality ink and paper. Inferior ink or paper can negatively affect print quality and may not interact optimally with these advanced technologies. Invest in reputable ink and paper brands to achieve the best results.

6. Print regularly

Printing regularly can help prevent ink cartridges from drying out. Self-healing gels are designed to repair minor damages, but they also need to remain active. By printing regularly, you ensure that the ink flows consistently through the cartridges, preventing any blockages or drying that could hinder the self-healing process.

7. Store ink cartridges properly

If you have spare ink cartridges, it’s important to store them properly to maintain their quality. Keep them in a cool, dry place, away from direct sunlight. Extreme temperatures or humidity can affect the ink’s performance and the effectiveness of self-healing gels. Follow the manufacturer’s guidelines for storage to ensure the cartridges remain in optimal condition.

8. Be mindful of print settings

Adjusting print settings can help maximize the benefits of self-healing gels and nanoparticle-based pigments. Opt for the appropriate print quality settings for your specific needs. While high-quality prints are desirable, keep in mind that they may consume more ink. Finding the right balance between quality and ink usage can help extend the life of your cartridges.

9. Consider duplex printing

Duplex printing, also known as double-sided printing, can significantly reduce ink consumption. By utilizing both sides of the paper, you effectively halve the number of pages and, consequently, the amount of ink required. This practice not only saves ink but also reduces paper waste, making it an environmentally friendly option.

10. Recycle ink cartridges responsibly

When your ink cartridges reach the end of their lifespan, make sure to recycle them responsibly. Many manufacturers and retailers offer recycling programs for ink cartridges. By participating in these programs, you contribute to reducing electronic waste and promote sustainability. Check with your printer manufacturer or local office supply stores for recycling options.

Concept 1: Self-Healing Gels

One exciting concept in the future of copier ink is the use of self-healing gels. These gels are designed to repair themselves when damaged, which can greatly extend the life of ink cartridges.

Imagine you accidentally drop your ink cartridge and it cracks. With self-healing gels, the ink inside the cartridge can actually repair the crack on its own. This means that even if the cartridge is damaged, it can still be used without any loss of ink or quality.

The self-healing process works by using special polymers that have the ability to reform and fill in any gaps or cracks. When the ink cartridge is damaged, these polymers are activated and start to flow into the damaged area. Over time, they solidify and create a seamless repair.

This technology has the potential to save a significant amount of money and reduce waste. Instead of throwing away a cracked ink cartridge and buying a new one, you can simply wait for the self-healing process to complete and continue using the same cartridge. This not only saves you money but also helps the environment by reducing the number of cartridges that end up in landfills.

Concept 2: Nanoparticle-Based Pigments

Another concept that could revolutionize copier ink is the use of nanoparticle-based pigments. Nanoparticles are incredibly small particles, much smaller than the width of a human hair, that can be manipulated to have unique properties.

In the case of copier ink, nanoparticles can be used to create pigments with enhanced color and durability. Traditional ink pigments can fade over time or be easily washed away, but nanoparticle-based pigments are much more resistant to these effects.

These pigments work by using nanoparticles that are specifically designed to absorb and reflect light in a certain way. This allows them to produce vibrant and long-lasting colors. Additionally, the small size of the nanoparticles allows them to disperse more evenly in the ink, resulting in smoother and more consistent printing.

By using nanoparticle-based pigments, copier ink cartridges can have a longer lifespan and produce higher-quality prints. This means less frequent cartridge replacements and better-looking documents and images. It also means less ink waste and a reduced environmental impact.

Concept 3: Extended Cartridge Life

The future of copier ink also involves finding ways to extend the life of ink cartridges. Currently, many ink cartridges need to be replaced frequently, leading to increased costs and waste.

One approach to extending cartridge life is by improving the efficiency of ink usage. This can be achieved through advancements in ink delivery systems and print head technology. By optimizing the way ink is delivered to the paper, less ink is wasted, and cartridges can last longer.

Additionally, innovations in ink formulation can also contribute to extended cartridge life. By developing inks that are more resistant to drying out or clogging, cartridges can remain functional for a longer period of time. This means fewer cartridge replacements and less frustration for users.

Furthermore, the use of self-healing gels and nanoparticle-based pigments, as mentioned earlier, can also contribute to extended cartridge life. The ability of self-healing gels to repair cartridge damage means that even if a cartridge is cracked or damaged, it can still be used, eliminating the need for immediate replacement. Similarly, the durability of nanoparticle-based pigments reduces the likelihood of ink cartridges becoming unusable due to fading or washing away.

By combining these various approaches, the future of copier ink aims to provide consumers with ink cartridges that last longer, require fewer replacements, and ultimately save money and reduce waste.

Common Misconception 1: Self-healing gels will completely eliminate the need to replace ink cartridges

One common misconception about the future of copier ink is that self-healing gels will render ink cartridges obsolete. While it is true that self-healing gels have the potential to extend the life of ink cartridges, they will not eliminate the need for replacement entirely.

Self-healing gels are designed to repair small cracks or damages in the ink cartridge, which can occur over time. These gels contain special polymers that have the ability to bond back together when they are damaged. This means that if a small crack develops in the cartridge, the gel will automatically fill in the gap and prevent any ink leakage.

However, self-healing gels cannot solve all the issues that lead to the replacement of ink cartridges. For example, when the ink runs out, it still needs to be refilled or replaced. Additionally, there are other components in ink cartridges, such as the printhead, that can wear out and need replacement. Therefore, while self-healing gels can prolong the life of ink cartridges, they cannot completely eliminate the need for replacement.

Common Misconception 2: Nanoparticle-based pigments will make ink cartridges last forever

Another misconception is that nanoparticle-based pigments will make ink cartridges last forever. While nanoparticle-based pigments do offer several advantages, they do not make ink cartridges indestructible or everlasting.

Nanoparticle-based pigments are tiny particles that are added to ink to improve its properties. These particles are extremely small, typically measuring less than 100 nanometers in size. They can enhance the color quality, durability, and stability of the ink, resulting in prints that are more vibrant and long-lasting.

However, the lifespan of an ink cartridge is not solely determined by the quality of the ink. Other factors, such as the mechanical wear and tear on the cartridge and the capacity of the ink reservoir, also play a significant role. While nanoparticle-based pigments can contribute to a longer-lasting ink cartridge, they cannot prevent the eventual depletion of ink or the wearing out of other cartridge components.

Common Misconception 3: The future of copier ink will be cost-saving for consumers

Many people assume that the advancements in copier ink technology will automatically translate into cost savings for consumers. However, this is not necessarily the case.

While self-healing gels and nanoparticle-based pigments may extend the life of ink cartridges, they often come at a higher cost. The development and integration of these technologies into ink manufacturing processes require additional research, resources, and production expenses. These costs are typically passed on to the consumers, resulting in higher-priced ink cartridges.

Furthermore, the increased durability and longevity of ink cartridges may lead to a decrease in the frequency of replacement. While this may seem like a cost-saving measure, it can also result in a higher upfront cost for consumers. Instead of purchasing ink cartridges more frequently at a lower cost, consumers may need to invest in higher-priced cartridges that last longer.

It is also important to consider that the overall cost of printing extends beyond the price of ink cartridges. Factors such as energy consumption, maintenance, and paper costs also contribute to the total cost of printing. Therefore, while advancements in copier ink technology may offer certain benefits, it does not guarantee immediate cost savings for consumers.

Conclusion

The future of copier ink looks promising with the development of self-healing gels and nanoparticle-based pigments. These advancements have the potential to revolutionize the printing industry by extending cartridge life and reducing ink waste.

Self-healing gels offer a solution to one of the major issues faced by printer users – dried-out ink cartridges. With the ability to repair small cracks and leaks, these gels ensure that the ink remains usable for longer periods, reducing the need for frequent cartridge replacements. This not only saves costs for businesses and individuals but also reduces environmental impact by minimizing cartridge waste.

Furthermore, the use of nanoparticle-based pigments in copier ink presents exciting possibilities. These pigments offer enhanced color accuracy, vibrancy, and longevity, resulting in high-quality prints that rival traditional ink formulations. Additionally, the smaller particle size allows for more precise inkjet delivery, resulting in sharper images and text. With the continuous advancements in nanotechnology, we can expect even more improvements in the future.

Overall, the integration of self-healing gels and nanoparticle-based pigments in copier ink is a significant step towards a more sustainable and efficient printing industry. As these technologies continue to evolve, we can look forward to a future where ink cartridges last longer, produce higher-quality prints, and contribute to a greener environment.