Revolutionizing Replication: The Rise of 3D Printing in Copier Technology

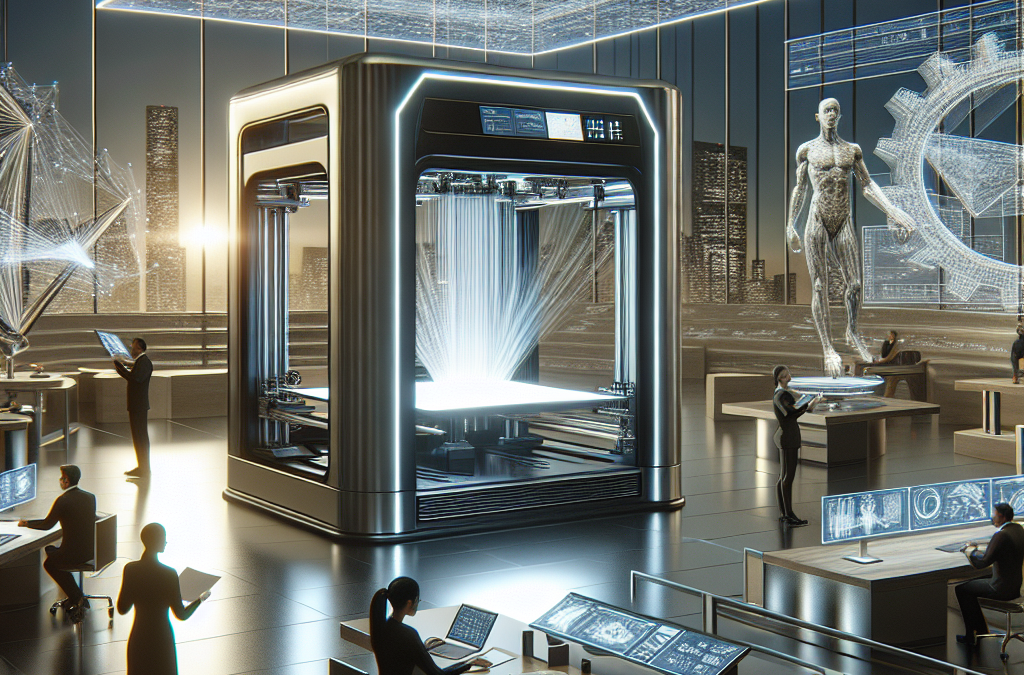

The world of copier technology is rapidly evolving, and one of the most exciting advancements on the horizon is the integration of 3D printing capabilities. Imagine being able to not only make copies of documents but also create three-dimensional objects with just a few clicks. This futuristic concept is becoming a reality, with companies like HP, Canon, and Xerox leading the charge in developing innovative 3D printing copiers. In this article, we will explore the latest breakthroughs in 3D printing technology, the potential applications for this technology, and the impact it could have on various industries.

3D printing, also known as additive manufacturing, has been around for several decades, but it has primarily been used in specialized industries such as aerospace and automotive. However, recent advancements have made it more accessible and affordable, paving the way for its integration into everyday copier technology. These new copiers will be capable of printing objects layer by layer using various materials, ranging from plastics to metals, and even biological materials. The possibilities are endless – from creating prototypes and spare parts to customizing consumer products and even printing human organs for medical purposes.

Key Takeaways:

1. 3D printing is revolutionizing copier technology by enabling the creation of three-dimensional objects from digital designs.

2. The future of copier technology lies in the integration of 3D printing capabilities, allowing businesses and individuals to print complex objects on demand.

3. 3D printing in copiers offers significant advantages such as reduced costs, increased customization options, and faster production times compared to traditional manufacturing methods.

4. The use of advanced materials in 3D printing copiers is expanding the range of applications, enabling the production of functional prototypes, medical devices, and even food items.

5. The potential for 3D printing in copiers to disrupt various industries, including manufacturing, healthcare, and automotive, is immense, opening up new opportunities for innovation and efficiency.

The Controversial Aspects of ‘The Future of Copier Technology: Innovations in 3D Printing’

1. Intellectual Property Concerns

One of the most controversial aspects surrounding the future of copier technology, specifically in the context of 3D printing, is the issue of intellectual property (IP) rights. With the ability to replicate physical objects with ease, there is a growing concern about the potential for copyright infringement and unauthorized reproduction of patented designs.

Proponents of 3D printing argue that it has the potential to democratize manufacturing and spur innovation by allowing individuals to create and customize their own products. However, critics worry that this technology could also enable the mass production of counterfeit goods, leading to significant financial losses for companies and undermining the value of original designs.

While there are existing laws and regulations in place to protect intellectual property, the rapid advancement of 3D printing technology has made it difficult for legal frameworks to keep up. Some argue that stricter regulations are needed to prevent the unauthorized replication of copyrighted objects, while others advocate for a more flexible approach that balances the rights of creators with the potential benefits of widespread access to 3D printing technology.

2. Ethical Implications of Replicating Weapons

Another controversial aspect of the future of copier technology, particularly in the field of 3D printing, is the potential for the replication of weapons. 3D printing has the capability to produce firearms and other dangerous weapons, raising concerns about public safety and national security.

Advocates of 3D printing argue that it can empower individuals to exercise their right to bear arms and enhance their personal security. They believe that restrictions on 3D-printed weapons would infringe upon individual freedoms and that the focus should be on addressing the root causes of violence rather than limiting access to technology.

On the other hand, opponents argue that the ease of access to 3D printing technology could make it easier for criminals and terrorists to obtain untraceable weapons. They advocate for stricter regulations to prevent the production and distribution of 3D-printed firearms, highlighting the need to balance personal freedoms with public safety concerns.

3. Environmental Impact and Sustainability

While 3D printing has the potential to revolutionize manufacturing and reduce waste by enabling on-demand production, there are concerns about its environmental impact and long-term sustainability.

Proponents of 3D printing argue that it can significantly reduce the carbon footprint associated with traditional manufacturing processes. By producing items locally and on-demand, 3D printing eliminates the need for large-scale transportation and excess inventory, leading to reduced energy consumption and greenhouse gas emissions.

However, critics point out that 3D printing relies heavily on plastic materials, which are derived from fossil fuels and contribute to pollution and waste. Additionally, the energy-intensive nature of 3D printing can offset some of the environmental benefits, especially if the energy used comes from non-renewable sources.

To address these concerns, researchers are exploring alternative materials for 3D printing, such as biodegradable plastics and sustainable biomaterials. They are also working on improving the energy efficiency of 3D printers and exploring ways to recycle and reuse printed objects.

The future of copier technology, particularly in the realm of 3D printing, presents several controversial aspects that need careful consideration. Intellectual property concerns, ethical implications of replicating weapons, and the environmental impact of 3D printing are just a few of the complex issues that need to be addressed as this technology continues to advance.

While there are valid arguments on both sides of these controversies, it is essential to find a balanced approach that protects intellectual property rights, ensures public safety, and promotes sustainable manufacturing practices. As 3D printing becomes more prevalent, it is crucial for policymakers, industry leaders, and society as a whole to engage in meaningful discussions and develop appropriate regulations and guidelines to navigate these challenges and unlock the full potential of this innovative technology.

The Rise of 3D Printing in Copier Technology

Over the past decade, 3D printing has emerged as a disruptive technology with the potential to revolutionize various industries. Copier technology is no exception. Traditional copiers have primarily been limited to reproducing two-dimensional documents, but the integration of 3D printing capabilities opens up a whole new world of possibilities. This section will explore how 3D printing is being incorporated into copier technology and the benefits it brings.

Enhancing Efficiency and Productivity

One of the key advantages of 3D printing in copier technology is its ability to enhance efficiency and productivity. With traditional copiers, businesses often rely on external suppliers or manufacturers to produce prototypes or parts. This process can be time-consuming and costly. However, with 3D printing capabilities integrated into copiers, businesses can now produce prototypes and parts in-house, eliminating the need for outsourcing. This not only saves time but also reduces costs and allows for faster iterations and improvements.

Empowering Customization and Personalization

3D printing in copier technology enables a new level of customization and personalization. With traditional copiers, businesses are limited to reproducing standard designs and templates. However, with 3D printing capabilities, businesses can now create unique and customized objects. For example, a furniture manufacturer can easily produce custom-designed pieces tailored to individual customer preferences. This empowers businesses to offer more personalized products and services, leading to increased customer satisfaction and loyalty.

Advancements in Materials and Applications

Another exciting aspect of 3D printing in copier technology is the continuous advancements in materials and applications. Initially, 3D printing was limited to plastics, but now a wide range of materials, including metals, ceramics, and even food, can be used. This opens up possibilities for various industries, such as aerospace, healthcare, and automotive, where durable and specialized materials are required. For instance, medical professionals can now 3D print patient-specific implants, improving surgical outcomes and patient care.

Addressing Environmental Concerns

3D printing in copier technology also has the potential to address environmental concerns. Traditional manufacturing processes often generate significant waste, as excess materials are discarded. In contrast, 3D printing is an additive manufacturing process that only uses the required amount of material, minimizing waste. Additionally, 3D printing allows for the use of recycled materials, further reducing the environmental impact. By promoting sustainable practices, copier technology with 3D printing capabilities can contribute to a greener and more sustainable future.

Challenges and Limitations

While the integration of 3D printing into copier technology brings numerous benefits, it also faces certain challenges and limitations. One of the primary challenges is the speed of 3D printing. Compared to traditional copiers, 3D printing processes can be relatively slow, especially when producing complex objects. Additionally, the cost of 3D printers and materials can still be prohibitive for some businesses. However, as technology advances and economies of scale are realized, these challenges are expected to diminish over time.

Case Study: 3D Printing in Architectural Design

An excellent example of the transformative potential of 3D printing in copier technology is its application in architectural design. Architects traditionally rely on physical models to communicate their ideas and concepts to clients. However, creating these models can be time-consuming and expensive. With 3D printing capabilities integrated into copiers, architects can now quickly and cost-effectively produce accurate and intricate models. This not only speeds up the design process but also allows for better visualization and understanding of the proposed structures.

The Future of Copier Technology: Beyond 3D Printing

While 3D printing is undoubtedly a game-changer in copier technology, the future holds even more exciting possibilities. Researchers are already exploring advanced techniques, such as 4D printing, where objects can self-assemble or change shape over time. Additionally, the integration of artificial intelligence and machine learning algorithms can further enhance copier technology, enabling automated design optimization and intelligent material selection. As technology continues to evolve, copier technology is poised to become an integral part of the broader digital manufacturing ecosystem.

The integration of 3D printing into copier technology marks a significant milestone in the evolution of the industry. The benefits of 3D printing, such as enhanced efficiency, customization, and material advancements, are transforming various sectors. While challenges and limitations exist, ongoing research and development efforts promise to overcome these hurdles. As we look to the future, it is clear that copier technology will continue to evolve, offering new possibilities and reshaping the way we create and reproduce physical objects.

1. to 3D Printing

Three-dimensional (3D) printing, also known as additive manufacturing, is a revolutionary technology that allows the creation of physical objects from a digital design. Unlike traditional printing methods that use ink or toner to reproduce images or text on paper, 3D printing builds objects layer by layer using various materials such as plastic, metal, or even biological substances.

2. The Printing Process

The process of 3D printing begins with the creation of a digital model using computer-aided design (CAD) software. This model is then sliced into thin layers, typically between 0.1 to 0.3 millimeters thick, using specialized software. The sliced model is then sent to the 3D printer.

The 3D printer reads the sliced model and starts the printing process. It deposits material layer by layer, following the instructions from the digital model. The most common method of 3D printing is called fused deposition modeling (FDM), where a plastic filament is melted and extruded through a nozzle to create each layer.

Other 3D printing technologies include stereolithography (SLA), which uses a liquid resin that solidifies when exposed to ultraviolet light, and selective laser sintering (SLS), which uses a laser to fuse powdered material together.

3. Materials Used in 3D Printing

3D printing allows for a wide range of materials to be used, depending on the desired properties of the final object. Plastics, such as acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA), are commonly used due to their affordability and versatility. These materials can be found in various colors and can even be mixed to create new shades.

Metal 3D printing has also gained significant attention in recent years. Using technologies like selective laser melting (SLM) or electron beam melting (EBM), metal powders such as titanium, aluminum, or stainless steel can be melted and solidified layer by layer to create complex metal parts with high precision.

Other materials used in 3D printing include ceramics, glass, concrete, and even biological substances like living cells or bioinks for tissue engineering applications.

4. Applications of 3D Printing in Copier Technology

While 3D printing is commonly associated with manufacturing prototypes or small-scale production, its potential in copier technology is vast. Here are some key applications:

4.1. Customized Parts and Accessories

3D printing enables the creation of customized parts and accessories for copiers. Instead of relying on traditional manufacturing methods that require tooling and long lead times, 3D printing allows for on-demand production of specific components. This can reduce costs, increase efficiency, and improve maintenance processes.

4.2. Prototyping and Testing

With 3D printing, copier manufacturers can quickly produce prototypes of new models or components. This enables them to test different designs, evaluate functionality, and make necessary modifications before mass production. Rapid prototyping using 3D printing accelerates the innovation cycle and reduces time to market.

4.3. Complex Internal Structures

3D printing can create copier components with intricate internal structures that are difficult or impossible to manufacture using traditional methods. This allows for improved performance, weight reduction, and enhanced functionality. For example, 3D printing can produce lightweight and optimized cooling channels within copier parts, improving overall efficiency.

4.4. Spare Parts Availability

One of the significant advantages of 3D printing in copier technology is the ability to produce spare parts on-demand, even for older or discontinued models. This eliminates the need for extensive inventory management and ensures that spare parts are readily available when needed, prolonging the lifespan of copiers.

5. Future Developments

The future of copier technology and 3D printing is promising. Researchers are exploring new materials, such as conductive filaments for printing electronic components directly into copiers, or self-healing materials that can repair themselves when damaged.

Advancements in multi-material 3D printing will enable the creation of copier parts with varying properties in a single print, opening up new possibilities for functionality and customization.

Furthermore, the integration of 3D scanning technologies with 3D printing will allow for the replication of existing copier parts without the need for manual modeling, simplifying the replacement process.

3D printing has the potential to revolutionize copier technology by enabling customized production, rapid prototyping, and the creation of complex internal structures. The ability to produce spare parts on-demand ensures the longevity of copiers and reduces maintenance costs. With ongoing advancements, the future of copier technology looks promising as 3D printing continues to evolve and expand its capabilities.

The Birth of Copier Technology

The history of copier technology dates back to the early 20th century when the need for duplicating documents became evident in various industries. The first known copier machine, called the “Photostat,” was invented by the New York-based company, The Photostat Corporation, in 1907. This machine used a photographic process to create duplicate copies of documents.

Over the next few decades, copier technology continued to evolve, with various improvements and innovations. In the 1930s, the “mimeograph” machine was introduced, which used a stencil and ink to create multiple copies of a document. This technology was widely used in schools and offices for several years.

The Rise of Xerography

The real breakthrough in copier technology came in 1938 when Chester Carlson, an American physicist, invented a process called xerography. Xerography, which means “dry writing,” revolutionized the way documents were copied.

Carlson’s invention involved using a photoconductive surface, a drum, and a dry powder toner to create copies of documents. This process eliminated the need for messy liquids and chemicals, making it more efficient and convenient. In 1949, the first commercial xerographic copier, the Xerox Model A, was introduced by the Haloid Company, which later became Xerox Corporation.

Xerography quickly gained popularity, and by the 1960s, copiers were becoming a common sight in offices around the world. Xerox dominated the market with its innovative machines, which could produce high-quality copies at a faster rate than previous technologies.

The Digital Revolution

In the 1980s, copier technology took another leap forward with the advent of digital copiers. Digital copiers used a combination of scanning and laser printing technology to create copies of documents. This allowed for more precise reproduction of images and text, as well as the ability to store and retrieve digital copies.

As computers became more prevalent in offices, copiers started to integrate with digital networks, enabling users to send and receive documents directly from their computers. This integration marked the beginning of the convergence of copier technology with other digital technologies.

The Emergence of 3D Printing

In the early 2000s, a new form of copier technology emerged that would revolutionize the manufacturing industry – 3D printing. Although the concept of 3D printing had been around since the 1980s, it was only in the early 2000s that it started to gain mainstream attention.

3D printing, also known as additive manufacturing, allows for the creation of three-dimensional objects by depositing successive layers of material. This technology has the potential to transform various industries, including manufacturing, healthcare, and even fashion.

Initially, 3D printers were expensive and primarily used by large corporations and research institutions. However, as the technology advanced and became more affordable, it started to find its way into smaller businesses and even homes.

Today, 3D printing has become more accessible and versatile than ever before. The technology has evolved to the point where it can produce highly complex objects with a wide range of materials, including plastics, metals, and even human tissue.

One of the most significant advancements in 3D printing is the development of desktop 3D printers. These compact machines allow individuals and small businesses to create prototypes, custom products, and even replacement parts with ease.

Furthermore, advancements in software and design tools have made it easier for users to create and modify 3D models. This has opened up new possibilities for innovation and creativity, as individuals can now design and manufacture their own unique products.

Looking ahead, the future of copier technology, particularly in the realm of 3D printing, holds tremendous potential. As the technology continues to evolve, we can expect to see further improvements in speed, precision, and material options.

Additionally, 3D printing is likely to play a significant role in sustainable manufacturing practices. The ability to produce objects on-demand and reduce waste could have a profound impact on the environment.

Copier technology has come a long way since its inception, from the early days of photographic copying to the digital revolution and the emergence of 3D printing. As we look to the future, it is clear that copier technology, particularly in the form of 3D printing, will continue to shape and transform various industries, offering new possibilities and opportunities for innovation.

FAQs

1. What is 3D printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding material layer by layer. It is a revolutionary technology that allows the creation of complex shapes and structures that were previously difficult or impossible to achieve using traditional manufacturing methods.

2. How does 3D printing work?

3D printing works by using a computer-aided design (CAD) software to create a digital model of the object. The software then slices the model into thin layers, and the 3D printer reads these layers and prints them one by one using a variety of materials, such as plastic, metal, or even biological materials.

3. What are the advantages of 3D printing over traditional manufacturing?

3D printing offers several advantages over traditional manufacturing methods. Firstly, it allows for greater design freedom, as complex geometries can be easily created. It also enables rapid prototyping, reducing the time and cost required to develop new products. Additionally, 3D printing can reduce material waste and energy consumption compared to traditional manufacturing processes.

4. How is 3D printing being used in the copier industry?

In the copier industry, 3D printing is being used to create spare parts and components for copiers. This eliminates the need for storing large inventories of spare parts and reduces the time required to replace faulty components. 3D printing also enables the customization of copiers to meet specific customer requirements.

5. Can 3D printers produce functional copiers?

While 3D printers can produce certain components of a copier, such as casings or small parts, they are not yet capable of producing fully functional copiers. However, researchers and manufacturers are continuously working on developing more advanced 3D printing technologies that may one day make it possible to produce complete copiers using this method.

6. Are there any limitations to 3D printing in the copier industry?

Yes, there are some limitations to 3D printing in the copier industry. One limitation is the size of the objects that can be printed. Most desktop 3D printers have a limited build volume, which restricts the size of the copier components that can be produced. Additionally, the speed of 3D printing is generally slower compared to traditional manufacturing methods, which may not be suitable for mass production.

7. What are some future innovations in 3D printing for copier technology?

There are several exciting innovations in 3D printing for copier technology on the horizon. One area of development is the use of advanced materials, such as conductive inks, which could enable the printing of electronic components directly onto the copier. Another area of focus is the development of faster and larger-scale 3D printers, which could make it possible to print complete copiers in the future.

8. How will 3D printing impact the copier industry?

3D printing has the potential to significantly impact the copier industry. It could transform the supply chain by reducing the need for large inventories of spare parts and enabling on-demand production. This could result in cost savings and increased efficiency for copier manufacturers. Additionally, 3D printing could allow for greater customization and personalization of copiers, meeting the unique needs of individual customers.

9. Are there any concerns regarding the use of 3D printing in copier technology?

One concern regarding the use of 3D printing in copier technology is the potential for intellectual property infringement. As 3D printers become more accessible, there is a risk of unauthorized reproduction of patented copier designs. Additionally, the quality and reliability of 3D-printed components may be a concern, as they may not meet the same standards as traditionally manufactured parts.

10. How long until 3D printing becomes mainstream in the copier industry?

It is difficult to predict exactly when 3D printing will become mainstream in the copier industry. While the technology is already being used for certain applications, such as spare parts production, widespread adoption may take some time. As the technology continues to advance and become more cost-effective, we can expect to see increased integration of 3D printing in the copier industry in the coming years.

1. Explore the world of 3D printing

Start by familiarizing yourself with the basics of 3D printing. Research different types of 3D printers, materials they use, and their capabilities. This will help you understand the potential applications and determine which type of printer suits your needs.

2. Choose the right 3D printer

Consider factors such as cost, size, print quality, and ease of use when selecting a 3D printer. Determine whether you need a desktop printer for personal use or a professional-grade printer for more complex projects. Read reviews and compare specifications to make an informed decision.

3. Learn 3D modeling

Acquiring basic 3D modeling skills will enable you to create or modify designs for 3D printing. There are numerous software options available, both free and paid, that cater to different skill levels. Start with beginner-friendly software like Tinkercad or Fusion 360 and gradually progress to more advanced tools.

4. Join online communities

Engage with the 3D printing community by joining online forums, social media groups, and specialized websites. These platforms provide a wealth of knowledge, troubleshooting advice, and inspiration. Connect with experienced enthusiasts who can guide you through your journey and help you overcome any challenges you may encounter.

5. Experiment with different materials

Don’t limit yourself to a single material. Explore the wide range of filaments available for 3D printing, including PLA, ABS, PETG, and more. Each material has its own unique properties and applications. Experimenting with different materials will allow you to discover their strengths and limitations.

6. Start with simple projects

When you’re new to 3D printing, it’s best to start with simple projects to build your confidence and skills. Begin with small, practical items like phone stands, keychains, or customized accessories. As you gain experience, gradually take on more complex designs and challenging projects.

7. Embrace open-source designs

Take advantage of the vast library of open-source designs available online. Websites like Thingiverse and MyMiniFactory offer a wide range of free downloadable designs created by the community. You can use these designs as a starting point or modify them to suit your specific needs.

8. Consider sustainability

3D printing can be a sustainable alternative to traditional manufacturing methods if used responsibly. Optimize your designs to minimize material waste and energy consumption. Recycle or repurpose failed prints whenever possible. By embracing sustainability, you can contribute to a greener future.

9. Collaborate and share

Collaborate with others who share your passion for 3D printing. Participate in maker spaces, workshops, or local meetups to exchange ideas and knowledge. Share your own designs and contribute to the community. By collaborating and sharing, you can inspire others and learn from their experiences.

10. Stay updated

The field of 3D printing is constantly evolving, with new technologies, materials, and techniques emerging regularly. Stay updated with the latest advancements by following industry news, attending conferences, and exploring online resources. This will ensure you remain at the forefront of the technology and continue to expand your skills.

Common Misconceptions about

Misconception 1: 3D printing is only useful for creating small objects

One of the most common misconceptions about 3D printing is that it is only useful for creating small objects. Many people believe that 3D printers are limited in size and can only produce small trinkets or prototypes. However, this is far from the truth.

In recent years, there have been significant advancements in 3D printing technology, allowing for the creation of much larger objects. Industrial-grade 3D printers are now capable of producing life-sized furniture, architectural models, and even entire houses. These printers use a process called additive manufacturing, where layers of material are built up to create the desired object.

Moreover, 3D printing is not limited to just one material. While plastic is commonly used, there are now printers capable of using metal, ceramics, and even biological materials. This opens up a whole new world of possibilities for manufacturing, healthcare, and other industries.

Misconception 2: 3D printing is too expensive for everyday use

Another misconception about 3D printing is that it is too expensive for everyday use. While it is true that some high-end 3D printers can be quite costly, the technology is becoming more affordable and accessible to the average consumer.

Over the past decade, the price of 3D printers has significantly decreased, making them more affordable for individuals and small businesses. There are now entry-level 3D printers available for a few hundred dollars, allowing hobbyists and enthusiasts to explore the possibilities of 3D printing without breaking the bank.

Additionally, the cost of materials for 3D printing has also decreased. Filaments, which are the most commonly used materials in consumer-grade 3D printers, now come in a variety of options at different price points. This makes it easier for users to find affordable materials for their projects.

Furthermore, the cost savings associated with 3D printing can often outweigh the initial investment. For example, businesses can save money by producing prototypes in-house rather than outsourcing them to a third-party manufacturer. In some cases, 3D printing can even reduce waste and material costs by only using the exact amount of material needed to create an object.

Misconception 3: 3D printing will replace traditional manufacturing methods entirely

One of the biggest misconceptions about 3D printing is that it will completely replace traditional manufacturing methods. While 3D printing has revolutionized certain aspects of manufacturing, it is unlikely to replace traditional methods entirely.

Traditional manufacturing methods, such as injection molding and CNC machining, have their own advantages and are often more efficient for mass production. These methods are well-established, reliable, and can produce high-quality products at a lower cost per unit compared to 3D printing.

However, 3D printing excels in areas where traditional methods fall short. It offers greater design freedom, allowing for the creation of complex geometries and intricate details that would be difficult or impossible to achieve with traditional methods. Additionally, 3D printing enables rapid prototyping, reducing the time and cost required to develop new products.

Rather than replacing traditional manufacturing methods, 3D printing is more likely to complement them. Many manufacturers are incorporating 3D printing into their existing workflows to enhance their capabilities and improve efficiency.

It is important to dispel common misconceptions about the future of copier technology and innovations in 3D printing. By understanding the capabilities and potential of 3D printing, we can fully appreciate its impact on various industries and embrace the opportunities it presents. 3D printing is not limited to small objects, it is becoming more affordable, and it will not replace traditional manufacturing methods entirely. As technology continues to advance, we can expect even more exciting developments in the field of 3D printing.

Conclusion

The future of copier technology is being revolutionized by the advancements in 3D printing. This technology is not only transforming the way we create physical objects, but also providing numerous benefits in various industries. The ability to print three-dimensional objects with precision and accuracy opens up new possibilities in fields such as healthcare, manufacturing, and architecture.

Throughout this article, we have explored the key innovations in 3D printing that are shaping the future of copier technology. From the development of faster and more efficient printers to the use of advanced materials, these advancements are driving the adoption of 3D printing in a wide range of applications. Additionally, the integration of artificial intelligence and machine learning is further enhancing the capabilities of 3D printers, enabling them to optimize designs and improve the overall printing process.