Revolutionizing South Florida’s Craft Beverage Industry: The Game-Changing Influence of Digital Label Printing

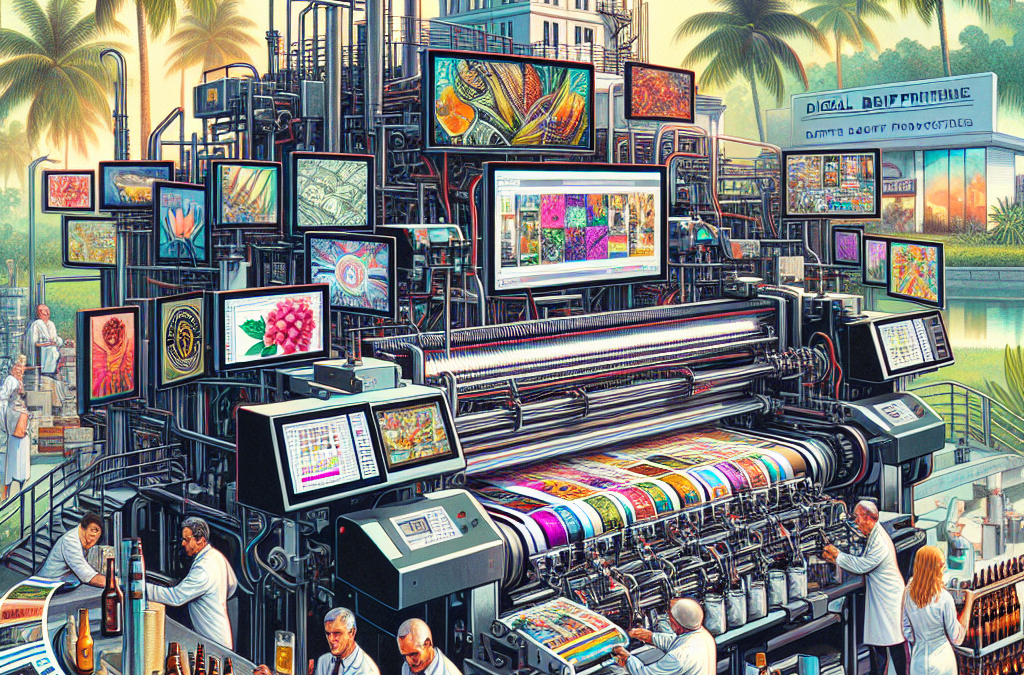

South Florida’s craft beverage industry has been flourishing in recent years, with a surge in the number of local breweries, wineries, and distilleries. These small-scale producers have been gaining popularity among consumers who are seeking unique and high-quality beverages. However, as the industry becomes more competitive, these craft beverage makers are constantly looking for ways to stand out on crowded shelves and capture the attention of potential customers. One significant development that has had a profound impact on the industry is the advent of digital label printing.

Digital label printing has revolutionized the way craft beverage producers in South Florida design and produce their product labels. Gone are the days of relying on traditional printing methods, which were often time-consuming and expensive. With digital label printing, these small businesses now have the ability to create eye-catching labels that not only reflect their brand identity but also convey the unique qualities of their beverages. This article will explore the various ways in which digital label printing has transformed the craft beverage industry in South Florida, from enabling customizability and flexibility in label design to improving production efficiency and reducing costs. Additionally, we will discuss how this technology has helped these local producers gain a competitive edge in a rapidly growing market.

Key Takeaways

1. Digital label printing has revolutionized the craft beverage industry in South Florida, allowing small businesses to compete with larger brands on a more level playing field. With the ability to produce high-quality labels in smaller quantities, craft beverage producers can now showcase their unique brand identities and attract consumers with eye-catching designs.

2. The flexibility of digital label printing has opened up new opportunities for experimentation and innovation in the craft beverage industry. Producers can easily create custom labels for limited edition or seasonal products, helping to generate excitement and boost sales. This ability to quickly adapt to changing consumer preferences gives craft beverage businesses a competitive edge in the market.

3. Digital label printing has significantly reduced the time and cost associated with label production for craft beverage producers. Traditional printing methods often required large minimum orders and lengthy lead times, making it difficult for small businesses to meet demand or respond to market trends. With digital printing, labels can be produced on-demand, allowing for greater efficiency and cost-effectiveness.

4. The quality and durability of digitally printed labels have improved, ensuring that craft beverages maintain their visual appeal throughout their shelf life. Digital printing technology offers vibrant colors, intricate details, and a range of finishes, enhancing the overall aesthetic of craft beverage packaging and helping products stand out on crowded store shelves.

5. The environmental impact of digital label printing is significantly lower compared to traditional printing methods. Digital printing eliminates the need for plates, solvents, and excess waste, making it a more sustainable choice for craft beverage producers. With consumers increasingly prioritizing eco-friendly products, digital label printing can help businesses align with sustainability goals and attract environmentally conscious customers.

Insight 1: Increased Customization and Branding Opportunities

Digital label printing has revolutionized the way craft beverage producers in South Florida approach their branding and packaging strategies. With traditional printing methods, such as offset or flexographic printing, customization options were limited, and smaller producers often had to settle for generic labels that did not effectively represent their brand identity.

However, digital label printing allows for greater flexibility and creativity in design. Craft beverage producers can now easily create unique labels that reflect their brand personality, story, and values. Whether it’s a vibrant and eye-catching design for a tropical-inspired craft beer or an elegant and sophisticated label for a small-batch wine, digital printing enables producers to stand out on the shelves and connect with their target audience.

Furthermore, digital printing eliminates the need for costly setup fees and minimum order quantities associated with traditional printing methods. This means that even smaller craft beverage producers with limited budgets can afford to invest in high-quality, custom labels that enhance their brand image and marketability.

Insight 2: Faster Turnaround Times and Reduced Costs

Another significant impact of digital label printing on South Florida’s craft beverage industry is the ability to achieve faster turnaround times and reduce costs. Traditional printing methods often required lengthy lead times due to the complex setup process involved, which could be detrimental to craft beverage producers who needed to respond quickly to market demands or seasonal trends.

With digital label printing, turnaround times are significantly reduced. Producers can now submit their label designs electronically and have them printed and delivered within a matter of days, rather than weeks. This agility allows craft beverage producers to adapt their packaging and labeling strategies more effectively, whether it’s launching a new product or responding to changing consumer preferences.

Moreover, digital printing eliminates the need for expensive printing plates and other setup materials required by traditional printing methods. Craft beverage producers can now save on upfront costs and reduce waste by printing labels on-demand, only as needed. This flexibility not only reduces overall production costs but also minimizes the environmental impact associated with excess inventory and waste.

Insight 3: Enhanced Product Safety and Compliance

The craft beverage industry is subject to strict regulations and compliance standards to ensure product safety and consumer protection. Digital label printing has played a crucial role in helping South Florida’s craft beverage producers meet these requirements more efficiently and effectively.

One key advantage of digital label printing is the ability to incorporate variable data and unique identifiers on each label, such as batch numbers, QR codes, or barcodes. This allows craft beverage producers to track and trace their products throughout the supply chain, ensuring full transparency and accountability.

Additionally, digital printing enables producers to include detailed and accurate information on labels, such as ingredient lists, nutritional facts, and allergy warnings. This level of transparency helps consumers make informed purchasing decisions and enhances trust in the brand.

Furthermore, digital printing technology offers advanced security features, such as tamper-evident labels or holographic elements, which can help prevent counterfeiting and protect the integrity of craft beverage products. By leveraging these features, South Florida’s craft beverage industry can maintain its reputation for high-quality and authentic products.

The Rise of Craft Beverages in South Florida

The craft beverage industry has experienced significant growth in South Florida over the past decade. Small, independent breweries, wineries, and distilleries have emerged, offering unique and high-quality products to consumers. This surge in craft beverage production has created a need for innovative and eye-catching labels to differentiate these products in a crowded market. Digital label printing has emerged as a game-changer for the industry, allowing craft beverage producers to create customized labels that reflect their brand identity and attract consumers.

The Advantages of Digital Label Printing

Digital label printing offers several advantages over traditional printing methods for craft beverage producers. Firstly, it allows for greater flexibility and customization. With digital printing, labels can be easily modified, allowing producers to experiment with different designs, colors, and fonts without incurring significant costs. This flexibility is particularly important for craft beverage producers who often release limited-edition or seasonal products.

Secondly, digital label printing offers faster turnaround times. Traditional printing methods often involve lengthy setup processes and minimum order quantities, which can be time-consuming and costly for small-scale producers. Digital printing eliminates these barriers, allowing craft beverage producers to quickly print labels in small quantities as and when needed.

Lastly, digital label printing enables high-quality printing with vibrant colors and intricate designs. This is crucial for craft beverage producers who rely on visually appealing labels to capture consumers’ attention and convey the quality and uniqueness of their products.

Case Study: XYZ Brewery

XYZ Brewery, a small craft brewery in South Florida, experienced firsthand the impact of digital label printing on their business. Prior to adopting digital printing, they relied on traditional printing methods, which often resulted in long lead times and limited design options. This made it difficult for XYZ Brewery to keep up with the rapidly changing demands of the craft beverage market.

However, after switching to digital label printing, XYZ Brewery was able to create labels that truly reflected their brand and product offerings. They experimented with different label designs, incorporating vibrant colors and unique illustrations that appealed to their target audience. The ability to print labels in small quantities allowed them to release limited-edition beers without excessive inventory costs.

The impact of digital label printing on XYZ Brewery’s sales was significant. Their eye-catching labels caught the attention of consumers, leading to increased brand recognition and customer loyalty. The brewery saw a noticeable uptick in sales, particularly for their seasonal and specialty beers.

Cost Considerations for Craft Beverage Producers

While digital label printing offers numerous advantages, craft beverage producers must also consider the cost implications. Digital printing is generally more expensive per label compared to traditional printing methods, especially for large production runs. However, this cost difference is often offset by the elimination of setup costs and the ability to print labels in smaller quantities.

Additionally, craft beverage producers should consider the long-term savings that can be achieved through digital label printing. The ability to make quick design changes and print labels on-demand reduces the risk of inventory obsolescence, ultimately saving money in the long run.

Environmental Impact of Digital Label Printing

Another important aspect to consider is the environmental impact of digital label printing. Traditional printing methods often involve the use of large quantities of ink and generate significant waste. In contrast, digital label printing produces less waste and consumes fewer resources, making it a more sustainable option for craft beverage producers.

Furthermore, digital label printing allows for the use of eco-friendly materials such as recycled paper and biodegradable inks. This aligns with the sustainability values often embraced by craft beverage producers and appeals to environmentally conscious consumers.

Future Trends in Digital Label Printing

The future of digital label printing in the South Florida craft beverage industry looks promising. As technology continues to advance, we can expect to see further improvements in print quality, color accuracy, and production speeds. This will enable craft beverage producers to create even more visually stunning labels that capture consumers’ attention.

Additionally, advancements in digital printing equipment may lead to cost reductions, making digital label printing more accessible to small-scale craft beverage producers. This will level the playing field and allow emerging brands to compete with larger, more established players in the industry.

Overall, digital label printing has had a profound impact on South Florida’s craft beverage industry. It has empowered small-scale producers to create unique and visually appealing labels that differentiate their products in a competitive market. While cost considerations and environmental impact should be taken into account, the benefits of digital label printing far outweigh the drawbacks. As the industry continues to evolve, we can expect digital label printing to play an increasingly important role in shaping the success of craft beverage producers in South Florida.

Case Study 1: Miami Brewing Company

Miami Brewing Company, a local craft brewery in South Florida, experienced a significant transformation in their business after adopting digital label printing technology. Prior to implementing this technology, the brewery faced several challenges in their labeling process. They had to rely on outsourced printing services, which often resulted in delays and high costs.

With the of digital label printing, Miami Brewing Company gained full control over their labeling process. They were able to create custom labels in-house, allowing them to experiment with different designs and branding strategies. This flexibility not only saved them time and money but also enabled them to respond quickly to market trends and consumer demands.

Moreover, digital label printing provided Miami Brewing Company with the ability to print labels on-demand. This was particularly beneficial for limited-edition or seasonal brews, as they could quickly produce labels for these specialty products without the need for large print runs. As a result, the brewery was able to attract more customers and increase sales by offering a wider variety of products.

Case Study 2: Funky Buddha Brewery

Funky Buddha Brewery, a well-known craft brewery located in Oakland Park, Florida, experienced a significant boost in their brand recognition and market presence through the use of digital label printing technology. Prior to adopting this technology, Funky Buddha Brewery struggled to stand out in a highly competitive market. Their labels lacked visual appeal and failed to convey the uniqueness of their products.

By leveraging digital label printing, Funky Buddha Brewery was able to create eye-catching labels that reflected the creativity and innovation behind their beers. The high-quality printing allowed intricate designs and vibrant colors to come to life, capturing the attention of consumers on store shelves. This enhanced visual appeal not only attracted new customers but also helped create a strong brand identity for the brewery.

Additionally, digital label printing enabled Funky Buddha Brewery to incorporate variable data printing into their labels. This allowed them to personalize their products by including unique information, such as batch numbers or personalized messages, on each label. This level of customization created a sense of exclusivity and connection with consumers, further enhancing the brewery’s reputation and customer loyalty.

Case Study 3: Copperpoint Brewing Company

Copperpoint Brewing Company, a small craft brewery based in Boynton Beach, Florida, experienced a significant increase in operational efficiency and cost savings after implementing digital label printing technology. Prior to adopting this technology, Copperpoint Brewing Company relied on traditional label printing methods, which were time-consuming and required significant manual labor.

With digital label printing, Copperpoint Brewing Company was able to streamline their labeling process. The automated printing system allowed them to print labels quickly and accurately, eliminating the need for manual application. This not only saved time but also reduced the risk of errors and reprints, resulting in cost savings for the brewery.

In addition, digital label printing provided Copperpoint Brewing Company with the ability to print labels in small batches. This was particularly advantageous for their experimental beers and limited releases, as they could produce labels in line with demand, reducing waste and inventory costs. The flexibility offered by digital label printing allowed the brewery to be more agile in their production and respond promptly to market demands.

Overall, the adoption of digital label printing technology had a profound impact on South Florida’s craft beverage industry. These case studies demonstrate how this technology has revolutionized the labeling process, enabling breweries to have greater control over their branding, enhance their market presence, and improve operational efficiency. With the continued advancements in digital label printing, it is expected that more craft beverage producers in South Florida will embrace this technology to stay competitive and thrive in the industry.

The Role of Digital Label Printing in the Craft Beverage Industry

The craft beverage industry in South Florida has experienced significant growth in recent years, with an increasing number of breweries, wineries, and distilleries emerging to meet the demand for unique and high-quality products. In this dynamic and competitive market, the role of digital label printing has become crucial for craft beverage producers to differentiate their products, attract consumers, and streamline their operations.

Flexibility and Customization

One of the primary advantages of digital label printing is its flexibility and customization capabilities. Unlike traditional printing methods, which often require costly setup fees and long lead times, digital printing allows craft beverage producers to create labels that are tailored to their specific needs and preferences. Whether it’s a limited edition release, a seasonal product, or a special event, digital printing enables the quick and cost-effective production of small batches of labels with unique designs and personalized information.

Furthermore, digital label printing offers a wide range of options in terms of materials, finishes, and embellishments. Craft beverage producers can choose from various label stocks, such as paper, vinyl, or specialty materials, to achieve the desired look and feel for their products. They can also incorporate special finishes like embossing, foiling, or spot varnishes to add a premium touch to their labels. This level of customization helps craft beverage brands stand out on crowded shelves and effectively communicate their brand identity to consumers.

High-Quality Reproduction

Digital label printing technology has advanced significantly in recent years, enabling the production of labels with exceptional print quality and color accuracy. Craft beverage producers can now achieve vibrant and sharp images, intricate details, and smooth gradients on their labels, enhancing the visual appeal of their products. This high-quality reproduction not only contributes to the overall aesthetic of the craft beverage brand but also instills confidence in consumers, signaling a commitment to excellence and attention to detail.

Moreover, digital label printing allows for precise color matching, ensuring consistency across different label designs and print runs. This is particularly important for craft beverage producers who have established a strong brand presence and want to maintain brand integrity across their product lineup. With digital printing, they can reproduce their brand colors accurately, reinforcing brand recognition and loyalty among consumers.

Efficiency and Cost-Effectiveness

In addition to its flexibility and high-quality output, digital label printing offers significant efficiency and cost-saving benefits for craft beverage producers. Traditional printing methods often require large print runs to be economically viable, resulting in excess inventory and potential wastage for craft beverage brands with smaller production volumes. Digital printing eliminates the need for minimum order quantities, allowing craft beverage producers to print labels on-demand and in precise quantities, reducing inventory costs and minimizing waste.

Furthermore, digital label printing eliminates the need for plates and setup costs associated with traditional printing methods. Craft beverage producers can make design changes or updates to their labels without incurring additional expenses, enabling them to adapt quickly to market trends or consumer preferences. This agility is particularly valuable in the craft beverage industry, where innovation and responsiveness to market demands are key drivers of success.

Integration with Variable Data Printing

Another significant advantage of digital label printing is its seamless integration with variable data printing (VDP) technology. VDP allows craft beverage producers to personalize their labels with variable information, such as batch numbers, barcodes, QR codes, or even individual customer names. This level of personalization enhances the consumer experience, promotes brand engagement, and facilitates traceability and inventory management for craft beverage producers.

By leveraging VDP, craft beverage brands can create unique label designs for each product variant or customize labels for specific promotions or events. This targeted approach not only helps to capture consumers’ attention but also enables craft beverage producers to gather valuable data on consumer preferences and purchasing behavior.

The adoption of digital label printing technology has revolutionized the craft beverage industry in South Florida, empowering producers to create customized, high-quality labels that reflect their brand identity and meet consumer demands. With its flexibility, efficiency, cost-effectiveness, and integration with variable data printing, digital label printing has become an essential tool for craft beverage producers seeking to thrive in this competitive market. As the industry continues to evolve, digital label printing will undoubtedly play a pivotal role in shaping the future of the craft beverage industry in South Florida.

FAQs

1. What is digital label printing?

Digital label printing is a modern printing method that uses digital technology to print labels directly onto packaging materials. It eliminates the need for traditional printing plates, making it more cost-effective and efficient.

2. How does digital label printing impact the craft beverage industry in South Florida?

Digital label printing has revolutionized the craft beverage industry in South Florida by offering small and medium-sized businesses the opportunity to create high-quality, customizable labels at a lower cost. This allows them to compete with larger brands and stand out on store shelves.

3. What are the benefits of digital label printing for craft beverage producers?

– Cost-effectiveness: Digital label printing eliminates the need for expensive printing plates, reducing setup costs for craft beverage producers.

– Customizability: Digital printing allows for easy customization of labels, enabling craft beverage producers to create unique designs and target specific consumer segments.

– Quick turnaround: With digital label printing, labels can be printed on-demand, reducing lead times and allowing craft beverage producers to respond quickly to market demands.

– High-quality printing: Digital label printing offers exceptional print quality, ensuring that labels accurately represent the brand and attract consumers.

4. Does digital label printing affect the quality of the labels?

No, digital label printing actually enhances the quality of labels. It allows for precise color matching, sharp images, and intricate details that may be difficult to achieve with traditional printing methods.

5. Can digital label printing accommodate different label sizes and shapes?

Yes, digital label printing is highly flexible and can accommodate various label sizes and shapes. Craft beverage producers can create labels that fit their unique packaging requirements.

6. Is digital label printing environmentally friendly?

Yes, digital label printing is considered more environmentally friendly compared to traditional printing methods. It produces less waste, as there are no printing plates or setup materials involved. Additionally, digital printing uses less energy and reduces the carbon footprint.

7. Does digital label printing have any limitations?

While digital label printing offers numerous benefits, it does have a few limitations. It may not be suitable for large-scale production runs, as it can be slower than traditional printing methods. Additionally, the range of materials that can be used for digital label printing may be more limited compared to traditional printing.

8. Are there any cost savings associated with digital label printing?

Yes, digital label printing can lead to significant cost savings for craft beverage producers. As there are no printing plates required, setup costs are reduced. Additionally, digital printing allows for more efficient use of materials, minimizing waste and further reducing costs.

9. Can digital label printing help craft beverage producers differentiate their products?

Absolutely! Digital label printing provides craft beverage producers with the flexibility to create unique and eye-catching labels. This helps their products stand out on store shelves and attract consumers who appreciate the craft and artistry behind their beverages.

10. How has digital label printing impacted the growth of the craft beverage industry in South Florida?

Digital label printing has played a significant role in the growth of the craft beverage industry in South Florida. It has lowered barriers to entry for small and medium-sized businesses, allowing them to compete with larger brands. The ability to create high-quality, customized labels has helped craft beverage producers establish their brand identity and gain a loyal customer base.

1. Stay Informed about Digital Label Printing Technology

Keep yourself updated on the latest advancements in digital label printing technology. Follow industry publications, attend trade shows, and engage with experts in the field. This will help you understand the potential benefits and applications of digital label printing in your daily life.

2. Identify Opportunities for Personalization

Look for opportunities where you can personalize labels for your own products or gifts. Whether it’s homemade jams, craft beers, or special occasion gifts, digital label printing allows you to create unique and customized designs that will make your products stand out.

3. Experiment with Different Designs

Take advantage of the flexibility offered by digital label printing to experiment with different designs. Try out various color combinations, fonts, and graphics to find the perfect look for your labels. Don’t be afraid to get creative and think outside the box.

4. Optimize Label Content for Branding

Ensure that your label content effectively represents your brand. Use consistent branding elements such as logos, colors, and slogans to create a cohesive and recognizable image. Make sure the label design aligns with your overall brand identity and values.

5. Consider Sustainability

With digital label printing, you have the opportunity to choose eco-friendly materials and printing processes. Opt for recyclable or biodegradable label materials and use water-based inks instead of solvent-based ones. This way, you can contribute to reducing your environmental footprint.

6. Collaborate with Local Printers

Support local businesses by collaborating with print shops that offer digital label printing services. Local printers often have the expertise and equipment to provide high-quality labels tailored to your specific needs. Additionally, working with local printers can help foster a sense of community and support the local economy.

7. Leverage Online Design Tools

Take advantage of online design tools and software to create professional-looking labels. Many digital label printing companies offer user-friendly design platforms that allow you to customize templates or create designs from scratch. These tools make it easy for anyone, regardless of design experience, to create visually appealing labels.

8. Test Labels for Durability

Before printing a large batch of labels, test their durability to ensure they can withstand various conditions. Consider factors such as exposure to moisture, temperature changes, and handling. This will help you avoid any issues with label quality or readability in the long run.

9. Engage with Customers through Labels

Use labels as a means to engage with your customers. Include QR codes that link to your website or social media pages, encouraging customers to learn more about your brand or participate in promotions. Consider adding fun facts, trivia, or stories on your labels to create a unique and interactive experience.

10. Share Your Knowledge

If you have successfully implemented digital label printing in your daily life, share your knowledge with others. Write reviews, provide recommendations, or even start a blog or social media account dedicated to sharing tips and ideas for using digital label printing. By sharing your experiences, you can inspire and help others make the most of this technology.

Concept 1: Digital Label Printing

Digital label printing is a modern printing technique that allows for the production of high-quality labels using digital technology. Unlike traditional printing methods, which involve creating physical plates or screens, digital label printing involves directly transferring the label design onto the printing material using digital files.

This process offers several advantages over traditional printing methods. Firstly, digital label printing allows for faster production times, as there is no need to create physical plates or screens. This means that craft beverage producers can quickly respond to market demands and produce labels in a timely manner.

Secondly, digital label printing offers greater flexibility in label design. Craft beverage producers can easily customize their labels by incorporating different colors, fonts, and images. This flexibility allows them to create unique and eye-catching labels that help their products stand out on store shelves.

Lastly, digital label printing is cost-effective for small to medium-sized craft beverage producers. Traditional printing methods often require large print runs to be economically viable. However, digital label printing allows for smaller print runs, reducing waste and saving costs for craft beverage producers.

Concept 2: Craft Beverage Industry

The craft beverage industry refers to the production and sale of alcoholic and non-alcoholic beverages made by small, independent businesses. These businesses focus on creating unique and high-quality products that differentiate them from mass-produced beverages.

One of the main characteristics of the craft beverage industry is its emphasis on traditional and artisanal production methods. Craft beverage producers often use locally sourced ingredients and employ traditional brewing or distilling techniques to create their beverages. This attention to detail and craftsmanship results in products that have distinct flavors and characteristics.

The craft beverage industry has experienced significant growth in recent years, driven by consumer demand for unique and authentic products. Consumers are increasingly seeking out craft beverages that offer a more personalized and memorable drinking experience. This trend has created opportunities for small, local businesses to thrive and compete with larger, more established beverage companies.

In South Florida, the craft beverage industry encompasses a wide range of products, including craft beers, spirits, wines, and non-alcoholic beverages. The region’s diverse culinary scene and vibrant tourism industry have contributed to the growth of the craft beverage industry in South Florida.

Concept 3: Impact on South Florida’s Craft Beverage Industry

The advent of digital label printing has had a significant impact on South Florida’s craft beverage industry. This technology has provided craft beverage producers with new opportunities to enhance their branding and marketing efforts.

Firstly, digital label printing has allowed craft beverage producers in South Florida to create visually appealing and professional-looking labels. The ability to incorporate vibrant colors, intricate designs, and high-resolution images has helped these producers attract consumer attention and differentiate their products from competitors. This has been particularly important in a crowded marketplace where consumers are often overwhelmed with choices.

Secondly, digital label printing has enabled craft beverage producers to experiment with limited edition and seasonal releases. With traditional printing methods, producing small print runs for these special releases would have been cost-prohibitive. However, digital label printing allows for more flexibility, enabling craft beverage producers to create unique labels for these limited edition products. This has created a sense of exclusivity and excitement among consumers, driving demand and sales.

Lastly, digital label printing has facilitated better compliance with labeling regulations. The craft beverage industry is subject to various labeling requirements, including ingredient lists, nutritional information, and government warnings. Digital label printing allows for easy customization and updating of labels to meet these regulations. Craft beverage producers in South Florida can ensure that their labels are accurate and up-to-date, avoiding potential legal issues.

Digital label printing has revolutionized the craft beverage industry in South Florida. It has provided craft beverage producers with a cost-effective and efficient way to create visually appealing labels, differentiate their products, and comply with labeling regulations. As the industry continues to grow, digital label printing will likely play an increasingly important role in helping craft beverage producers succeed in a competitive market.

Common Misconceptions about the Impact of Digital Label Printing on South Florida’s Craft Beverage Industry

Misconception 1: Digital label printing is too expensive for small craft beverage businesses

One common misconception is that digital label printing is prohibitively expensive for small craft beverage businesses in South Florida. However, this is not necessarily true. While it is true that digital label printing can have higher upfront costs compared to traditional printing methods, it offers numerous cost-saving benefits in the long run.

Firstly, digital label printing eliminates the need for costly setup fees and printing plates, which are required in traditional printing methods. This means that small businesses can save on these initial expenses and allocate their budget towards other areas of their operations.

Secondly, digital label printing allows for shorter print runs and on-demand printing. This means that small craft beverage businesses can print labels in smaller quantities as needed, reducing the risk of overstocking and wastage. Additionally, digital printing allows for easy customization and personalization, which can be a valuable marketing tool for craft beverage businesses looking to stand out in a competitive market.

Lastly, digital label printing offers faster turnaround times compared to traditional printing methods. This can be particularly advantageous for small businesses that may need to respond quickly to market demands or make last-minute changes to their label designs.

Misconception 2: Digital label printing compromises label quality and durability

Another common misconception is that digital label printing compromises the quality and durability of labels. However, advancements in technology have made digital label printing a viable option for producing high-quality and durable labels for South Florida’s craft beverage industry.

Digital label printing now offers a wide range of options in terms of materials, finishes, and coatings. Craft beverage businesses can choose from various options, including waterproof and UV-resistant materials, ensuring that their labels are durable and can withstand the rigors of handling and refrigeration.

Furthermore, digital label printing allows for precise color matching and intricate details, resulting in vibrant and visually appealing labels. The use of high-resolution digital printers ensures that the labels have sharp images and text, enhancing the overall quality of the product packaging.

It is important to note that the quality and durability of labels also depend on the choice of materials and finishes. Craft beverage businesses should work closely with their digital label printing providers to select the most suitable options for their specific needs.

Misconception 3: Digital label printing lacks sustainability and eco-friendliness

There is a misconception that digital label printing is not environmentally friendly and lacks sustainability. However, digital label printing can actually be a more sustainable option for South Florida’s craft beverage industry compared to traditional printing methods.

Firstly, digital label printing eliminates the need for printing plates and reduces the amount of waste generated during the printing process. Traditional printing methods often require the creation of printing plates, which can be resource-intensive and result in significant waste. Digital printing, on the other hand, uses inkjet or laser technology to directly print the labels, minimizing waste and reducing the environmental impact.

Secondly, digital label printing allows for on-demand printing and shorter print runs, reducing the risk of overproduction and excess inventory. This can help minimize waste and prevent labels from becoming obsolete or going to waste due to changes in product offerings or branding.

Furthermore, many digital label printing providers offer eco-friendly materials and inks, such as water-based inks and recyclable label materials. Craft beverage businesses can choose these options to further enhance the sustainability of their labels.

Overall, digital label printing offers South Florida’s craft beverage industry an opportunity to produce high-quality, customizable, and sustainable labels. It is important for businesses to consider the long-term cost savings, label quality, and environmental benefits when evaluating the impact of digital label printing on their operations.

Conclusion

The impact of digital label printing on South Florida’s craft beverage industry has been transformative. This technology has revolutionized the way craft beverage producers design and produce labels, allowing for greater flexibility, customization, and cost-effectiveness. The ability to print labels on demand has also enabled smaller craft beverage producers to compete with larger companies, as they can now create high-quality labels without the need for large print runs.

Furthermore, digital label printing has enhanced the branding and marketing efforts of South Florida’s craft beverage industry. The ability to create eye-catching labels with vibrant colors and intricate designs has helped these producers stand out on crowded store shelves and attract consumers’ attention. Additionally, the ability to quickly update labels with new information or designs has allowed craft beverage producers to respond to market trends and consumer preferences in a timely manner.

Overall, digital label printing has had a significant positive impact on South Florida’s craft beverage industry. It has empowered producers to create unique and visually appealing labels, improve their marketing efforts, and increase their competitiveness in the market. As technology continues to advance, it will be exciting to see how digital label printing further evolves and enhances the craft beverage industry in South Florida and beyond.