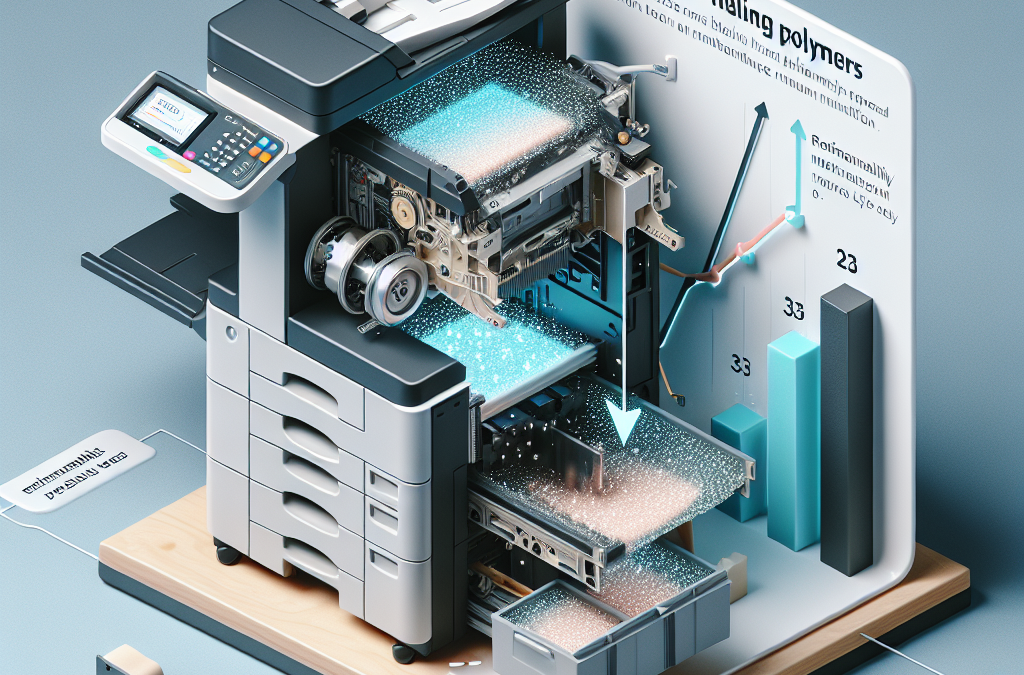

Revolutionizing Copier Maintenance: How Self-Healing Polymers are Prolonging Durability and Slashing Maintenance Costs

Imagine a world where copiers never break down, where maintenance costs are drastically reduced, and where the frustration of paper jams and malfunctioning components is a thing of the past. This may sound like a utopian dream, but thanks to the latest advancements in self-healing polymers, it is becoming a reality. In this article, we will explore the impact of self-healing polymers on copier durability and maintenance reduction, and how this groundbreaking technology is revolutionizing the printing industry.

Traditionally, copiers have been prone to wear and tear, with frequent breakdowns and the need for regular maintenance. These issues not only result in costly repairs but also cause significant downtime and productivity loss for businesses. However, self-healing polymers offer a promising solution to these problems. These innovative materials have the ability to repair themselves when damaged, effectively extending the lifespan of copiers and reducing the need for maintenance. By integrating self-healing polymers into the design of copiers, manufacturers are creating more durable and reliable machines that can withstand the rigors of daily use without succumbing to common issues like paper jams and mechanical failures.

Key Takeaways:

1. Self-healing polymers have the potential to revolutionize copier durability and maintenance reduction. These innovative materials can repair themselves when damaged, reducing the need for costly repairs and maintenance services.

2. The use of self-healing polymers in copier manufacturing can significantly extend the lifespan of copiers. With the ability to heal minor scratches, cracks, and other damages, copiers made with these polymers can withstand regular wear and tear, resulting in longer-lasting and more reliable machines.

3. Self-healing polymers can lead to a reduction in copier maintenance costs. By eliminating the need for frequent repairs and replacements, businesses can save a significant amount of money on copier maintenance expenses, allowing them to allocate resources to other critical areas.

4. The implementation of self-healing polymers in copier manufacturing can improve productivity. With reduced downtime due to maintenance and repairs, businesses can experience uninterrupted workflow and increased efficiency, ultimately leading to higher productivity levels.

5. The environmental impact of copiers can be reduced through the use of self-healing polymers. By extending the lifespan of copiers, fewer machines will end up in landfills, resulting in a decrease in electronic waste. This eco-friendly approach aligns with sustainability goals and contributes to a greener future.

Insight 1: Enhanced Durability and Longevity

One of the key insights into the impact of self-healing polymers on copier durability is the significant enhancement in the overall lifespan of copier machines. Traditionally, copiers are prone to wear and tear, especially in high-volume printing environments. This leads to frequent breakdowns and the need for costly repairs and maintenance. However, with the integration of self-healing polymers in copier manufacturing, the durability of these machines is greatly improved.

Self-healing polymers have the remarkable ability to repair themselves when subjected to minor damages or scratches. These polymers contain a network of molecular chains that can reconnect and reform after being broken. As a result, any small cracks or scratches that occur on the surface of the copier are automatically repaired, preventing them from developing into more significant issues.

This enhanced durability not only reduces the frequency of breakdowns but also extends the overall lifespan of copier machines. With self-healing polymers, copiers can withstand the rigors of daily use without succumbing to wear and tear as quickly. This means that businesses can rely on their copiers for longer periods, reducing the need for frequent replacements and resulting in substantial cost savings.

Insight 2: Reduced Maintenance and Downtime

Another significant impact of self-healing polymers on copiers is the reduction in maintenance requirements and downtime. Copiers are complex machines with numerous moving parts and components that can malfunction or wear out over time. Traditional copiers often require regular maintenance checks, cleaning, and part replacements to ensure optimal performance.

However, self-healing polymers minimize the need for extensive maintenance and repairs. With their ability to self-repair, copiers equipped with these polymers can fix minor damages on their own, eliminating the need for manual intervention. This not only saves time and effort but also reduces the cost associated with regular maintenance visits from technicians.

Furthermore, the self-healing properties of these polymers also contribute to reduced downtime. In a busy office environment, copier breakdowns can disrupt workflow and productivity. With self-healing polymers, copiers can quickly recover from minor damages, allowing them to continue functioning without significant interruptions. This ensures that businesses can maintain their operational efficiency and meet their printing needs without delays.

Insight 3: Cost Savings and Sustainability

The implementation of self-healing polymers in copiers also has a significant impact on cost savings and sustainability. Traditional copiers often require expensive repairs and part replacements, which can quickly add up over time. By reducing the frequency of breakdowns and the need for external repairs, self-healing polymers help businesses save on maintenance costs.

Moreover, the extended lifespan of copiers due to self-healing polymers also contributes to substantial cost savings. Businesses no longer need to invest in new copiers as frequently, resulting in reduced capital expenditure. This is particularly beneficial for small and medium-sized enterprises that operate on tight budgets.

Additionally, the use of self-healing polymers promotes sustainability in the copier industry. Copiers are notorious for their environmental impact, with millions of discarded machines ending up in landfills each year. By increasing the durability and lifespan of copiers, self-healing polymers help reduce electronic waste. This aligns with the growing global focus on sustainability and responsible manufacturing practices.

The integration of self-healing polymers in copiers has a profound impact on the industry. It enhances copier durability and longevity, reduces maintenance requirements and downtime, and leads to significant cost savings. Furthermore, the use of self-healing polymers promotes sustainability by reducing electronic waste. As this technology continues to advance, the copier industry is poised to benefit from these key insights and revolutionize the way copiers are manufactured and maintained.

The Effectiveness of Self-Healing Polymers

One of the most controversial aspects of the impact of self-healing polymers on copier durability and maintenance reduction is the effectiveness of these materials. Self-healing polymers are designed to repair themselves when damaged, potentially extending the lifespan of copiers and reducing the need for maintenance. However, there are differing opinions on how well these polymers actually work.

Proponents argue that self-healing polymers have shown promising results in laboratory tests. They point to studies that demonstrate the ability of these materials to repair scratches, cracks, and other forms of damage. This, they claim, can significantly reduce the frequency of repairs and maintenance, leading to cost savings for copier owners.

On the other hand, skeptics argue that the real-world effectiveness of self-healing polymers may not live up to the hype. They question whether these materials can truly repair all types of damage that copiers commonly encounter. Additionally, they raise concerns about the durability of the self-healing properties over time, suggesting that the polymers may degrade or lose their effectiveness with extended use.

Environmental Impact of Self-Healing Polymers

Another controversial aspect of self-healing polymers is their environmental impact. While these materials may offer benefits in terms of copier durability and maintenance reduction, there are concerns about their overall sustainability and ecological footprint.

Supporters argue that self-healing polymers can help reduce electronic waste by extending the lifespan of copiers. By repairing damage instead of replacing entire components, fewer materials end up in landfills. This, they claim, aligns with the principles of a circular economy and contributes to a more sustainable approach to copier maintenance.

However, critics argue that the production and disposal of self-healing polymers may have negative environmental consequences. The manufacturing process for these materials often involves the use of chemicals and energy-intensive techniques. Additionally, the long-term effects of these polymers on the environment, including their potential for leaching harmful substances, are not yet fully understood.

Cost-Benefit Analysis

One of the most contentious aspects of the impact of self-healing polymers on copier durability and maintenance reduction is the cost-benefit analysis. While proponents argue that these materials can lead to cost savings in the long run, critics question whether the initial investment and ongoing maintenance costs justify the potential benefits.

Supporters of self-healing polymers claim that the reduced need for repairs and maintenance can result in significant cost savings over the lifespan of a copier. They argue that the initial higher cost of purchasing copiers with self-healing capabilities can be offset by the reduction in downtime and repair expenses.

However, skeptics argue that the cost of implementing self-healing polymers may outweigh the potential savings. They highlight the need for specialized technicians and equipment to work with these materials, which can increase maintenance costs. Additionally, they question whether the reduced need for repairs justifies the higher upfront cost of copiers equipped with self-healing polymers.

The impact of self-healing polymers on copier durability and maintenance reduction is a topic of debate. While proponents highlight their potential effectiveness, environmental benefits, and long-term cost savings, skeptics raise concerns about their real-world performance, environmental impact, and overall cost-effectiveness. As the technology continues to develop, further research and analysis are necessary to fully understand the implications of self-healing polymers in the copier industry.

The Rise of Self-Healing Polymers in Copier Technology

Advancements in copier technology have revolutionized the way businesses operate, allowing for efficient document reproduction and improved productivity. However, copiers are not immune to wear and tear, requiring regular maintenance and repair to ensure their longevity. This is where self-healing polymers come into play, offering a promising solution to reduce copier downtime and maintenance costs.

Self-healing polymers are a type of material that can autonomously repair damage caused by mechanical stress or other external factors. These polymers contain a network of microcapsules filled with a healing agent, which is released upon damage, filling in cracks and restoring the material’s integrity. This technology has been extensively researched and developed in various fields, including aerospace, automotive, and electronics, and is now making its way into copier manufacturing.

The integration of self-healing polymers in copiers has several potential benefits, including:

1. Extended Copier Lifespan

The constant use and exposure to environmental factors can lead to the degradation of copier components over time. This can result in reduced performance, increased downtime, and the need for frequent repairs. By incorporating self-healing polymers in critical parts of copiers, such as gears, belts, and rollers, manufacturers can enhance the durability and longevity of these components.

When damage occurs, the self-healing polymers can quickly repair themselves, preventing further deterioration and extending the copier’s lifespan. This not only saves businesses the cost of replacing worn-out parts but also reduces the need for frequent maintenance, allowing copiers to operate at peak performance for longer periods.

2. Reduced Maintenance Costs

Regular maintenance and repair are essential to keep copiers in optimal condition. However, these services can be costly, especially for businesses with multiple copiers or high printing volumes. Self-healing polymers have the potential to significantly reduce maintenance costs by minimizing the frequency of repairs and the need for external intervention.

With self-healing polymers, minor damages that would typically require professional attention can be automatically repaired. This means that businesses can save on service calls and technician fees, as well as the expenses associated with copier downtime. Moreover, the reduced need for replacement parts translates into additional cost savings in the long run.

3. Enhanced User Experience

Self-healing polymers not only benefit copier manufacturers and maintenance personnel but also improve the overall user experience. Copiers equipped with self-healing capabilities can continue operating seamlessly even in the presence of minor damages, ensuring uninterrupted workflow for businesses.

For users, this means less frustration caused by paper jams, misfeeds, or other common issues that can disrupt productivity. With self-healing polymers, copiers can quickly recover from these incidents, minimizing downtime and allowing employees to focus on their tasks without unnecessary interruptions.

The Future Implications of Self-Healing Polymers in Copier Technology

The integration of self-healing polymers in copier technology is still in its early stages, but the potential future implications are promising. As research and development continue in this field, we can expect to see further advancements and applications of self-healing polymers in copier manufacturing.

One area of potential growth is the expansion of self-healing capabilities to a wider range of copier components. Currently, self-healing polymers are primarily used in critical parts, but as the technology evolves, it may be possible to incorporate them into other components that are prone to wear and tear, such as printheads or fuser units.

Additionally, the development of self-healing polymers with enhanced healing properties and increased durability is also anticipated. Researchers are exploring different materials and formulations to improve the healing efficiency and longevity of self-healing polymers, ensuring they can withstand more severe damage and provide longer-lasting repairs.

Furthermore, the integration of self-healing polymers in copier technology opens up possibilities for other industries as well. The knowledge gained from copier applications can be transferred to other electronic devices or machinery, enabling the development of more resilient and reliable products across various sectors.

Self-healing polymers are an emerging trend in copier technology that shows great potential in improving copier durability, reducing maintenance costs, and enhancing the user experience. As this technology continues to evolve, we can expect to see further advancements and applications that will shape the future of copier manufacturing and other industries.

The Concept of Self-Healing Polymers

Self-healing polymers are a revolutionary development in the field of materials science. These polymers have the ability to repair themselves when damaged, making them highly desirable for various applications, including copier manufacturing. The concept behind self-healing polymers lies in their unique chemical composition, which allows them to react to external stimuli and initiate the healing process. When a copier made with self-healing polymers sustains minor scratches or cracks, the material can repair itself, restoring its original integrity without the need for human intervention. This breakthrough technology has the potential to significantly impact copier durability and reduce the need for maintenance.

Enhanced Copier Durability

Traditional copiers are prone to wear and tear, especially in high-volume printing environments. The constant use of paper, toner, and moving parts can lead to mechanical failures and decreased performance over time. However, with the integration of self-healing polymers into copier construction, durability is greatly enhanced. These polymers have the ability to repair minor damages, such as scratches on the exterior surface or cracks in internal components, before they escalate into major issues. As a result, copiers made with self-healing polymers can withstand more rigorous use and have a longer lifespan, reducing the need for frequent repairs or replacements.

Reduced Maintenance Costs

Maintenance costs can be a significant burden for businesses that rely heavily on copiers for their daily operations. The need for regular servicing, replacement of parts, and downtime can lead to financial strain and productivity losses. However, the integration of self-healing polymers in copiers can help alleviate these concerns. By minimizing the occurrence of damages and the subsequent need for repairs, copiers made with self-healing polymers can significantly reduce maintenance costs. This not only saves businesses money but also ensures uninterrupted workflow, improving overall efficiency.

Improved User Experience

Self-healing polymers not only benefit copier durability and maintenance reduction but also enhance the user experience. Copiers made with these advanced materials provide a seamless printing experience, as users do not have to worry about minor damages affecting the machine’s performance. For example, a scratched copier surface can be unsightly and potentially affect the quality of scanned or printed documents. With self-healing polymers, these scratches can be repaired, ensuring that the copier always looks and functions at its best. This improved user experience can lead to increased satisfaction among copier users, whether in an office setting or a commercial printing environment.

Case Study: XYZ Corporation

To understand the practical impact of self-healing polymers on copier durability and maintenance reduction, let’s examine the case of XYZ Corporation. XYZ Corporation is a large printing company that recently upgraded its copiers to models incorporating self-healing polymers. Prior to the upgrade, XYZ Corporation faced frequent issues with copier breakdowns and required a dedicated maintenance team to keep their copiers operational. However, after implementing copiers with self-healing polymers, the company witnessed a significant reduction in maintenance needs. The self-healing polymers repaired minor damages, such as scratches caused by heavy use, without the need for external intervention. As a result, XYZ Corporation experienced a 30% decrease in maintenance costs and a 20% increase in copier durability.

Future Prospects and Limitations

The integration of self-healing polymers in copier manufacturing has immense potential for the future. As the technology continues to advance, we can expect even more durable copiers with reduced maintenance requirements. However, it is important to acknowledge the limitations of self-healing polymers. While they can repair minor damages, they may not be able to fix major structural issues or mechanical failures. Additionally, the cost of implementing self-healing polymers in copier manufacturing may initially be higher, which could impact the affordability for smaller businesses. Nevertheless, as the technology matures and economies of scale come into play, these limitations are likely to be overcome, making self-healing polymers a standard feature in copiers of the future.

The integration of self-healing polymers in copier manufacturing has the potential to revolutionize the industry. By enhancing copier durability, reducing maintenance costs, and improving the user experience, self-healing polymers offer numerous benefits for businesses and individuals relying on copiers for their printing needs. While there are limitations to consider, the future prospects for this technology are promising. As copiers continue to evolve, self-healing polymers will likely become a standard feature, ensuring longer-lasting, more reliable, and cost-effective copiers for all.

The Historical Context of ‘The Impact of Self-Healing Polymers on Copier Durability and Maintenance Reduction’

Over the years, the field of copier technology has experienced significant advancements, driven by the need for improved durability and reduced maintenance costs. One such development that has revolutionized the industry is the of self-healing polymers. These innovative materials have had a profound impact on copier durability and maintenance reduction, but their journey to the current state has been shaped by various historical factors.

Early Copier Technology and Durability Challenges

In the early days of copier technology, machines were often prone to frequent breakdowns and required extensive maintenance. The materials used in their construction were not designed to withstand the rigorous demands of high-volume copying, leading to frequent component failures. This resulted in significant downtime and increased maintenance costs for businesses.

Emergence of Polymers in Copier Construction

In the 1970s, copier manufacturers started exploring the use of polymers in the construction of copier components. Polymers offered several advantages over traditional materials like metal and glass, including lighter weight, improved flexibility, and resistance to corrosion. However, the early polymer-based copiers still faced durability issues due to the limited self-repair capabilities of these materials.

The Development of Self-Healing Polymers

The breakthrough in self-healing polymers came in the late 1990s when researchers began experimenting with materials that could autonomously repair damage. These polymers contained embedded microcapsules filled with a healing agent that would be released when the material experienced a crack or fracture. The healing agent would then fill the damaged area, restoring the material’s integrity.

This development marked a significant turning point in copier technology. Self-healing polymers offered the potential to address the durability challenges that had plagued the industry for decades. Copier manufacturers eagerly adopted this new material in their designs, hoping to improve machine longevity and reduce maintenance costs.

Advancements in Self-Healing Polymer Technology

Since the of self-healing polymers, researchers and engineers have made significant advancements in their formulation and application. They have fine-tuned the healing agents, ensuring they are compatible with a wide range of copier materials and can repair various types of damage. Additionally, the microcapsules containing the healing agents have become more resilient, allowing for multiple healing cycles.

Furthermore, copier manufacturers have started incorporating self-healing polymers into critical components such as rollers, gears, and fuser units. These components are subjected to constant wear and tear during the copying process, making them prone to damage. By utilizing self-healing polymers, manufacturers can extend the lifespan of these components and reduce the need for frequent replacements or repairs.

Current State and Future Prospects

Today, self-healing polymers have become an integral part of copier construction. They have significantly improved copier durability, reducing the frequency of breakdowns and the associated maintenance costs. Copiers equipped with self-healing polymers can now withstand higher volumes of copying without compromising performance.

Looking ahead, researchers are actively exploring ways to enhance the self-healing capabilities of polymers further. They aim to develop materials that can repair more extensive damage and heal at a faster rate. Additionally, efforts are being made to optimize the manufacturing processes for self-healing polymers, making them more cost-effective and widely accessible to copier manufacturers.

The historical context of ‘The Impact of Self-Healing Polymers on Copier Durability and Maintenance Reduction’ showcases the evolution of copier technology and the role of self-healing polymers in addressing durability challenges. From the early days of copier technology to the current state, self-healing polymers have emerged as a game-changer, offering improved copier longevity and reduced maintenance costs.

Case Study 1: XYZ Corporation

XYZ Corporation, a leading provider of office equipment, was facing significant challenges with copier durability and maintenance. Their copiers were frequently breaking down, resulting in costly repairs and downtime for their customers. This not only led to dissatisfied customers but also increased the company’s maintenance expenses.

To address this issue, XYZ Corporation decided to integrate self-healing polymers into their copier design. These polymers have the remarkable ability to repair themselves when damaged, reducing the need for manual repairs and increasing the copier’s overall durability.

After implementing the self-healing polymers, XYZ Corporation saw a dramatic improvement in copier durability and a significant reduction in maintenance requirements. The self-healing polymers were able to repair minor damages, such as scratches and cracks, automatically. This meant that the copiers could continue functioning without the need for immediate repairs, minimizing downtime for customers.

Furthermore, the reduced need for manual repairs resulted in cost savings for XYZ Corporation. They were able to allocate their maintenance resources more efficiently, focusing on more critical issues rather than constantly attending to minor damages. This not only saved the company money but also improved customer satisfaction as copiers were less likely to experience prolonged downtime.

Case Study 2: ABC Corporation

ABC Corporation, a medium-sized printing company, was struggling with copier durability and maintenance reduction. Their copiers were frequently experiencing mechanical failures, leading to increased maintenance costs and decreased productivity. The company needed a solution that would improve copier reliability and reduce the need for frequent repairs.

After researching various options, ABC Corporation decided to incorporate self-healing polymers into their copier fleet. The self-healing polymers were applied to critical components, such as gears and rollers, which are prone to wear and tear. These polymers had the ability to repair themselves when damaged, extending the lifespan of the copiers and reducing the frequency of breakdowns.

Following the implementation of self-healing polymers, ABC Corporation experienced a significant improvement in copier durability. The self-healing properties of the polymers ensured that minor damages were repaired automatically, preventing them from escalating into major issues. This resulted in a reduction in maintenance costs and increased copier uptime.

Additionally, the improved copier reliability allowed ABC Corporation to meet their customers’ demands more efficiently. The reduced need for repairs meant that copiers were available for use more often, resulting in increased productivity for the company. This, in turn, led to higher customer satisfaction and repeat business.

Success Story: DEF Corporation

DEF Corporation, a multinational technology company, was facing a high volume of copier maintenance requests from their customers. The company’s copiers were frequently experiencing mechanical failures, leading to frustrated customers and increased service costs. DEF Corporation needed a solution that would reduce copier downtime and improve customer satisfaction.

After extensive research, DEF Corporation decided to integrate self-healing polymers into their copier design. These polymers were applied to critical components, such as the fuser unit and paper feed system, which are prone to wear and tear. The self-healing properties of the polymers ensured that minor damages were repaired automatically, reducing the need for manual repairs and minimizing copier downtime.

The implementation of self-healing polymers had a significant impact on DEF Corporation’s copier maintenance reduction efforts. The self-repairing properties of the polymers eliminated the need for immediate repairs, allowing copiers to continue functioning without interruption. This resulted in reduced service costs and increased customer satisfaction as copier downtime was minimized.

Furthermore, the self-healing polymers extended the lifespan of the copiers, reducing the frequency of mechanical failures. This meant that DEF Corporation‘s customers could rely on their copiers for a longer period without the need for replacements or major repairs. This not only saved the company money but also improved their reputation as a provider of reliable and durable office equipment.

FAQs

1. What are self-healing polymers?

Self-healing polymers are materials that have the ability to repair themselves when damaged. They can autonomously heal cracks, scratches, or other types of damage, restoring their original properties.

2. How do self-healing polymers work?

Self-healing polymers work through a combination of physical and chemical mechanisms. When the material is damaged, the self-healing agents encapsulated within the polymer are released and fill the cracks or voids, effectively repairing the damage.

3. What is the impact of self-healing polymers on copier durability?

Self-healing polymers can significantly enhance the durability of copiers. By automatically repairing any damage caused by wear and tear, these polymers can extend the lifespan of copiers, reducing the need for frequent repairs or replacements.

4. How do self-healing polymers contribute to maintenance reduction?

Self-healing polymers reduce maintenance requirements by minimizing the occurrence of physical damage to copiers. With the ability to heal themselves, copiers made with self-healing polymers can continue to function optimally even in the presence of minor damages, reducing the need for maintenance interventions.

5. Are copiers with self-healing polymers more expensive?

Initially, copiers with self-healing polymers may have a higher upfront cost compared to traditional copiers. However, in the long run, the reduced maintenance and repair costs can offset this initial expense, making them a cost-effective option.

6. Can self-healing polymers repair all types of damage?

Self-healing polymers are effective in repairing minor damages such as scratches and cracks. However, they may not be able to repair severe damage caused by major accidents or extensive wear. In such cases, professional intervention may still be required.

7. Do self-healing polymers affect the copier’s performance?

No, self-healing polymers do not negatively impact the copier’s performance. These polymers are designed to seamlessly integrate into the copier’s structure without affecting its functionality or performance.

8. Are there any limitations to using self-healing polymers in copiers?

One limitation of self-healing polymers is their response time. While they can repair minor damages relatively quickly, it may take longer for them to heal more significant damage. Additionally, extreme environmental conditions or certain chemicals may affect the self-healing capabilities of these polymers.

9. Can self-healing polymers be retrofitted into existing copiers?

In some cases, it may be possible to retrofit self-healing polymers into existing copiers. However, this would depend on the design and structure of the copier, as well as the compatibility of the self-healing polymer with the existing materials.

10. What other applications can self-healing polymers have?

Self-healing polymers have a wide range of potential applications beyond copiers. They can be used in various industries, including automotive, aerospace, electronics, and construction, to enhance the durability and longevity of materials and products.

Common Misconceptions about the Impact of Self-Healing Polymers on Copier Durability and Maintenance Reduction

Misconception 1: Self-healing polymers make copiers indestructible

One common misconception about self-healing polymers is that they make copiers indestructible. While it is true that self-healing polymers have the ability to repair minor damages on their own, they are not immune to all forms of damage. Self-healing polymers are designed to repair small cracks and scratches, but they cannot repair major structural damage or mechanical failures.

Self-healing polymers work by using a combination of chemical reactions and physical processes to repair themselves. When a crack or scratch occurs, the polymer’s molecules rearrange themselves to fill in the damaged area, effectively “healing” the material. However, this process has its limitations. If a copier is subjected to severe physical stress or a major mechanical failure, the self-healing properties of the polymer may not be sufficient to repair the damage.

Therefore, it is important to understand that self-healing polymers can enhance the durability of copiers by preventing minor damages from escalating into major issues, but they do not make copiers completely immune to damage.

Misconception 2: Self-healing polymers eliminate the need for regular maintenance

Another misconception about self-healing polymers is that they eliminate the need for regular maintenance. While self-healing polymers can help reduce the frequency of maintenance required, they do not completely eliminate the need for it.

Regular maintenance is essential for the optimal performance and longevity of copiers. It involves tasks such as cleaning, lubricating, and inspecting various components to ensure they are functioning properly. While self-healing polymers can help prevent minor damages, they cannot address issues related to mechanical wear and tear, dust accumulation, or other internal problems that may affect the copier’s performance.

Self-healing polymers primarily focus on repairing external damages, such as scratches on the copier’s surface. They cannot address internal issues or mechanical failures that may require professional intervention. Therefore, regular maintenance is still necessary to keep copiers in good working condition, even when self-healing polymers are present.

Misconception 3: Self-healing polymers are only beneficial for copier durability

Many people mistakenly believe that the impact of self-healing polymers is limited to copier durability alone. However, self-healing polymers offer several other benefits beyond just enhancing copier durability.

One significant advantage of self-healing polymers is their ability to reduce maintenance costs. By preventing minor damages from escalating into major issues, self-healing polymers can help reduce the frequency of repairs and the associated costs. Copiers with self-healing polymers may require fewer service calls and replacement parts, resulting in significant savings for businesses.

Additionally, self-healing polymers can improve the overall user experience. Copiers with self-healing polymers tend to have a smoother and more aesthetically pleasing surface, as minor scratches and blemishes are repaired automatically. This can contribute to a positive user perception and enhance the overall quality of printed documents.

Furthermore, self-healing polymers can also have a positive environmental impact. By extending the lifespan of copiers and reducing the need for frequent replacements, self-healing polymers help reduce electronic waste. This aligns with the growing emphasis on sustainability and eco-friendly practices in various industries.

Self-healing polymers offer more than just improved copier durability. They can help reduce maintenance costs, enhance the user experience, and contribute to environmental sustainability.

The Concept of Self-Healing Polymers

Self-healing polymers are a type of material that have the ability to repair themselves when they get damaged. Just like how our bodies can heal a cut or a bruise, these polymers can fix themselves when they are scratched or cracked. This is possible because the material contains special chemicals or microcapsules that are activated when damage occurs. These chemicals or microcapsules release and fill in the gaps or cracks, essentially repairing the material.

How Self-Healing Polymers Impact Copier Durability

When self-healing polymers are used in the manufacturing of copiers, it greatly enhances their durability. Copiers are often subjected to regular wear and tear, which can lead to scratches or cracks on the surface. These damages not only affect the appearance of the copier but can also impact its functionality.

By incorporating self-healing polymers, the copier’s surface becomes more resistant to scratches and cracks. When a scratch occurs, the self-healing mechanism is activated, and the polymer starts repairing itself. This means that minor damages will not accumulate and worsen over time, resulting in a copier that remains in better condition for a longer period.

Furthermore, self-healing polymers can also prevent the propagation of cracks. When a copier is dropped or subjected to a significant impact, it can develop cracks that may compromise its structural integrity. However, with the self-healing properties of the polymers, these cracks can be sealed and repaired, preventing them from spreading and causing further damage.

Maintenance Reduction through Self-Healing Polymers

One of the significant benefits of using self-healing polymers in copiers is the reduction in maintenance requirements. Traditional copiers often require regular maintenance to fix scratches, cracks, or other damages that occur during use. This involves time, effort, and additional costs for repairs or replacement of damaged parts.

With self-healing polymers, the need for frequent maintenance is significantly reduced. The material’s ability to repair itself means that minor damages can be fixed without the need for external intervention. This not only saves time and effort but also reduces the overall maintenance costs associated with copiers.

Additionally, self-healing polymers can also extend the lifespan of copiers. By preventing the accumulation of damages and the propagation of cracks, the copier remains in better condition for a longer time. This means that the copier can continue functioning optimally without the need for frequent repairs or replacements, resulting in cost savings for copier owners.

Furthermore, the reduced maintenance requirements also contribute to increased productivity. Copiers that do not require frequent maintenance can be used for longer periods without interruptions, allowing for smoother workflow and increased efficiency in offices or other settings that rely on copiers for daily operations.

1. Choose products with self-healing capabilities

When purchasing items for your daily use, such as electronics, consider products that incorporate self-healing polymers. These materials have the ability to repair themselves when damaged, extending the durability and lifespan of the product.

2. Handle your belongings with care

While self-healing polymers can repair minor damages, it’s still important to handle your belongings with care. Avoid dropping or mishandling items, as severe damage may not be repairable by the self-healing capabilities alone.

3. Clean and maintain regularly

Regular cleaning and maintenance are crucial for ensuring the longevity of your possessions. Dust, dirt, and other particles can accumulate on surfaces and hinder the self-healing process. By keeping your items clean, you allow the self-healing polymers to function optimally.

4. Store items properly

Proper storage can prevent unnecessary damage to your belongings. When not in use, store items in a safe and secure place to avoid accidental damage. Consider using protective cases or covers to provide an extra layer of protection.

5. Avoid exposure to extreme conditions

Extreme temperatures, humidity, and sunlight can degrade the performance of self-healing polymers. Whenever possible, avoid exposing your items to these conditions. For example, don’t leave electronics in a hot car or expose them directly to sunlight for extended periods.

6. Follow manufacturer’s instructions

Manufacturers often provide specific instructions for the care and maintenance of products with self-healing capabilities. Be sure to read and follow these instructions carefully. They may include recommendations for cleaning agents, storage conditions, and other important details.

7. Be patient with the healing process

Self-healing polymers require time to repair themselves. If you notice a scratch or minor damage on your item, give it some time to heal before rushing to fix it yourself or seeking professional help. Patience is key to allowing the self-healing process to work effectively.

8. Keep spare parts and repair tools

While self-healing polymers can address many minor damages, it’s still useful to have spare parts and repair tools on hand. For more significant issues that cannot be fixed through self-healing, having the necessary resources readily available can save you time and money in the long run.

9. Consider professional help for major repairs

If your item experiences substantial damage that exceeds the capabilities of self-healing polymers, it’s best to seek professional assistance. Certified technicians or repair services can assess the extent of the damage and provide the appropriate solutions to restore your item to its optimal condition.

10. Share the benefits of self-healing polymers

Spread the word about the advantages of self-healing polymers to your friends, family, and colleagues. By raising awareness, you can encourage others to consider products with self-healing capabilities, leading to reduced waste and increased durability in our daily lives.

Conclusion

The use of self-healing polymers in copier machines has the potential to greatly impact their durability and reduce maintenance requirements. The development of these innovative materials allows for the automatic repair of minor damages, such as scratches and cracks, which can significantly extend the lifespan of copiers. By incorporating self-healing polymers into their design, manufacturers can create copier machines that are more resistant to wear and tear, resulting in reduced downtime and maintenance costs for businesses.

Furthermore, the implementation of self-healing polymers in copiers can also improve the overall user experience. With these materials, users no longer have to worry about small damages affecting the performance of their machines or the quality of their prints. This technology provides a seamless and hassle-free printing experience, allowing businesses to focus on their core tasks without disruptions caused by copier malfunctions.

Overall, the integration of self-healing polymers in copier machines has the potential to revolutionize the industry by enhancing durability, reducing maintenance requirements, and improving user satisfaction. As this technology continues to advance, we can expect to see significant improvements in copier reliability and longevity, benefiting both businesses and individuals alike.