Revolutionizing Paper Handling: How Soft Robotics is Transforming Adaptive Mechanisms

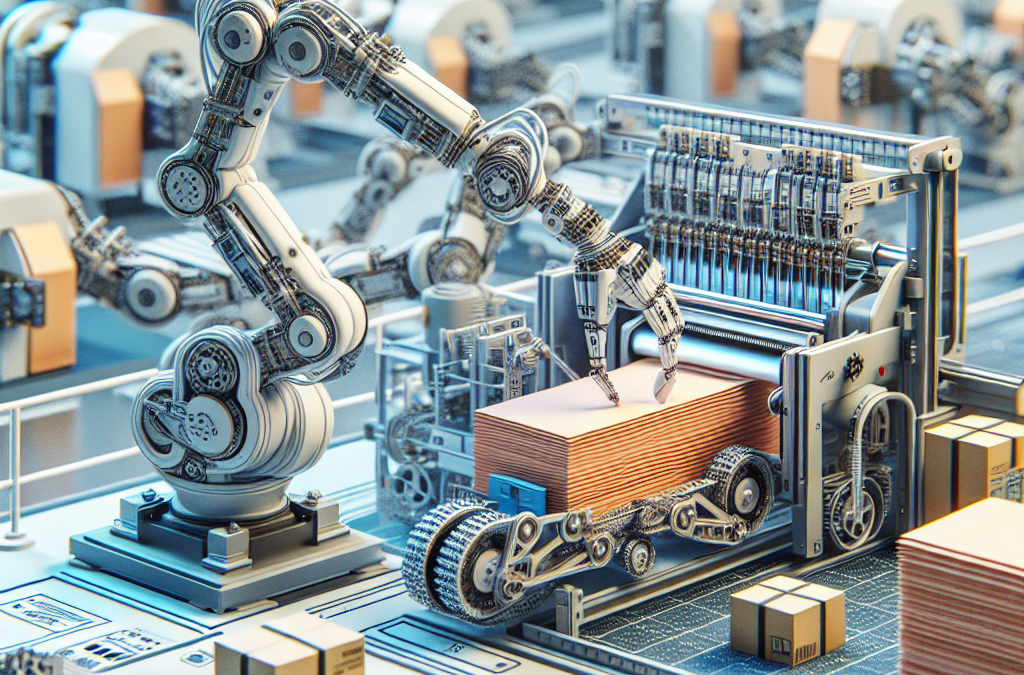

In the world of automation and robotics, the ability to handle delicate objects with precision and care has always posed a challenge. This is particularly true when it comes to paper handling mechanisms, where traditional rigid robots often struggle to maintain the necessary finesse. However, a new solution is emerging in the form of soft robotics, a field that combines the flexibility and adaptability of biological systems with the power and precision of machines. In this article, we will explore the role of soft robotics in adaptive paper handling mechanisms, delving into the innovative technologies and applications that are revolutionizing the way we handle paper.

Soft robotics, a rapidly growing field at the intersection of engineering and biology, offers a promising solution to the limitations of traditional rigid robots in handling delicate materials such as paper. By incorporating soft and flexible materials, soft robots can mimic the dexterity and compliance of human hands, allowing for gentler and more precise manipulation. This opens up a range of possibilities in industries that heavily rely on paper handling, such as printing, packaging, and mail sorting.

Key Takeaways:

1. Soft robotics offers a promising solution for adaptive paper handling mechanisms, revolutionizing the way paper is handled in various industries.

2. Soft robotic grippers provide enhanced dexterity and flexibility, allowing for gentle and precise handling of delicate paper materials.

3. The compliance and adaptability of soft robotic systems enable them to handle a wide range of paper sizes, shapes, and textures with ease.

4. Soft robotics can significantly improve the efficiency and productivity of paper handling processes, reducing the risk of damage and increasing overall throughput.

5. The integration of soft robotics with advanced sensing technologies enables real-time feedback and control, ensuring optimal handling and preventing errors or accidents.

Controversial Aspect 1: Ethical implications of replacing human workers

One of the most controversial aspects surrounding the role of soft robotics in adaptive paper handling mechanisms is the potential impact on human workers. As automation technology advances, there is a concern that the widespread adoption of soft robotics in industries like paper handling could lead to job losses and unemployment.

Proponents argue that soft robotics can improve efficiency and productivity, leading to cost savings for businesses. They believe that by automating repetitive and physically demanding tasks, soft robotics can free up human workers to focus on more complex and creative aspects of their jobs. This could ultimately lead to higher job satisfaction and better career opportunities.

However, critics argue that the displacement of human workers by robots can have detrimental effects on individuals and communities. They highlight the potential loss of livelihoods and the social and economic consequences that may arise from widespread job automation. Additionally, they raise concerns about the unequal distribution of wealth and power that could result from the concentration of resources in the hands of a few.

While there are valid arguments on both sides, it is essential to consider the ethical implications of replacing human workers with soft robotics. Striking a balance between technological advancements and the well-being of workers should be a priority.

Controversial Aspect 2: Environmental impact of soft robotics

Another controversial aspect of the role of soft robotics in adaptive paper handling mechanisms is the environmental impact of these technologies. Soft robotics often rely on complex mechanisms and materials, including sensors, actuators, and synthetic polymers, which can have significant environmental consequences.

Advocates argue that soft robotics can contribute to sustainability efforts by reducing energy consumption and waste production. They believe that these technologies can optimize processes, leading to more efficient use of resources in industries like paper handling. For example, soft robotic grippers can adapt to different shapes and sizes of paper, reducing the amount of material wasted during handling and processing.

However, critics raise concerns about the carbon footprint associated with the production and disposal of soft robotics components. The manufacturing processes and materials used in these technologies may require significant amounts of energy and generate harmful byproducts. Additionally, the disposal of soft robotics components at the end of their lifecycle can contribute to electronic waste and pollution.

It is crucial to carefully evaluate the environmental impact of soft robotics in adaptive paper handling mechanisms and consider ways to mitigate any negative consequences. This may involve developing more sustainable materials and manufacturing processes, as well as implementing responsible recycling and disposal practices.

Controversial Aspect 3: Safety and reliability concerns

Safety and reliability are also controversial aspects when it comes to the role of soft robotics in adaptive paper handling mechanisms. Soft robots, by their nature, are designed to interact with delicate and fragile objects, such as paper. Ensuring the safety of both the robots and the objects they handle is of utmost importance.

Proponents argue that soft robotics can offer enhanced safety compared to traditional rigid robots. The compliant nature of soft robots reduces the risk of injury in case of accidental contact with humans. Soft grippers can also provide a gentler touch, minimizing the potential for damage to delicate paper products.

However, critics express concerns about the reliability and precision of soft robotics systems. They argue that the complex nature of soft robots and their reliance on sensors and actuators can lead to failures and errors. In industries where precision and accuracy are crucial, such as paper handling, any malfunction or error could result in significant financial losses.

Addressing safety and reliability concerns requires thorough testing, quality control, and continuous improvement of soft robotics technologies. It is essential to establish rigorous standards and guidelines to ensure the safe and reliable operation of these systems in paper handling and other industries.

The role of soft robotics in adaptive paper handling mechanisms brings forth several controversial aspects. Ethical implications of replacing human workers, environmental impact, and safety and reliability concerns all require careful consideration. Striking a balance between technological advancements and ethical considerations, mitigating environmental impact, and ensuring the safety and reliability of soft robotics systems are crucial for the responsible integration of these technologies in the paper handling industry.

The Evolution of Paper Handling Mechanisms

Paper handling mechanisms have come a long way since the invention of the printing press. From manual feeding to automated systems, the goal has always been to improve efficiency and accuracy in handling paper. However, traditional paper handling mechanisms have limitations when it comes to adapting to different paper sizes, weights, and textures. This is where soft robotics comes into play.

Understanding Soft Robotics

Soft robotics is a branch of robotics that focuses on the development of flexible and compliant materials and structures to create robots with soft and adaptive properties. Unlike traditional robots that are rigid and have limited flexibility, soft robots can deform and conform to different shapes and surfaces. This makes them ideal for applications such as paper handling, where the ability to adapt to varying paper properties is crucial.

Benefits of Soft Robotics in Paper Handling

Soft robotics offers several advantages when it comes to paper handling mechanisms. Firstly, the soft and compliant nature of these robots allows them to handle delicate papers without causing any damage. This is particularly important in industries such as printing and packaging, where preserving the quality of the paper is essential. Additionally, soft robots can adapt to different paper sizes and shapes, eliminating the need for manual adjustments or specialized equipment for each paper type.

Case Study: Soft Robotics in Printing Industry

The printing industry is one of the sectors that can benefit greatly from the integration of soft robotics in paper handling mechanisms. In traditional printing presses, paper jams and misfeeds are common issues that result in costly downtime. By implementing soft robotics, printers can improve the reliability and efficiency of their paper handling systems. Soft robots can gently grip and manipulate the paper, reducing the chances of jams and misfeeds. Furthermore, they can adapt to different paper sizes and textures, allowing for seamless transitions between different print jobs.

Challenges and Limitations

While soft robotics offers promising solutions for adaptive paper handling, there are still challenges and limitations to overcome. One of the main challenges is the development of robust and reliable soft actuators and sensors. Soft actuators need to be able to exert sufficient force and torque to handle paper while maintaining their flexibility. Similarly, sensors need to accurately detect and respond to changes in paper properties. Another challenge is the integration of soft robotics into existing paper handling systems, as retrofitting can be complex and costly.

Future Applications and Innovations

The potential applications of soft robotics in adaptive paper handling mechanisms extend beyond the printing industry. In the packaging industry, soft robots can improve the efficiency of packaging processes by handling different types of paper-based packaging materials. In offices and libraries, soft robots can assist in document sorting and filing tasks. As soft robotics technology continues to advance, we can expect to see more innovative applications in various industries.

Collaboration between Soft Robotics and AI

Soft robotics can be further enhanced by the integration of artificial intelligence (AI). By combining soft robotic capabilities with AI algorithms, paper handling mechanisms can become even more adaptive and intelligent. AI can enable soft robots to learn and adapt to different paper properties in real-time, optimizing their gripping and manipulation techniques. This collaboration between soft robotics and AI has the potential to revolutionize paper handling processes, making them more efficient and autonomous.

Soft robotics has opened up new possibilities for adaptive paper handling mechanisms. By leveraging the flexibility and adaptability of soft robots, industries such as printing and packaging can improve efficiency, reduce downtime, and enhance the quality of their operations. While there are still challenges to overcome, the future looks promising for soft robotics in the field of paper handling.

Case Study 1: Soft Robotics in Automated Document Sorting

In the bustling world of logistics and package handling, efficient and accurate document sorting is crucial. Traditional mechanical systems often struggle to handle delicate and irregularly shaped papers, leading to errors and delays. However, the integration of soft robotics in adaptive paper handling mechanisms has revolutionized the process.

One notable success story in this field is the collaboration between a leading logistics company and a soft robotics startup. The goal was to develop a system that could handle various types of documents, including envelopes, invoices, and even crumpled papers.

The solution involved the use of soft grippers, which are made of flexible materials that mimic the human hand’s ability to grasp objects of different shapes and sizes. These grippers were attached to robotic arms that could move with precision and dexterity.

By employing machine learning algorithms, the system was trained to recognize and classify different types of documents. The soft grippers would then adapt their shape and grip strength based on the characteristics of each paper, ensuring a secure and damage-free handling process.

The result was a significant improvement in sorting accuracy and efficiency. The soft robotics system could handle delicate papers without tearing or damaging them, reducing the number of errors and minimizing the need for manual intervention. This not only saved time and resources but also improved customer satisfaction by ensuring timely delivery.

Case Study 2: Soft Robotics in Book Conservation

Preserving historical books and manuscripts is a delicate task that requires utmost care and precision. The use of soft robotics in adaptive paper handling mechanisms has proven to be a game-changer in the field of book conservation.

One remarkable example is the collaboration between a renowned library and a team of robotics engineers. Their objective was to develop a system that could turn the pages of fragile and valuable books without causing any damage.

The team designed a soft robotic finger that could mimic the gentle touch of a human hand. The finger was made of soft and flexible materials, allowing it to conform to the contours of each page and apply minimal pressure.

Using computer vision algorithms, the system was trained to identify the edges of the pages and determine the optimal position for the robotic finger to turn them. The soft robotic finger would then carefully lift the page and turn it, replicating the motion of a human reader.

This innovative approach to book conservation has significantly reduced the risk of tearing or creasing delicate pages. The soft robotics system can handle books of various sizes, thicknesses, and conditions, ensuring a consistent and gentle page-turning process.

Furthermore, the system can be programmed to detect and avoid pages with loose or detached bindings, preventing further damage. This level of adaptability and precision has revolutionized the field of book conservation, allowing libraries and museums to preserve and share their valuable collections with greater ease and confidence.

Case Study 3: Soft Robotics in Paper Recycling

The recycling industry plays a vital role in reducing waste and promoting sustainability. However, the process of sorting and separating different types of paper can be challenging, especially when dealing with mixed or contaminated materials. Soft robotics has emerged as a valuable tool in improving paper recycling efficiency.

One successful implementation of soft robotics in paper recycling is a collaboration between a recycling plant and a robotics research institute. The aim was to develop a system that could handle and sort various types of paper waste, including newspapers, cardboard, and glossy magazines.

The system integrated soft robotic grippers with advanced sensors and computer vision technology. The soft grippers were designed to adapt their shape and grip strength based on the type and condition of the paper being handled.

Using machine learning algorithms, the system was trained to recognize and classify different types of paper waste, as well as detect and remove contaminants such as plastic or metal objects.

The soft robotics system proved to be highly effective in improving the accuracy and efficiency of paper recycling. It could handle mixed batches of paper waste, separating them into different categories with minimal human intervention.

By automating the sorting process, the recycling plant significantly reduced labor costs and processing time. Moreover, the system’s adaptability and flexibility allowed it to handle a wide range of paper waste, making recycling more efficient and economically viable.

Overall, the integration of soft robotics in adaptive paper handling mechanisms has revolutionized various industries, from logistics and book conservation to paper recycling. These case studies demonstrate the significant improvements in accuracy, efficiency, and adaptability that soft robotics brings to the handling of delicate and irregularly shaped papers. As technology continues to advance, we can expect even more innovative applications of soft robotics in the future.

FAQs

1. What is soft robotics?

Soft robotics is a subfield of robotics that focuses on the development and application of robots made from soft, flexible materials. These robots are designed to mimic the movements and capabilities of living organisms, offering unique advantages in various applications.

2. What are adaptive paper handling mechanisms?

Adaptive paper handling mechanisms refer to robotic systems that are specifically designed to handle and manipulate paper or paper-like materials. These mechanisms are capable of adapting to the varying characteristics and demands of paper, such as size, weight, and fragility.

3. How can soft robotics benefit paper handling?

Soft robotics can offer several benefits in paper handling applications. The soft, flexible nature of the robots allows them to handle delicate paper materials without causing damage. Additionally, the adaptability of soft robotics enables them to handle different sizes and shapes of paper, making them versatile and efficient.

4. What are some common applications of soft robotics in paper handling?

Soft robotics has found applications in various areas of paper handling, including sorting, packaging, folding, and printing. These robots can be programmed to perform precise movements, allowing them to accurately handle paper products in manufacturing, packaging, and distribution processes.

5. How do soft robots handle fragile paper materials?

Soft robots are designed with compliant materials that can gently grip and manipulate fragile paper materials without causing tears or creases. The robots can be programmed to exert the appropriate amount of force and use specialized gripping mechanisms to ensure safe handling.

6. Can soft robots handle different sizes and shapes of paper?

Yes, one of the key advantages of soft robotics in paper handling is their ability to adapt to different sizes and shapes of paper. The soft, flexible nature of these robots allows them to conform to the contours of the paper, enabling efficient handling of various paper products.

7. Are soft robots more efficient than traditional robotic systems in paper handling?

Soft robots can offer increased efficiency in paper handling compared to traditional robotic systems. The adaptability and compliance of soft robots enable them to handle a wider range of paper products without the need for complex and time-consuming reprogramming or reconfiguring.

8. Are there any limitations to using soft robotics in paper handling?

While soft robotics offers many advantages in paper handling, there are some limitations to consider. Soft robots may have lower payload capacities compared to rigid robots, which can limit their ability to handle large or heavy paper products. Additionally, the development and maintenance of soft robotic systems may require specialized expertise and resources.

9. Can soft robotics improve the automation of paper handling processes?

Yes, soft robotics has the potential to significantly improve the automation of paper handling processes. The adaptability and dexterity of soft robots allow them to perform complex tasks, such as sorting and folding, with high precision and speed, reducing the need for manual intervention and increasing overall productivity.

10. What does the future hold for soft robotics in paper handling?

The future of soft robotics in paper handling looks promising. As advancements in materials science and robotics continue, we can expect to see even more sophisticated soft robotic systems that can handle a wider range of paper products and perform increasingly complex tasks. Soft robotics has the potential to revolutionize the paper industry, enhancing efficiency, productivity, and product quality.

Common Misconception 1: Soft robotics is not as effective as traditional robotics in paper handling mechanisms

One common misconception about soft robotics in adaptive paper handling mechanisms is that it is not as effective as traditional robotics. This misconception stems from the belief that soft robotics lacks the strength and precision necessary for handling delicate and fragile materials like paper.

However, this belief is not entirely accurate. Soft robotics has made significant advancements in recent years, and it offers several advantages over traditional robotics in paper handling mechanisms.

Firstly, soft robots are inherently compliant and flexible, allowing them to adapt to the shape and texture of the objects they handle. This flexibility enables soft robots to handle delicate materials like paper without causing damage. Traditional robots, on the other hand, often rely on rigid grippers that can exert excessive force and lead to tearing or crumpling of the paper.

Secondly, soft robots can achieve a higher degree of dexterity and precision compared to their traditional counterparts. Soft robotic grippers can be designed with intricate features such as variable stiffness and controllable compliance, allowing them to grasp and manipulate paper with greater finesse. This level of control is especially crucial when dealing with tasks that require delicate movements, such as folding or unfolding paper.

Lastly, soft robotics offers the potential for safer human-robot interaction. Traditional robots can pose a risk to human operators due to their rigid structures and high forces. Soft robots, on the other hand, are inherently safer to work with as they are designed to be intrinsically compliant and have lower impact forces. This makes them suitable for collaborative applications where humans and robots work side by side, such as in the printing and packaging industry.

Common Misconception 2: Soft robotics is limited in terms of load capacity for paper handling

Another common misconception about soft robotics in adaptive paper handling mechanisms is that it is limited in terms of load capacity. It is often believed that soft robots lack the strength to handle large stacks of paper or heavy paper rolls.

While it is true that soft robots may have limitations in terms of load capacity compared to traditional robots, they are by no means incapable of handling paper in bulk.

Soft robotic systems can be designed with multiple soft grippers or actuators that work in tandem to distribute the load evenly. By using multiple grippers, the load can be divided, reducing the strain on each individual gripper. This allows soft robots to handle larger stacks of paper or heavier paper rolls without compromising their performance.

Additionally, soft robots can be integrated with other mechanisms, such as suction cups or vacuum-based systems, to enhance their load-carrying capabilities. By combining different gripping methods, soft robots can achieve a higher load capacity while still maintaining the necessary flexibility and adaptability for handling paper.

It is worth noting that the load capacity of a soft robotic system can be tailored to specific application requirements. By carefully designing the soft grippers and actuators, engineers can optimize the system for the desired load capacity, striking a balance between strength and flexibility.

Common Misconception 3: Soft robotics is too expensive for practical implementation in paper handling mechanisms

One prevailing misconception about soft robotics in adaptive paper handling mechanisms is that it is too expensive for practical implementation. The belief is that the advanced materials and technologies used in soft robotics make it cost-prohibitive for widespread adoption in industries that require paper handling.

While it is true that soft robotics technology is still relatively new and may involve higher upfront costs compared to traditional robotics, the long-term benefits and potential cost savings make it a viable option for practical implementation in paper handling mechanisms.

Soft robotics offers the advantage of being highly customizable and adaptable. This means that soft robotic systems can be specifically tailored to the requirements of paper handling applications, resulting in improved efficiency and reduced waste. By minimizing the risk of damage to paper products, soft robotics can help companies save costs associated with product defects, reprints, and waste disposal.

Furthermore, as soft robotics technology continues to evolve and gain wider acceptance, economies of scale are likely to come into play. With increased demand and production volume, the cost of soft robotic components and systems is expected to decrease, making it more affordable for practical implementation in various industries.

It is also important to consider the potential for soft robotics to improve overall operational efficiency. The flexibility and adaptability of soft robots can enable more streamlined and automated paper handling processes, reducing the need for manual labor and increasing productivity. These efficiency gains can offset the initial investment in soft robotics technology.

Addressing these common misconceptions about the role of soft robotics in adaptive paper handling mechanisms is crucial for promoting a better understanding of this emerging field. Soft robotics offers unique advantages, such as flexibility, precision, and safety, making it a viable and effective solution for various paper handling applications. While there may be some limitations and initial costs associated with soft robotics, the long-term benefits and potential cost savings make it a promising technology for the future of paper handling.

Concept 1: Soft Robotics

Soft robotics is a field of study that focuses on creating robots made of flexible materials, such as rubber or silicone, instead of rigid metals. These robots are designed to mimic the movements and capabilities of living organisms, like animals or humans. Unlike traditional robots, which are often made of hard materials and have rigid joints, soft robots are more flexible and can adapt to different environments and tasks.

One of the main advantages of soft robotics is their ability to interact with delicate objects, like paper, without causing damage. The soft materials used in these robots allow them to grasp and manipulate objects with a gentle touch, reducing the risk of tearing or creasing the paper. This makes them ideal for handling fragile materials in various industries, such as packaging, printing, or even in medical settings.

Concept 2: Adaptive Paper Handling Mechanisms

Adaptive paper handling mechanisms refer to the systems or devices that are designed to handle paper in a flexible and adjustable manner. These mechanisms can include various components, such as robotic arms, grippers, or sensors, which work together to ensure the efficient and safe handling of paper.

Traditionally, paper handling mechanisms have been rigid and inflexible, often relying on fixed grips or rollers to move paper from one place to another. However, these mechanisms can be problematic when dealing with different types of paper, such as thin or irregularly shaped sheets. The rigid nature of traditional mechanisms can cause damage to the paper or result in inaccurate handling.

Adaptive paper handling mechanisms, on the other hand, are designed to adapt to the specific characteristics of the paper being handled. They can adjust their grip strength, shape, or movement patterns to accommodate different types of paper. This flexibility allows for more precise and controlled handling, reducing the risk of errors or damages.

Concept 3:

Soft robotics plays a crucial role in the development and improvement of adaptive paper handling mechanisms. By utilizing soft materials and flexible designs, soft robots can provide several benefits in the context of paper handling.

Firstly, soft robots can offer a gentle touch when handling paper, reducing the risk of damage. The flexible materials used in soft robots allow them to conform to the shape of the paper and distribute forces evenly, minimizing the chances of tearing or creasing. This is particularly important when dealing with delicate or valuable documents, such as historical manuscripts or fragile artworks.

Secondly, soft robots can adapt to different types of paper, including those with irregular shapes or varying thicknesses. Traditional mechanisms often struggle with such variations, leading to inaccuracies or mishandling. Soft robots, with their flexible and adjustable nature, can easily conform to the unique characteristics of each paper, ensuring precise and reliable handling.

Furthermore, soft robots can be equipped with sensors and feedback systems that allow them to monitor and adjust their grip strength or movement in real-time. This enables them to detect any changes in the paper’s condition, such as slipping or folding, and make immediate adjustments to prevent damage. Such adaptability and responsiveness make soft robots highly efficient and safe in handling paper.

Soft robotics and adaptive paper handling mechanisms are revolutionizing the way we handle and manipulate paper. The use of soft materials and flexible designs in robots allows for gentle and precise handling, reducing the risk of damage to delicate or valuable documents. With their adaptability and responsiveness, soft robots ensure accurate and efficient paper handling, even with varying shapes or thicknesses. As technology continues to advance in this field, we can expect further improvements in the role of soft robotics in adaptive paper handling mechanisms.

1. Stay Updated on Soft Robotics Technology

To make the most of the knowledge from “The Role of Soft Robotics in Adaptive Paper Handling Mechanisms” in your daily life, it is essential to stay updated on the latest developments in soft robotics technology. Follow reputable sources, such as scientific journals, industry news websites, and conferences, to keep yourself informed about advancements in this field.

2. Explore Soft Robotics Applications

Soft robotics has a wide range of applications beyond paper handling mechanisms. Take the time to explore how this technology is being used in other industries, such as healthcare, manufacturing, and agriculture. Understanding different applications can inspire you to find innovative ways to apply soft robotics principles in your own life.

3. Join Online Communities and Forums

Engaging with like-minded individuals can be a great way to learn and share knowledge. Join online communities and forums dedicated to soft robotics or related fields. Participate in discussions, ask questions, and share your own insights. This will help you connect with experts and enthusiasts who can provide valuable guidance and support.

4. Start Small with DIY Soft Robotics Projects

If you want to apply the knowledge from the research paper in a practical way, consider starting small with do-it-yourself (DIY) soft robotics projects. There are numerous online resources, tutorials, and kits available that can help you get started. Building your own soft robotic gripper or simple automation system can be a fun and educational way to apply the principles you have learned.

5. Collaborate with Others

Collaboration can foster creativity and accelerate learning. Seek out opportunities to collaborate with individuals or groups who have expertise in soft robotics or related fields. By working together, you can combine your skills and knowledge to tackle more complex projects or explore new applications of soft robotics technology.

6. Apply Soft Robotics Principles to Everyday Tasks

Look for ways to apply soft robotics principles to everyday tasks and challenges. For example, you can design a soft robotic gripper to handle delicate objects, automate repetitive tasks using soft robotic actuators, or develop adaptive systems that adjust to changing environmental conditions. By incorporating soft robotics concepts into your daily life, you can enhance efficiency, safety, and convenience.

7. Experiment and Iterate

Soft robotics is a field that encourages experimentation and iteration. Don’t be afraid to try new ideas, even if they seem unconventional at first. Embrace the iterative process of designing, testing, and refining your projects. Learn from failures and use them as opportunities to improve your understanding and skills in soft robotics.

8. Attend Workshops and Training Programs

To deepen your knowledge and practical skills in soft robotics, consider attending workshops and training programs. These events provide hands-on experience, expert guidance, and networking opportunities. Look for workshops organized by universities, research institutions, or industry associations to gain valuable insights and practical knowledge.

9. Explore Open-Source Soft Robotics Platforms

Open-source soft robotics platforms offer a wealth of resources and tools for enthusiasts. Platforms like Soft Robotics Toolkit and Robotic Materials provide access to designs, tutorials, and community support. By exploring these platforms, you can leverage existing knowledge and contribute to the growing field of soft robotics.

10. Think Beyond Paper Handling

While the research paper focuses on soft robotics in adaptive paper handling mechanisms, don’t limit yourself to this specific application. Soft robotics principles can be applied to various domains, including healthcare, assistive technology, and exploration. Think beyond paper handling and explore how soft robotics can solve challenges in other areas of interest to you.

Conclusion

Soft robotics has emerged as a promising field in the development of adaptive paper handling mechanisms. The ability of soft robots to conform to the shape of objects and exert gentle yet precise forces makes them ideal for handling delicate materials like paper. This article has explored various applications of soft robotics in paper handling, including sorting, folding, and gripping.

One key insight from this article is the potential for soft robots to revolutionize the paper industry by improving efficiency and reducing waste. Soft robotic grippers, for example, can adapt to different shapes and sizes of paper, allowing for more accurate and reliable handling. Additionally, the use of soft robots in folding mechanisms can automate complex folding tasks, saving time and labor costs.

Furthermore, the integration of soft robotics with artificial intelligence and machine learning algorithms opens up new possibilities for adaptive paper handling. These technologies can enable soft robots to learn and adapt to different paper types, sizes, and handling requirements, further enhancing their versatility and efficiency.

Overall, the role of soft robotics in adaptive paper handling mechanisms is a rapidly evolving field with significant potential for advancements. As researchers continue to innovate and refine soft robotic technologies, we can expect to see further improvements in paper handling processes, leading to increased productivity and sustainability in the paper industry.