Revolutionizing Paper Handling: How Soft Robotics are Transforming the Industry

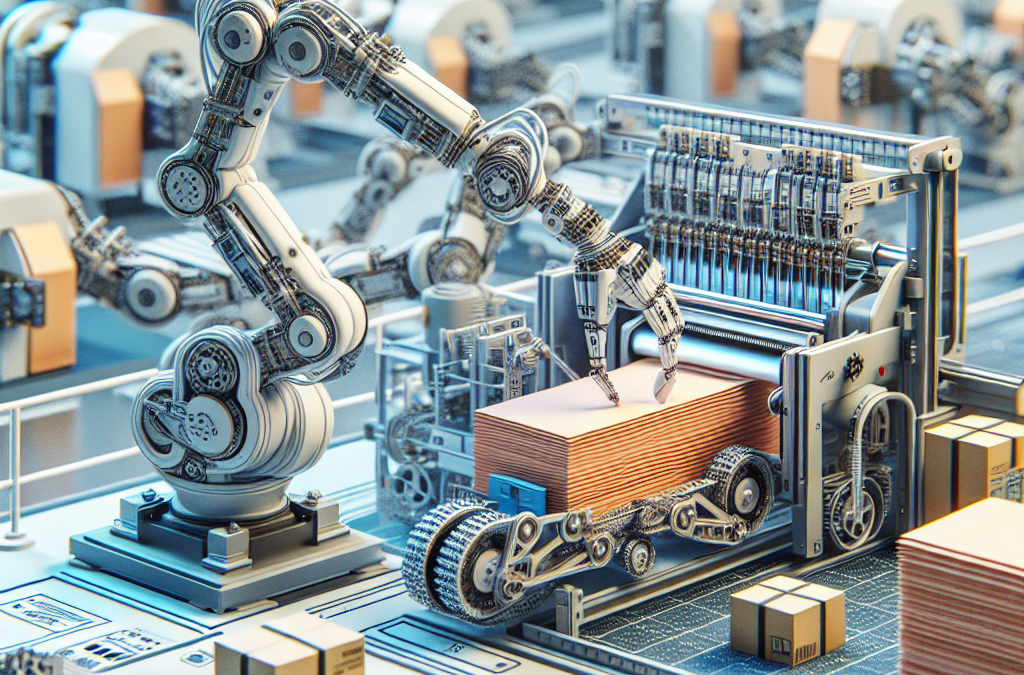

In the ever-evolving world of robotics, a new frontier is emerging that promises to revolutionize the way we handle paper. Soft robotics, a field that combines the flexibility and adaptability of soft materials with the precision and control of robotics, is paving the way for innovative solutions in paper handling mechanisms. From delicate book page turning to automated document sorting, soft robotics is proving to be a game-changer in industries that heavily rely on paper-based processes.

This article explores the role of soft robotics in adaptive paper handling mechanisms, delving into the potential applications and benefits of this emerging technology. We will examine how soft robots, with their compliant and dexterous nature, can delicately handle fragile paper materials without causing damage. Additionally, we will explore how soft robotics can enhance the efficiency and accuracy of paper handling tasks, ultimately leading to improved productivity and cost savings. Join us as we delve into the exciting world of soft robotics and its transformative impact on paper handling mechanisms.

Key Takeaways

1. Soft robotics is revolutionizing the field of adaptive paper handling mechanisms by offering flexible and gentle manipulation of delicate paper materials.

2. Soft robotic grippers, made of compliant materials such as silicone, are capable of mimicking the human hand’s dexterity and sensitivity, enabling precise and safe handling of paper sheets.

3. Soft robotic systems can adapt to variations in paper size, shape, and stiffness, making them ideal for tasks such as sorting, stacking, and feeding paper in industries like printing, packaging, and mail processing.

4. The compliance and adaptability of soft robotics allow for the development of cost-effective and versatile paper handling solutions that can reduce production downtime and increase efficiency.

5. The integration of soft robotics with advanced sensing technologies, such as computer vision and tactile sensors, further enhances the capabilities of adaptive paper handling mechanisms, enabling autonomous and intelligent operation.

Insight 1: Enhancing Efficiency and Precision in Paper Handling

One of the key insights into the role of soft robotics in adaptive paper handling mechanisms is the significant enhancement in efficiency and precision that it brings to the industry. Traditionally, paper handling mechanisms have relied on rigid and inflexible machinery that often struggled to adapt to the varying shapes, sizes, and conditions of different types of paper. This resulted in frequent jams, misalignments, and damaged paper, leading to delays, errors, and increased costs for businesses.

However, with the of soft robotics, these challenges are being overcome. Soft robotic systems are designed with flexible and compliant materials that mimic the capabilities of human muscles and tendons. This allows them to gently grip, manipulate, and transport paper with a level of dexterity and adaptability that was previously unattainable with rigid machinery.

Soft robotic grippers, for example, can adjust their shape and grip strength to accommodate different paper sizes and textures, ensuring a secure hold without causing any damage. This adaptability not only reduces the occurrence of jams and misalignments but also minimizes the need for manual intervention and adjustments, leading to increased operational efficiency and productivity.

Furthermore, the precision offered by soft robotics in paper handling mechanisms is a game-changer for industries that require high accuracy, such as printing, packaging, and document processing. The compliant nature of soft robotic grippers allows for gentle and controlled movements, reducing the risk of tearing or wrinkling delicate paper. This level of precision ensures that each sheet of paper is handled with care, resulting in improved print quality, reduced waste, and enhanced customer satisfaction.

Insight 2: Enabling Safe and Collaborative Human-Robot Interaction

Another crucial insight into the role of soft robotics in adaptive paper handling mechanisms is its ability to enable safe and collaborative human-robot interaction. In traditional paper handling systems, the presence of rigid machinery posed a significant safety risk to human operators, especially in close proximity to moving parts or during maintenance tasks.

Soft robotics, on the other hand, offers a safer alternative. The compliant and flexible nature of soft robotic grippers reduces the risk of injury in case of accidental contact with human operators. The materials used in soft robotics are often lightweight and have inherent elasticity, minimizing the force exerted on the surroundings and reducing the likelihood of accidents.

This safety aspect opens up opportunities for collaborative workflows, where humans and robots can work side by side in shared spaces. Soft robotic grippers can be integrated into collaborative robots, also known as cobots, allowing them to handle paper while working alongside human operators. This collaboration not only improves overall productivity but also enables businesses to optimize their workforce by assigning humans to more complex tasks that require cognitive skills, while leaving repetitive and physically demanding paper handling tasks to the robots.

Moreover, soft robotics also facilitates intuitive interaction between humans and robots. The compliant nature of soft robotic grippers makes them more forgiving in terms of interaction forces, allowing operators to directly interact with the grippers without the need for complex programming or specialized training. This intuitive interaction simplifies the integration of soft robotics into existing workflows, making it easier for businesses to adopt and benefit from this technology.

Insight 3: Enabling Flexibility and Adaptability in Paper Handling Systems

The third key insight into the role of soft robotics in adaptive paper handling mechanisms is its ability to enable flexibility and adaptability in paper handling systems. Traditional rigid machinery often required dedicated setups and adjustments for specific paper sizes, formats, or production requirements. This lack of flexibility limited the versatility of paper handling systems and made them less responsive to changing market demands.

Soft robotics, with its inherent flexibility, overcomes these limitations. Soft robotic grippers can adapt their shape and grip strength on the fly, allowing them to handle a wide range of paper sizes, formats, and conditions without the need for manual adjustments or reconfiguration. This adaptability enables businesses to quickly switch between different paper types or production runs, reducing downtime and increasing operational agility.

Furthermore, the flexibility of soft robotics extends beyond the physical handling of paper. Soft robotic systems can be easily integrated with computer vision and machine learning algorithms to enable intelligent paper handling. By analyzing visual cues, soft robotic grippers can automatically adjust their grip or handling strategy based on the specific requirements of each paper item. For example, they can detect and compensate for misaligned or skewed paper, ensuring accurate processing and reducing the risk of errors.

This flexibility and adaptability offered by soft robotics in paper handling systems not only improves overall operational efficiency but also opens up new possibilities for customization and personalization. Businesses can easily accommodate unique customer requests or tailor their paper handling processes to specific industry standards, giving them a competitive edge in the market.

Controversial Aspect 1: Job Displacement

One of the most controversial aspects of incorporating soft robotics into adaptive paper handling mechanisms is the potential job displacement it may cause. As soft robots become more advanced and capable, they have the potential to replace human workers in various industries, including paper handling. This raises concerns about the impact on employment rates and the livelihoods of those who currently work in these fields.

Proponents argue that soft robotics can lead to increased efficiency, productivity, and cost-effectiveness. By automating paper handling tasks, companies can reduce labor costs and improve overall operations. This, in turn, could lead to increased profitability and competitiveness in the market. Additionally, proponents argue that the implementation of soft robotics could create new job opportunities in the design, maintenance, and programming of these systems.

On the other hand, critics argue that the potential job losses outweigh the benefits. They express concerns about the social and economic consequences of widespread job displacement. They argue that the loss of employment opportunities could lead to increased inequality and social unrest. Critics also highlight the importance of human interaction and the unique skills that humans bring to certain tasks, such as problem-solving, adaptability, and creativity, which may be lacking in robotic systems.

Controversial Aspect 2: Ethical Considerations

The use of soft robotics in adaptive paper handling mechanisms also raises ethical considerations. As these technologies become more advanced, questions arise about the ethical treatment of robots and their potential impact on human well-being.

Proponents argue that soft robotics can improve workplace safety by reducing the risk of injuries associated with manual paper handling tasks. By automating these tasks, workers can be protected from repetitive strain injuries and other physical strains. Proponents also argue that soft robots can enhance productivity and quality by consistently performing tasks without fatigue or human error.

Critics, however, raise concerns about the potential exploitation and mistreatment of robots. They argue that as robots become more human-like in appearance and behavior, there is a risk of treating them as mere tools without considering their well-being. Critics also raise concerns about the impact of automation on human dignity and the potential devaluation of certain types of work that are essential for human development and fulfillment.

Controversial Aspect 3: Environmental Impact

The environmental impact of incorporating soft robotics in adaptive paper handling mechanisms is another controversial aspect. While proponents argue that these technologies can lead to more sustainable practices, critics highlight potential negative consequences.

Proponents argue that soft robotics can reduce waste and energy consumption by optimizing paper handling processes. Soft robots can be programmed to handle paper with precision, minimizing the risk of damage and reducing the need for reprints. This can lead to significant savings in paper and ink usage. Additionally, proponents argue that the use of soft robotics can contribute to the development of more eco-friendly materials and manufacturing processes.

Critics, however, point out that the production and disposal of robotic systems can have a significant environmental impact. The manufacturing process of soft robots often involves the use of non-renewable resources and energy-intensive processes. Additionally, the disposal of these systems at the end of their lifecycle can contribute to electronic waste. Critics argue that the overall environmental benefits of soft robotics need to be carefully evaluated and compared to alternative approaches to paper handling.

The role of soft robotics in adaptive paper handling mechanisms presents several controversial aspects. these include concerns about job displacement, ethical considerations, and the environmental impact. while proponents highlight potential benefits such as increased efficiency, workplace safety, and sustainability, critics raise concerns about employment rates, the treatment of robots, and the overall environmental consequences. as these technologies continue to advance, it is crucial to engage in thoughtful discussions and consider the potential implications from a balanced perspective.

Trend 1: Integration of Soft Robotics in Paper Handling Systems

One of the emerging trends in the field of paper handling mechanisms is the integration of soft robotics technology. Soft robotics refers to the use of flexible and deformable materials to create robots that can interact with objects in a more delicate and adaptive manner. This technology has shown great potential in various industries, and now it is being applied to improve the efficiency and effectiveness of paper handling systems.

Traditional paper handling mechanisms often rely on rigid and precise movements, which can be problematic when dealing with delicate or irregularly shaped paper. Soft robotics offers a solution by enabling robots to manipulate paper with a gentle touch, adjusting their grip and movements according to the shape and fragility of the paper. This allows for more accurate and reliable handling, reducing the risk of damage and improving overall productivity.

Furthermore, the integration of soft robotics in paper handling systems also opens up new possibilities for automation. Soft robots can be programmed to perform complex tasks such as sorting, folding, and stacking paper, eliminating the need for manual intervention. This not only saves time and labor costs but also reduces the risk of human error.

Trend 2: Enhanced Sensing and Feedback Mechanisms

Another emerging trend in the field of adaptive paper handling mechanisms is the development of enhanced sensing and feedback mechanisms. Traditional paper handling systems often rely on predefined parameters and fixed motions, which can be limiting when dealing with variations in paper size, weight, and texture.

With advances in sensor technology and artificial intelligence, paper handling systems can now incorporate real-time feedback and adaptive control mechanisms. Sensors can detect the properties of the paper being handled, such as its thickness, moisture content, and surface texture. This information is then fed into the control system, which adjusts the gripping force, movement speed, and trajectory of the paper handling mechanism accordingly.

By incorporating enhanced sensing and feedback mechanisms, paper handling systems can adapt to different types of paper and ensure optimal handling performance. This not only improves the efficiency and reliability of the system but also reduces the risk of paper jams, misfeeds, and other operational issues.

Trend 3: Integration with Artificial Intelligence and Machine Learning

The integration of soft robotics in adaptive paper handling mechanisms also paves the way for the application of artificial intelligence (AI) and machine learning (ML) techniques. AI and ML algorithms can analyze large amounts of data collected from the paper handling system, including sensor readings, operational parameters, and performance metrics.

By analyzing this data, AI and ML algorithms can identify patterns, optimize control parameters, and even predict potential issues before they occur. For example, by continuously monitoring the performance of the paper handling system, AI algorithms can detect signs of wear and tear in the gripping mechanism and schedule preventive maintenance before a failure occurs.

Furthermore, AI and ML algorithms can also learn from human operators’ expertise and adapt the paper handling system’s behavior accordingly. This can lead to improved efficiency, reduced downtime, and better overall performance.

Future Implications

The emerging trends in the role of soft robotics in adaptive paper handling mechanisms have significant implications for various industries. The integration of soft robotics technology allows for more delicate and adaptive handling of paper, reducing the risk of damage and improving overall productivity.

Enhanced sensing and feedback mechanisms enable paper handling systems to adapt to different types of paper, ensuring optimal performance and reducing operational issues. The integration of artificial intelligence and machine learning techniques further enhances the system’s capabilities, enabling predictive maintenance, optimization, and learning from human expertise.

In the future, we can expect to see further advancements in soft robotics technology, leading to even more sophisticated and efficient paper handling systems. These systems will not only improve productivity and reduce costs but also enable new possibilities in industries such as printing, packaging, and logistics.

Overall, the role of soft robotics in adaptive paper handling mechanisms is a promising field with vast potential for innovation and improvement. As technology continues to evolve, we can expect to see more advanced, efficient, and intelligent paper handling systems that will revolutionize the way we handle paper in various industries.

The Evolution of Paper Handling Mechanisms

Paper handling mechanisms have played a crucial role in various industries, from printing and packaging to mail sorting and document processing. Over the years, these mechanisms have evolved to become more efficient and versatile. Traditional paper handling mechanisms were often rigid and limited in their ability to adapt to different sizes, shapes, and textures of paper. However, with the advent of soft robotics, a new era of adaptive paper handling mechanisms has emerged.

Understanding Soft Robotics

Soft robotics is a field of robotics that focuses on the development of robots with soft and flexible materials, such as elastomers and polymers, as opposed to traditional rigid materials like metal and plastic. These soft robots mimic the movements and behaviors of living organisms, allowing them to interact with delicate objects, including paper, in a gentle and precise manner. Soft robotics has opened up new possibilities for adaptive paper handling mechanisms.

Advantages of Soft Robotics in Paper Handling

Soft robotics offers several advantages when it comes to paper handling. Firstly, the soft and flexible nature of these robots allows them to conform to the shape of the paper, ensuring a secure grip and minimizing the risk of damage. Unlike traditional rigid grippers, soft robotic grippers can adjust their shape and apply gentle pressure to hold the paper without causing creases or tears.

Furthermore, soft robots can adapt to different sizes and thicknesses of paper, making them highly versatile. They can handle everything from thin sheets of paper to thick cardboard with ease. This adaptability is particularly useful in industries where paper sizes and types vary widely.

Additionally, soft robots are inherently safe to use around humans. Their soft and compliant nature reduces the risk of injury in case of accidental contact, making them ideal for applications where human-robot collaboration is necessary. This is particularly relevant in settings like packaging lines or document processing centers, where humans and robots often work in close proximity.

Applications of Soft Robotics in Paper Handling

The applications of soft robotics in paper handling are vast and diverse. One notable application is in the field of printing, where soft robots can handle delicate and valuable prints without causing any damage. These robots can precisely position the prints, ensuring accurate alignment and reducing the risk of misprints. Soft robots can also handle sheets of paper during the printing process, allowing for seamless automation.

In the packaging industry, soft robots are revolutionizing the way products are packaged. They can handle various types of packaging materials, including paper-based boxes and bags, with ease. Soft robots can pick up, manipulate, and place these materials with precision, enabling efficient and reliable packaging processes.

Another application of soft robotics in paper handling is in mail sorting. Soft robots can handle envelopes and packages of different sizes and shapes, ensuring accurate sorting and reducing the risk of errors. Their adaptability allows them to handle various types of mail, from letters to bulky packages, making the sorting process more efficient and reliable.

Case Studies: Soft Robotics in Action

To illustrate the real-world impact of soft robotics in adaptive paper handling mechanisms, let’s explore a couple of case studies. In one case, a printing company implemented soft robotic grippers in their printing press. These grippers were able to handle delicate prints without causing any damage, resulting in a significant reduction in misprints and waste. The company also reported improved productivity and reduced downtime due to the seamless automation enabled by soft robotics.

In another case, a packaging company integrated soft robotic arms into their packaging line. These arms were able to handle various types of paper-based packaging materials, such as boxes and bags, with precision. The company experienced a substantial increase in packaging speed and accuracy, leading to improved customer satisfaction and cost savings.

The Future of Soft Robotics in Paper Handling

The role of soft robotics in adaptive paper handling mechanisms is still evolving, and the future looks promising. As soft robotics technology continues to advance, we can expect even more sophisticated and capable robots that can handle a wider range of paper-related tasks. These robots may possess enhanced sensory capabilities to detect and adjust to different paper properties, further improving their adaptability.

Furthermore, the integration of soft robotics with other emerging technologies, such as artificial intelligence and machine learning, holds great potential. Intelligent soft robots could learn from their interactions with paper and continuously improve their handling capabilities, making them even more efficient and precise.

Soft robotics is revolutionizing the way we handle paper. Its adaptive and versatile nature offers numerous advantages over traditional rigid mechanisms. From printing and packaging to mail sorting, soft robotics is transforming industries and enabling more efficient and reliable paper handling processes.

Soft robotics is an emerging field that focuses on designing and developing robots with flexible and compliant materials, allowing them to interact safely and effectively with delicate objects. In recent years, soft robotics has found applications in various industries, including healthcare, manufacturing, and logistics. One area where soft robotics has shown great potential is in adaptive paper handling mechanisms. This article will provide a technical breakdown of the role of soft robotics in adaptive paper handling mechanisms.

1. Soft Grippers

Soft grippers are a key component of adaptive paper handling mechanisms. Unlike traditional rigid grippers, soft grippers are made of flexible materials such as elastomers or textiles. These grippers can conform to the shape of the paper, providing a gentle and secure grip without causing any damage. The compliance of soft grippers allows them to adapt to different paper sizes and shapes, making them highly versatile in handling various types of paper.

2. Variable Stiffness Actuators

Variable stiffness actuators play a crucial role in adaptive paper handling mechanisms. These actuators can change their stiffness or compliance based on the requirements of the task. By adjusting the stiffness, the actuators can provide the necessary force to grip and manipulate the paper without crushing or tearing it. Soft robotics enables the integration of variable stiffness actuators into paper handling mechanisms, ensuring precise and controlled movements.

3. Sensing and Feedback Systems

Soft robotics in adaptive paper handling mechanisms often incorporates sensing and feedback systems to enhance performance and safety. These systems can include tactile sensors, force sensors, and vision systems. Tactile sensors provide information about the contact force between the gripper and the paper, allowing for delicate and precise manipulation. Force sensors enable the system to detect excessive forces that could potentially damage the paper, triggering appropriate adjustments. Vision systems can aid in paper detection, alignment, and tracking, ensuring accurate handling and positioning.

4. Compliance Control

Compliance control is a critical aspect of adaptive paper handling mechanisms. Soft robotics enables the implementation of compliant control strategies that allow the gripper to adapt to the changing properties of the paper. This control can be achieved through various methods, such as pneumatic or hydraulic actuation, shape memory alloys, or even embedded sensors that detect the paper’s stiffness and adjust the grip accordingly. Compliance control ensures that the gripper maintains a secure grip on the paper while preventing excessive deformation or damage.

5. Human-Robot Interaction

Soft robotics in adaptive paper handling mechanisms also considers human-robot interaction aspects. The compliant and flexible nature of soft grippers reduces the risk of injury in case of accidental contact with humans. Additionally, soft robotics allows for safe collaboration between humans and robots in paper handling tasks. The ability of soft grippers to conform to different objects, including human hands, enables cooperative manipulation and handover of paper, facilitating efficient and ergonomic workflows.

Soft robotics plays a crucial role in the development of adaptive paper handling mechanisms. The use of soft grippers, variable stiffness actuators, sensing and feedback systems, compliance control, and considerations for human-robot interaction enable safe and efficient handling of delicate paper. As the field of soft robotics continues to advance, we can expect further improvements in the capabilities and performance of adaptive paper handling mechanisms, revolutionizing industries that rely on precise and gentle paper manipulation.

The Emergence of Soft Robotics

Soft robotics, a field that focuses on the design and development of robots with soft and flexible materials, emerged as a distinct area of research in the late 1990s. The traditional rigid robots, while efficient in many applications, faced limitations in tasks that required delicate manipulation, adaptability, and interaction with humans or fragile objects.

Early Applications in Adaptive Paper Handling

One of the early applications of soft robotics was in the field of adaptive paper handling mechanisms. In the early 2000s, paper handling systems were primarily based on rigid robotic arms and grippers, which often resulted in damage to the paper or inefficient handling.

Researchers recognized the potential of soft robotics in overcoming these challenges. By utilizing compliant materials and novel actuation methods, they aimed to develop adaptive mechanisms that could handle paper with greater dexterity, precision, and care.

Advancements in Soft Actuators

One of the key advancements in the evolution of soft robotics for paper handling was the development of soft actuators. Soft actuators are the components responsible for generating motion in soft robots. They mimic the functionality of muscles, allowing for more natural and flexible movements.

Over the years, researchers have explored various types of soft actuators, such as pneumatic artificial muscles, dielectric elastomer actuators, and shape memory alloys. These actuators provided the necessary flexibility and compliance required for adaptive paper handling mechanisms.

Integration of Sensing and Control Systems

Another critical aspect in the evolution of soft robotics for paper handling was the integration of sensing and control systems. Soft robots needed to sense the properties of the paper, such as its position, orientation, and stiffness, in order to adapt their grasping and manipulation strategies.

Researchers developed innovative sensing technologies, such as tactile sensors and vision systems, to enable soft robots to gather real-time information about the paper. These sensors were integrated with advanced control algorithms, allowing the robots to make intelligent decisions and adjust their movements accordingly.

Collaborative Robotics

Collaborative robotics, which focuses on human-robot interaction and cooperation, played a significant role in the advancement of adaptive paper handling mechanisms. Soft robots offered inherent safety advantages compared to their rigid counterparts, making them suitable for working alongside humans without the need for extensive safety measures.

This collaboration between humans and soft robots opened up new possibilities in paper handling applications. Soft robots could assist humans in tasks such as sorting, folding, and packaging paper, increasing efficiency and reducing the risk of repetitive strain injuries.

Current State and Future Directions

Today, soft robotics has made significant strides in the development of adaptive paper handling mechanisms. Researchers continue to refine the design of soft actuators, improve sensing capabilities, and enhance control algorithms for more precise and efficient paper manipulation.

Furthermore, the integration of artificial intelligence and machine learning techniques holds promise for further advancements in adaptive paper handling. These technologies can enable soft robots to learn from experience, adapt to different paper types and conditions, and optimize their performance over time.

As the field of soft robotics continues to evolve, it is expected that adaptive paper handling mechanisms will become even more sophisticated, enabling robots to handle a wide range of paper-based tasks with unprecedented dexterity and precision.

FAQs

1. What is soft robotics?

Soft robotics is a field of robotics that focuses on the development of robots made from soft and flexible materials. Unlike traditional rigid robots, soft robots are designed to mimic the movements and behaviors of living organisms, allowing them to interact with delicate objects and navigate complex environments more effectively.

2. What are adaptive paper handling mechanisms?

Adaptive paper handling mechanisms refer to robotic systems that are specifically designed to handle paper and paper-based products. These mechanisms can perform tasks such as picking up, sorting, folding, and stacking paper in a highly flexible and adaptive manner.

3. How can soft robotics benefit paper handling?

Soft robotics offers several advantages for paper handling applications. The soft and flexible nature of these robots allows them to handle delicate paper products without causing damage. They can also adapt their shape and stiffness to conform to the irregularities of paper surfaces, enabling more precise and gentle manipulation. Additionally, soft robots can navigate through cluttered environments and tight spaces, making them ideal for tasks such as sorting and organizing paper documents.

4. What are some examples of soft robotic paper handling mechanisms?

There are various soft robotic paper handling mechanisms that have been developed. Some examples include grippers with soft fingers that can delicately pick up and manipulate paper sheets, soft suction cups that provide gentle yet reliable adhesion to paper surfaces, and soft robotic arms with multiple degrees of freedom for complex paper folding and stacking tasks.

5. How do soft robotic paper handling mechanisms work?

Soft robotic paper handling mechanisms typically use a combination of soft materials, actuators, and sensors. The soft materials, such as silicone or elastomers, provide the necessary flexibility and compliance. Actuators, such as pneumatic or hydraulic systems, are used to control the movement and deformation of the soft parts. Sensors, such as pressure sensors or vision systems, can be integrated to provide feedback and enable precise manipulation of paper objects.

6. What are the advantages of using soft robotics in paper handling over traditional methods?

Soft robotics offers several advantages over traditional methods of paper handling. Firstly, the soft and compliant nature of these robots reduces the risk of damaging delicate paper products. Secondly, soft robots can adapt to different shapes and sizes of paper, allowing for more versatile handling capabilities. Thirdly, the flexibility of soft robots enables them to navigate complex environments, such as stacks of paper or cluttered desks, with ease. Finally, soft robotics can provide more precise and controlled manipulation of paper objects, leading to improved efficiency and accuracy.

7. Are there any limitations to using soft robotics in paper handling?

While soft robotics brings many benefits to paper handling, there are some limitations to consider. Soft robots often require complex control systems and sophisticated sensors, which can increase the overall cost of implementation. Additionally, the soft materials used in these robots may not be as durable as traditional rigid materials, requiring regular maintenance and replacement. Furthermore, the performance of soft robots may be affected by environmental factors such as temperature and humidity. However, ongoing research and advancements in soft robotics are addressing these limitations.

8. What are the potential applications of soft robotics in paper handling?

Soft robotics has a wide range of potential applications in paper handling. Some examples include automated document sorting in offices, robotic assistants for bookstores or libraries, automated packaging of paper products in manufacturing facilities, and robotic systems for mail sorting and processing in postal services. The adaptability and gentle handling capabilities of soft robots make them well-suited for these tasks.

9. Are there any real-world implementations of soft robotics in paper handling?

Yes, there have been several real-world implementations of soft robotics in paper handling. For example, researchers have developed soft robotic grippers that can delicately handle paper sheets without causing damage. Soft robotic arms have also been used for tasks such as folding and stacking paper documents. These implementations demonstrate the potential of soft robotics in improving efficiency and accuracy in paper handling tasks.

10. What is the future outlook for soft robotics in paper handling?

The future outlook for soft robotics in paper handling is promising. Ongoing research and development efforts are focused on improving the capabilities and performance of soft robotic systems. Advances in materials, sensors, and control systems are expected to further enhance the adaptability, precision, and robustness of soft robots in paper handling applications. As a result, we can anticipate increased adoption of soft robotics in various industries that rely on paper handling.

Concept 1: Soft Robotics

Soft robotics is a field of robotics that focuses on creating robots made of flexible materials, such as rubber or silicone, instead of rigid materials like metal or plastic. These robots are designed to mimic the movements and behaviors of living organisms. Soft robots have the advantage of being more adaptable and versatile compared to traditional robots, as their soft bodies allow them to interact with their environment in a more natural and flexible way.

Concept 2: Adaptive Paper Handling Mechanisms

Adaptive paper handling mechanisms refer to the systems and devices that are used to handle paper or documents in a way that can adapt to different sizes, shapes, and conditions of the paper. These mechanisms are typically found in printers, scanners, and other paper-based devices. The goal of adaptive paper handling is to ensure that the paper is handled smoothly and accurately, without causing any damage or misalignment.

Concept 3:

Soft robotics can play a significant role in improving adaptive paper handling mechanisms. By incorporating soft robotic components into these mechanisms, it becomes possible to achieve more precise and gentle manipulation of paper. Soft robotic grippers, for example, can be designed to adjust their grip strength and shape to match the size and shape of the paper being handled. This allows for a more secure grip and reduces the risk of paper jams or misalignment.

Another advantage of using soft robotics in adaptive paper handling is the ability to detect and respond to changes in the paper’s condition. Soft sensors can be integrated into the robotic system to measure parameters such as paper thickness, moisture content, or surface roughness. This information can then be used to dynamically adjust the handling mechanism to ensure optimal performance. For instance, if the paper is too thin, the system can reduce the gripping force to prevent tearing.

Furthermore, soft robotics can enable more efficient and versatile paper handling. Soft robotic systems can be designed to handle a wide range of paper sizes and types without the need for extensive reconfiguration or adjustments. This flexibility is particularly beneficial in environments where different paper sizes or types are frequently encountered, such as offices or printing facilities.

In summary, soft robotics offers a promising solution for improving adaptive paper handling mechanisms. By leveraging the flexibility and adaptability of soft materials, these mechanisms can achieve more precise and gentle manipulation of paper, detect changes in paper condition, and handle a wider range of paper sizes and types. These advancements can lead to more efficient and reliable paper-based devices, ultimately enhancing our everyday interactions with paper documents.

1. Embrace the concept of soft robotics

Soft robotics is a rapidly evolving field that focuses on creating robots with flexible and deformable structures. By understanding the principles behind soft robotics, you can start thinking about how these concepts can be applied to everyday tasks.

2. Explore adaptive paper handling mechanisms

Adaptive paper handling mechanisms are a specific application of soft robotics that can greatly improve our interactions with paper-based materials. Take the time to explore the various mechanisms and understand how they can be integrated into your daily life.

3. Consider the benefits of soft grippers

Soft grippers are a key component of adaptive paper handling mechanisms. These grippers use compliant materials to gently grasp and manipulate paper without causing damage. Consider using soft grippers for delicate tasks, such as handling important documents or organizing paperwork.

4. Experiment with different materials

Soft robotics allows for the use of a wide range of materials, including silicone, elastomers, and textiles. Experiment with different materials to find the ones that best suit your needs. For example, silicone grippers may provide a better grip on glossy paper, while textile-based grippers may be more suitable for handling delicate or fragile documents.

5. Customize adaptive mechanisms to your needs

One of the advantages of soft robotics is its flexibility and adaptability. Don’t be afraid to customize adaptive mechanisms to better suit your specific requirements. Whether it’s adjusting the grip strength or modifying the shape of the gripper, tailoring the mechanism to your needs can enhance its functionality.

6. Integrate soft robotics into your workspace

Consider incorporating soft robotics into your workspace to streamline your paper handling tasks. This could involve using soft grippers attached to robotic arms for automated sorting or implementing soft robotic actuators to create adjustable paper trays. By integrating soft robotics into your workspace, you can optimize efficiency and reduce the risk of repetitive strain injuries.

7. Stay updated with the latest advancements

Soft robotics is a rapidly evolving field, with new advancements and research being published regularly. Stay updated with the latest developments by following scientific journals, attending conferences, or joining online communities. By staying informed, you can discover new applications and techniques that may further enhance your daily life.

8. Collaborate with experts

If you’re passionate about incorporating soft robotics into your daily life but lack the technical expertise, consider collaborating with experts in the field. Reach out to researchers, engineers, or robotics enthusiasts who can provide guidance and support. Collaborative efforts can lead to innovative solutions and a deeper understanding of soft robotics.

9. Start small and gradually expand

Soft robotics can be complex, so it’s essential to start small and gradually expand your knowledge and skills. Begin by tackling simple projects, such as building a basic soft gripper or designing a paper sorting mechanism. As you gain experience and confidence, you can take on more ambitious projects and explore advanced applications.

10. Inspire others and share your experiences

If you find success in incorporating soft robotics into your daily life, don’t hesitate to inspire others and share your experiences. Whether it’s through social media, blog posts, or local workshops, spreading awareness about the potential of soft robotics can encourage others to explore and embrace this innovative technology.

Conclusion

Soft robotics has emerged as a promising field that offers innovative solutions for adaptive paper handling mechanisms. This article has explored the various applications and advantages of soft robotics in the paper industry. Firstly, soft robots provide a safer and more efficient alternative to traditional rigid robots when it comes to handling delicate and fragile paper products. The inherent compliance and flexibility of soft robots allow them to adapt to the shape and texture of different paper materials, reducing the risk of damage during handling. Additionally, soft robots can perform complex tasks such as folding, cutting, and sorting with precision, enabling automation in paper processing.

Moreover, the use of soft robotics in adaptive paper handling mechanisms has the potential to revolutionize the industry by improving productivity and reducing costs. Soft robots can be easily reconfigured and reprogrammed to handle different paper sizes, shapes, and weights, eliminating the need for specialized equipment for each paper product. This flexibility not only saves time but also reduces the capital investment required. Furthermore, the integration of soft robots with smart sensors and machine learning algorithms enables real-time monitoring and optimization of paper handling processes, leading to enhanced efficiency and quality control.

Soft robotics holds great promise in transforming the paper industry by providing adaptable, safe, and cost-effective solutions for paper handling mechanisms. As the field continues to advance, we can expect to see further innovations and applications that will revolutionize the way paper is processed, improving productivity and quality in this essential industry.