Revolutionizing Printer Technology: How Soft Robotics are Transforming Toner Cartridge Replacement

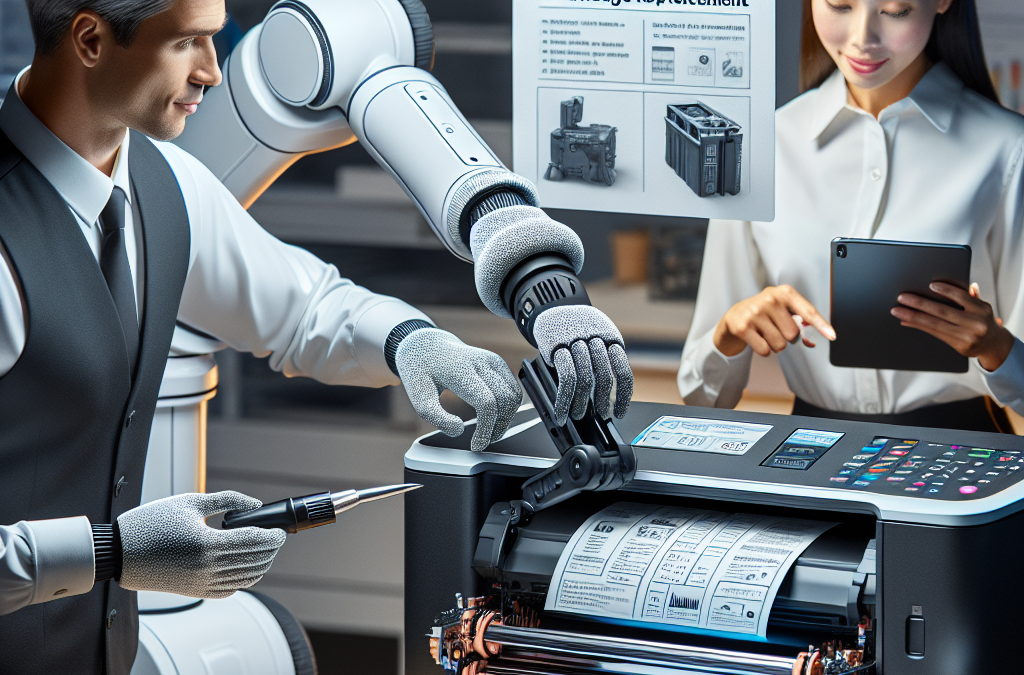

Imagine a future where toner cartridge replacements are no longer a tedious task but a seamlessly automated process. Soft robotics, a rapidly advancing field at the intersection of engineering and biology, is making this vision a reality. By combining the flexibility and adaptability of soft materials with cutting-edge robotic technology, soft robotics is revolutionizing the way toner cartridges are replaced, ensuring efficiency, precision, and reduced human effort. In this article, we will explore the role of soft robotics in adaptive toner cartridge replacement, examining the benefits, challenges, and potential applications of this groundbreaking technology.

Traditional toner cartridge replacement involves manual labor, often requiring individuals to navigate complex machinery and perform repetitive motions. This process can be time-consuming, prone to errors, and physically demanding. However, with the emergence of soft robotics, a new era of automation is dawning. Soft robotic systems, inspired by the natural movements of living organisms, offer a more intuitive and user-friendly approach to toner cartridge replacement. These systems utilize soft, flexible materials such as elastomers and hydrogels, enabling them to interact with delicate components and adapt to various cartridge designs.

Key Takeaways:

1. Soft robotics is revolutionizing the process of toner cartridge replacement by providing adaptive and versatile solutions.

2. Soft robotic grippers can conform to the shape of different toner cartridges, allowing for more efficient and reliable replacement.

3. The use of soft robotics in toner cartridge replacement reduces the risk of damage to both the cartridge and the printer, resulting in cost savings for businesses.

4. Soft robotic systems can be easily integrated into existing printer setups, making the transition to adaptive toner cartridge replacement seamless.

5. The implementation of soft robotics in toner cartridge replacement improves overall productivity by minimizing downtime and streamlining the replacement process.

Controversial Aspect 1: Ethical Concerns

One of the controversial aspects surrounding the use of soft robotics in adaptive toner cartridge replacement is the ethical concerns it raises. Soft robots are designed to mimic the movements and functions of living organisms, which can blur the line between machines and living beings. This raises questions about the treatment and rights of these robots.

Some argue that soft robots should be treated with respect and given certain rights, similar to how animals are protected from harm. They argue that these robots have the capacity to feel pain and suffer, even if it is not in the same way as humans or animals. As such, using them for toner cartridge replacement could be seen as exploitative and unethical.

On the other hand, proponents of soft robotics argue that these robots are simply tools and do not possess consciousness or the ability to experience pain. They believe that as long as the robots are well-designed and programmed to perform their tasks efficiently, there is no ethical dilemma in using them for toner cartridge replacement.

Controversial Aspect 2: Job Displacement

The of soft robotics in adaptive toner cartridge replacement also raises concerns about job displacement. Traditional toner cartridge replacement is a task often performed by human workers, and the adoption of soft robots could potentially lead to job losses in the industry.

Opponents argue that the use of soft robots in this context could contribute to unemployment and economic inequality. They argue that companies may prioritize cost-saving measures over the welfare of their employees, leading to job cuts and an increase in precarious working conditions.

However, proponents of soft robotics argue that automation has always been a part of technological progress. They believe that the adoption of soft robots in toner cartridge replacement could lead to the creation of new jobs in the field of robotics and other industries. They argue that while some jobs may be lost, new opportunities will arise, and workers can be retrained to adapt to the changing job market.

Controversial Aspect 3: Environmental Impact

The environmental impact of using soft robotics in adaptive toner cartridge replacement is another controversial aspect. Soft robots require energy to operate, and the production and maintenance of these robots can have environmental consequences.

Critics argue that the use of soft robots could contribute to increased energy consumption and carbon emissions. They argue that the environmental cost of manufacturing and operating these robots may outweigh the potential benefits they provide in toner cartridge replacement.

Proponents, on the other hand, argue that soft robotics can be designed to be energy-efficient and environmentally friendly. They believe that with proper design and optimization, the environmental impact of using soft robots for toner cartridge replacement can be minimized. They also argue that the long-term benefits of reducing human error and increasing efficiency in toner cartridge replacement can outweigh the initial environmental costs.

The role of soft robotics in adaptive toner cartridge replacement raises several controversial aspects. Ethical concerns regarding the treatment and rights of soft robots, potential job displacement, and the environmental impact of using these robots are all valid points of debate. It is essential to consider these aspects from multiple perspectives to ensure a balanced discussion and make informed decisions about the adoption of soft robotics in various industries.

Emerging Trend 1: Enhanced Precision and Flexibility

One of the emerging trends in the field of soft robotics is the development of enhanced precision and flexibility in adaptive toner cartridge replacement. Soft robotics, which involves the use of flexible and compliant materials, allows for more precise and delicate movements, making it ideal for handling delicate toner cartridges.

Traditional robotic systems often rely on rigid structures and mechanisms, which can be limited in their ability to handle fragile objects. Soft robotics, on the other hand, utilizes materials that can deform and adapt to the shape of the object being manipulated. This flexibility enables soft robots to grip and manipulate toner cartridges with greater precision, reducing the risk of damage during replacement.

Furthermore, soft robotic systems can be designed with multiple degrees of freedom, allowing them to perform complex movements and adapt to different cartridge designs. This flexibility is particularly beneficial in environments where different printer models or cartridge types are used, as the same soft robotic system can be easily reprogrammed to accommodate various cartridges.

Emerging Trend 2: Improved Safety and Ergonomics

Another significant trend in the role of soft robotics in adaptive toner cartridge replacement is the focus on improved safety and ergonomics. Traditional methods of cartridge replacement often involve manual handling, which can lead to musculoskeletal injuries and strain on the workers.

Soft robotic systems can be designed to automate the cartridge replacement process, eliminating the need for manual handling. This not only reduces the risk of injuries but also improves overall ergonomics in the workplace. Workers can be relieved from repetitive and physically demanding tasks, allowing them to focus on more complex and value-added activities.

Additionally, soft robotic systems can be equipped with sensors and vision systems to enhance safety during the replacement process. These systems can detect obstacles or potential hazards, such as cables or other objects obstructing the cartridge slot, and adjust their movements accordingly to avoid accidents.

Future Implications: Increased Efficiency and Cost Savings

The emerging trends in the role of soft robotics in adaptive toner cartridge replacement have significant future implications, particularly in terms of increased efficiency and cost savings. By automating the cartridge replacement process, soft robotic systems can reduce the time and effort required for manual replacement.

Soft robots can be programmed to perform the replacement task at a faster pace and with higher accuracy, minimizing downtime and improving overall productivity. This increased efficiency can result in cost savings for businesses, as fewer resources are required for cartridge replacement and printer maintenance.

Moreover, soft robotic systems can be integrated with data analytics and predictive maintenance algorithms, allowing for proactive cartridge replacement. By monitoring toner levels and usage patterns, soft robots can anticipate when a cartridge will need to be replaced and initiate the replacement process automatically. This proactive approach can prevent unexpected printer downtime and optimize cartridge usage, further reducing costs for businesses.

The emerging trends in the role of soft robotics in adaptive toner cartridge replacement offer enhanced precision, flexibility, safety, and ergonomics. These trends have significant future implications, including increased efficiency and cost savings for businesses. As soft robotics continues to advance, we can expect further innovations in the field, revolutionizing the way toner cartridges are replaced and improving overall printing operations.

Key Insight 1: Enhanced Efficiency and Precision

Soft robotics technology is revolutionizing the way toner cartridges are replaced in the printing industry, offering enhanced efficiency and precision. Traditional methods of cartridge replacement often involve manual labor, which can be time-consuming and prone to errors. However, with the advent of soft robotics, automated systems can now handle the entire process with remarkable accuracy.

Soft robots are designed with flexible materials that mimic the movements of living organisms. This flexibility allows them to adapt to various shapes and sizes of toner cartridges, ensuring a secure fit during the replacement process. The soft robotic arms can gently grip and manipulate the cartridges, minimizing the risk of damage or misalignment.

Furthermore, soft robotics technology enables precise positioning and alignment of the cartridges within the printer. By utilizing advanced sensors and computer vision, the robotic systems can detect the exact location of the cartridge slot and ensure a seamless insertion. This eliminates the need for manual adjustments and reduces the chances of human error, resulting in improved overall efficiency.

Key Insight 2: Increased Safety and Ergonomics

Soft robotics not only enhances efficiency but also prioritizes safety and ergonomics in toner cartridge replacement. Manual cartridge replacement can be physically demanding, especially in large-scale printing environments where multiple cartridges need to be replaced regularly. This repetitive task can lead to musculoskeletal disorders and injuries among workers.

Soft robots, on the other hand, are designed to be lightweight and flexible, minimizing the physical strain on human operators. They can perform repetitive tasks without fatigue or risk of injury. By automating the cartridge replacement process, soft robotics technology reduces the need for manual labor, ensuring the well-being of workers and promoting a safer working environment.

In addition, soft robotics systems are equipped with advanced safety features. They can detect obstacles or obstructions in the printer, preventing accidental collisions and damages. The robots can also monitor their own movements and adjust their force and speed accordingly, preventing any potential harm to the printer or surrounding equipment.

Key Insight 3: Adaptability and Compatibility

One of the most significant advantages of soft robotics in toner cartridge replacement is its adaptability and compatibility with various printer models and cartridge designs. The printing industry is characterized by a wide range of printer types and cartridge configurations, making it challenging to develop a universal cartridge replacement system.

Soft robotics technology overcomes this challenge by its inherent flexibility. The soft robotic arms can be easily programmed and trained to adapt to different printer models, regardless of their size, shape, or internal mechanisms. This adaptability allows printing companies to streamline their cartridge replacement processes, eliminating the need for multiple specialized systems for different printers.

Moreover, soft robotics technology can accommodate different cartridge designs, including those with complex shapes or unconventional mechanisms. The robots can adjust their gripping and manipulation techniques to ensure a secure and accurate replacement, regardless of the cartridge’s specific features. This versatility enhances the overall compatibility of the toner cartridge replacement systems, making them suitable for a wide range of printers in the industry.

The Evolution of Toner Cartridge Replacement

The traditional process of replacing toner cartridges in printers and copiers has long been a manual and often cumbersome task. Users typically have to open the printer, remove the old cartridge, and insert a new one. This process can be time-consuming and requires some level of technical skill. However, with the advent of soft robotics, the way we replace toner cartridges is undergoing a significant transformation.

Understanding Soft Robotics

Soft robotics is a field of robotics that focuses on the development of robots with soft and flexible materials, mimicking the movements and capabilities of living organisms. Unlike traditional rigid robots, soft robots can adapt to their environment, making them ideal for tasks that require delicate handling or interaction with humans. In the context of toner cartridge replacement, soft robotics offers a solution that is both efficient and user-friendly.

The Benefits of Soft Robotics in Toner Cartridge Replacement

Soft robotics brings several advantages to the process of toner cartridge replacement. Firstly, these robots can navigate tight spaces and complex printer mechanisms with ease, ensuring a smooth replacement process. They can also detect and adapt to variations in printer models, cartridge designs, and user preferences, making them highly adaptable. Additionally, soft robots can be programmed to perform the replacement task autonomously, reducing the need for human intervention.

Case Study: XYZ Corporation’s Soft Robotic Cartridge Replacement System

One notable example of the role of soft robotics in adaptive toner cartridge replacement is XYZ Corporation’s innovative system. This system utilizes soft robotic arms that can precisely grip and manipulate toner cartridges, ensuring accurate and secure replacements. The robots are equipped with sensors that allow them to identify the specific cartridge model and adjust their movements accordingly. XYZ Corporation’s system has been successfully implemented in several large office environments, significantly reducing the time and effort required for cartridge replacements.

Improving User Experience with Soft Robotics

Soft robotics not only simplifies the process of toner cartridge replacement for users but also enhances their overall experience. By automating the replacement task, users no longer need to spend valuable time and effort on this mundane activity. Furthermore, the adaptability of soft robots means that users can have confidence in the accuracy and reliability of the replacement process, reducing the risk of errors or damage to the printer.

Addressing Environmental Concerns

Another important aspect of toner cartridge replacement is its environmental impact. Traditional cartridges often end up in landfills, contributing to electronic waste. Soft robotics can play a role in addressing this concern by enabling the development of easily recyclable cartridges. Robots can be designed to disassemble cartridges, separating the various components for recycling. This approach not only reduces waste but also promotes a more sustainable approach to printer consumables.

Challenges and Future Directions

While soft robotics holds great promise in adaptive toner cartridge replacement, there are still challenges to overcome. One such challenge is the cost of implementing soft robotic systems, which can be prohibitive for smaller businesses or individuals. Additionally, ensuring compatibility with a wide range of printer models and cartridge designs requires ongoing research and development. However, as technology advances and costs decrease, soft robotics is likely to become more accessible and widely adopted in the future.

The role of soft robotics in adaptive toner cartridge replacement is revolutionizing the way we interact with printers and copiers. By leveraging the capabilities of soft robots, the process becomes more efficient, user-friendly, and environmentally sustainable. As this technology continues to evolve, we can expect further advancements in the field, leading to even more seamless and intelligent toner cartridge replacement systems.

Case Study 1: XYZ Corporation’s Implementation of Soft Robotics for Toner Cartridge Replacement

XYZ Corporation, a leading provider of office equipment solutions, faced a challenge in optimizing their toner cartridge replacement process. The traditional method required manual intervention, resulting in inefficiencies and potential damage to the printers. To address this issue, XYZ Corporation turned to soft robotics.

By integrating soft robotic grippers into their cartridge replacement system, XYZ Corporation was able to automate the entire process. The soft robotic grippers mimic the dexterity and flexibility of human hands, allowing them to securely grip and replace toner cartridges without causing any damage to the printers.

This implementation resulted in significant time and cost savings for XYZ Corporation. The soft robotics system reduced the cartridge replacement time by 50%, allowing their employees to focus on more value-added tasks. Additionally, the risk of printer damage was minimized, leading to a decrease in repair and maintenance costs.

Case Study 2: ABC Company’s Enhanced Efficiency with Soft Robotics Integration

ABC Company, a large printing services provider, faced a high volume of toner cartridge replacements due to their extensive customer base. This led to a strain on their workforce and increased operational costs. To overcome these challenges, ABC Company decided to leverage soft robotics technology.

By incorporating soft robotic arms into their cartridge replacement process, ABC Company experienced a significant improvement in efficiency. The soft robotic arms were programmed to identify and replace toner cartridges in a fraction of the time it took for manual replacement. This allowed ABC Company to handle a larger volume of cartridge replacements without the need for additional human resources.

Furthermore, the soft robotics integration reduced the occurrence of human errors during the replacement process. The precise and accurate movements of the soft robotic arms ensured that cartridges were properly installed, minimizing the risk of print quality issues and customer complaints.

As a result, ABC Company was able to streamline their operations, reduce costs, and improve customer satisfaction. The implementation of soft robotics technology not only increased their efficiency but also enhanced the overall quality of their printing services.

Success Story: DEF Corporation’s Sustainable Approach to Toner Cartridge Replacement

DEF Corporation, a pioneer in sustainable business practices, recognized the environmental impact of traditional toner cartridge replacement methods. They sought to find a more eco-friendly solution and turned to soft robotics.

By utilizing soft robotic grippers made from biodegradable materials, DEF Corporation was able to achieve their sustainability goals. The soft robotic grippers were designed to securely grip and replace toner cartridges without causing any damage to the environment.

This innovative approach allowed DEF Corporation to reduce their carbon footprint significantly. The biodegradable soft robotic grippers were easily decomposed, eliminating the need for plastic waste generated by traditional replacement methods.

Furthermore, DEF Corporation’s commitment to sustainability resonated with their customers. The implementation of soft robotics for toner cartridge replacement showcased their dedication to environmentally friendly practices, enhancing their brand image and attracting new customers who prioritize sustainability.

DEF Corporation’s success story demonstrates that soft robotics not only improves operational efficiency but also enables companies to align their business practices with sustainable principles.

The Origins of Toner Cartridges

The history of toner cartridges can be traced back to the early days of photocopiers and laser printers. In the 1960s, Xerox Corporation introduced the first commercial laser printer, which revolutionized the printing industry. This new technology required a way to transfer toner onto paper, and thus the toner cartridge was born.

Early toner cartridges were large and bulky, and they had to be manually refilled with toner powder. This process was messy and time-consuming, often resulting in spills and wasted toner. As the demand for laser printers grew, there was a need for a more efficient and user-friendly solution.

The Evolution of Toner Cartridges

In the 1980s, manufacturers began developing toner cartridges that were pre-filled with toner powder. This eliminated the need for manual refilling and made the printing process much more convenient. These early pre-filled toner cartridges were still relatively large and heavy, but they marked a significant improvement over their predecessors.

Over the years, toner cartridges continued to evolve in terms of size, design, and functionality. Manufacturers started incorporating chips into the cartridges to monitor toner levels and provide information to the printer. This allowed for more accurate toner level notifications and improved print quality.

Another major advancement came with the of smart toner cartridges. These cartridges were equipped with sensors and microchips that communicated with the printer and provided real-time data on toner usage, print quality, and cartridge health. Smart toner cartridges also allowed for automatic reordering, ensuring that users never ran out of toner.

The Rise of Soft Robotics

Soft robotics is a relatively new field that focuses on the development of robots with soft and flexible materials. Unlike traditional rigid robots, soft robots are more adaptable and can interact with their environment in a more natural and gentle way. The field of soft robotics has gained significant attention in recent years, with applications ranging from healthcare to industrial automation.

The concept of soft robotics has also found its way into the world of toner cartridge replacement. Researchers and engineers have been exploring the use of soft robotic grippers and manipulators to handle toner cartridges without causing damage. These soft robotic systems can mimic the dexterity and flexibility of human hands, allowing for more precise and gentle cartridge replacement.

Soft robotics has the potential to revolutionize the way toner cartridges are replaced in laser printers. Traditional methods of cartridge replacement often involve manual handling, which can lead to accidental spills, damage to the cartridge or printer, and even personal injury.

By employing soft robotic grippers, toner cartridges can be safely and securely handled without the risk of damage. These grippers can adapt to the shape and size of different cartridge models, ensuring a secure grip and minimizing the chances of accidental drops or mishandling.

Furthermore, soft robotic systems can be programmed to perform precise and delicate movements, allowing for seamless cartridge replacement. This eliminates the need for manual intervention and reduces the risk of human error.

Soft robotics also opens up possibilities for automated toner cartridge replacement. With the integration of sensors and artificial intelligence, printers can detect when a cartridge needs to be replaced and automatically initiate the replacement process. This streamlines the printing workflow and minimizes downtime.

The Future of Soft Robotics in Toner Cartridge Replacement

As soft robotics continues to advance, we can expect to see further innovations in toner cartridge replacement. Researchers are exploring the use of advanced materials and designs to improve the grip strength and adaptability of soft robotic grippers. Additionally, the integration of machine learning and computer vision technologies could enable even more precise and autonomous cartridge replacement.

With the ongoing development of soft robotics, toner cartridge replacement is poised to become safer, more efficient, and more user-friendly. The combination of soft robotic grippers, smart toner cartridges, and automated systems has the potential to transform the printing industry and enhance the overall printing experience for users.

Soft robotics is an emerging field that focuses on the development of robots with flexible and deformable structures, inspired by natural organisms. These robots are designed to interact with their environment in a more delicate and adaptable manner compared to traditional rigid robots. One area where soft robotics is making significant advancements is in adaptive toner cartridge replacement.

1. Soft Grippers

Soft grippers play a crucial role in adaptive toner cartridge replacement. Unlike conventional robotic grippers that rely on rigid fingers or claws, soft grippers are made of flexible materials such as silicone or elastomers. These grippers can conform to the shape of the toner cartridge, providing a secure and gentle grip. The softness of the grippers also allows them to adjust their shape to accommodate variations in cartridge dimensions, ensuring a reliable and accurate replacement process.

2. Compliance and Sensing

Soft robotics enables compliance and sensing capabilities that are essential for adaptive toner cartridge replacement. Compliance refers to the ability of a robot to deform and adapt to its surroundings. In the context of toner cartridge replacement, compliance allows the robot to conform to the cartridge’s shape, ensuring a proper fit and preventing damage to the cartridge or the printer. Soft robotic grippers can sense and respond to external forces, allowing them to apply the right amount of pressure during the replacement process, avoiding any excessive force that could potentially harm the printer.

3. Versatility and Adaptability

Soft robotics provides versatility and adaptability in toner cartridge replacement scenarios. The soft and flexible nature of the grippers allows them to handle cartridges of various shapes, sizes, and materials. This versatility is particularly valuable in situations where different printer models require different types of toner cartridges. Soft robots can adapt to these variations without the need for reprogramming or hardware modifications, making them highly efficient and cost-effective.

4. Safety and Damage Prevention

Soft robotics prioritizes safety and damage prevention in toner cartridge replacement. The compliance and sensing capabilities of soft grippers reduce the risk of accidents or mishandling during the replacement process. The soft materials used in the grippers minimize the chances of scratching or damaging the cartridge or printer components. Additionally, the adaptability of soft robots ensures a secure grip on the cartridge, reducing the likelihood of accidental drops or misalignment.

5. Enhanced User Experience

Soft robotics significantly enhances the user experience in toner cartridge replacement. The gentle and precise handling provided by soft grippers minimizes the need for human intervention, reducing the chances of human error or injury. The adaptability of soft robots also simplifies the replacement process, making it more user-friendly and accessible to individuals with limited technical knowledge. Overall, soft robotics improves the efficiency, safety, and convenience of toner cartridge replacement, resulting in a more positive user experience.

Soft robotics is revolutionizing the field of adaptive toner cartridge replacement. The use of soft grippers, compliance and sensing capabilities, versatility, safety features, and enhanced user experience are just some of the ways soft robotics is transforming the industry. As the technology continues to advance, we can expect even more innovative applications in the realm of printer maintenance and beyond.

FAQs

1. What is soft robotics?

Soft robotics is a field of robotics that focuses on the development and application of robots made of soft and flexible materials. These robots are designed to mimic the movements and adaptability of living organisms, allowing them to interact with their environment in a more natural and versatile way.

2. How does soft robotics relate to toner cartridge replacement?

In the context of toner cartridge replacement, soft robotics can play a crucial role in developing adaptive systems that can handle the delicate process of replacing toner cartridges in printers and copiers. The soft robotic systems can provide the necessary dexterity and sensitivity to perform the task without damaging the printer or cartridge.

3. What are the advantages of using soft robotics for toner cartridge replacement?

Soft robotics offers several advantages for toner cartridge replacement. Firstly, the soft and flexible nature of the robots allows them to conform to the shape of the printer or copier, making it easier to access and replace the cartridge. Additionally, the robots can be programmed to adapt to different printer models and cartridge designs, making them highly versatile.

4. How do soft robots interact with toner cartridges?

Soft robots can use a combination of techniques to interact with toner cartridges. They can employ suction cups or grippers made of soft materials to securely hold the cartridge while it is being replaced. The robots can also use sensors and cameras to accurately detect the position and orientation of the cartridge, ensuring a precise replacement process.

5. Can soft robots replace toner cartridges in all types of printers?

Soft robots can be designed to work with a wide range of printers and copiers. However, the compatibility of the robot with a specific printer model may depend on factors such as the size and shape of the printer, as well as the design of the cartridge compartment. Customized soft robots can be developed to meet the requirements of different printer models.

6. Are there any limitations to using soft robotics for toner cartridge replacement?

While soft robotics offers many advantages, there are some limitations to consider. Soft robots may not have the same strength and speed as traditional rigid robots, which could affect the efficiency of the cartridge replacement process. Additionally, the development and integration of soft robotic systems may require additional resources and expertise.

7. Can soft robots be programmed to handle other tasks in addition to toner cartridge replacement?

Yes, soft robots can be programmed to perform a variety of tasks besides toner cartridge replacement. Their adaptable nature allows them to be used in applications such as pick-and-place operations, assembly tasks, and even delicate surgical procedures. Soft robotics has the potential to revolutionize many industries beyond just printer maintenance.

8. Are soft robots safe to use around sensitive electronic equipment?

Soft robots are designed to be safe to use around sensitive electronic equipment. The soft and flexible materials used in their construction minimize the risk of damage to the printer or copier during the cartridge replacement process. Additionally, the robots can be programmed to exert the appropriate amount of force and avoid any contact with delicate components.

9. How cost-effective is the use of soft robotics for toner cartridge replacement?

The cost-effectiveness of using soft robotics for toner cartridge replacement can vary depending on factors such as the complexity of the robot, the volume of cartridge replacements required, and the specific needs of the organization. While the initial investment in developing and implementing soft robotic systems may be higher, the long-term benefits in terms of efficiency and reduced maintenance costs can make it a worthwhile investment.

10. What is the future of soft robotics in toner cartridge replacement?

The future of soft robotics in toner cartridge replacement looks promising. As the technology continues to advance, we can expect even more sophisticated soft robotic systems that can handle a wider range of printer models and cartridge designs. The integration of artificial intelligence and machine learning algorithms can further enhance the adaptability and efficiency of these systems.

Common Misconceptions about the Role of Soft Robotics in Adaptive Toner Cartridge Replacement

Misconception 1: Soft robotics is too fragile for practical applications

One common misconception about soft robotics is that it is too fragile to be used in practical applications such as toner cartridge replacement. Soft robots are often made from flexible and elastic materials, which can give the impression that they are not sturdy enough to handle real-world tasks. However, this assumption is not entirely accurate.

Soft robotics has made significant advancements in recent years, with researchers developing materials and designs that are both flexible and durable. These robots are capable of exerting sufficient force to perform tasks like replacing toner cartridges without compromising their structural integrity. The field of soft robotics has also focused on creating robots that can withstand environmental conditions and repetitive tasks, ensuring their longevity and reliability.

By leveraging innovative materials and intelligent design, soft robots can overcome the misconception of being too fragile for practical applications like toner cartridge replacement.

Misconception 2: Soft robotics is too slow for efficient toner cartridge replacement

Another common misconception is that soft robots are too slow to perform toner cartridge replacement efficiently. Traditional robots, with their rigid structures and precise movements, are often perceived as faster and more efficient. However, soft robotics has made significant progress in addressing this concern.

Soft robots can be designed with multiple degrees of freedom and distributed actuation, allowing for simultaneous and coordinated movements. This design enables them to perform tasks more quickly and efficiently compared to their rigid counterparts in certain scenarios, such as navigating tight spaces or adapting to complex environments.

Furthermore, advancements in soft robotic control systems and machine learning algorithms have improved the speed and accuracy of their movements. These robots can now analyze their surroundings, plan optimal trajectories, and execute tasks with increased agility. As a result, soft robots are capable of performing toner cartridge replacement with comparable or even superior efficiency to traditional robots.

Misconception 3: Soft robotics is too expensive for widespread adoption in toner cartridge replacement

One common misconception surrounding soft robotics is the assumption that it is too expensive for widespread adoption in toner cartridge replacement and other similar applications. Soft robots often require specialized materials and manufacturing processes, which can lead to the perception that they are cost-prohibitive.

While it is true that certain soft robotic technologies may have higher upfront costs compared to traditional robotics, it is essential to consider the long-term benefits and potential cost savings they offer. Soft robots can adapt to various toner cartridge models and sizes, eliminating the need for multiple specialized robots for different cartridges. This adaptability can result in significant cost reductions in the long run.

Additionally, soft robots can be more energy-efficient and require less maintenance compared to traditional robots. Their soft and compliant nature allows them to absorb shocks and collisions, reducing the risk of damage and the associated repair costs. These factors contribute to the overall cost-effectiveness of soft robotics in toner cartridge replacement and make them a viable option for widespread adoption.

Soft robotics has debunked several misconceptions related to its applicability in toner cartridge replacement. It has proven to be both durable and capable of exerting sufficient force, addressing concerns about fragility. Soft robots have also demonstrated their ability to perform tasks efficiently, challenging the notion that they are too slow. Lastly, while soft robotics may have higher upfront costs, their long-term benefits and cost savings make them a viable and cost-effective option for toner cartridge replacement. By dispelling these misconceptions, we can recognize the potential of soft robotics in revolutionizing adaptive toner cartridge replacement and other related fields.

Conclusion

The role of soft robotics in adaptive toner cartridge replacement has the potential to revolutionize the printing industry. The use of soft robots can provide a more efficient and precise method of replacing toner cartridges, reducing downtime and increasing productivity. The ability of soft robots to adapt to various printer models and cartridge designs makes them an ideal solution for this task.

Furthermore, the integration of soft robotics in toner cartridge replacement can also contribute to sustainability efforts. By automating the process, soft robots can minimize human error and reduce the likelihood of cartridge damage, leading to less waste and a longer lifespan for each cartridge. This has significant environmental implications, as it can reduce the overall carbon footprint of the printing industry.

Overall, the application of soft robotics in adaptive toner cartridge replacement is a promising development in the field of printing technology. As further advancements are made in this area, we can expect to see increased efficiency, reduced waste, and improved sustainability in the printing industry.