Pushing the Boundaries: Exploring Revolutionary Materials Reshaping the Future of Printing

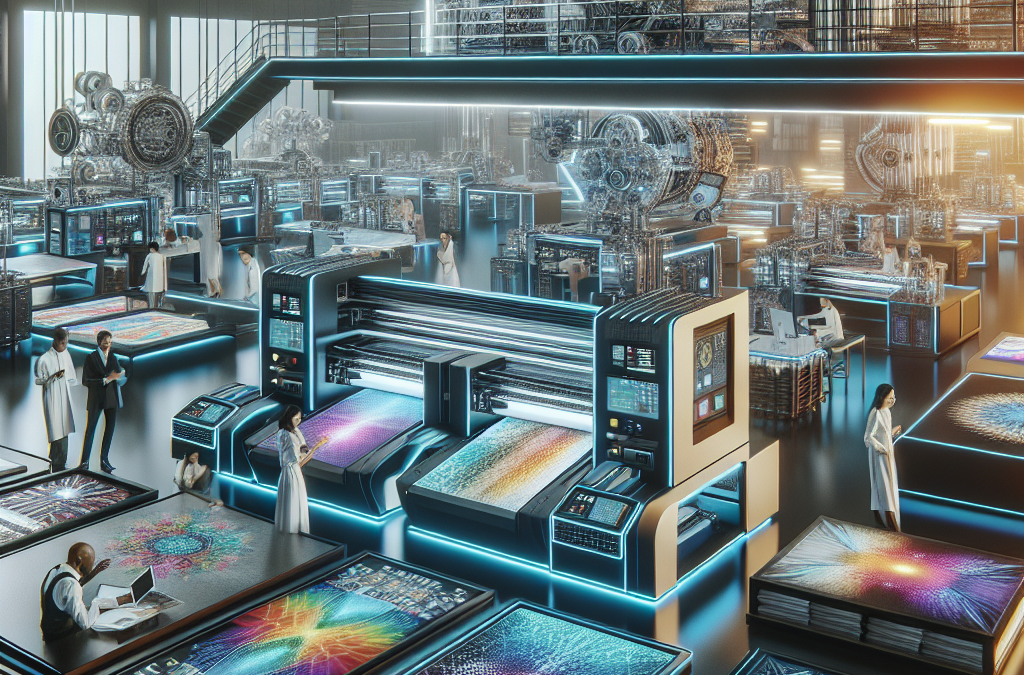

In a world where technology is constantly evolving, even the way we print documents has undergone a remarkable transformation. Gone are the days when paper was the only medium for printing; today, cutting-edge printing techniques are pushing the boundaries of what can be printed on. From edible materials to fabrics and even living cells, the possibilities seem endless. In this article, we will explore the fascinating world of unconventional materials for printing, delving into the innovative techniques and applications that are revolutionizing the printing industry.

Printing has come a long way since Johannes Gutenberg introduced the printing press in the 15th century. While paper has been the go-to medium for centuries, recent advancements have opened up a whole new realm of possibilities. Imagine printing on a material that you can eat, like chocolate or sugar, creating intricate designs that are not only visually appealing but also delicious. Or picture printing on fabrics, enabling the creation of personalized clothing, accessories, and even home decor items. And what about printing living cells, paving the way for groundbreaking developments in the field of bioprinting? These are just a few examples of the unconventional materials that are pushing the boundaries of printing technology. In this article, we will dive into the world of unconventional printing materials and explore the cutting-edge techniques that are making it all possible.

Key Takeaways

1. Exploring unconventional materials for printing opens up new possibilities for creativity and innovation in various industries.

2. Conductive ink allows for the printing of functional electronic circuits on a range of materials, revolutionizing fields such as wearable technology and smart packaging.

3. Bio-ink, made from living cells, enables the printing of human organs and tissues, offering hope for advancements in regenerative medicine and personalized healthcare.

4. 3D printing with materials like metal and ceramics allows for the creation of complex, durable, and high-performance parts, transforming industries such as aerospace and manufacturing.

5. Sustainable printing materials, such as algae-based ink and recycled plastics, reduce environmental impact and promote a more eco-friendly approach to printing.

Eco-friendly Printing: The Rise of Sustainable Materials

With the increasing concern for the environment, the printing industry is undergoing a significant transformation. Traditional paper-based printing methods are being replaced by innovative techniques that utilize unconventional and eco-friendly materials. This emerging trend in printing is not only reducing the industry’s carbon footprint but also opening up new opportunities for creative and sustainable designs.

One of the most notable developments in eco-friendly printing is the use of recycled materials. Instead of relying on virgin paper, manufacturers are now utilizing post-consumer waste, such as discarded paper, cardboard, and even plastic, to create printing substrates. These materials undergo a thorough recycling process, resulting in high-quality paper-like sheets that can be used for a wide range of printing applications.

Additionally, alternative materials such as bamboo, hemp, and even agricultural waste are being explored as printing mediums. These materials offer several advantages over traditional paper, including faster growth rates, lower water requirements, and reduced chemical usage. Furthermore, they can be easily replenished, making them a more sustainable option for the printing industry.

The implications of this trend are far-reaching. By adopting eco-friendly printing practices, businesses can align themselves with the growing demand for sustainable solutions. This not only enhances their brand image but also attracts environmentally conscious customers. Moreover, the reduced reliance on traditional paper production helps conserve forests and reduces water and energy consumption.

In the future, we can expect to see a widespread adoption of eco-friendly printing materials and techniques. As technology advances, the quality and versatility of these materials will continue to improve, making them a viable alternative to traditional paper. This shift towards sustainability in printing not only benefits the environment but also drives innovation and creativity in the industry.

Functional Printing: From Paper to 3D Objects

Printing is no longer limited to two-dimensional paper surfaces. Advancements in technology have paved the way for functional printing, where unconventional materials are used to create three-dimensional objects with specific functionalities. This emerging trend is revolutionizing industries such as manufacturing, healthcare, and even fashion.

One of the key materials driving functional printing is conductive ink. This ink contains tiny particles of conductive materials, such as silver or copper, which allow for the creation of electronic circuits and components. With functional printing, it is now possible to print flexible and customizable electronics, such as wearable sensors, smart labels, and even medical devices.

Another exciting development in functional printing is the use of bioactive materials. These materials have the ability to interact with living organisms, making them ideal for applications in healthcare and biotechnology. For example, researchers are exploring the use of biocompatible materials to print artificial organs, prosthetics, and even drug delivery systems.

The implications of functional printing are immense. In the manufacturing industry, it enables the production of complex and customized parts with reduced waste and cost. In healthcare, it opens up new possibilities for personalized medicine and patient-specific treatments. Moreover, functional printing allows for the integration of electronics and functionality into everyday objects, creating a new paradigm for design and innovation.

Looking ahead, functional printing is expected to continue evolving and expanding into new areas. As materials and printing techniques improve, we can anticipate the development of more advanced and sophisticated functional objects. This trend has the potential to reshape industries and revolutionize the way we design, manufacture, and interact with the world around us.

Biodegradable Printing: A Sustainable Solution for Packaging

The issue of plastic waste has become a global concern, and the packaging industry is under pressure to find sustainable alternatives. Biodegradable printing is emerging as a promising solution, offering the ability to create packaging materials that break down naturally without harming the environment.

One of the key materials in biodegradable printing is bioplastics. These plastics are derived from renewable sources, such as cornstarch or sugarcane, and can be easily composted or degraded by natural processes. By utilizing bioplastics in printing, manufacturers can create packaging materials that are not only functional but also environmentally friendly.

In addition to bioplastics, other biodegradable materials such as algae-based inks and cellulose-based substrates are being explored. These materials offer similar properties to traditional printing materials but have minimal impact on the environment. By incorporating these materials into the printing process, companies can reduce their carbon footprint and contribute to a more sustainable future.

The implications of biodegradable printing go beyond just packaging. As consumers become more conscious of the environmental impact of their choices, demand for sustainable products is on the rise. By adopting biodegradable printing practices, businesses can differentiate themselves in the market and attract environmentally conscious customers. Moreover, the use of biodegradable materials helps reduce the accumulation of plastic waste in landfills and oceans.

Looking ahead, biodegradable printing is poised to become the norm in the packaging industry. As technology advances, we can expect to see more innovative materials and techniques that offer enhanced functionality and sustainability. This trend not only addresses the urgent need for eco-friendly packaging but also drives innovation and creativity in the printing industry.

The Controversial Aspects of ‘Beyond Paper: Unconventional Materials for Cutting-Edge Printing’

1. Environmental Impact

One of the most controversial aspects surrounding the use of unconventional materials for cutting-edge printing is the potential environmental impact. Traditional printing methods already have a significant carbon footprint, and the of new materials raises concerns about exacerbating this issue.

Proponents of unconventional materials argue that they offer a more sustainable alternative to traditional paper. For example, printing on materials like stone, fabric, or even food waste can reduce the demand for wood pulp and decrease deforestation. Additionally, some unconventional materials, such as bioplastics, are biodegradable, further reducing their environmental impact.

However, critics argue that the production and disposal of these materials may still have negative consequences. The manufacturing process for unconventional materials often involves energy-intensive procedures and the use of chemicals that could potentially harm ecosystems. Moreover, the disposal of these materials may present challenges, as some may not be easily recyclable or compostable.

2. Quality and Durability

Another controversial aspect of using unconventional materials for cutting-edge printing is the potential impact on the quality and durability of printed products. Traditional paper has been refined over centuries to provide optimal printing surfaces, but using alternative materials may compromise these qualities.

Proponents argue that unconventional materials can offer unique textures and visual effects that enhance the printed product’s appeal. For example, printing on fabrics can create a tactile experience, while using metals or plastics can add a metallic or glossy finish. These materials also provide opportunities for innovative designs and applications.

However, critics raise concerns about the longevity of prints on unconventional materials. Traditional paper has proven to be durable, resistant to fading, and capable of preserving printed content for extended periods. Unconventional materials may not possess these same qualities, potentially leading to deterioration or loss of information over time. Furthermore, the suitability of these materials for various printing techniques, such as inkjet or laser printing, may vary, affecting the overall quality of the final product.

3. Accessibility and Affordability

The accessibility and affordability of unconventional materials for cutting-edge printing is a controversial aspect that impacts both producers and consumers. While these materials offer exciting possibilities, their availability and cost may limit their widespread adoption.

Proponents argue that the use of unconventional materials can democratize printing by providing alternatives to traditional paper that are more readily available or cheaper to produce. For instance, printing on agricultural waste or recycled materials can reduce costs and make printing more accessible to a wider range of individuals and businesses.

However, critics contend that the current market for unconventional materials is limited, making them less accessible to smaller printing businesses or individuals. The production of these materials often requires specialized equipment or processes, which can drive up costs. Additionally, the demand for unconventional materials may not yet be sufficient to achieve economies of scale, further hindering affordability.

A Balanced Viewpoint

It is essential to approach the use of unconventional materials for cutting-edge printing with a balanced viewpoint. While these materials offer exciting possibilities, it is crucial to consider the potential environmental impact, the quality and durability of prints, as well as the accessibility and affordability for all stakeholders involved.

Finding a balance between innovation and sustainability is key. Manufacturers should strive to develop unconventional materials that have a minimal environmental impact throughout their lifecycle. This includes using eco-friendly production processes, ensuring recyclability or compostability, and exploring ways to reduce energy consumption.

Moreover, continued research and development are necessary to improve the quality and durability of prints on unconventional materials. Understanding the long-term effects of these materials on print preservation and exploring new printing techniques specific to each material can help address concerns regarding their longevity.

Lastly, efforts should be made to increase the accessibility and affordability of unconventional materials. This can be achieved through collaborations between material producers, printing businesses, and policymakers, aiming to reduce costs, develop standardized processes, and promote the use of these materials in various industries.

While the use of unconventional materials for cutting-edge printing presents exciting possibilities, it is essential to address the controversial aspects surrounding their environmental impact, quality and durability, as well as accessibility and affordability. by considering these factors and working towards sustainable and inclusive solutions, the printing industry can embrace innovation while minimizing potential drawbacks.

Insight 1: Revolutionary Materials Pushing the Boundaries of Printing

The printing industry has undergone a significant transformation in recent years, thanks to the emergence of unconventional materials that are revolutionizing the way we print. Beyond traditional paper, novel materials such as metal, plastic, fabric, and even food substances are being used to create cutting-edge prints. This shift towards unconventional materials has opened up new possibilities and expanded the applications of printing in various industries.

One of the key impacts of these unconventional materials is the ability to print on non-traditional surfaces. For example, printing on metal allows for durable and weather-resistant signage and labels, making it ideal for outdoor applications. Similarly, printing on fabric enables the creation of customized clothing, accessories, and home decor items. This versatility has not only expanded the reach of printing but has also given businesses and individuals the opportunity to personalize and differentiate their products.

Moreover, the use of unconventional materials has also led to advancements in functional printing. For instance, conductive inks made from silver nanoparticles can be printed on flexible substrates, enabling the production of electronic devices such as wearable sensors and smart packaging. This integration of functionality into printed materials has opened up a whole new realm of possibilities, from interactive packaging that provides real-time information to medical devices that can be customized for individual patients.

In addition to expanding the applications of printing, these unconventional materials have also had a profound impact on sustainability. Traditional paper production requires the cutting down of trees and consumes a significant amount of water and energy. In contrast, printing on unconventional materials such as recycled plastics or biodegradable materials reduces the environmental footprint associated with printing. This shift towards more sustainable materials aligns with the growing demand for eco-friendly practices across industries and reflects a commitment to reducing waste and carbon emissions.

Insight 2: Challenges and Opportunities in Adopting Unconventional Materials

While the use of unconventional materials in printing offers numerous benefits, it also presents challenges that need to be addressed. One of the main challenges is the compatibility of these materials with existing printing technologies. Traditional printing presses and equipment are designed to work with paper, and adapting them to handle unconventional materials can be complex and costly. Printers need to invest in specialized machinery and undergo training to ensure they can effectively work with these materials.

Another challenge is the development of suitable inks and coatings for unconventional materials. Each material requires specific ink formulations to ensure proper adhesion, color vibrancy, and durability. Manufacturers and ink suppliers are continuously researching and developing new formulations to meet the unique requirements of different materials. This ongoing innovation is crucial to unlocking the full potential of unconventional materials in printing.

However, these challenges also present opportunities for innovation and collaboration. Printers, material suppliers, and technology developers are working together to develop new solutions and overcome the barriers associated with using unconventional materials. This collaboration has led to the creation of hybrid printing technologies that combine traditional and digital printing methods, allowing for seamless integration of unconventional materials into existing workflows. Moreover, partnerships between material suppliers and printers have resulted in the development of customized solutions tailored to specific industries or applications.

Insight 3: Transforming Industries and Enabling New Possibilities

The adoption of unconventional materials in printing is transforming various industries and enabling new possibilities. One industry that has greatly benefited from this shift is the fashion and textile industry. With the ability to print on fabric, designers can now create intricate patterns, vibrant colors, and even three-dimensional textures directly onto garments. This eliminates the need for traditional fabric dyeing processes, reducing water consumption and chemical waste. Furthermore, it enables on-demand production, reducing inventory waste and enabling customization at scale.

The packaging industry is also experiencing a revolution with the use of unconventional materials. Brands can now create packaging that not only protects and promotes their products but also provides interactive experiences for consumers. Smart packaging with embedded sensors or augmented reality features can enhance product information, engage customers, and track product authenticity. This has significant implications for brand differentiation, consumer engagement, and supply chain traceability.

Additionally, the healthcare industry is benefiting from the use of unconventional materials in printing. Customized medical devices, such as prosthetics and implants, can now be 3D printed using biocompatible materials. This allows for a more precise fit and reduces the cost and lead time associated with traditional manufacturing processes. Furthermore, the integration of functional printing enables the creation of personalized drug delivery systems and diagnostic devices, revolutionizing the field of personalized medicine.

The adoption of unconventional materials in printing is driving innovation, expanding applications, and promoting sustainability in the industry. the ability to print on non-traditional surfaces, the advancement of functional printing, and the focus on eco-friendly materials are transforming industries and enabling new possibilities. while challenges exist, collaboration and innovation are key to unlocking the full potential of these materials and pushing the boundaries of printing further. as technology continues to evolve, we can expect even more unconventional materials to emerge, further revolutionizing the printing industry.

The Rise of Unconventional Materials in Printing

The world of printing has evolved significantly over the years, moving beyond traditional paper and venturing into new and unconventional materials. This section will explore the reasons behind this shift and the advantages of using unconventional materials for cutting-edge printing. We will delve into the various industries that have embraced these materials and how they have revolutionized the printing process.

Exploring Alternative Substrates for Printing

In this section, we will discuss the wide range of alternative substrates that are being used in cutting-edge printing. From fabrics and plastics to metals and ceramics, printers are pushing the boundaries of what can be printed on. We will explore the unique properties and applications of these materials, showcasing examples of how they have been used in various industries.

The Role of 3D Printing in Material Innovation

3D printing has been a game-changer in the world of printing, allowing for the creation of complex objects and structures. This section will focus on how 3D printing has contributed to the development of unconventional materials for printing. We will discuss the materials used in 3D printing, such as biodegradable plastics and carbon fiber composites, and how they are reshaping the manufacturing industry.

Unconventional Materials in Packaging and Labeling

Packaging and labeling play a crucial role in product branding and consumer engagement. In this section, we will explore how unconventional materials are being used to create innovative packaging and labeling solutions. We will discuss the advantages of using materials like bioplastics, metal foils, and holographic films, and how they enhance product visibility, sustainability, and overall consumer experience.

Unconventional Materials in Art and Design

Artists and designers are constantly pushing the boundaries of creativity, and unconventional materials have become a valuable tool in their repertoire. This section will showcase examples of how artists and designers are using unconventional materials, such as wood, glass, and even food, to create unique and thought-provoking pieces. We will explore the impact of these materials on the art world and how they challenge traditional notions of what can be considered art.

Unconventional Materials in Advertising and Signage

Advertising and signage are essential for businesses to attract customers and create brand awareness. This section will discuss how unconventional materials are being used in advertising and signage to create eye-catching and memorable displays. We will explore materials like vinyl, acrylic, and LED lights, and how they are transforming the advertising landscape. Case studies of successful campaigns will be highlighted to illustrate the effectiveness of these unconventional materials.

The Future of Unconventional Materials in Printing

In this section, we will look ahead and discuss the future of unconventional materials in printing. We will explore emerging technologies and materials, such as conductive inks and smart fabrics, and their potential applications in various industries. We will also discuss the challenges and opportunities that lie ahead as printers continue to push the boundaries of what is possible with unconventional materials.

Environmental Considerations and Sustainability

As the world becomes more conscious of environmental issues, sustainability has become a key consideration in printing. This section will explore how unconventional materials can contribute to a more sustainable printing industry. We will discuss the advantages of using materials like recycled paper, biodegradable plastics, and plant-based inks, and how they can help reduce waste and carbon footprint.

Challenges and Limitations of Unconventional Materials

While unconventional materials offer exciting possibilities, they also come with their own set of challenges and limitations. In this section, we will discuss some of the common issues faced when working with unconventional materials, such as compatibility with printing technologies, durability, and cost. We will also explore how these challenges are being addressed through research and innovation.

In conclusion, the use of unconventional materials in cutting-edge printing has opened up a world of possibilities. From 3D printing to innovative packaging and signage, these materials have revolutionized the way we think about printing. As technology continues to advance and sustainability becomes increasingly important, we can expect to see even more exciting developments in the world of unconventional materials for printing.

The Advent of Printing: From Paper to Unconventional Materials

Printing has been a fundamental part of human communication for centuries, with paper being the primary medium for most of its history. However, as technology has advanced, so too has the desire to push the boundaries of what can be printed on. The concept of using unconventional materials for printing has gradually evolved over time, leading to the development of cutting-edge techniques and applications in the modern era.

Early Innovations and Limitations

In the early days of printing, the use of unconventional materials was virtually non-existent. The invention of the printing press by Johannes Gutenberg in the 15th century revolutionized the spread of information, but it was limited to paper as the medium. Gutenberg’s press relied on movable type, which required a flat and flexible surface to transfer ink onto. Paper was the most practical choice due to its availability, affordability, and ease of use.

Explorations in Alternative Materials

As printing technology advanced and new materials became accessible, printers began to experiment with alternative mediums. In the 19th century, for example, printing on fabrics gained popularity, allowing for the creation of intricate patterns on textiles. This breakthrough opened up new possibilities for the fashion and textile industries, enabling the mass production of printed fabrics.

Industrial Revolution and Technological Innovations

The Industrial Revolution of the 18th and 19th centuries brought about significant advancements in printing technology. The of steam-powered presses and the development of lithography techniques expanded the range of materials that could be printed on. Lithography, which involved transferring ink from a flat surface onto paper or other materials, allowed for more detailed and vibrant prints.

The Rise of Digital Printing

The late 20th century witnessed a paradigm shift in printing with the advent of digital technology. Digital printing eliminated the need for physical printing plates, opening up new possibilities for unconventional materials. This shift was driven by the increasing demand for personalized and on-demand printing, as well as the desire to print on a wider range of surfaces.

Exploring Unconventional Materials

As digital printing technology advanced, so did the exploration of unconventional materials. Artists, designers, and innovators began experimenting with materials such as metal, glass, wood, plastics, and even food items. The ability to print directly onto these materials, either through inkjet or laser printing, allowed for unique and eye-catching designs that were previously unimaginable.

Applications and Impact

The use of unconventional materials in printing has had a profound impact on various industries. In architecture and interior design, for example, 3D printing has revolutionized the creation of intricate and customized structures. Printing on unconventional materials has also found applications in the fashion industry, where designers can create garments with embedded electronics or unique patterns on unconventional fabrics.

Challenges and Future Outlook

While the possibilities of printing on unconventional materials are vast, there are still challenges to overcome. The compatibility of printing techniques with different materials, the durability of prints, and the cost-effectiveness of the process remain areas of ongoing research and development. However, with advancements in materials science, nanotechnology, and printing technologies, the future of printing on unconventional materials looks promising.

The evolution of printing from paper to unconventional materials has been a journey driven by technological advancements and the desire for innovation. From the early days of paper-based printing to the current state of cutting-edge techniques, the exploration of unconventional materials has expanded the horizons of what can be printed on. As technology continues to advance, we can expect even more exciting possibilities in the world of printing on unconventional materials.

The Case of Sustainable Printing: Using Algae Ink

In recent years, the printing industry has been exploring alternative materials that are not only innovative but also environmentally friendly. One such case study is the use of algae ink for printing purposes. Algae ink is derived from microalgae, a sustainable and renewable resource that has gained attention for its potential to revolutionize the printing industry.

Algae ink offers several advantages over traditional ink made from petroleum-based products. Firstly, microalgae can be grown in large quantities using minimal resources, making it a highly sustainable option. Additionally, algae ink has a lower carbon footprint as it does not require the extraction and processing of fossil fuels. This makes it an attractive choice for companies looking to reduce their environmental impact.

One success story in the use of algae ink is the collaboration between a printing company and a biotechnology firm. The printing company, known for its commitment to sustainability, was looking for a more eco-friendly alternative to traditional ink. They partnered with the biotechnology firm, which had developed a method to extract ink from microalgae.

The printing company successfully integrated algae ink into their production process, resulting in a significant reduction in their carbon emissions. By switching to algae ink, they were able to align their printing operations with their sustainability goals, attracting environmentally conscious clients and gaining a competitive edge in the market.

Revolutionizing Packaging: Printing with Biodegradable Materials

The packaging industry has long been criticized for its contribution to waste and pollution. However, advancements in printing technology have opened up new possibilities for using biodegradable materials in packaging design.

One notable case study is the collaboration between a packaging company and a research institute. The packaging company was looking for a way to reduce the environmental impact of their products while maintaining their high-quality standards. They partnered with the research institute, which had developed a biodegradable material that could be used for printing.

The packaging company successfully incorporated the biodegradable material into their printing process, allowing them to create sustainable packaging solutions. The biodegradable material not only met their quality requirements but also offered the added benefit of being environmentally friendly. This innovation helped the company attract eco-conscious customers and position themselves as leaders in sustainable packaging.

The success of this case study demonstrates that printing with biodegradable materials can be a game-changer for the packaging industry. By embracing this technology, companies can reduce their environmental impact and meet the growing demand for sustainable packaging solutions.

Personalized Healthcare: 3D Printing with Living Cells

The field of healthcare has also witnessed the application of unconventional materials in cutting-edge printing. One remarkable success story is the use of 3D printing with living cells to create personalized medical devices and tissues.

In this case study, a medical research institution collaborated with a 3D printing company to develop a method for printing with living cells. The goal was to create custom-made implants and tissues that could be used in various medical procedures.

The collaboration resulted in the successful creation of 3D-printed organs, such as ears and blood vessels, using living cells. This breakthrough allowed for the production of personalized medical devices that closely match the patient’s anatomy, increasing the chances of successful outcomes.

The use of living cells in 3D printing has the potential to revolutionize the healthcare industry. It offers the possibility of creating complex, functional tissues and organs that can be used for transplantation, reducing the need for traditional donor organs. This technology has the potential to save lives and improve the quality of life for patients in need of organ replacements.

These case studies demonstrate the power of unconventional materials in cutting-edge printing. from sustainable algae ink to biodegradable packaging materials and 3d printing with living cells, these innovations have the potential to transform industries and make a positive impact on the environment and healthcare. as technology continues to advance, we can expect to see even more groundbreaking applications of unconventional materials in printing.

FAQs for

1. What are unconventional materials for printing?

Unconventional materials for printing refer to any materials other than traditional paper that can be used for printing purposes. These materials can include fabrics, plastics, metals, ceramics, glass, wood, and even food items.

2. Why would someone choose unconventional materials for printing?

Using unconventional materials for printing offers a range of benefits. It allows for unique and eye-catching designs, adds texture and dimension to printed products, and can enhance the durability and functionality of printed items. Additionally, using unconventional materials can help businesses stand out in a crowded market and create memorable experiences for their customers.

3. What printing techniques are used with unconventional materials?

Various printing techniques can be used with unconventional materials, depending on the material and desired outcome. Common techniques include screen printing, digital printing, sublimation printing, UV printing, and 3D printing. Each technique has its own advantages and is chosen based on factors such as material compatibility, resolution requirements, and production volume.

4. Can unconventional materials be used for commercial printing?

Yes, unconventional materials can be used for commercial printing. In fact, many businesses are now exploring the use of unconventional materials to create unique marketing materials, packaging, and promotional items. The versatility of these materials allows for creative and innovative designs that can help businesses differentiate themselves from their competitors.

5. Are there any limitations to using unconventional materials for printing?

While unconventional materials offer exciting possibilities, there are some limitations to consider. Some materials may be more challenging to print on due to their texture or composition. Additionally, the cost of materials and specialized printing techniques may be higher compared to traditional paper printing. It’s important to carefully evaluate the feasibility and cost-effectiveness of using unconventional materials for each specific project.

6. Can unconventional materials be recycled?

The recyclability of unconventional materials used for printing varies depending on the specific material. Some materials, such as paper and certain plastics, have established recycling processes. However, materials like metals and ceramics may require specialized recycling methods. It’s important to research and consider the environmental impact of using unconventional materials and explore recycling options for each material used.

7. Are there any safety considerations when using unconventional materials for printing?

When using unconventional materials for printing, it’s essential to consider safety aspects. Some materials may emit fumes or require specific handling procedures. For example, certain inks used in 3D printing can release volatile organic compounds (VOCs) during the printing process. It’s important to follow safety guidelines provided by manufacturers and ensure proper ventilation when working with unconventional materials.

8. What industries can benefit from using unconventional materials for printing?

Many industries can benefit from using unconventional materials for printing. Fashion and apparel companies can create unique fabric prints, while the automotive industry can use unconventional materials for interior design elements. The food and beverage industry can explore edible printing, and the healthcare industry can benefit from 3D printed medical devices. The possibilities are virtually endless, and any industry that values creativity and innovation can find ways to incorporate unconventional materials into their printing processes.

9. Are there any notable examples of successful use of unconventional materials in printing?

Yes, there are several notable examples of successful use of unconventional materials in printing. For instance, Adidas collaborated with Parley for the Oceans to create shoes made from recycled ocean plastic. Coca-Cola introduced plant-based bottles made from sugarcane. Additionally, 3D printing has been used to create intricate jewelry designs and even prosthetic limbs. These examples demonstrate the potential of unconventional materials in pushing the boundaries of printing technology.

10. How can I get started with using unconventional materials for printing?

If you’re interested in using unconventional materials for printing, start by researching the specific material you want to work with and the printing techniques that are compatible with it. Consider reaching out to printing service providers who specialize in unconventional materials to discuss your project requirements and explore the feasibility and cost implications. Experimentation and creativity are key, so don’t be afraid to think outside the box and try new ideas.

Common Misconceptions about ‘Beyond Paper: Unconventional Materials for Cutting-Edge Printing’

Misconception 1: Unconventional printing materials are limited in their applications

Unconventional materials for printing, such as metal, fabric, ceramics, and even food, are often mistakenly believed to have limited applications. Many people assume that these materials are only suitable for artistic or niche projects. However, the reality is that the use of unconventional materials in printing has expanded significantly in recent years, offering a wide range of practical applications across various industries.

Contrary to popular belief, unconventional materials can be used to create functional and durable products. For example, metal printing has revolutionized the manufacturing industry by enabling the production of complex and lightweight components for aerospace and automotive sectors. Similarly, fabric printing has found applications in the fashion industry, allowing designers to create unique and customizable clothing items. Moreover, the use of food-based inks in printing has opened up possibilities in the culinary world, allowing chefs to create edible decorations and personalized food items.

Misconception 2: Unconventional printing materials are expensive and inaccessible

Another common misconception is that using unconventional materials for printing is prohibitively expensive and only accessible to a select few. While it is true that some unconventional materials may have higher costs compared to traditional printing materials like paper, advancements in technology and increased market demand have made these materials more affordable and accessible.

The cost of unconventional materials for printing has significantly decreased as the technology has evolved. For instance, the cost of 3D printing metal objects has decreased by more than 90% over the past decade, making it more accessible to a wider range of industries and businesses. Additionally, the availability of online marketplaces and specialized suppliers has made it easier for individuals and businesses to source unconventional printing materials at competitive prices.

Furthermore, the accessibility of unconventional printing materials has been enhanced by the development of user-friendly printers and software. These advancements have made it easier for individuals with limited technical expertise to experiment with unconventional materials and explore their creative potential.

Misconception 3: Unconventional printing materials are not environmentally friendly

There is a common misconception that using unconventional materials for printing is detrimental to the environment. This misconception stems from the belief that unconventional materials are inherently wasteful or require excessive energy consumption. However, the reality is that many unconventional printing materials offer environmental benefits when compared to traditional printing methods.

One of the key advantages of using unconventional materials is the potential for recycling and reusing. For example, in 3D printing, materials such as plastic can be melted down and reused, reducing waste and minimizing the environmental impact. Moreover, the use of unconventional materials like biodegradable plastics or plant-based inks can further enhance the environmental friendliness of printing processes.

Additionally, advancements in printing technology have led to more efficient use of materials, reducing waste and minimizing the overall environmental footprint. For instance, 3D printing allows for precise and targeted material deposition, minimizing excess material usage compared to traditional subtractive manufacturing methods.

It is important to note that the environmental impact of printing, whether using conventional or unconventional materials, depends on various factors such as the energy source used, waste management practices, and the lifecycle of the printed products. Therefore, it is crucial for businesses and individuals to make informed choices, considering the environmental implications of their printing practices.

The misconceptions surrounding unconventional materials for cutting-edge printing often stem from limited awareness and outdated information. It is important to recognize the expanding applications, affordability, and environmental benefits associated with these materials. As technology continues to advance, it is expected that the use of unconventional materials in printing will become even more prevalent, offering innovative solutions across a wide range of industries.

The world of printing is constantly evolving, and the use of unconventional materials is pushing the boundaries of what is possible. In this article, we explored some of the cutting-edge techniques and materials that are being used in the industry today. From printing with food to creating circuits on fabric, the possibilities are endless.

One key insight from this exploration is the potential for sustainability. By utilizing materials such as algae-based ink and recycled plastics, the printing industry can reduce its environmental impact. This not only benefits the planet but also opens up new opportunities for businesses to market themselves as eco-friendly.

Another important point is the versatility of unconventional materials. Whether it’s printing on glass, wood, or even human skin, the ability to print on a variety of surfaces opens up a whole new world of creative possibilities. Artists and designers can now experiment with textures and dimensions, creating truly unique and immersive experiences.

In conclusion, the use of unconventional materials in printing is revolutionizing the industry. From sustainability to creativity, these materials offer a host of benefits that traditional paper simply cannot match. As technology continues to advance, we can expect to see even more exciting developments in the world of printing, pushing the boundaries of what is possible and inspiring a new generation of artists and innovators.