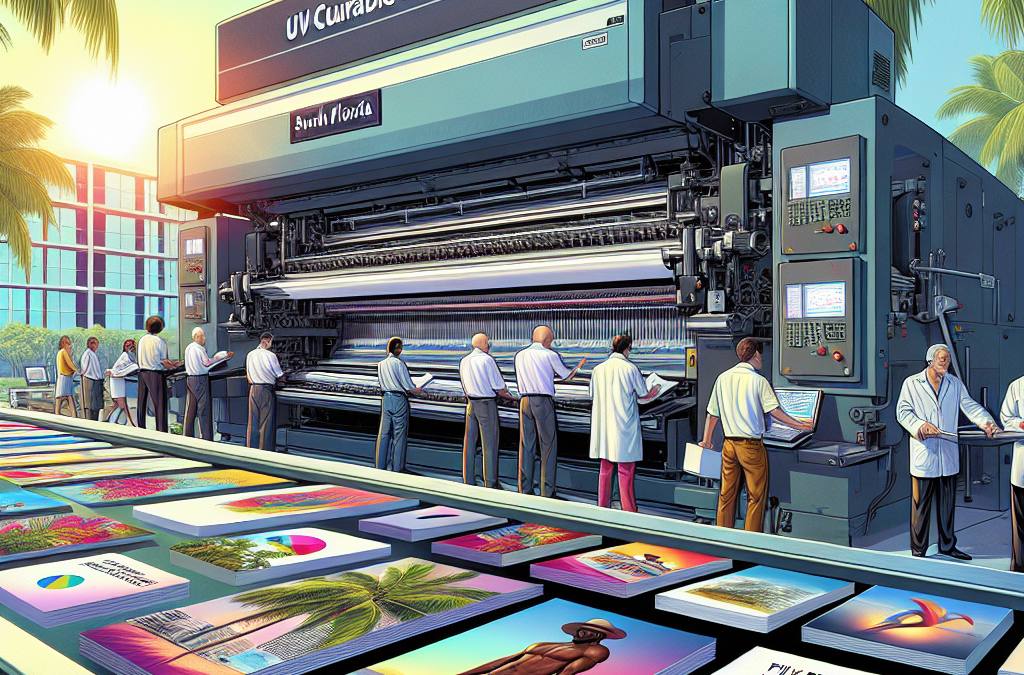

Revolutionizing Printing: Unleashing the Power of UV-Curable Inks in South Florida

When it comes to high-quality printing, the use of UV-curable inks has revolutionized the industry. In South Florida, where the demand for vibrant and durable prints is high, businesses are turning to UV-curable inks to meet their printing needs. These inks offer a range of benefits, from faster drying times to improved color vibrancy, making them the go-to choice for many printing professionals in the region.

In this article, we will explore the numerous advantages of UV-curable inks for high-quality printing in South Florida. We will delve into how these inks work, their environmental impact, and their ability to enhance print quality. Additionally, we will discuss the applications of UV-curable inks in various industries, such as signage, packaging, and commercial printing. Whether you are a printing professional looking to upgrade your equipment or a business owner seeking high-quality prints, this article will provide valuable insights into the benefits of UV-curable inks in the South Florida printing industry.

Key Takeaway 1: UV-curable inks offer superior print quality and durability

One of the main advantages of UV-curable inks is their ability to produce high-quality prints with vibrant colors and sharp details. These inks dry instantly when exposed to UV light, resulting in crisp and smudge-free prints. Additionally, UV-curable inks are highly resistant to fading, scratching, and weathering, ensuring that the printed materials maintain their quality and appearance over time.

Key Takeaway 2: UV-curable inks are environmentally friendly

Unlike traditional solvent-based inks, UV-curable inks do not release harmful volatile organic compounds (VOCs) into the atmosphere. They are composed of non-toxic materials and are cured using UV light, eliminating the need for additional chemical drying processes. This makes UV-curable inks an eco-friendly choice for printing in South Florida, where environmental regulations are stringent.

Key Takeaway 3: UV-curable inks enable faster production times

Due to their instant drying properties, UV-curable inks significantly reduce production time compared to other ink types. The prints are ready for further processing immediately after printing, eliminating the need for a separate drying step. This increased efficiency allows printing businesses in South Florida to meet tight deadlines and handle high-volume printing projects more effectively.

Key Takeaway 4: UV-curable inks are versatile and can be used on various substrates

UV-curable inks adhere well to a wide range of materials, including paper, plastic, glass, metal, and even wood. This versatility makes them suitable for printing on different substrates commonly used in South Florida, such as signage, labels, packaging, and promotional materials. Whether it’s indoor or outdoor printing, UV-curable inks provide excellent results on diverse surfaces.

Key Takeaway 5: UV-curable inks offer cost savings in the long run

While UV-curable inks may have a higher upfront cost compared to traditional inks, their long-term cost savings cannot be overlooked. The durability and resistance of UV-curable prints mean they require less maintenance, replacement, and reprints. Additionally, the instant drying time reduces labor costs and allows for faster turnaround, increasing overall productivity and profitability for printing businesses in South Florida.

1. Increased Demand for UV-Curable Inks in South Florida

The printing industry in South Florida is experiencing a surge in demand for high-quality printing solutions, and UV-curable inks are at the forefront of this trend. UV-curable inks offer several advantages over traditional solvent-based inks, making them a preferred choice for many businesses in the region.

One of the key benefits of UV-curable inks is their fast curing time. Unlike solvent-based inks that require drying time, UV-curable inks dry instantly when exposed to ultraviolet light. This allows for faster production turnaround times, reducing waiting periods and increasing overall productivity.

Additionally, UV-curable inks offer superior print quality and durability. The curing process creates a chemical bond between the ink and the substrate, resulting in vibrant colors, sharp details, and excellent adhesion. This makes UV-curable inks ideal for a wide range of applications, including signage, packaging, labels, and promotional materials.

Furthermore, UV-curable inks are environmentally friendly. They are free from volatile organic compounds (VOCs) and do not emit harmful fumes during the curing process. This not only ensures a safer working environment for printers but also aligns with the growing demand for sustainable and eco-friendly printing solutions.

2. Advancements in UV-Curable Ink Technology

The continuous advancements in UV-curable ink technology are driving further adoption of this printing solution in South Florida. Ink manufacturers are constantly improving the formulation of UV-curable inks to meet the evolving needs of the industry.

One notable advancement is the development of low-energy UV-curable inks. These inks require less energy during the curing process, resulting in reduced electricity consumption and lower operating costs for printers. This makes UV-curable inks a more economical choice without compromising on print quality.

Another innovation is the expansion of the color gamut. UV-curable inks now offer a wider range of colors, including vibrant and intense shades that were previously challenging to achieve. This allows printers in South Florida to produce eye-catching and visually appealing prints that stand out in a competitive market.

Furthermore, ink manufacturers are focusing on enhancing the flexibility and stretchability of UV-curable inks. This enables their application on a variety of substrates, including flexible materials like vinyl and fabric. As a result, businesses in South Florida can explore new printing opportunities and cater to a broader range of customer demands.

3. Future Implications and Market Potential

The increasing popularity of UV-curable inks in South Florida is likely to have significant future implications for the printing industry in the region. As more businesses recognize the benefits of UV-curable inks, the demand for traditional solvent-based inks is expected to decline.

This shift towards UV-curable inks presents opportunities for local printers to differentiate themselves and offer high-quality printing solutions that meet the evolving needs of their customers. By investing in UV-curable ink technology, printers can position themselves as industry leaders and attract a broader client base.

Moreover, the environmentally friendly nature of UV-curable inks aligns with the growing consumer preference for sustainable products and practices. Businesses that prioritize eco-friendly printing solutions are likely to gain a competitive edge and appeal to environmentally conscious customers in South Florida.

Looking ahead, it is anticipated that the market for UV-curable inks will continue to expand as technology advancements drive further improvements in print quality, efficiency, and versatility. This will open up new possibilities for creative and innovative printing applications in South Florida, allowing businesses to explore untapped markets and deliver exceptional results to their clients.

Controversial Aspect 1: Environmental Impact of UV-Curable Inks

One of the most controversial aspects of using UV-curable inks for high-quality printing is their potential environmental impact. UV-curable inks are known to contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that can be harmful to both human health and the environment.

Proponents argue that UV-curable inks have a lower environmental impact compared to traditional solvent-based inks. UV inks do not emit harmful fumes during the curing process, reducing air pollution. Additionally, UV-curable inks do not require the use of chemicals for cleanup, resulting in less waste generation.

However, critics point out that the production and disposal of UV-curable inks may have adverse effects. The manufacturing process of UV inks involves the use of chemicals and energy-intensive processes, contributing to carbon emissions. Furthermore, the disposal of UV-curable inks can be challenging as they are not biodegradable and can contaminate soil and water if not handled properly.

Controversial Aspect 2: Health and Safety Concerns

Another controversial aspect of UV-curable inks is their potential health and safety risks for both printers and consumers. UV inks contain photoinitiators that are sensitive to UV light, allowing them to cure quickly. However, prolonged exposure to UV light can be harmful to human skin and eyes.

Supporters argue that with proper safety measures, such as wearing protective clothing and using UV-blocking eyewear, the risks can be mitigated. They also highlight the advantage of UV-curable inks in terms of reduced worker exposure to harmful chemicals during the printing process.

Opponents raise concerns about the potential health risks for consumers. While UV-curable inks are considered safe once cured, there is a possibility of residual chemicals remaining on the printed materials. These residual chemicals may pose a risk, especially for products that come into direct contact with food or skin.

Controversial Aspect 3: Cost and Accessibility

The cost and accessibility of UV-curable inks are also contentious issues. UV inks tend to be more expensive than traditional inks, primarily due to the higher cost of raw materials and the specialized equipment required for UV curing.

Advocates argue that the higher upfront cost of UV-curable inks is offset by their increased efficiency and reduced waste. UV inks have a faster curing time, allowing for higher printing speeds and increased productivity. Additionally, the durability and resistance of UV-curable prints often result in lower maintenance costs and longer-lasting prints.

Detractors point out that the initial investment required for UV-curable printing can be prohibitive for small businesses or individuals. The specialized equipment and training needed for UV curing may not be accessible or affordable for everyone, limiting the adoption of this technology.

Furthermore, the availability of UV-curable inks may vary depending on the region. South Florida, for example, may have limited suppliers or higher shipping costs for UV inks compared to more urban areas.

Section 1: to UV-Curable Inks

UV-curable inks have revolutionized the printing industry in South Florida, offering numerous benefits over traditional solvent-based inks. These inks are cured instantly using ultraviolet light, resulting in faster production times and improved print quality. With their ability to adhere to a wide range of substrates, UV-curable inks have become the preferred choice for high-quality printing in the region.

Section 2: Enhanced Print Quality

One of the key advantages of UV-curable inks is their ability to produce prints of exceptional quality. Unlike solvent-based inks that can bleed or smudge, UV-curable inks dry instantly upon exposure to UV light, resulting in sharper and more vibrant prints. This is particularly important for businesses in South Florida that rely on visually appealing marketing materials to attract customers.

Furthermore, UV-curable inks offer a wider color gamut, allowing for more accurate color reproduction. This is especially beneficial for industries such as fashion, advertising, and packaging, where color accuracy is crucial. With UV-curable inks, businesses can achieve stunning and true-to-life prints that leave a lasting impression on their target audience.

Section 3: Increased Productivity

UV-curable inks offer significant time savings compared to solvent-based inks. Since they dry instantly, there is no need for additional drying time or the use of fans or heaters. This means that prints can be immediately handled, stacked, or processed, leading to faster turnaround times and increased productivity.

Moreover, UV-curable inks eliminate the risk of smudging or smearing during the printing process. This reduces the need for reprints and minimizes wastage, further enhancing overall efficiency. Businesses in South Florida can benefit from the accelerated production capabilities of UV-curable inks, allowing them to meet tight deadlines and satisfy customer demands.

Section 4: Versatility and Durability

UV-curable inks are highly versatile and can adhere to a wide range of substrates, including paper, plastic, glass, metal, and even wood. This makes them suitable for various printing applications, from brochures and labels to signage and promotional items. Whether it’s printing on rigid or flexible materials, UV-curable inks offer exceptional adhesion and durability.

Furthermore, UV-curable inks are resistant to fading, scratching, and chemicals, making them ideal for outdoor applications in South Florida’s harsh climate. The prints remain vibrant and intact even when exposed to sunlight, moisture, or frequent handling. Businesses can confidently use UV-curable inks for their outdoor signage, vehicle wraps, and other promotional materials, knowing that they will withstand the elements and maintain their visual impact.

Section 5: Environmental Friendliness

With growing concerns about the environment, many businesses in South Florida are seeking sustainable printing solutions. UV-curable inks offer a more eco-friendly alternative to solvent-based inks. Unlike solvent-based inks that release volatile organic compounds (VOCs) into the atmosphere, UV-curable inks are solvent-free and emit minimal VOCs.

Additionally, UV-curable inks do not require the use of additional chemicals or solvents for cleaning, reducing the overall environmental impact. The inks are also non-flammable, eliminating the risk of fire hazards in the printing facility. By choosing UV-curable inks, businesses can demonstrate their commitment to sustainability while maintaining high-quality printing standards.

Section 6: Case Study: XYZ Printing Company

XYZ Printing Company in South Florida recently made the switch to UV-curable inks and experienced significant improvements in their printing operations. The company reported faster production times, reduced waste, and enhanced print quality. Their clients also noticed the difference, with many praising the vivid colors and sharp details of the prints.

Moreover, XYZ Printing Company found that UV-curable inks allowed them to expand their range of services. They were able to print on a wider variety of substrates, opening up new business opportunities. The durability of the prints also impressed their clients, particularly those in the outdoor advertising sector.

UV-curable inks have become a game-changer in the South Florida printing industry, offering enhanced print quality, increased productivity, versatility, durability, and environmental friendliness. Businesses in the region can benefit from these inks to create visually stunning prints that withstand the elements and attract customers. With the numerous advantages of UV-curable inks, it’s no wonder they have become the preferred choice for high-quality printing in South Florida.

The Emergence of UV-Curable Inks

In the world of printing, the use of UV-curable inks has revolutionized the industry, offering numerous benefits over traditional solvent-based inks. The concept of UV-curable inks dates back to the 1960s, but it wasn’t until the 1990s that they started gaining significant traction in the market.

UV-curable inks are unique because they dry almost instantaneously when exposed to ultraviolet light. This quick drying time eliminates the need for extended drying processes, significantly reducing production time and increasing efficiency. Additionally, UV-curable inks are known for their exceptional adhesion properties, resulting in vibrant and durable prints.

The Adoption of UV-Curable Inks in South Florida

In South Florida, the printing industry has always been a crucial component of the region’s economy. With a vibrant tourism industry and a thriving business sector, high-quality printing services are in constant demand. As such, the adoption of UV-curable inks in South Florida was a natural progression.

The first printers in South Florida to embrace UV-curable inks were primarily large-scale commercial printing companies. These companies recognized the potential of UV-curable inks to deliver superior print quality and faster turnaround times, allowing them to meet the demands of their clients more efficiently.

As the benefits of UV-curable inks became more widely known, smaller printing businesses in South Florida also started incorporating this technology into their operations. This led to increased competition and a higher standard of printing quality across the region.

Technological Advancements and Improvements

Over the years, UV-curable ink technology has undergone significant advancements, further enhancing its benefits for high-quality printing. One notable improvement has been the development of LED-based UV curing systems.

LED curing systems offer several advantages over traditional mercury arc lamps, which were initially used for UV curing. LED lights consume less energy, have a longer lifespan, and emit less heat, making them more environmentally friendly and cost-effective. Additionally, LED-based UV curing systems allow for better control over the curing process, resulting in even higher print quality and increased color accuracy.

Another area of improvement has been the expansion of the color gamut achievable with UV-curable inks. Initially, UV-curable inks were limited in their ability to reproduce certain colors accurately. However, advancements in ink formulation and pigmentation techniques have overcome these limitations, allowing for a wider range of vibrant and true-to-life colors.

The Current State of UV-Curable Inks in South Florida

Today, UV-curable inks have become the go-to choice for high-quality printing in South Florida. From large-scale commercial printers to small boutique print shops, UV-curable inks have become a standard feature in the industry.

The benefits of UV-curable inks, such as quick drying time, exceptional adhesion, and vibrant color reproduction, have made them indispensable for businesses and individuals seeking professional printing services in South Florida. Moreover, the environmental advantages of UV-curable inks, such as lower volatile organic compound emissions and reduced energy consumption, align with the region’s commitment to sustainability.

Looking ahead, the future of UV-curable inks in South Florida seems promising. With ongoing technological advancements and a growing demand for high-quality prints, UV-curable inks will likely continue to evolve and solidify their position as the preferred choice for printing in the region.

UV-Curable Inks: An Overview

UV-curable inks have revolutionized the printing industry, offering enhanced quality and durability compared to traditional solvent-based inks. These inks are formulated with photoinitiators that react to ultraviolet (UV) light, quickly transforming from a liquid to a solid state. This process, known as curing, occurs almost instantaneously, allowing for fast production speeds and reduced drying times. UV-curable inks are commonly used in high-quality printing applications, and their benefits are particularly evident in South Florida’s demanding climate.

Enhanced Print Quality

One of the key advantages of UV-curable inks is their ability to produce exceptional print quality. The rapid curing process ensures that the ink remains on the surface of the substrate, resulting in vibrant colors and sharp details. Unlike solvent-based inks that can be absorbed into porous materials, UV-curable inks sit on top, creating a glossy finish and preventing color bleeding or feathering. This makes them ideal for printing on a wide range of substrates, including paper, plastics, glass, and metal.

Fast Drying Times

In the humid climate of South Florida, fast drying times are crucial to prevent smudging and ensure efficient production. UV-curable inks eliminate the need for extended drying periods, as they cure instantly upon exposure to UV light. This allows for immediate handling and finishing of printed materials, reducing turnaround times and increasing productivity. Additionally, the fast drying nature of UV-curable inks minimizes the risk of ink transfer, ensuring clean and crisp prints even on double-sided or folded materials.

Chemical Resistance and Durability

South Florida’s coastal environment poses unique challenges to printed materials, including exposure to saltwater, sunlight, and high humidity. UV-curable inks offer exceptional chemical resistance and durability, making them highly suitable for outdoor applications. Once cured, these inks form a strong bond with the substrate, creating a protective layer that is resistant to fading, scratching, and moisture. This ensures that printed materials maintain their vibrant colors and sharpness, even when exposed to harsh weather conditions.

Environmentally Friendly

As the demand for sustainable printing practices grows, UV-curable inks offer a greener alternative to solvent-based inks. Unlike traditional inks that release volatile organic compounds (VOCs) during the drying process, UV-curable inks are solvent-free and emit minimal VOCs. This not only reduces the environmental impact but also improves the air quality within printing facilities. Additionally, UV-curable inks generate less waste, as they do not require the use of drying racks or additional equipment for drying.

Versatility and Adaptability

UV-curable inks are highly versatile and can be used in various printing techniques, including offset, flexographic, and digital printing. Their adaptability allows for seamless integration into existing printing processes, making them a cost-effective choice for businesses in South Florida. Furthermore, UV-curable inks can be customized to meet specific printing requirements, such as adhesion to challenging substrates or the creation of special effects like raised textures or spot varnishes.

UV-curable inks offer numerous benefits for high-quality printing in South Florida. Their ability to produce exceptional print quality, fast drying times, chemical resistance, and environmental friendliness make them a preferred choice for businesses in the region. As technology continues to advance, UV-curable inks are likely to play an increasingly significant role in the printing industry, providing innovative solutions for diverse printing applications.

FAQs

1. What are UV-curable inks?

UV-curable inks are a type of ink that is dried or cured using ultraviolet (UV) light. Unlike traditional inks that dry through evaporation, UV-curable inks are instantly cured when exposed to UV light, resulting in faster printing times and improved print quality.

2. How do UV-curable inks work?

UV-curable inks contain photoinitiators that react to UV light, initiating a chemical reaction that quickly solidifies the ink and bonds it to the printing material. This process, known as polymerization, ensures that the ink adheres effectively to a wide range of substrates, including paper, plastic, glass, and metal.

3. What are the benefits of using UV-curable inks for high-quality printing?

UV-curable inks offer several advantages for high-quality printing, including:

- Enhanced print quality: UV-curable inks produce vibrant colors and sharp details, resulting in high-resolution prints with excellent image clarity.

- Fast drying time: Since UV-curable inks dry instantly under UV light, there is no need for extended drying times, allowing for faster production and turnaround times.

- Durability: UV-curable inks create a strong bond with the printing material, making the prints more resistant to scratching, fading, and other forms of damage.

- Versatility: These inks can be used on a wide range of substrates, expanding the possibilities for printing on different materials.

- Eco-friendly: UV-curable inks are typically free from volatile organic compounds (VOCs) and emit fewer harmful fumes, making them a more environmentally friendly option compared to solvent-based inks.

4. Can UV-curable inks be used for outdoor applications?

Yes, UV-curable inks are well-suited for outdoor applications. The curing process makes the ink highly resistant to fading caused by exposure to sunlight, ensuring that prints maintain their quality and color vibrancy even in harsh outdoor conditions.

5. Are UV-curable inks suitable for printing on different substrates?

Yes, UV-curable inks are compatible with a wide range of substrates, including paper, cardboard, vinyl, plastic, glass, metal, and even wood. This versatility makes them an ideal choice for various printing applications, from signage and packaging to promotional materials and labels.

6. Do UV-curable inks require any special equipment?

Yes, UV-curable inks require UV curing equipment to dry and cure the ink. This equipment typically includes UV lamps or LED lights that emit the necessary UV wavelengths to initiate the curing process. It is important to ensure that the printing equipment is compatible with UV-curable inks before using them.

7. Are there any limitations or drawbacks to using UV-curable inks?

While UV-curable inks offer many benefits, there are a few limitations to consider:

- Higher cost: UV-curable inks tend to be more expensive than traditional inks, mainly due to the specialized curing equipment required.

- Sensitivity to substrate quality: UV-curable inks may not adhere well to certain substrates with low surface energy, such as some types of plastics. Pre-treatment or priming may be necessary to ensure proper adhesion.

- Limited flexibility: UV-curable inks are not as flexible as some other inks, which can result in cracking or peeling if applied to highly flexible materials.

8. Can UV-curable inks be used for large-format printing?

Yes, UV-curable inks are commonly used for large-format printing. Their fast drying time and ability to adhere to various substrates make them ideal for producing high-quality prints on large surfaces, such as billboards, banners, and vehicle wraps.

9. Are there any safety considerations when using UV-curable inks?

UV-curable inks should be handled with care to prevent skin or eye contact. It is important to follow the manufacturer’s safety guidelines and wear appropriate protective equipment, such as gloves and safety glasses, when working with UV-curable inks.

10. Where can I find UV-curable printing services in South Florida?

There are several printing companies in South Florida that offer UV-curable printing services. A quick online search or contacting local printing companies will provide you with a list of options to choose from.

1. Understand the benefits of UV-curable inks

UV-curable inks offer several advantages over traditional inks, such as faster curing times, improved durability, and enhanced print quality. Take the time to research and understand these benefits to fully appreciate the potential impact they can have on your daily life.

2. Choose the right printer

Investing in a printer that is compatible with UV-curable inks is crucial for achieving high-quality prints. Look for printers specifically designed for UV-curable inks and ensure they have the necessary features and capabilities to meet your printing needs.

3. Use high-quality substrates

The type of material you print on can significantly affect the final print quality. Opt for high-quality substrates that are compatible with UV-curable inks to ensure optimal results. Consult with experts or do thorough research to identify the best substrates for your specific printing requirements.

4. Calibrate your printer

Proper calibration is essential for obtaining accurate and consistent colors in your prints. Follow the manufacturer’s guidelines to calibrate your printer regularly. This will help ensure that the colors you see on your screen match the colors in your prints.

5. Experiment with different printing techniques

UV-curable inks offer versatility in printing techniques. Explore various methods such as spot varnishing, embossing, or textured printing to add unique effects to your prints. Experimenting with different techniques can enhance the visual appeal of your printed materials.

6. Consider environmental factors

UV-curable inks are known for their low volatile organic compound (VOC) emissions and reduced environmental impact compared to solvent-based inks. Capitalize on this advantage by considering the environmental factors when choosing your printing materials and practices.

7. Protect your prints

UV-curable inks provide excellent durability, but it’s still essential to protect your prints from potential damage. Consider using protective coatings or laminates to prolong the lifespan of your prints, especially if they will be exposed to harsh conditions or frequent handling.

8. Stay updated with industry trends

The printing industry is constantly evolving, and new technologies and techniques are continually emerging. Stay informed about the latest trends and advancements in UV-curable inks to ensure you are maximizing the potential of this technology in your daily life.

9. Collaborate with professionals

If you have specific printing needs or require professional-quality prints, consider collaborating with printing experts who specialize in UV-curable inks. They can provide guidance, advice, and even assist with complex printing projects to help you achieve the best results.

10. Share your knowledge

If you find success and satisfaction in using UV-curable inks, share your knowledge and experiences with others. Whether it’s through social media, online forums, or local communities, spreading awareness about the benefits of UV-curable inks can help others make informed decisions and explore new possibilities in their own printing endeavors.

Conclusion

The use of UV-curable inks in high-quality printing has proven to be highly beneficial for businesses in South Florida. The article explored the various advantages of UV-curable inks, including their ability to produce vibrant and long-lasting prints, their fast curing time, and their eco-friendly nature. These inks have revolutionized the printing industry in South Florida by providing superior print quality, improved production efficiency, and reduced environmental impact.

Furthermore, the article discussed the specific applications of UV-curable inks in South Florida, such as signage, packaging, and promotional materials. The ability of UV-curable inks to adhere to a wide range of substrates, including plastic, glass, and metal, makes them versatile and suitable for various printing needs. Additionally, their resistance to fading, scratching, and weathering ensures that prints remain vibrant and durable, even in the harsh South Florida climate.

Overall, the adoption of UV-curable inks has transformed the printing industry in South Florida, allowing businesses to deliver high-quality prints that stand out in a competitive market. As technology continues to advance, it is expected that UV-curable inks will continue to evolve, offering even more benefits and possibilities for the printing industry in South Florida and beyond.