Maximizing Efficiency and Minimizing Waste: The Key to Effective Printing Equipment Lifecycle Management

Picture this: you’ve just purchased a brand new printer for your office. It’s sleek, efficient, and promises to make your work life a breeze. But have you ever stopped to think about what happens to that printer once it reaches the end of its life? What about the environmental impact of all those ink cartridges you go through? In this article, we will dive into the often overlooked world of lifecycle management for printing equipment. From the initial purchase to the final disposal, we will explore the various stages and considerations involved in managing your printing equipment in a sustainable and responsible manner. So, whether you’re a small business owner or an individual looking to make more eco-friendly choices, read on to discover how you can make a positive impact through the lifecycle management of your printing equipment.

Key Takeaways:

1. Plan for the entire lifecycle: Effective management of printing equipment requires a comprehensive approach that considers the entire lifecycle, from purchase to disposal. By planning ahead, businesses can minimize costs, maximize efficiency, and reduce environmental impact.

2. Choose the right equipment: Selecting the right printing equipment is crucial to ensure long-term success. Consider factors such as printing volume, functionality, and energy efficiency to find equipment that meets your specific needs and aligns with your sustainability goals.

3. Implement maintenance and monitoring practices: Regular maintenance and monitoring are essential for prolonging the lifespan of your printing equipment. Implementing preventive maintenance measures and monitoring usage patterns can help identify issues early on, prevent downtime, and extend the equipment’s lifespan.

4. Optimize energy consumption: Printing equipment can be energy-intensive, so finding ways to optimize energy consumption is key. Utilize energy-saving features, such as sleep mode and automatic power-off, and consider investing in energy-efficient models to reduce both costs and environmental impact.

5. Responsible disposal: When it’s time to retire your printing equipment, it’s important to handle the disposal responsibly. Explore options for recycling or donating the equipment to minimize waste and support sustainability initiatives. Additionally, ensure that any sensitive data stored on the equipment is properly erased to protect your business and customers.

By following these key takeaways, businesses can effectively manage the lifecycle of their printing equipment, reduce costs, improve efficiency, and contribute to a more sustainable future.

Controversial Aspect 1: Environmental Impact of Printing Equipment

One of the most controversial aspects of the lifecycle management of printing equipment is its environmental impact. The production, use, and disposal of printers and related materials contribute to various environmental issues, including resource depletion, pollution, and waste generation.

On one hand, the production of printers requires the extraction of raw materials, such as metals and plastics, which can have a significant environmental impact. Additionally, the manufacturing process itself can release greenhouse gases and other harmful emissions. Critics argue that the energy consumption and carbon footprint associated with the production and operation of printers are substantial.

However, proponents of the printing industry highlight the advancements in technology and the efforts made by manufacturers to reduce their environmental impact. Many companies now produce printers with energy-saving features, use recycled materials in their manufacturing processes, and implement responsible waste management practices. They argue that printing equipment is essential for businesses and individuals alike and that the industry is actively working towards sustainability.

Controversial Aspect 2: Planned Obsolescence

Another controversial aspect of lifecycle management is the concept of planned obsolescence. Planned obsolescence refers to the practice of designing products with a limited lifespan, encouraging consumers to replace them more frequently.

Critics argue that printer manufacturers intentionally design their products to become outdated or malfunction after a certain period, forcing consumers to buy newer models. This practice not only leads to unnecessary waste but also puts a strain on consumers’ finances. They argue that manufacturers should focus on creating durable and long-lasting printers, reducing the need for frequent upgrades.

However, supporters of planned obsolescence argue that it drives innovation and economic growth. They claim that rapid technological advancements necessitate the development of new products to meet changing consumer demands. Additionally, they argue that planned obsolescence allows for affordable access to new features and improved performance. They contend that consumers have the choice to continue using older printers or upgrade based on their needs and preferences.

Controversial Aspect 3: E-Waste Management

The management of electronic waste, or e-waste, is another controversial aspect of printing equipment lifecycle management. E-waste refers to discarded electronic devices, including printers, which can contain hazardous materials that pose risks to human health and the environment if not properly handled.

Critics argue that the current e-waste management practices are inadequate and that a significant amount of electronic waste ends up in landfills or is illegally exported to developing countries. They emphasize the need for stricter regulations and better recycling infrastructure to ensure responsible disposal of printing equipment.

Supporters of the industry acknowledge the e-waste problem but argue that progress has been made in recent years. They highlight initiatives by manufacturers and governments to promote e-waste recycling and the development of more sustainable disposal methods. They argue that raising awareness and improving education about proper e-waste management is crucial to address this issue effectively.

The lifecycle management of printing equipment is a complex and controversial topic. the environmental impact, planned obsolescence, and e-waste management are just a few of the contentious aspects surrounding this industry. while critics raise valid concerns about sustainability and consumer exploitation, supporters argue for the industry’s efforts towards innovation and responsible practices. achieving a balanced approach to address these controversies requires collaboration between manufacturers, consumers, and policymakers to find sustainable solutions that minimize environmental impact and ensure the long-term viability of the printing industry.

The Rise of Managed Print Services

In recent years, there has been a significant shift in the way businesses manage their printing equipment. Many companies are now opting for Managed Print Services (MPS), which is the outsourcing of print management to a third-party provider. This emerging trend is transforming the lifecycle management of printing equipment and has the potential to revolutionize the industry in the future.

MPS offers a wide range of benefits for businesses. Firstly, it allows companies to reduce costs by optimizing their printing infrastructure. MPS providers analyze the printing needs of a company and recommend the most efficient equipment and processes to minimize waste and save money. They also take care of maintenance, repairs, and supplies, ensuring that the printing equipment is always in optimal condition.

Another advantage of MPS is improved security and compliance. With the increasing threat of data breaches, businesses need to ensure that their printing environment is secure. MPS providers offer enhanced security features such as user authentication, secure printing, and data encryption. They also help businesses comply with industry regulations and standards, such as HIPAA or GDPR, by implementing secure document workflows and tracking.

The future implications of the rise of MPS are significant. As more companies adopt this approach, the demand for traditional printer sales is expected to decline. Instead, manufacturers and vendors will focus on providing MPS solutions and services. This shift will require companies to adapt their business models, retrain their sales force, and develop new revenue streams.

Furthermore, the rise of MPS will drive innovation in printing technology. MPS providers are constantly looking for ways to improve efficiency, reduce costs, and enhance security. This will lead to the development of new printing technologies, such as advanced document management systems, cloud-based printing solutions, and mobile printing capabilities. These innovations will not only benefit businesses but also contribute to a more sustainable and environmentally friendly printing industry.

The Circular Economy Approach to Printing Equipment

In recent years, there has been a growing emphasis on sustainability and environmental responsibility. This trend has extended to the lifecycle management of printing equipment, with businesses adopting a circular economy approach. This emerging trend focuses on reducing waste, reusing materials, and recycling components to minimize the environmental impact of printing equipment.

The circular economy approach starts with the design phase, where manufacturers aim to create products that are durable, easy to repair, and recyclable. This ensures that the equipment has a longer lifespan and can be easily maintained and upgraded. Manufacturers are also exploring the use of eco-friendly materials and energy-efficient technologies to reduce the environmental footprint of their products.

Once the equipment reaches the end of its life cycle, businesses are encouraged to recycle or repurpose it instead of sending it to landfill. This involves disassembling the equipment and separating the different components for recycling. Some companies even offer take-back programs, where they collect old equipment from customers and ensure proper recycling or refurbishment.

The future implications of the circular economy approach to printing equipment are promising. As more businesses adopt this approach, the demand for sustainable printing solutions will increase. Manufacturers will be incentivized to design products that are environmentally friendly and can be easily recycled or repurposed. This will not only reduce waste but also create new opportunities for the recycling industry and stimulate the development of innovative recycling technologies.

Furthermore, the circular economy approach will drive the adoption of remanufactured or refurbished printing equipment. Instead of buying brand new printers, businesses can opt for high-quality refurbished equipment that has been restored to its original condition. This not only saves money but also reduces the demand for new resources and minimizes the environmental impact of the printing industry.

The Integration of IoT and Big Data Analytics

The integration of Internet of Things (IoT) technology and big data analytics is revolutionizing the lifecycle management of printing equipment. IoT devices, such as sensors and smart printers, collect data about the performance, usage, and maintenance needs of the equipment. This data is then analyzed using big data analytics tools to gain insights and optimize the management of printing assets.

By leveraging IoT and big data analytics, businesses can proactively monitor the health and performance of their printing equipment. They can detect potential issues before they become major problems, schedule maintenance or repairs in a timely manner, and optimize the usage of consumables such as ink or toner. This not only improves the efficiency and reliability of the equipment but also reduces downtime and costs.

Furthermore, the integration of IoT and big data analytics enables predictive maintenance. By analyzing historical data and patterns, businesses can predict when a printer is likely to fail or require maintenance. This allows them to schedule maintenance activities in advance, minimizing disruptions to workflow and ensuring that the equipment is always in optimal condition.

The future implications of IoT and big data analytics in the lifecycle management of printing equipment are vast. As technology advances, IoT devices will become more sophisticated, collecting even more data and providing real-time insights. This will enable businesses to further optimize their printing infrastructure, improve productivity, and reduce costs.

Moreover, the integration of IoT and big data analytics will enable the development of intelligent printing systems. These systems will be able to learn from the data collected and make autonomous decisions, such as adjusting print settings based on user preferences or optimizing energy consumption. This will not only enhance the user experience but also contribute to a more sustainable and efficient printing industry.

The Growing Importance of Lifecycle Management in the Printing Equipment Industry

The printing equipment industry has witnessed significant advancements in technology over the years, leading to more efficient and sophisticated machines. However, with these advancements also comes the challenge of managing the lifecycle of these equipment. From the moment of purchase to disposal, proper lifecycle management is crucial for both businesses and the environment. Here are three key insights into the impact of lifecycle management on the printing equipment industry.

1. Cost Savings and Efficiency

One of the primary benefits of effective lifecycle management is the potential for cost savings and increased efficiency. By carefully managing the lifecycle of printing equipment, businesses can minimize downtime, reduce repair costs, and maximize the lifespan of their machines. This approach ensures that the equipment is always in optimal condition, minimizing the risk of unexpected breakdowns and the need for costly emergency repairs.

Lifecycle management also allows businesses to plan and budget for equipment upgrades or replacements in a more strategic manner. By monitoring the performance and usage patterns of their printing equipment, companies can identify when it is more cost-effective to invest in new, more efficient models. This approach not only saves money in the long run but also ensures that businesses are using the most up-to-date technology, leading to improved productivity and competitiveness.

2. Environmental Sustainability

In an era of increasing environmental awareness, proper lifecycle management of printing equipment is essential for reducing the industry’s ecological footprint. The production, use, and disposal of printing equipment can have significant environmental impacts, including energy consumption, waste generation, and the release of harmful substances.

Lifecycle management helps mitigate these impacts by promoting sustainable practices throughout the equipment’s lifespan. For instance, manufacturers can design printers with energy-saving features, such as automatic power-off modes, to minimize energy consumption during use. Additionally, businesses can implement recycling programs to ensure that obsolete or damaged equipment is properly disposed of or refurbished, reducing electronic waste.

By adopting a comprehensive approach to lifecycle management, the printing equipment industry can contribute to a more sustainable future. This not only benefits the environment but also enhances the industry’s reputation and appeal to environmentally conscious consumers.

3. Enhanced Security and Compliance

In an era of increasing data breaches and privacy concerns, lifecycle management plays a crucial role in ensuring the security of printing equipment. Many modern printers are equipped with advanced features, such as network connectivity and cloud integration, which make them vulnerable to cyber-attacks. Failure to manage the lifecycle of these machines properly can expose businesses to significant security risks.

Lifecycle management includes implementing regular software updates and security patches to protect against known vulnerabilities. It also involves monitoring and managing access controls, user authentication, and data encryption to safeguard sensitive information. By proactively managing the lifecycle of their printing equipment, businesses can minimize the risk of data breaches and ensure compliance with industry regulations, such as the General Data Protection Regulation (GDPR).

Furthermore, lifecycle management enables businesses to track and manage the disposal of printing equipment in a secure manner. This is particularly important when dealing with devices that store sensitive data, such as hard drives in multifunction printers. Proper disposal procedures, such as data wiping or physical destruction, ensure that confidential information does not fall into the wrong hands.

Effective lifecycle management is crucial for the printing equipment industry. it offers cost savings, improved efficiency, environmental sustainability, enhanced security, and compliance. as technology continues to evolve, businesses must prioritize lifecycle management to stay ahead of the competition, reduce their environmental impact, and protect sensitive data.

1. Evaluating Your Printing Equipment Needs

When it comes to managing the lifecycle of your printing equipment, it all starts with evaluating your needs. Before making any purchase, it is crucial to assess your printing requirements. Consider factors such as the volume of printing, the types of documents you need to produce, and the quality of prints required. By understanding your needs, you can make an informed decision about the type of printing equipment that will best suit your organization.

2. Researching and Selecting the Right Printing Equipment

Once you have evaluated your needs, the next step is to research and select the right printing equipment. This involves considering various factors such as the type of printer (inkjet or laser), the size and speed of the printer, connectivity options, and additional features like scanning and copying. Take the time to compare different brands and models, read reviews, and seek recommendations from industry experts to ensure you make a well-informed decision.

3. Managing the Installation and Setup Process

After purchasing your printing equipment, proper installation and setup are essential for optimal performance. Depending on the complexity of the printer, you may need professional assistance to ensure everything is correctly connected and configured. It is crucial to follow the manufacturer’s instructions and recommendations during this process to avoid any potential issues or performance limitations.

4. Regular Maintenance and Cleaning

To prolong the lifespan of your printing equipment, regular maintenance and cleaning are crucial. This includes tasks such as cleaning the printer heads, replacing ink or toner cartridges, and ensuring proper ventilation to prevent overheating. Following the manufacturer’s guidelines for maintenance schedules and procedures will help keep your equipment in optimal condition and minimize downtime.

5. Upgrading and Updating Your Printing Equipment

Technology is constantly evolving, and so are printing solutions. It is important to stay up to date with the latest advancements in printing technology to ensure your equipment remains efficient and meets your evolving needs. Regularly assess your printing requirements and consider upgrading or updating your equipment when necessary. This could involve investing in faster printers, printers with advanced security features, or printers that support mobile printing.

6. Implementing Print Management Software

Print management software can significantly enhance the efficiency and control of your printing operations. These tools allow you to monitor and manage printing activities, track usage and costs, implement print policies, and even secure sensitive documents. By implementing print management software, you can optimize your printing processes, reduce waste, and improve overall productivity.

7. Responsible Disposal and Recycling

As your printing equipment reaches the end of its lifecycle, it is important to handle its disposal responsibly. Many components of printers, such as ink cartridges and toner cartridges, can be recycled. Research local recycling programs or contact the manufacturer to explore options for recycling or proper disposal. By disposing of your printing equipment responsibly, you can minimize environmental impact and support sustainability efforts.

8. Monitoring and Analyzing Printing Costs

Printing costs can quickly add up, especially in large organizations. Monitoring and analyzing printing costs is crucial for effective lifecycle management of your printing equipment. Implementing print tracking and cost allocation systems can provide valuable insights into your printing expenses, helping you identify areas for cost reduction and optimize your printing practices.

9. Training and Educating Users

Properly educating users on the use and maintenance of printing equipment is essential for its optimal performance and longevity. Conduct training sessions to familiarize users with the features and functionalities of the equipment, as well as best practices for printing efficiency. By empowering users with the necessary knowledge, you can minimize user-related issues and ensure the equipment is used correctly.

10. Partnering with Managed Print Services Providers

For organizations looking to streamline their printing operations, partnering with managed print services providers can be a game-changer. These providers offer comprehensive print management solutions, including equipment procurement, maintenance, supplies, and even monitoring and analytics. By outsourcing the management of your printing equipment, you can focus on your core business while ensuring efficient and cost-effective printing operations.

1. Purchase

When considering the purchase of printing equipment, there are several key factors to take into account. Firstly, it is important to evaluate the specific needs of your organization in terms of printing volume, speed, and quality. This will help determine the type of printer or multifunction device (MFD) that best suits your requirements.

1.1 Printer Types

There are various types of printers available on the market, including laser printers, inkjet printers, and thermal printers. Laser printers are ideal for high-volume printing and offer fast printing speeds, while inkjet printers are more suitable for color printing and photo printing. Thermal printers are commonly used for printing labels and receipts.

1.2 Environmental Considerations

In recent years, environmental concerns have become increasingly important in the decision-making process. It is crucial to consider the energy efficiency of the printer, as well as its environmental certifications, such as ENERGY STAR. Additionally, choosing a printer that supports duplex (double-sided) printing can significantly reduce paper waste.

2. Installation and Configuration

Once the printing equipment is purchased, proper installation and configuration are essential for optimal performance and longevity.

2.1 Physical Installation

During physical installation, it is important to ensure that the printer is placed in a well-ventilated area to prevent overheating. Proper grounding and electrical safety measures should be followed to avoid electrical hazards. It is also crucial to connect the printer to a stable power source to prevent power fluctuations that could damage the device.

2.2 Network Configuration

For networked printers or MFDs, configuring the device to connect to the organization’s network is necessary. This involves assigning a static IP address, configuring network protocols, and setting up user authentication if required. Network security measures, such as enabling encryption and firewalls, should also be implemented to protect sensitive data.

3. Regular Maintenance

Regular maintenance is crucial to ensure the longevity and optimal performance of printing equipment.

3.1 Cleaning

Cleaning the printer regularly helps prevent paper jams, smudged prints, and other performance issues. This includes cleaning the paper path, print heads, and rollers. It is important to follow the manufacturer’s guidelines and use recommended cleaning materials to avoid damaging the printer.

3.2 Firmware Updates

Firmware updates provided by the printer manufacturer often include bug fixes, performance improvements, and security patches. Regularly updating the printer’s firmware ensures that it operates at its best and remains protected against potential vulnerabilities.

3.3 Consumables Replacement

Replacing consumables, such as ink cartridges or toner cartridges, is essential for maintaining print quality. It is important to use genuine manufacturer cartridges to avoid compatibility issues and ensure optimal performance. Additionally, recycling used cartridges is a sustainable practice that reduces environmental impact.

4. Troubleshooting and Repair

Inevitably, printing equipment may encounter issues that require troubleshooting and repair.

4.1 Diagnostic Tools

Manufacturers often provide diagnostic tools that can help identify and resolve common printer issues. These tools can assist in diagnosing problems with paper feed, print quality, or connectivity. Following the manufacturer’s troubleshooting guides can save time and potentially avoid costly repairs.

4.2 Service and Support

In cases where troubleshooting does not resolve the issue, contacting the manufacturer’s service and support team is recommended. They can provide expert assistance and, if necessary, arrange for a technician to repair the printer. It is important to keep track of warranty information and ensure timely repairs are carried out.

5. Disposal and Recycling

When the printing equipment reaches the end of its life cycle, proper disposal and recycling are essential to minimize environmental impact.

5.1 E-Waste Regulations

Different regions have specific regulations regarding the disposal of electronic waste (e-waste). It is important to comply with these regulations to ensure responsible disposal. Many manufacturers offer recycling programs or partner with recycling organizations to properly dispose of printing equipment.

5.2 Data Security

Before disposing of any printing equipment, it is crucial to ensure that all sensitive data stored on the device’s hard drive is securely erased. This can be achieved through data wiping or physical destruction of the hard drive. Protecting sensitive information is vital to prevent data breaches or unauthorized access.

5.3 Component Recycling

Printing equipment contains various components, such as plastics, metals, and circuit boards, which can be recycled. Disassembling the device and separating the different materials for recycling helps reduce the environmental impact of electronic waste. Many recycling facilities specialize in electronic component recycling.

5.4 Donations and Resale

If the printing equipment is still in working condition, donating or reselling it can be a viable option. Many organizations or individuals may benefit from acquiring used printing equipment at a lower cost. However, it is important to ensure that all personal or sensitive data is securely erased before transferring ownership.

Disclaimer: The information provided in this article is for informational purposes only and should not be considered as professional advice. Always consult the manufacturer’s guidelines and seek professional assistance when necessary.

FAQs

1. How can I ensure I purchase the right printing equipment for my needs?

When purchasing printing equipment, it’s important to assess your specific needs and requirements. Consider factors such as the volume of printing, types of documents, desired features, and budget. Research different models, read reviews, and consult with experts to make an informed decision.

2. What should I consider when choosing between inkjet and laser printers?

Inkjet printers are generally more affordable and suitable for home or small office use, while laser printers are faster and more efficient for high-volume printing. Consider factors such as print quality, speed, cost per page, and the type of documents you will be printing to determine which option is best for you.

3. How can I extend the lifespan of my printing equipment?

Regular maintenance is key to prolonging the lifespan of your printing equipment. Follow the manufacturer’s guidelines for cleaning and servicing, use high-quality ink or toner cartridges, and avoid overloading the printer. Additionally, ensure the printer is in a well-ventilated area and protected from dust and debris.

4. What should I do with old or outdated printing equipment?

When disposing of old or outdated printing equipment, it’s important to consider environmentally friendly options. Look for recycling programs offered by the manufacturer or local electronic waste recycling centers. Some organizations also accept donations of used printers for refurbishment or repurposing.

5. How can I reduce the environmental impact of printing equipment?

To reduce the environmental impact of printing equipment, consider implementing the following practices:

- Print only when necessary and use digital alternatives whenever possible.

- Opt for duplex printing to save paper.

- Recycle used paper and cartridges.

- Choose energy-efficient printers and enable power-saving features.

6. What steps should I take to securely dispose of sensitive documents?

When disposing of sensitive documents, it’s important to take steps to protect your confidential information. Consider shredding the documents using a cross-cut shredder or hiring a professional shredding service. Alternatively, you can also explore digital options for securely storing and disposing of sensitive information.

7. How often should I update my printing equipment?

The frequency of updating your printing equipment depends on various factors, including technological advancements, changing business needs, and the condition of your current equipment. As a general guideline, consider reviewing your printing equipment every 3-5 years to assess if an upgrade is necessary.

8. What are the benefits of managed print services?

Managed print services can provide several benefits, including:

- Cost savings through optimized printing practices and reduced waste.

- Increased efficiency and productivity by streamlining print workflows.

- Proactive maintenance and support, minimizing downtime.

- Enhanced security measures to protect sensitive information.

9. Are there any alternatives to printing equipment for document management?

Yes, there are alternatives to traditional printing equipment for document management. Consider implementing digital document management systems, which allow for electronic storage, retrieval, and sharing of documents. Digital signatures, cloud storage, and collaboration tools can also help reduce the reliance on physical printing.

10. What should I do if I encounter technical issues with my printing equipment?

If you encounter technical issues with your printing equipment, try the following troubleshooting steps:

- Check for any error messages or notifications on the printer’s display.

- Ensure the printer is properly connected to the power source and the computer.

- Update the printer drivers and firmware.

- Clean the printer heads or replace ink/toner cartridges if necessary.

- If the issue persists, consult the printer’s user manual or contact the manufacturer’s support for further assistance.

Concept 1: Lifecycle Management

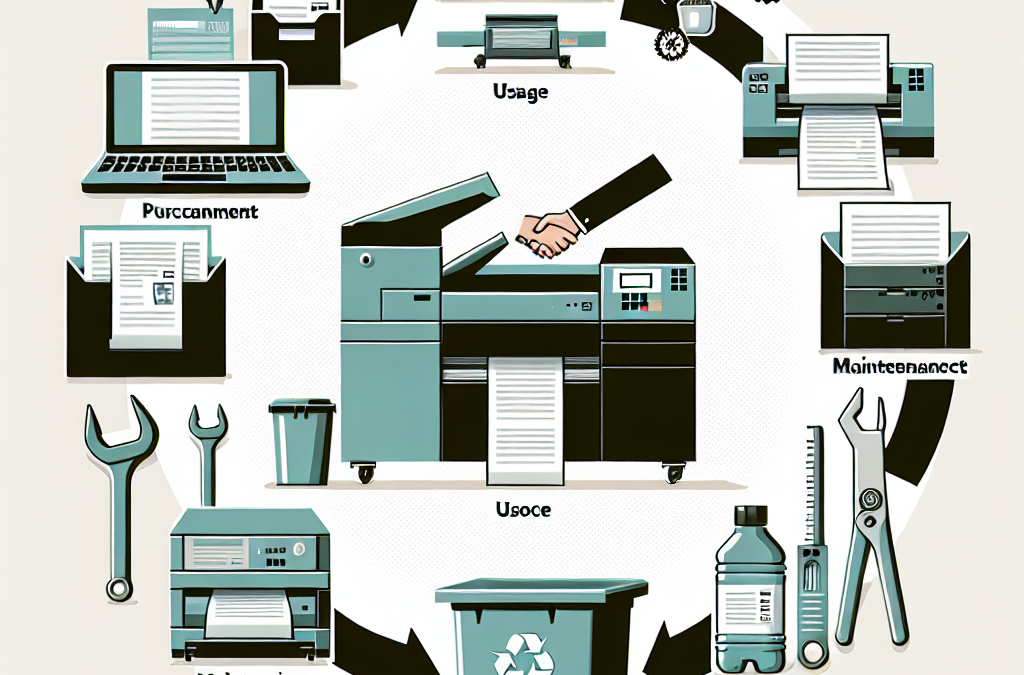

Lifecycle management refers to the process of overseeing the entire lifespan of a product, from its creation to its disposal. In the context of printing equipment, it involves carefully managing every stage, including purchasing, usage, maintenance, and finally, disposal.

When you buy a printer, it’s not just a one-time transaction. Lifecycle management recognizes that the printer will go through various phases, and it’s important to consider each one to ensure optimal performance, cost-effectiveness, and environmental sustainability.

Concept 2: Planned Obsolescence

Planned obsolescence is a strategy used by manufacturers to intentionally design products with a limited lifespan. This means that after a certain period, the product becomes outdated or stops working efficiently, encouraging consumers to replace it with a newer model.

In the case of printing equipment, planned obsolescence may involve using components that have a shorter lifespan or limiting software updates to older models. Manufacturers do this to boost sales and keep the market competitive. However, it can also lead to increased waste and environmental impact as more printers end up in landfills.

Concept 3: Extended Producer Responsibility

Extended Producer Responsibility (EPR) is a concept that holds manufacturers accountable for the environmental impact of their products throughout their lifecycle. It encourages manufacturers to take responsibility for the proper disposal and recycling of their products.

In the context of printing equipment, EPR means that manufacturers should provide options for returning or recycling old printers when they reach the end of their useful life. This ensures that the equipment is disposed of in an environmentally friendly manner and that valuable materials can be recovered and reused.

Why Lifecycle Management Matters

By understanding and implementing lifecycle management, you can make informed decisions about your printing equipment. It allows you to consider factors beyond the initial purchase price and take into account the long-term costs, environmental impact, and sustainability.

Benefits of Lifecycle Management

Lifecycle management offers several benefits:

1. Cost Savings: By carefully managing your printing equipment throughout its lifecycle, you can identify opportunities to reduce costs. This may involve optimizing energy usage, implementing efficient maintenance practices, or extending the lifespan of the equipment through upgrades or repairs.

2. Environmental Sustainability: Proper lifecycle management helps minimize the environmental impact of printing equipment. By choosing energy-efficient models, recycling old printers, and reducing waste through responsible disposal, you contribute to a more sustainable future.

3. Improved Performance: Regular maintenance and upgrades can help ensure that your printing equipment operates at its best. By monitoring its lifecycle, you can identify when it’s time for repairs, updates, or even replacement, ensuring that you always have reliable and efficient printing capabilities.

Lifecycle management is crucial for optimizing the performance, cost-effectiveness, and environmental sustainability of your printing equipment. By understanding the concept, being aware of planned obsolescence, and supporting extended producer responsibility, you can make informed decisions and contribute to a more sustainable printing industry.

1. Assess your printing needs

Before purchasing any printing equipment, take the time to assess your actual printing needs. Consider factors such as the volume of printing, types of documents, and the quality required. This will help you choose the right equipment that meets your specific requirements and avoids unnecessary expenses.

2. Research and compare different models

Don’t rush into buying the first printer you come across. Take the time to research and compare different models from various manufacturers. Look for reviews, specifications, and user experiences to make an informed decision. Consider factors like print speed, cost per page, energy efficiency, and durability.

3. Opt for energy-efficient printers

When purchasing a printer, opt for energy-efficient models. Look for printers with ENERGY STAR certification, as they are designed to consume less energy while maintaining high performance. This not only reduces your environmental footprint but also saves you money on electricity bills in the long run.

4. Use high-quality and recycled paper

To reduce the environmental impact of your printing activities, choose high-quality paper that can be recycled. Recycled paper helps conserve natural resources, reduces water and energy consumption, and minimizes waste. Additionally, using high-quality paper improves print quality and reduces the likelihood of paper jams.

5. Print double-sided whenever possible

Make it a habit to print double-sided whenever possible. This simple practice can significantly reduce paper consumption and save costs. Most modern printers have a duplex printing feature that allows you to print on both sides automatically. Adjust your printing settings accordingly to maximize paper savings.

6. Implement print management software

Consider implementing print management software to monitor and control your printing activities. These tools can help you track print volumes, set printing quotas, and enforce print policies. By optimizing your printing practices, you can reduce waste, improve efficiency, and save money.

7. Regularly maintain and clean your printer

Regular maintenance and cleaning of your printer are essential to ensure optimal performance and longevity. Follow the manufacturer’s guidelines for cleaning and replacing printer components, such as ink cartridges and printheads. This will help prevent printing issues, reduce downtime, and extend the lifespan of your equipment.

8. Dispose of printing equipment responsibly

When it’s time to dispose of your printing equipment, make sure to do so responsibly. Many printers and cartridges contain hazardous materials that can harm the environment if not properly handled. Check with local recycling centers or electronic waste collection facilities for proper disposal methods. Some manufacturers also offer recycling programs for their products.

9. Consider leasing or renting

If you have fluctuating printing needs or want to avoid the upfront cost of purchasing equipment, consider leasing or renting printers. This allows you to access the latest technology without the long-term commitment. It also ensures that you can upgrade or downgrade your equipment as needed, reducing the risk of owning outdated or underutilized devices.

10. Stay informed about new technologies

Keep yourself updated on advancements in printing technology and sustainability practices. Subscribe to industry newsletters, follow relevant blogs, and attend trade shows or webinars. Staying informed will help you make informed decisions, optimize your printing processes, and stay ahead of the curve in terms of environmental responsibility.

Remember, implementing these tips is a step towards sustainable printing practices that benefit both your wallet and the environment. By being mindful of your printing habits and making conscious choices, you can reduce waste, save resources, and contribute to a greener future.

In conclusion, effective lifecycle management of printing equipment is crucial for businesses to optimize their printing processes, reduce costs, and minimize their environmental impact. From the initial purchase to the final disposal, there are several key points and insights to consider. Firstly, conducting a thorough needs assessment and evaluating the total cost of ownership can help businesses make informed decisions when purchasing printing equipment. It is important to consider factors such as energy efficiency, maintenance requirements, and compatibility with existing systems.

Once the equipment is in use, regular maintenance and monitoring are essential to ensure optimal performance and longevity. Implementing a proactive maintenance schedule, training staff on proper usage, and monitoring print volumes can help identify and address issues before they become major problems. Additionally, businesses should explore options for reducing paper waste, such as duplex printing and digital document management systems.

When it comes to disposal, proper recycling and responsible disposal methods should be followed to minimize the environmental impact. Partnering with reputable recycling companies or returning equipment to manufacturers for proper disposal can ensure that hazardous materials are handled safely and valuable resources are recovered.

By following these key points and insights, businesses can effectively manage the lifecycle of their printing equipment, leading to cost savings, improved efficiency, and a reduced environmental footprint. Embracing sustainable practices in printing equipment management not only benefits the bottom line but also contributes to a greener future.