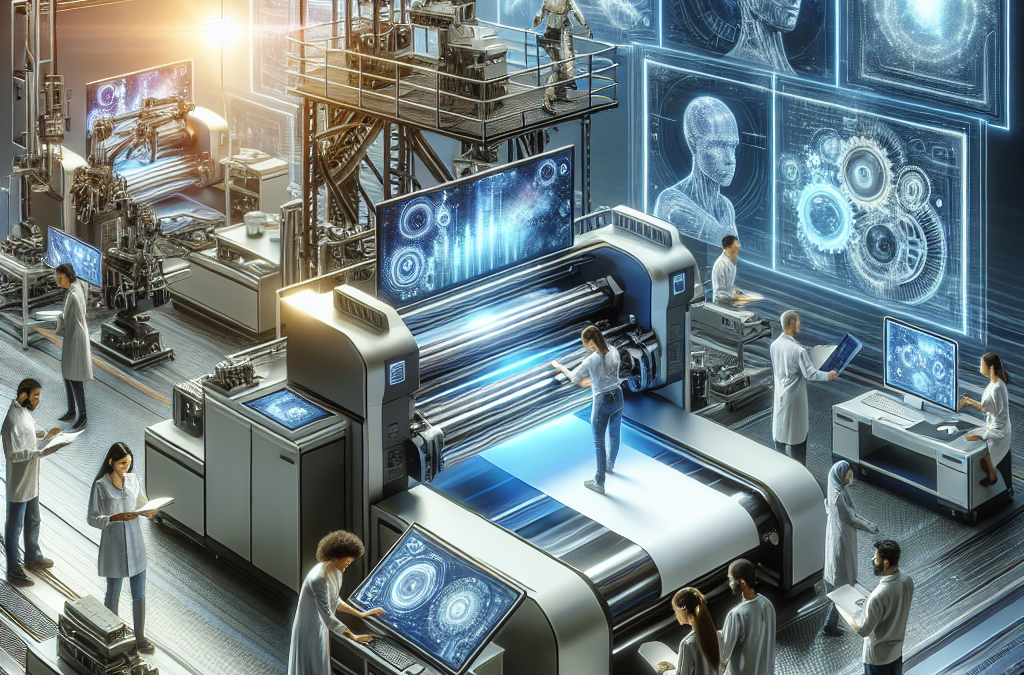

Revolutionizing the Printing Industry: Cutting-Edge Innovations Taking Commercial Printing to New Heights in 2024

In today’s fast-paced world, where technology is constantly evolving, the commercial printing industry has not been left behind. As we step into the year 2024, the landscape of commercial printing is witnessing a revolution of innovations that are set to redefine the way businesses communicate and market their products. From advanced digital printing techniques to sustainable materials and personalized printing experiences, this article explores the cutting-edge innovations that are reshaping the commercial printing industry and how they are enabling businesses to stay ahead in a competitive market.

First and foremost, digital printing has taken center stage in the commercial printing industry. With advancements in technology, digital printers have become faster, more efficient, and capable of producing high-quality prints. The of UV-curable inks has further enhanced the capabilities of digital printing, allowing for printing on a wide range of materials, including glass, metal, and plastics. Moreover, the rise of variable data printing has enabled businesses to create personalized marketing materials, tailoring their messages to individual customers. This level of customization not only enhances the effectiveness of marketing campaigns but also strengthens customer engagement and brand loyalty.

Key Takeaways:

1. Advanced 3D Printing Technology Revolutionizes Commercial Printing:

The year 2024 brings unprecedented advancements in 3D printing technology, transforming the landscape of commercial printing. With the ability to print intricate and customizable designs, businesses can now create unique and personalized products for their customers, opening up new opportunities for creativity and innovation.

2. Eco-Friendly Printing Solutions Gain Momentum:

In response to growing environmental concerns, the commercial printing industry has embraced eco-friendly printing solutions. In 2024, we see a significant shift towards sustainable practices, with the adoption of biodegradable inks, recycled materials, and energy-efficient printing processes. This not only reduces the industry’s carbon footprint but also appeals to eco-conscious consumers.

3. Integration of Augmented Reality Enhances Print Media:

Augmented reality (AR) has emerged as a powerful tool for enhancing print media. In 2024, commercial printers are integrating AR technology into their products, creating interactive experiences that bridge the gap between physical and digital worlds. From interactive advertisements to immersive storytelling, AR brings a new dimension to printed materials, captivating consumers and boosting engagement.

4. Personalization Takes Center Stage:

With the advancement of data analytics and variable printing capabilities, personalization has become a key focus in commercial printing. In 2024, businesses are leveraging customer insights to create highly targeted and customized printed materials. Whether it’s personalized direct mail campaigns or individualized packaging, this trend enhances customer experiences and drives higher response rates.

5. Smart Printing Solutions Streamline Workflows:

The integration of smart technologies, such as Internet of Things (IoT) devices and cloud-based platforms, has revolutionized commercial printing workflows. In 2024, printers are equipped with intelligent sensors and automated processes, enabling real-time monitoring, predictive maintenance, and seamless collaboration. These smart printing solutions improve efficiency, reduce downtime, and enhance overall productivity in the industry.

As we delve deeper into the world of commercial printing in 2024, these key takeaways highlight the exciting innovations that are reshaping the industry and empowering businesses to stay ahead in a rapidly evolving market.

Inkjet Printing: The Future of Commercial Printing

Inkjet printing has been around for several decades, but recent advancements have taken this technology to a whole new level. With its ability to print on a wide range of substrates and its cost-effective nature, inkjet printing is emerging as the future of commercial printing.

One of the key advantages of inkjet printing is its versatility. Unlike traditional printing methods such as offset or flexography, inkjet printers can print on various surfaces, including paper, plastic, glass, fabric, and even metal. This opens up a world of possibilities for businesses looking to create unique and eye-catching printed materials.

Furthermore, inkjet printing offers significant cost savings compared to traditional printing methods. The elimination of plates and setup costs, as well as the ability to print on demand, makes inkjet printing a cost-effective solution for small to medium-sized businesses. Additionally, inkjet printers have become faster and more efficient, allowing for high-speed production without compromising quality.

The future implications of inkjet printing are vast. As technology continues to advance, we can expect to see even more innovative applications of this printing method. For example, 3D inkjet printing is already being explored, which could revolutionize industries such as manufacturing and prototyping. Additionally, the ability to print with specialty inks, such as conductive or fluorescent inks, opens up opportunities for the production of interactive and dynamic printed materials.

Eco-Friendly Printing: A Sustainable Approach

With growing concerns about the environment, the printing industry is making significant strides towards sustainability. Eco-friendly printing methods are emerging as a trend in commercial printing, driven by the need to reduce waste, energy consumption, and harmful emissions.

One of the key innovations in eco-friendly printing is the development of soy-based and vegetable-based inks. These inks are made from renewable resources and have a lower environmental impact compared to traditional petroleum-based inks. They also offer comparable print quality and performance, making them a viable alternative for businesses looking to reduce their carbon footprint.

Another aspect of eco-friendly printing is the use of recycled and FSC-certified paper. Recycled paper reduces the demand for virgin materials and minimizes waste. On the other hand, FSC-certified paper ensures that the paper used in printing comes from responsibly managed forests.

Furthermore, advancements in digital printing technology have also contributed to eco-friendly printing. Digital printing eliminates the need for traditional printing plates, reducing waste and chemical usage. It also allows for on-demand printing, reducing excess inventory and minimizing the risk of obsolescence.

The future implications of eco-friendly printing are significant. As businesses and consumers become more environmentally conscious, the demand for sustainable printing practices will continue to grow. This trend will likely drive further innovations in materials, inks, and printing processes, ultimately leading to a more sustainable and greener printing industry.

Personalized Printing: Tailoring to Individual Needs

In the era of customization and personalization, commercial printing is embracing the trend of personalized printing. This innovative approach allows businesses to tailor their printed materials to individual customers, creating a more engaging and targeted experience.

One of the key technologies driving personalized printing is variable data printing (VDP). VDP enables businesses to customize each printed piece with unique content, such as names, addresses, or personalized messages. This level of personalization enhances the effectiveness of marketing campaigns, as personalized materials tend to have higher engagement rates.

Moreover, advancements in data analytics and digital printing technology have made it easier to collect and utilize customer data for personalized printing. Businesses can now leverage customer information, such as purchase history or browsing behavior, to create highly targeted and relevant printed materials. This personalized approach not only increases customer satisfaction but also improves the overall return on investment for businesses.

The future implications of personalized printing are promising. As technology continues to advance, we can expect to see even more sophisticated personalization techniques. For instance, augmented reality (AR) and variable imaging can be combined to create interactive and personalized printed materials. This could revolutionize industries such as retail, where customers can visualize products in their own space before making a purchase.

Inkjet printing, eco-friendly printing, and personalized printing are emerging trends in commercial printing with significant future implications. these innovations offer businesses new opportunities for creativity, sustainability, and customer engagement. as technology continues to evolve, we can expect further advancements in these areas, ultimately shaping the future of the printing industry.

The Environmental Impact of Commercial Printing

Commercial printing has long been criticized for its negative environmental impact. The production of paper and ink, as well as the energy consumption involved in the printing process, contribute to deforestation, greenhouse gas emissions, and waste generation. However, recent innovations in commercial printing have aimed to address these concerns and reduce the industry’s environmental footprint.

One of the controversial aspects of these innovations is the use of eco-friendly materials. Some argue that the shift towards sustainable paper and ink options is a positive step towards reducing environmental harm. These materials are often made from recycled or responsibly sourced fibers and use non-toxic, vegetable-based inks. Proponents of these innovations argue that they help preserve forests, reduce water consumption, and minimize air pollution.

On the other hand, critics argue that the use of eco-friendly materials in commercial printing is not enough to offset the industry’s overall impact. They claim that the demand for paper products remains high, leading to continued deforestation and habitat destruction. Additionally, the recycling process for paper can be energy-intensive and may not always be economically viable.

Another controversial aspect is the adoption of digital printing technologies. Digital printing eliminates the need for traditional printing plates, reducing waste and setup time. It also allows for on-demand printing, reducing overproduction and inventory waste. Proponents argue that digital printing is a more sustainable alternative to traditional offset printing methods.

However, critics question the overall sustainability of digital printing. They argue that the energy consumption associated with running digital printing presses, as well as the disposal of electronic waste from outdated equipment, can still have a significant environmental impact. Additionally, the use of digital printing may lead to an increase in electronic devices’ production, which also has environmental consequences.

The Impact on Employment in the Printing Industry

As with any technological advancement, innovations in commercial printing have raised concerns about the impact on employment in the industry. The automation and digitization of printing processes have led to fears of job displacement and a decline in traditional printing jobs.

Proponents argue that these innovations can lead to increased efficiency and productivity, allowing printing companies to remain competitive in a rapidly evolving market. They argue that while some jobs may be eliminated, new roles will be created to support the implementation and maintenance of new technologies. Additionally, the shift towards digital printing may open up opportunities in graphic design, digital marketing, and online publishing.

Critics, however, express concern for the workers whose jobs may be at risk. They argue that the transition to digital printing may disproportionately affect older, less technologically skilled workers who may struggle to adapt to the changing industry. Furthermore, they suggest that the overall number of jobs created may not be sufficient to offset the loss of traditional printing jobs, leading to unemployment and economic hardship for affected individuals and communities.

The Ethical Implications of Data-Driven Printing

Data-driven printing, also known as variable data printing, is another innovation that has sparked controversy in the commercial printing industry. This technology allows for personalized printing, where each printed piece can be customized based on the recipient’s preferences, demographics, or browsing history.

Proponents argue that data-driven printing offers a more targeted and effective marketing approach. By tailoring printed materials to individual recipients, companies can increase engagement and response rates, ultimately leading to higher sales and customer satisfaction. They believe that this innovation can revolutionize the industry by providing more relevant and personalized content to consumers.

However, critics raise concerns about privacy and data security. They argue that the collection and use of personal data for targeted printing may infringe on individuals’ privacy rights. Additionally, they express concerns about the potential for data breaches or misuse of personal information, as well as the ethical implications of using consumer data for commercial purposes without explicit consent.

While innovations in commercial printing have brought about positive changes, they also raise controversial aspects that need careful consideration. the environmental impact of commercial printing, the impact on employment, and the ethical implications of data-driven printing all require a balanced approach to ensure the industry’s sustainability and responsible practices. as the industry continues to evolve, it is crucial to address these concerns and find solutions that benefit both businesses and the environment while respecting individual rights and well-being.

Key Insight 1: Digital Printing Revolutionizes the Commercial Printing Industry

Digital printing has been a game-changer for the commercial printing industry, and in 2024, we are witnessing even more significant advancements in this field. Traditional offset printing methods are gradually being replaced by digital printing technologies that offer increased efficiency, flexibility, and cost-effectiveness.

One of the key innovations in digital printing is the development of high-speed, high-resolution printers that can handle a wide range of substrates. These printers utilize advanced inkjet or laser technology to produce vibrant and precise prints, making them suitable for various applications, including marketing materials, packaging, and personalized products.

Moreover, digital printing allows for on-demand printing, eliminating the need for large print runs and reducing waste. This not only saves costs but also enables businesses to respond quickly to market demands and customize their prints to target specific audiences. With the advancements in digital printing, businesses can now efficiently print small batches or even individual prints without compromising quality or incurring excessive costs.

Another significant development in digital printing is the integration of variable data printing (VDP) capabilities. VDP enables businesses to personalize each printed piece by customizing text, images, or other elements based on individual recipient data. This level of personalization enhances the effectiveness of marketing campaigns, as it allows businesses to deliver tailored messages to their target audience, resulting in higher engagement and conversion rates.

Overall, the continuous advancements in digital printing technology are transforming the commercial printing industry. Businesses can now benefit from faster turnaround times, reduced costs, increased customization options, and improved print quality, making digital printing the preferred choice for many companies.

Key Insight 2: Sustainability Takes Center Stage in Commercial Printing

In recent years, sustainability has become a significant concern across various industries, and the commercial printing sector is no exception. In 2024, we are witnessing a shift towards more sustainable printing practices, driven by the increasing demand for eco-friendly solutions and the industry’s commitment to reducing its environmental impact.

One of the key innovations in sustainable printing is the adoption of environmentally friendly printing materials and processes. For instance, there is a growing emphasis on using recycled or FSC-certified paper and soy or vegetable-based inks instead of traditional petroleum-based inks. These alternatives not only reduce the industry’s carbon footprint but also offer comparable print quality and performance.

Additionally, advancements in printing technologies have led to significant improvements in energy efficiency. Modern printing equipment is designed to consume less energy and minimize waste during the printing process. Furthermore, the development of waterless printing technologies has eliminated the need for water-intensive processes, reducing water consumption and minimizing the environmental impact.

Moreover, the concept of circular economy is gaining traction in the commercial printing industry. This approach focuses on reducing waste by reusing or recycling materials. Print service providers are implementing strategies to collect and recycle unused prints, paper waste, and printing equipment, ensuring that valuable resources are not wasted and minimizing the industry’s contribution to landfills.

The growing focus on sustainability in commercial printing not only aligns with the global environmental goals but also offers businesses a competitive advantage. Consumers are increasingly conscious of the environmental impact of their purchasing decisions and are more likely to support companies that prioritize sustainability. By adopting sustainable printing practices, businesses can enhance their brand image, attract environmentally conscious customers, and contribute to a greener future.

Key Insight 3: Integration of Artificial Intelligence and Automation Streamlines Workflows

Artificial Intelligence (AI) and automation technologies are revolutionizing various industries, and the commercial printing sector is no exception. In 2024, we are witnessing the integration of AI and automation in commercial printing workflows, leading to increased efficiency, reduced costs, and improved quality control.

One of the key applications of AI in commercial printing is in prepress operations. AI algorithms can analyze and optimize design files, ensuring that they are print-ready and minimizing the risk of errors. This automation eliminates the need for manual intervention, reduces turnaround times, and enhances overall productivity.

Furthermore, AI-powered software can analyze customer data and provide valuable insights for print service providers. By leveraging AI analytics, businesses can gain a better understanding of their customers’ preferences, behavior, and buying patterns. This information can then be used to develop targeted marketing campaigns, optimize print designs, and improve customer engagement.

Automation technologies are also transforming the production process in commercial printing. Robotic systems can handle repetitive tasks, such as loading and unloading paper, operating printing presses, or performing quality inspections. This automation not only reduces labor costs but also minimizes the risk of human errors, ensuring consistent print quality and faster turnaround times.

Additionally, the integration of AI and automation enables real-time monitoring and control of printing processes. Print service providers can track various parameters, such as ink levels, color accuracy, or machine performance, and make adjustments on the fly to ensure optimal results. This level of control improves quality control, reduces waste, and enhances customer satisfaction.

The integration of ai and automation in commercial printing workflows is revolutionizing the industry. businesses can benefit from streamlined processes, reduced costs, improved quality control, and enhanced customer insights. as technology continues to advance, we can expect even more innovative applications of ai and automation in the commercial printing sector, further driving its growth and transformation.

The Rise of Digital Printing

Digital printing has revolutionized the commercial printing industry in recent years, and in 2024, we can expect to see even more advancements in this technology. One of the key innovations in digital printing is the improvement in print quality. High-resolution printing has become the norm, allowing for sharper images and more vibrant colors. Additionally, digital printing has become faster and more efficient, enabling businesses to meet tight deadlines and handle large print volumes with ease. With the continued development of digital printing technology, we can expect to see even more precise color matching, faster print speeds, and improved cost-effectiveness.

Personalization and Variable Data Printing

In the age of personalization, businesses are increasingly looking for ways to tailor their marketing materials to individual customers. Variable data printing (VDP) allows for the customization of each printed piece, whether it’s a direct mailer, brochure, or packaging. In 2024, we can expect to see further advancements in VDP, making it easier for businesses to create personalized marketing campaigns. For example, using customer data, businesses can dynamically change text, images, and even offers to create a more targeted and engaging experience for each recipient. This level of personalization not only increases the effectiveness of marketing campaigns but also enhances the overall customer experience.

Environmentally Friendly Printing

With growing concerns about the environment, the commercial printing industry has been making significant strides in adopting more sustainable practices. In 2024, we can expect to see further innovations in environmentally friendly printing. One such innovation is the development of eco-friendly inks. These inks are made from renewable resources and have lower levels of volatile organic compounds (VOCs), reducing their impact on air quality. Additionally, printing companies are investing in energy-efficient equipment and implementing recycling programs to minimize waste. By embracing sustainable printing practices, businesses can reduce their carbon footprint and appeal to environmentally conscious consumers.

3D Printing in Commercial Applications

While 3D printing has been predominantly associated with prototyping and small-scale production, it is increasingly finding its way into commercial printing applications. In 2024, we can expect to see further advancements in 3D printing technology, enabling businesses to create unique and customized products. For example, in the fashion industry, 3D printing can be used to create intricate and personalized accessories. In the packaging industry, 3D printing can be utilized to produce custom-designed packaging solutions that stand out on the shelves. As the technology continues to evolve, 3D printing will become more accessible and affordable, opening up new possibilities for businesses in various sectors.

Integration of Augmented Reality

Augmented reality (AR) has gained traction in recent years, and in 2024, we can expect to see its integration into commercial printing. AR allows businesses to enhance printed materials with digital content, creating interactive and immersive experiences for customers. For example, a printed catalog can be brought to life with AR, allowing customers to view 3D product models, access additional information, or even make purchases directly from the catalog. This integration of AR not only adds value to printed materials but also provides businesses with valuable data and insights into customer behavior and preferences.

Smart Packaging and IoT

The rise of the Internet of Things (IoT) has paved the way for smart packaging, which combines printed materials with embedded sensors and connectivity. In 2024, we can expect to see further advancements in smart packaging, enabling businesses to track and monitor products throughout the supply chain. For example, temperature-sensitive products can be equipped with sensors that monitor and report any deviations in temperature, ensuring product quality and safety. Smart packaging can also be used to engage customers by providing them with real-time information, such as product usage tips or personalized offers. This integration of printed materials with IoT technology adds a new level of functionality and interactivity to packaging.

Print-to-Digital Integration

While digital marketing has gained prominence, print materials still play a crucial role in many marketing campaigns. In 2024, we can expect to see further integration between print and digital channels, creating a seamless and cohesive customer experience. For example, printed materials can be enhanced with QR codes or augmented reality to direct customers to digital content, such as videos or interactive websites. Conversely, digital campaigns can be complemented with personalized print materials, such as direct mailers or brochures, to reinforce brand messaging. By integrating print and digital channels, businesses can maximize the impact of their marketing campaigns and reach customers through multiple touchpoints.

Advancements in Large Format Printing

Large format printing has become increasingly popular for various applications, such as signage, banners, and vehicle wraps. In 2024, we can expect to see advancements in large format printing technology, allowing for even greater versatility and quality. For example, UV-curable inks are becoming more prevalent, offering improved durability and resistance to fading. Additionally, advancements in inkjet technology are enabling large format printers to achieve higher print speeds without compromising quality. These advancements in large format printing will enable businesses to create eye-catching and impactful visuals for both indoor and outdoor advertising.

Automation and Workflow Optimization

Automation has been transforming industries across the board, and commercial printing is no exception. In 2024, we can expect to see further automation and workflow optimization in the printing process. For example, automated prepress workflows can streamline file preparation and imposition, reducing errors and speeding up production. Robotic systems can handle tasks such as material handling and finishing, increasing efficiency and reducing labor costs. Additionally, cloud-based platforms and software solutions are enabling seamless collaboration and file sharing between different stakeholders in the printing process. These automation and workflow optimization solutions will help businesses save time, reduce costs, and improve overall productivity.

The Future of Commercial Printing

Looking ahead, the future of commercial printing is filled with exciting possibilities. As technology continues to advance, we can expect to see further innovations in print quality, personalization, sustainability, and integration with digital channels. The commercial printing industry will continue to adapt and evolve to meet the changing needs of businesses and consumers. By embracing these innovations, businesses can leverage the power of print to engage customers, enhance their brand image, and drive business growth. As we enter 2024, the commercial printing industry is poised for a new era of innovation and transformation.

The Early Days of Commercial Printing

Commercial printing has a rich history that dates back centuries. The origins of commercial printing can be traced back to ancient civilizations, where the use of stamps and seals for printing purposes was prevalent. However, it was not until the invention of the printing press by Johannes Gutenberg in the 15th century that commercial printing truly took off.

Gutenberg’s invention revolutionized the way information was disseminated. The printing press allowed for the mass production of books, making them more accessible to a wider audience. This marked the beginning of a new era in commercial printing, as it opened up opportunities for the dissemination of knowledge and the spread of ideas.

The Rise of Industrialization

The 19th century witnessed significant advancements in commercial printing, thanks to the rise of industrialization. The of steam-powered presses and the development of new printing techniques, such as lithography, brought about a new level of efficiency and quality in the printing industry.

Lithography, invented by Alois Senefelder in 1796, allowed for the printing of high-quality images and illustrations. This technique, which involved the use of a flat stone or metal plate, made it possible to reproduce intricate designs with great precision. As a result, commercial printing began to incorporate more visual elements, making printed materials more visually appealing and engaging.

The Digital Revolution

The late 20th century marked another significant turning point in the history of commercial printing with the advent of digital technology. The of computers and digital printing technology revolutionized the industry, making printing faster, more cost-effective, and highly customizable.

Digital printing eliminated the need for traditional printing plates, allowing for on-demand printing and shorter print runs. This development made it possible for businesses to print smaller quantities of materials without incurring significant costs. Additionally, digital printing allowed for variable data printing, enabling the personalization of printed materials, such as direct mail campaigns and promotional materials.

The Internet and Online Printing

The rise of the internet in the late 20th century and the early 21st century brought about yet another transformation in the commercial printing industry. With the widespread availability of the internet, online printing services emerged, offering businesses and individuals the convenience of ordering printed materials online.

Online printing services provided a platform for customers to upload their designs, select printing options, and have their materials delivered to their doorstep. This shift in the printing industry empowered small businesses and individuals to access professional printing services without the need for a physical print shop.

The Current State of Commercial Printing

As we enter 2024, commercial printing continues to evolve and adapt to the changing needs of businesses and consumers. Technological advancements, such as 3D printing and augmented reality, are pushing the boundaries of what is possible in the printing industry.

3D printing has gained significant traction in recent years, allowing for the creation of three-dimensional objects layer by layer. This technology has found applications in various industries, including manufacturing, healthcare, and even fashion. 3D printing has the potential to revolutionize the way products are manufactured and customized, offering businesses new opportunities for innovation.

Augmented reality (AR) is another technology that is making its mark in the commercial printing industry. AR combines virtual elements with the real world, enhancing the printed materials’ interactivity and engagement. For example, printed advertisements can be scanned with a smartphone, triggering virtual content or animations that provide additional information or entertainment.

Moreover, sustainability has become a key focus in the printing industry. Many companies are adopting eco-friendly printing practices, using recycled materials, vegetable-based inks, and energy-efficient equipment. This shift towards sustainability reflects the growing awareness of environmental issues and the need for responsible business practices.

The history of commercial printing is a testament to human ingenuity and innovation. from the invention of the printing press to the digital revolution and the emergence of new technologies, commercial printing has continuously evolved to meet the changing needs of society. as we move into the future, it is exciting to see how commercial printing will continue to push boundaries and shape the way we communicate and engage with printed materials.

Advanced Digital Printing Technologies

1. High-Speed Inkjet Printing

In recent years, high-speed inkjet printing has revolutionized the commercial printing industry. This technology enables faster and more efficient printing processes, making it ideal for high-volume production. High-speed inkjet printers use tiny nozzles to spray ink onto the paper, resulting in sharp and vibrant prints. These printers can achieve speeds of up to 1,000 feet per minute, significantly reducing production time and costs.

One of the key advancements in high-speed inkjet printing is the development of faster drying inks. Traditional inkjet inks take time to dry, leading to smudging and longer production times. However, manufacturers have introduced quick-drying inks that allow for immediate finishing and handling of the prints. This advancement has greatly improved the efficiency of high-speed inkjet printing.

2. UV Printing

UV printing is another innovative technology that has gained popularity in the commercial printing industry. Unlike traditional printing methods that use solvent-based inks, UV printing utilizes ultraviolet light to cure the ink instantly. This process eliminates the need for drying time, making UV printing extremely efficient for high-speed production.

UV printing offers several advantages, including enhanced color vibrancy, sharper details, and increased durability. The UV-cured inks adhere better to various substrates, such as paper, plastic, and metal, allowing for more versatile printing options. Additionally, UV printing is more environmentally friendly as it does not emit volatile organic compounds (VOCs) like solvent-based inks do.

3. Variable Data Printing

Variable data printing (VDP) is a technology that allows for personalized and customized printing on a large scale. It enables the printing of unique text, images, or graphics on each individual piece without slowing down the production process. VDP is particularly useful for direct mail campaigns, personalized marketing materials, and transactional documents like invoices and statements.

Advancements in VDP software and hardware have made it easier to integrate variable data into the printing process. Software solutions can now seamlessly merge databases with design templates, allowing for efficient and accurate customization. This technology has opened up new possibilities for targeted marketing campaigns, improving customer engagement and response rates.

Specialty Finishing Techniques

1. Metallic Inks and Foils

To add a touch of luxury and sophistication to printed materials, metallic inks and foils have become increasingly popular. Metallic inks contain tiny metallic particles that create a shimmering effect when printed. Foils, on the other hand, are applied using heat and pressure, resulting in a reflective and eye-catching finish.

Recent advancements in metallic inks and foils have expanded the range of colors and effects available. Printers can now achieve metallic finishes in various shades, including gold, silver, copper, and even holographic effects. These specialty finishes are commonly used in packaging, invitations, business cards, and high-end marketing materials.

2. Embossing and Debossing

Embossing and debossing are techniques used to create raised or depressed patterns on printed materials, respectively. These finishing techniques add texture and depth to designs, making them visually appealing and tactile. Embossing and debossing can be applied to a wide range of materials, including paper, cardstock, and even flexible packaging.

Recent advancements in embossing and debossing technologies have improved precision and efficiency. Computer-controlled systems now allow for more intricate and detailed designs, enhancing the overall quality of the finished product. Additionally, new embossing and debossing tools have been developed to accommodate various substrates and thicknesses, providing greater flexibility in design options.

3. Spot Gloss and Matte Coatings

Spot gloss and matte coatings are used to create contrasting finishes on printed materials, adding visual interest and enhancing certain elements of the design. Spot gloss coatings provide a glossy, reflective finish to specific areas, while matte coatings offer a non-reflective, velvety texture. These coatings can be applied selectively, highlighting logos, images, or text.

Advancements in coating technologies have made spot gloss and matte coatings more precise and consistent. Printers can now achieve sharper edges and smoother finishes, resulting in a higher-quality appearance. Additionally, new formulations of coatings have improved durability, making the prints more resistant to scratches and scuffs.

Automation and Workflow Solutions

1. Print Management Software

Print management software has become essential for streamlining and automating the printing workflow. These software solutions enable efficient job submission, preflighting, color management, and proofing, reducing errors and improving overall productivity. Print management software also integrates with other systems, such as customer relationship management (CRM) and enterprise resource planning (ERP), for seamless order management and tracking.

Recent advancements in print management software have focused on enhancing user experience and customization. User-friendly interfaces and intuitive dashboards make it easier for operators to manage multiple print jobs simultaneously. Additionally, cloud-based solutions have emerged, allowing for remote access and collaboration, further improving workflow efficiency.

2. Web-to-Print Platforms

Web-to-print platforms have revolutionized the way customers order and personalize printed materials. These online portals enable users to upload their designs, select printing options, and place orders directly from their web browsers. Web-to-print platforms offer convenience, speed, and customization options, making them popular among businesses and individuals alike.

Advancements in web-to-print platforms have focused on improving user experience and expanding functionality. New features, such as real-time design previews, interactive templates, and variable data integration, allow for more accurate customization and faster order processing. Additionally, web-to-print platforms now offer seamless integration with print management software, ensuring a smooth transition from online ordering to production.

3. Automated Finishing Equipment

Automated finishing equipment has significantly improved the efficiency and accuracy of post-printing processes. These machines can perform tasks such as cutting, folding, binding, and laminating with minimal human intervention. Automated finishing equipment reduces labor costs, eliminates errors, and increases production speeds, making it an essential component of modern commercial printing operations.

Recent advancements in automated finishing equipment have focused on versatility and precision. New machines can handle a wide range of substrates, including different paper weights, sizes, and textures. They also feature advanced sensors and computer-controlled systems that ensure precise cutting, folding, and binding, resulting in high-quality finished products.

Case Study 1: 3D Printing Revolutionizes Packaging Design

In 2024, 3D printing technology has made significant strides in the commercial printing industry, revolutionizing the way packaging design is approached. One success story that exemplifies this is the collaboration between a renowned cosmetics brand and a printing company specializing in 3D printing.

The cosmetics brand was looking to launch a new line of luxury skincare products and wanted packaging that would reflect the high-end nature of their brand. They approached the printing company with a vision of intricate, geometric designs that would be impossible to achieve with traditional printing methods.

Using their state-of-the-art 3D printers, the printing company was able to bring the brand’s vision to life. The packaging was created using a combination of different materials, including biodegradable plastics and metallic finishes, resulting in a stunning and unique design that captured the essence of the brand.

The use of 3D printing allowed for intricate details and textures that would have been impossible to achieve with traditional printing methods. The packaging not only looked visually appealing but also had a tactile element that enhanced the overall user experience.

This case study highlights how 3D printing has opened up new possibilities in packaging design, allowing brands to create innovative and eye-catching packaging that sets them apart from their competitors.

Case Study 2: Personalized Direct Mail Campaign Boosts Sales

Direct mail has long been a popular marketing strategy, but in 2024, advancements in commercial printing have taken it to a whole new level. A successful case study in this regard is the implementation of a personalized direct mail campaign by a leading e-commerce company.

The company wanted to increase customer engagement and drive sales by sending out personalized catalogs to their existing customer base. However, they didn’t want to simply print generic catalogs with the customer’s name on the cover. They wanted to create a truly personalized experience that would resonate with each individual recipient.

To achieve this, the company partnered with a printing company that offered variable data printing capabilities. Variable data printing allows for the customization of each printed piece with unique text, images, and even offers based on the recipient’s preferences and purchase history.

The result was a highly targeted and personalized direct mail campaign that generated impressive results. By tailoring the content of each catalog to the recipient’s interests and past purchases, the company saw a significant increase in response rates and sales.

This case study demonstrates how innovations in commercial printing, such as variable data printing, can transform traditional marketing strategies like direct mail into highly effective and personalized campaigns that resonate with customers on an individual level.

Case Study 3: Sustainable Printing Practices Reduce Environmental Impact

In recent years, there has been a growing emphasis on sustainability in all industries, including commercial printing. One success story in this area is the implementation of sustainable printing practices by a large publishing company.

The publishing company recognized the environmental impact of traditional printing methods, such as the use of harmful chemicals and excessive waste. They wanted to reduce their carbon footprint and adopt more sustainable practices without compromising on the quality of their printed materials.

To achieve this, the company partnered with a printing company that specialized in eco-friendly printing solutions. The printing company utilized vegetable-based inks, which are non-toxic and biodegradable, instead of traditional petroleum-based inks. They also implemented waterless printing technology, which eliminates the need for water in the printing process, reducing water consumption and waste.

Additionally, the printing company offered a range of recycled and FSC-certified paper options, ensuring that the materials used in the printing process were sourced sustainably.

By adopting these sustainable printing practices, the publishing company was able to significantly reduce their environmental impact while maintaining the quality and integrity of their printed materials. This case study highlights how innovations in commercial printing can contribute to a more sustainable future by offering eco-friendly alternatives to traditional printing methods.

Overall, these case studies demonstrate the exciting innovations and success stories in commercial printing in 2024. From 3D printing revolutionizing packaging design to personalized direct mail campaigns boosting sales and sustainable printing practices reducing environmental impact, these advancements are shaping the future of the industry.

FAQs

1. What are some of the latest innovations in commercial printing?

Commercial printing has seen several exciting innovations in 2024. Some of the latest advancements include:

- 3D printing technology for commercial applications

- Printed electronics for interactive packaging

- Augmented reality (AR) printing for enhanced customer experiences

- Nanographic printing for high-quality prints with faster production times

- Variable data printing for personalized marketing materials

2. How does 3D printing technology impact the commercial printing industry?

3D printing technology has revolutionized the commercial printing industry. It allows businesses to create three-dimensional objects using a variety of materials, including plastics, metals, and even food. This innovation has opened up new possibilities for product prototyping, customized manufacturing, and on-demand production.

3. What are the benefits of using printed electronics in commercial printing?

Printed electronics involve the integration of electronic components into printed materials, such as packaging or signage. The benefits of using printed electronics in commercial printing include:

- Cost-effectiveness compared to traditional electronic manufacturing processes

- Flexibility in design and customization

- Enhanced interactivity and functionality

- Integration of sensors, displays, and power sources

4. How does augmented reality (AR) printing enhance customer experiences?

AR printing combines printed materials with digital content to create interactive experiences for customers. By scanning a printed image or code with a smartphone or tablet, users can access additional information, videos, or 3D models. This technology enhances customer engagement, provides immersive product demonstrations, and enables virtual try-on experiences.

5. What is nanographic printing, and how does it improve commercial printing?

Nanographic printing is a digital printing technology that uses nanotechnology-based inks and a unique printing process. It offers several advantages, including:

- High print quality with sharp details and vibrant colors

- Fast production speeds, making it suitable for high-volume printing

- Compatibility with a wide range of substrates, including paper, plastic, and metal

- Reduced ink consumption and waste

6. How does variable data printing benefit marketing campaigns?

Variable data printing allows businesses to personalize marketing materials by incorporating unique information for each recipient. This technology enables targeted advertising, customized promotions, and personalized messages, which can significantly increase the effectiveness of marketing campaigns. By tailoring content to individual customers, businesses can improve customer engagement and response rates.

7. Are there any eco-friendly innovations in commercial printing?

Yes, the commercial printing industry is actively adopting eco-friendly innovations. Some of these include:

- Use of soy-based or vegetable-based inks instead of petroleum-based inks

- Recycling and responsible waste management practices

- Energy-efficient printing processes and equipment

- Transition to digital printing, reducing paper waste and chemical usage

8. How do advancements in commercial printing impact the packaging industry?

Advancements in commercial printing have had a significant impact on the packaging industry. With innovations like printed electronics and AR printing, packaging can now offer interactive features, track products in real-time, and provide personalized experiences. Additionally, improved printing technologies allow for more visually appealing and informative packaging designs, helping products stand out on store shelves.

9. How can businesses benefit from adopting these new printing technologies?

Businesses can benefit from adopting new printing technologies in several ways:

- Improved product customization and personalization

- Enhanced customer engagement and brand experiences

- Increased operational efficiency and faster production times

- Cost savings through reduced waste and optimized printing processes

- Competitive advantage in the market by leveraging innovative printing solutions

10. What can we expect from the future of commercial printing?

The future of commercial printing holds even more exciting possibilities. Some potential developments include:

- Advancements in 3D printing technology for larger-scale production

- Integration of artificial intelligence and machine learning for automated printing processes

- Further improvements in print quality and color accuracy

- Expanded use of sustainable materials and eco-friendly practices

- Continued convergence of digital and print media for multi-channel marketing campaigns

Common Misconceptions about

Misconception 1: Commercial printing is becoming obsolete in the digital age

With the rise of digital media and online advertising, there is a common misconception that commercial printing is becoming obsolete. However, this is far from the truth. In fact, the commercial printing industry has been evolving and embracing new technologies to stay relevant in the digital age.

One of the key innovations in commercial printing is the integration of digital printing technology. Digital printing allows for shorter print runs, faster turnaround times, and personalized printing options. This means that businesses can still leverage the power of print advertising while adapting to the demands of the digital world.

Furthermore, commercial printers are now offering a wide range of value-added services to complement their printing capabilities. These services include graphic design, data management, variable data printing, and cross-media marketing integration. By providing these additional services, commercial printers are able to offer a more comprehensive solution to their clients, helping them reach their target audience effectively.

Misconception 2: Commercial printing is harmful to the environment

Another common misconception about commercial printing is that it is harmful to the environment. While it is true that traditional printing methods have had a negative impact on the environment in the past, the industry has made significant strides in adopting sustainable practices.

One of the major innovations in commercial printing is the shift towards eco-friendly materials and processes. Many commercial printers now use soy-based inks, which are more environmentally friendly compared to traditional petroleum-based inks. Additionally, they are investing in energy-efficient printing equipment and implementing recycling programs to minimize waste.

Moreover, advancements in technology have led to the development of digital printing presses that produce less waste compared to traditional offset printing. Digital printing allows for on-demand printing, reducing the need for excessive inventory and minimizing paper waste. This not only benefits the environment but also helps businesses save costs by eliminating the need for large print runs.

Misconception 3: Commercial printing is a one-size-fits-all solution

Many people believe that commercial printing offers a one-size-fits-all solution, limiting creativity and customization. However, this is not the case in the current landscape of commercial printing.

One of the most exciting innovations in commercial printing is the ability to produce highly customized and personalized print materials. Variable data printing technology allows businesses to tailor their printed materials to individual recipients, incorporating personalized text, images, and even offers. This level of customization helps businesses create more targeted and effective marketing campaigns, increasing engagement and response rates.

Furthermore, commercial printers now offer a wide range of printing options, including different paper stocks, finishes, and embellishments. This allows businesses to create unique and eye-catching print materials that stand out from the competition. Whether it’s a luxury brochure with foil stamping or a die-cut invitation, commercial printing offers endless possibilities for creative expression.

As we can see, there are several common misconceptions about innovations in commercial printing in 2024. It is important to recognize that commercial printing is not becoming obsolete but rather adapting to the digital age with the integration of digital printing technology and value-added services. The industry is also making significant efforts to reduce its environmental impact through the use of eco-friendly materials and processes. Lastly, commercial printing is no longer a one-size-fits-all solution, with the ability to produce highly customized and personalized print materials. By debunking these misconceptions, we can appreciate the continued relevance and potential of commercial printing in the modern business landscape.

1. Personalized Marketing

Incorporate the latest innovations in commercial printing into your marketing strategies. Use variable data printing to create personalized materials that cater to individual preferences and interests. This can help you connect with your target audience on a deeper level and increase engagement.

2. Interactive Print

Explore the possibilities of interactive print. Incorporate augmented reality (AR) or QR codes into your printed materials to provide an immersive and engaging experience for your customers. This can be a powerful tool to drive customer interaction and enhance brand awareness.

3. Sustainable Printing

Consider the environmental impact of your printing practices. Opt for eco-friendly materials and processes, such as using recycled paper and vegetable-based inks. By adopting sustainable printing practices, you can reduce your carbon footprint and appeal to environmentally conscious consumers.

4. 3D Printing

Embrace the world of 3D printing. Explore how this technology can be integrated into your business operations. Whether it’s creating prototypes, customized products, or even architectural models, 3D printing can offer you new opportunities for innovation and efficiency.

5. Print-on-Demand

Take advantage of print-on-demand services. Instead of producing large quantities of printed materials in advance, consider printing on demand to reduce waste and storage costs. This approach allows you to have more flexibility and control over your inventory.

6. Variable Packaging

Think beyond traditional packaging. With variable packaging, you can create unique and personalized packaging designs for each product. This can help you stand out on the shelves and create a memorable unboxing experience for your customers.

7. Smart Labels

Explore the use of smart labels in your product packaging. These labels can provide additional information, such as expiration dates, nutritional facts, or even interactive elements. This can enhance the user experience and provide valuable insights to your customers.

8. Print-to-Mobile Integration

Bridge the gap between print and digital by integrating print materials with mobile technology. Incorporate QR codes or NFC tags that lead customers to your website, social media profiles, or special promotions. This can help you drive traffic and conversions in the digital realm.

9. Variable Signage

Consider using variable signage to capture attention and deliver personalized messages. With digital printing, you can easily change the content of your signs based on factors like time of day, location, or customer demographics. This dynamic approach can make your signage more relevant and impactful.

10. Collaborate with Print Experts

Engage with professionals in the commercial printing industry to stay updated on the latest trends and technologies. Building relationships with print experts can help you understand the possibilities and limitations of the innovations discussed in ‘Innovations in Commercial Printing: What’s New in 2024’. They can provide valuable insights and guidance to help you implement these innovations effectively.

By incorporating these practical tips and advice into your daily life, you can leverage the knowledge from ‘Innovations in Commercial Printing: What’s New in 2024’ to enhance your marketing strategies, reduce environmental impact, embrace new technologies, and create memorable experiences for your customers. Stay curious, explore the possibilities, and collaborate with experts to make the most of these innovations in your business.

In conclusion, the commercial printing industry has witnessed significant advancements in 2024, revolutionizing the way businesses approach printing and marketing. The of digital printing technologies has allowed for faster turnaround times, improved print quality, and enhanced customization options. This has enabled businesses to create personalized and targeted marketing materials that resonate with their target audience, leading to higher engagement and conversion rates. Additionally, the integration of artificial intelligence and automation has streamlined the printing process, reducing costs and increasing efficiency.

Furthermore, the emergence of sustainable printing practices has been a key focus in 2024. With increasing environmental concerns, commercial printers have adopted eco-friendly materials and processes, such as soy-based inks and recycled paper, to minimize their carbon footprint. This shift towards sustainability not only aligns with consumer preferences but also helps businesses enhance their brand image as socially responsible entities.

Looking ahead, the future of commercial printing seems promising, with continued advancements in technology and a growing emphasis on sustainability. As businesses strive to stand out in a crowded marketplace, innovative printing solutions will play a crucial role in helping them capture the attention of their target audience and drive business growth. By embracing these new technologies and practices, businesses can stay ahead of the curve and leverage the power of print to achieve their marketing goals in the ever-evolving digital landscape.