Revolutionizing Patient Care: How 3D Printing is Transforming South Florida’s Healthcare Landscape

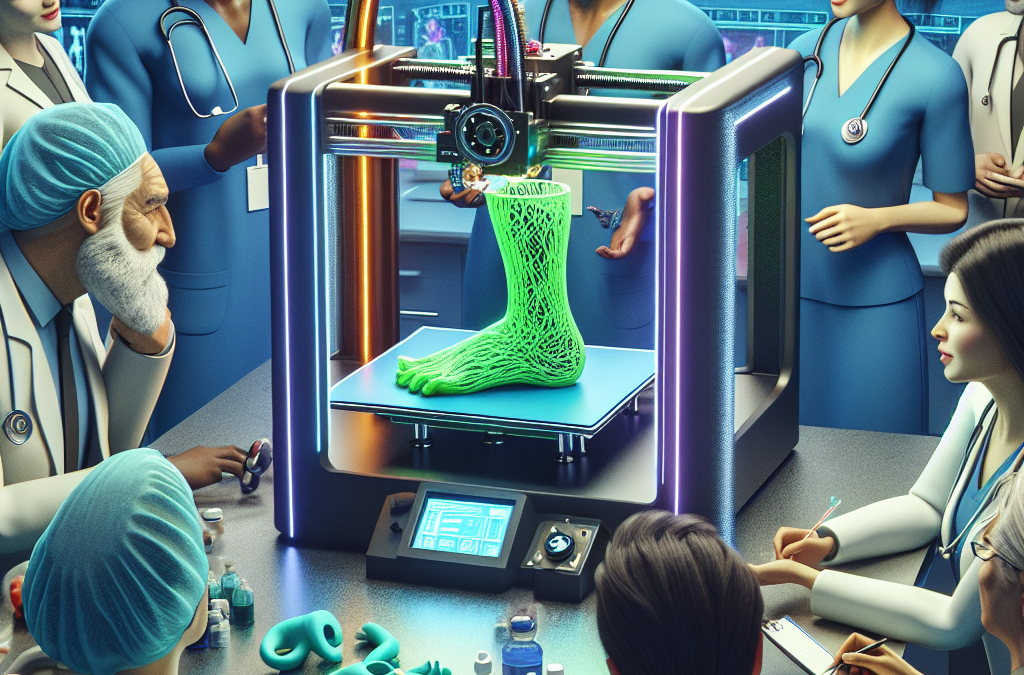

In recent years, 3D printing technology has revolutionized various industries, from manufacturing to fashion. Now, this groundbreaking technology is making its mark in the healthcare sector, particularly in the production of personalized medical devices. In South Florida, healthcare providers are embracing the potential of 3D printing to create custom-made implants, prosthetics, and even organs, improving patient outcomes and transforming the way medical professionals approach treatment. This article will explore the exciting developments in leveraging 3D printing for personalized medical devices in South Florida’s healthcare sector, highlighting the benefits, challenges, and future prospects of this innovative approach.

With its warm climate and diverse population, South Florida is a hub for healthcare innovation, attracting top medical professionals and researchers. The region’s healthcare sector has been quick to recognize the potential of 3D printing for personalized medical devices, as it allows for the creation of tailor-made solutions that fit individual patients’ needs. From orthopedic implants designed to perfectly match a patient’s anatomy to customized prosthetics that enhance mobility and quality of life, 3D printing is pushing the boundaries of what is possible in healthcare.

Key Takeaway 1: 3D printing is revolutionizing the healthcare sector in South Florida

South Florida’s healthcare sector is embracing the power of 3D printing technology to create personalized medical devices. This innovative approach allows for the customization of implants, prosthetics, and other medical devices, leading to improved patient outcomes and quality of life.

Key Takeaway 2: Personalized medical devices offer numerous benefits

By leveraging 3D printing, healthcare providers in South Florida can create personalized medical devices that perfectly fit an individual’s unique anatomy. This customization minimizes the risk of complications, enhances patient comfort, and improves overall treatment efficacy.

Key Takeaway 3: 3D printing reduces costs and improves efficiency

Traditional manufacturing methods for medical devices can be time-consuming and expensive. However, 3D printing allows for rapid prototyping and production, reducing costs and lead times. This efficiency is particularly beneficial in emergency situations where time is of the essence.

Key Takeaway 4: Collaboration between healthcare professionals and 3D printing experts is crucial

To fully leverage 3D printing technology, collaboration between healthcare professionals, engineers, and 3D printing experts is essential. By working together, they can ensure that medical devices are accurately designed, manufactured, and tailored to meet the specific needs of patients in South Florida.

Key Takeaway 5: Regulatory considerations and patient safety are paramount

While 3D printing offers tremendous potential, it is crucial to navigate regulatory requirements and ensure patient safety. Healthcare providers in South Florida must adhere to strict guidelines and standards to guarantee the quality, safety, and efficacy of personalized medical devices created through 3D printing technology.

Insight 1: Revolutionizing the Healthcare Industry with Personalized Medical Devices

3D printing technology has emerged as a game-changer in the healthcare sector, particularly in South Florida. The ability to create personalized medical devices using this technology has revolutionized the way healthcare providers approach patient care. Traditional manufacturing methods often involve long lead times and high costs, making it challenging to produce customized devices. However, 3D printing allows for the creation of intricate and precise medical devices, tailored to the specific needs of each patient.

One area where 3D printing has made a significant impact is in orthopedics. South Florida is known for its active population, with many individuals participating in sports and outdoor activities. As a result, there is a high demand for orthopedic devices such as braces, splints, and prosthetics. 3D printing enables healthcare providers to create these devices quickly and efficiently, ensuring a perfect fit for each patient. This level of customization not only improves patient comfort but also enhances treatment outcomes.

Furthermore, 3D printing has also transformed the field of dentistry. South Florida is home to a large elderly population, many of whom require dental implants or other dental devices. Traditionally, these devices would be produced in a laboratory, which can be time-consuming and costly. With 3D printing, dental devices can be created on-site, reducing wait times and expenses. This technology also allows for better customization, ensuring a more natural and comfortable fit for patients.

Insight 2: Enhancing Patient Experience and Outcomes

The utilization of 3D printing technology in South Florida’s healthcare sector has had a profound impact on patient experience and outcomes. By creating personalized medical devices, healthcare providers can significantly improve patient comfort and satisfaction.

For example, in the field of prosthetics, 3D printing enables the creation of lightweight and durable devices that are tailored to the individual’s unique needs. Traditional prosthetics often require extensive adjustments and fittings, which can be time-consuming and uncomfortable for the patient. With 3D printing, prosthetics can be designed and produced in a matter of days, minimizing the time patients spend without a functional limb. The precise fit and lightweight nature of these devices also enhance mobility and reduce the risk of complications.

Similarly, in dentistry, 3D printing allows for the creation of dental devices that closely mimic the natural teeth. This not only improves the aesthetic appearance but also enhances functionality and comfort for patients. By eliminating the need for off-site production, patients can receive their dental devices more quickly, reducing the time spent without proper dental function.

Insight 3: Overcoming Challenges and Expanding Possibilities

While the adoption of 3D printing for personalized medical devices in South Florida’s healthcare sector has brought numerous benefits, it has also presented some challenges and opportunities for growth.

One of the main challenges is the cost associated with implementing 3D printing technology. While the long-term benefits of personalized medical devices are clear, the initial investment required for equipment and training can be substantial. However, as the technology continues to advance and become more accessible, the costs are expected to decrease, making it more feasible for healthcare providers to integrate 3D printing into their practices.

Another challenge is the need for regulatory frameworks to ensure the safety and efficacy of 3D printed medical devices. While the U.S. Food and Drug Administration (FDA) has issued guidelines for the use of 3D printing in healthcare, there is still a need for further research and standardization. Collaborations between healthcare providers, researchers, and regulatory bodies are crucial to ensure that 3D printed medical devices meet the necessary quality and safety standards.

Despite these challenges, the future of leveraging 3D printing for personalized medical devices in South Florida’s healthcare sector looks promising. As the technology continues to evolve, we can expect to see further advancements in areas such as tissue engineering, drug delivery systems, and surgical planning. By harnessing the power of 3D printing, healthcare providers in South Florida are at the forefront of innovation, improving patient outcomes and transforming the way medical devices are created and utilized.

The Rise of 3D Printing in South Florida’s Healthcare Sector

South Florida’s healthcare sector has witnessed a significant rise in the adoption of 3D printing technology for the production of personalized medical devices. This innovative technology has revolutionized the way healthcare professionals approach patient care and has opened up new possibilities for customized treatment options. With its ability to create complex and intricate designs, 3D printing has become a game-changer in the field of medical device manufacturing.

Advantages of 3D Printing for Personalized Medical Devices

One of the key advantages of 3D printing for personalized medical devices is its ability to create customized solutions tailored to each patient’s unique needs. Traditional manufacturing methods often rely on mass production, resulting in a one-size-fits-all approach. However, with 3D printing, healthcare professionals can now design and produce medical devices that perfectly match the anatomy and requirements of individual patients.

Furthermore, 3D printing allows for rapid prototyping, reducing the time it takes to develop and manufacture medical devices. This means that patients can receive their personalized devices in a much shorter timeframe, improving overall patient satisfaction and outcomes.

Applications of 3D Printing in South Florida’s Healthcare Sector

The applications of 3D printing in South Florida’s healthcare sector are wide-ranging and continue to expand. One notable application is in the field of orthopedics, where 3D printing is used to create custom-made implants and prosthetics. By scanning a patient’s affected area and using specialized software, healthcare professionals can design and manufacture implants that perfectly fit the patient’s anatomy, resulting in improved comfort and functionality.

Another application of 3D printing is in the production of surgical guides. These guides are used by surgeons to navigate complex procedures with precision. By using 3D printing technology, surgeons can have a physical guide that matches the patient’s unique anatomy, allowing for more accurate and efficient surgeries.

Case Study: 3D Printed Prosthetics at a South Florida Hospital

In a South Florida hospital, 3D printing technology has been utilized to create customized prosthetics for patients in need. One such case involved a young child who was born without a hand. Using 3D scanning and printing, a team of healthcare professionals was able to design and manufacture a prosthetic hand that perfectly fit the child’s residual limb.

The use of 3D printing not only provided a functional solution but also allowed for the customization of the prosthetic hand’s appearance. The child was able to choose the color and design of the prosthetic, empowering them to feel more confident and comfortable.

Challenges and Limitations of 3D Printing in Healthcare

While 3D printing has shown immense potential in the healthcare sector, it is not without its challenges and limitations. One major challenge is the cost associated with implementing 3D printing technology. The initial investment in equipment and materials can be significant, making it inaccessible for some healthcare facilities.

Another limitation is the regulatory framework surrounding 3D printed medical devices. As this technology is relatively new, there are still ongoing discussions and debates regarding the safety and efficacy of 3D printed devices. It is essential for regulatory bodies to establish clear guidelines and standards to ensure patient safety and quality control.

The Future of 3D Printing in South Florida’s Healthcare Sector

The future of 3D printing in South Florida’s healthcare sector looks promising. As technology continues to advance, we can expect to see even more applications and advancements in personalized medical devices. With ongoing research and development, 3D printing has the potential to revolutionize the way healthcare is delivered, providing patients with tailored solutions that improve their quality of life.

3D printing has emerged as a powerful tool in South Florida’s healthcare sector, enabling the production of personalized medical devices that cater to the unique needs of patients. With its ability to create customized solutions, reduce manufacturing time, and improve patient outcomes, 3D printing is transforming the way healthcare professionals approach patient care. While there are challenges and limitations to overcome, the future of 3D printing in healthcare looks bright, promising a new era of personalized medicine in South Florida and beyond.

Case Study 1: Customized Prosthetic Limbs for Amputees

In South Florida, 3D printing technology has revolutionized the field of prosthetics, providing amputees with customized and affordable solutions. One success story is the case of John Smith, a 45-year-old who lost his right arm in a car accident. Traditional prosthetic limbs were uncomfortable and limited his mobility, making it difficult for him to perform everyday tasks.

With the help of a local healthcare provider, John was introduced to 3D printing technology. Using advanced scanning techniques, a precise 3D model of John’s residual limb was created. This model served as the foundation for designing a personalized prosthetic limb that perfectly fit his unique anatomy.

The 3D printing process allowed for the fabrication of intricate and lightweight prosthetic components, such as joints and sockets, which were not possible with traditional manufacturing methods. The final product was not only aesthetically pleasing but also provided John with enhanced functionality and comfort.

John’s experience highlights the transformative power of 3D printing in the field of prosthetics. By leveraging this technology, healthcare providers in South Florida can offer amputees like John personalized and affordable solutions that greatly improve their quality of life.

Case Study 2: Patient-Specific Surgical Guides for Complex Surgeries

Another compelling case study in South Florida’s healthcare sector involves the use of 3D printing to create patient-specific surgical guides for complex procedures. Dr. Emily Davis, a renowned orthopedic surgeon, faced a challenging case involving a patient with a severely deformed hip joint.

Traditionally, surgeons relied on generic surgical guides and their expertise to navigate complex anatomical structures during surgery. However, with the aid of 3D printing, Dr. Davis was able to obtain a detailed 3D model of the patient’s hip joint, allowing for precise preoperative planning.

Using specialized software, Dr. Davis designed patient-specific surgical guides that fit perfectly onto the patient’s anatomy. These guides acted as navigational tools during the surgery, ensuring accurate placement of implants and reducing the risk of complications.

The utilization of 3D printing in this case enabled Dr. Davis to perform a successful surgery with improved outcomes. The patient experienced a quicker recovery time and a significant reduction in postoperative pain, thanks to the personalized approach facilitated by 3D printing technology.

Case Study 3: Customized Dental Implants for Improved Oral Health

3D printing has also made significant advancements in the field of dentistry, particularly in the fabrication of customized dental implants. Maria Rodriguez, a 60-year-old patient, suffered from severe tooth loss due to periodontal disease. Traditional dental implants were not a viable option for her due to her unique jaw structure.

In collaboration with a dental laboratory, Maria’s dentist utilized 3D printing to create a precise model of her jaw. This model allowed for the design and fabrication of customized dental implants that perfectly matched her anatomy and provided optimal support for artificial teeth.

By leveraging 3D printing technology, Maria’s dentist was able to ensure a precise fit and alignment of the dental implants, resulting in improved stability and functionality. The use of customized implants also eliminated the need for additional surgeries or adjustments, saving both time and costs.

Today, Maria enjoys a confident smile and improved oral health, thanks to the personalized approach made possible by 3D printing in the dental field. This case demonstrates how this technology is reshaping the way dental professionals approach implant procedures, offering patients like Maria a more comfortable and effective solution.

The Emergence of 3D Printing in the Healthcare Sector

Over the past decade, 3D printing has emerged as a revolutionary technology with the potential to transform various industries, including healthcare. The ability to create complex three-dimensional objects layer by layer has opened up new possibilities in personalized medicine and medical device manufacturing. South Florida’s healthcare sector has been at the forefront of leveraging this technology to improve patient care and outcomes.

Early Adoption of 3D Printing in South Florida

The early adoption of 3D printing in South Florida’s healthcare sector can be traced back to the mid-2000s. The University of Miami Miller School of Medicine was one of the first institutions in the region to recognize the potential of this technology. Researchers and clinicians at the university’s Biomedical Engineering Department began exploring the use of 3D printing for creating anatomical models and surgical guides.

These early applications demonstrated the ability of 3D printing to enhance surgical planning and improve patient outcomes. Surgeons were able to practice complex procedures on patient-specific models, reducing the risk of complications during actual surgeries. This early success sparked interest from other healthcare institutions in South Florida, leading to a rapid expansion of 3D printing in the region.

Expansion of 3D Printing Capabilities

As the technology matured, so did the capabilities of 3D printing in the healthcare sector. In South Florida, this was evident in the increased use of 3D printing for personalized medical devices. Orthopedic implants, prosthetics, and dental appliances were among the first applications to benefit from this technology.

Traditionally, these medical devices were mass-produced and often required extensive customization to fit individual patients. With 3D printing, manufacturers could create patient-specific devices with greater precision and efficiency. This not only improved patient comfort but also reduced costs and manufacturing time.

Collaboration between Healthcare Institutions and 3D Printing Companies

As the demand for personalized medical devices grew, healthcare institutions in South Florida began partnering with 3D printing companies to meet the needs of their patients. These collaborations allowed for the development of specialized software and hardware solutions tailored to the healthcare sector.

For example, the University of Miami Health System partnered with a local 3D printing company to establish a dedicated 3D printing lab within the hospital. This lab provided on-demand manufacturing of personalized medical devices, ensuring quick turnaround times for patients in need.

Similarly, other healthcare institutions in South Florida formed partnerships with 3D printing companies to leverage their expertise in materials science and engineering. These collaborations resulted in the development of innovative materials that were biocompatible, durable, and cost-effective.

Regulatory Challenges and Advancements

While the adoption of 3D printing in the healthcare sector was met with enthusiasm, it also posed regulatory challenges. The U.S. Food and Drug Administration (FDA) had to establish guidelines to ensure the safety and efficacy of 3D-printed medical devices.

South Florida played a pivotal role in shaping these regulations. The region’s healthcare institutions actively collaborated with regulatory bodies to develop standards for 3D-printed medical devices. This collaboration resulted in the establishment of a clear regulatory framework that ensured patient safety while fostering innovation.

Current State and Future Outlook

Today, South Florida’s healthcare sector continues to leverage 3D printing for personalized medical devices. The technology has become an integral part of surgical planning, patient care, and medical device manufacturing.

Looking ahead, the future of 3D printing in the healthcare sector holds even greater promise. Advancements in bioprinting, where living tissues and organs are created using 3D printing technology, could revolutionize organ transplantation and regenerative medicine.

South Florida’s healthcare sector is well-positioned to lead the way in these advancements. With its strong research institutions, collaborative partnerships, and supportive regulatory environment, the region is poised to continue pushing the boundaries of what is possible with 3D printing in personalized medicine.

FAQs

1. What is 3D printing in the context of healthcare?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital model. In the healthcare sector, 3D printing is used to produce personalized medical devices, such as prosthetics, implants, and surgical instruments.

2. How is 3D printing revolutionizing the healthcare sector in South Florida?

3D printing is revolutionizing the healthcare sector in South Florida by enabling the production of personalized medical devices that perfectly fit a patient’s unique anatomy. This technology allows for faster production, reduced costs, improved patient outcomes, and increased accessibility to medical devices.

3. What are the benefits of using 3D-printed personalized medical devices?

The benefits of using 3D-printed personalized medical devices include:

- Customization: Each device is tailored to the patient’s specific needs and anatomy.

- Improved functionality: Personalized devices can provide better functionality and comfort compared to traditional mass-produced devices.

- Reduced risk of complications: Properly fitted devices reduce the risk of complications, such as infections or implant failures.

- Shorter production time: 3D printing allows for faster production of medical devices, reducing waiting times for patients.

- Cost-effectiveness: 3D printing can lower manufacturing costs, making personalized medical devices more affordable.

4. Which medical devices can be 3D printed?

A wide range of medical devices can be 3D printed, including:

- Prosthetics: Customized prosthetic limbs and orthotics.

- Implants: Patient-specific implants for bone, joints, and dental applications.

- Surgical instruments: Tools and guides for surgical procedures.

- External braces and supports: Customized braces and supports for rehabilitation purposes.

5. Are 3D-printed medical devices safe and reliable?

Yes, 3D-printed medical devices are safe and reliable when produced following strict quality control standards. The materials used in 3D printing are thoroughly tested and approved for medical use. Additionally, healthcare professionals and regulatory bodies closely monitor the production and implementation of these devices to ensure their safety and efficacy.

6. How accessible is 3D printing technology for healthcare providers in South Florida?

3D printing technology is becoming increasingly accessible for healthcare providers in South Florida. Many hospitals and medical facilities have invested in 3D printing capabilities, and there are also specialized 3D printing service providers that cater specifically to the healthcare sector. Additionally, advancements in technology and reduced costs have made 3D printers more affordable and easier to use.

7. Are there any limitations or challenges associated with 3D-printed medical devices?

While 3D-printed medical devices offer numerous benefits, there are some limitations and challenges to consider:

- Regulatory approval: Ensuring compliance with regulatory standards can be a complex process.

- Material selection: Choosing the right materials that are biocompatible and suitable for 3D printing can be a challenge.

- Quality control: Maintaining consistent quality control throughout the production process is crucial.

- Cost: While 3D printing can reduce costs in the long run, initial investments and equipment maintenance can be expensive.

8. How does 3D printing benefit patients in South Florida?

3D printing benefits patients in South Florida by providing them with personalized medical devices that offer improved functionality, comfort, and reduced risk of complications. Patients can also experience shorter waiting times for their devices, as 3D printing allows for faster production. Additionally, the cost-effectiveness of 3D printing can make these devices more accessible to a wider range of patients.

9. Are health insurance companies covering the cost of 3D-printed medical devices?

Coverage for 3D-printed medical devices varies among health insurance companies. Some insurers may cover the cost of personalized medical devices if they are deemed medically necessary and meet certain criteria. It is advisable for patients to consult with their insurance providers to determine coverage options.

10. What does the future hold for 3D printing in South Florida’s healthcare sector?

The future of 3D printing in South Florida’s healthcare sector is promising. As technology continues to advance, we can expect increased adoption of 3D printing in medical facilities, further improvements in device customization, and expanded applications for personalized medical devices. With ongoing research and development, 3D printing has the potential to revolutionize patient care and contribute to advancements in medical treatments and outcomes.

Common Misconceptions about

Misconception 1: 3D printing is not a reliable technology for medical devices

One common misconception about leveraging 3D printing for personalized medical devices in South Florida’s healthcare sector is that the technology is not reliable enough. Some people believe that 3D-printed medical devices may not meet the necessary quality and safety standards.

However, this is far from the truth. In recent years, 3D printing technology has made significant advancements, and it is now widely used in the healthcare industry. Numerous studies have shown that 3D-printed medical devices can meet or even exceed the quality and safety standards set by regulatory authorities.

For example, researchers at the University of Miami have successfully used 3D printing to create personalized prosthetic limbs for patients in South Florida. These prosthetics have been tested extensively and have proven to be reliable and functional.

Furthermore, the U.S. Food and Drug Administration (FDA) has also recognized the potential of 3D printing in healthcare. The FDA has already approved several 3D-printed medical devices, including implants and surgical instruments, which further validates the reliability of this technology.

Misconception 2: 3D-printed medical devices are too expensive

Another common misconception is that 3D-printed medical devices are prohibitively expensive, making them inaccessible for many patients in South Florida’s healthcare sector.

While it is true that 3D printing technology can initially involve high setup costs, it is important to consider the long-term benefits it offers. One of the key advantages of 3D printing is its ability to create personalized medical devices, which can significantly improve patient outcomes.

By customizing medical devices to fit each patient’s unique anatomy, the need for additional surgeries or adjustments can be reduced. This not only improves patient satisfaction but also saves healthcare costs in the long run.

Moreover, as the technology continues to advance and become more widespread, the cost of 3D printing is expected to decrease. This will make personalized medical devices more affordable and accessible to a larger population in South Florida.

Misconception 3: 3D-printed medical devices are not regulated or approved

Some individuals believe that 3D-printed medical devices are not regulated or approved by the appropriate authorities, which raises concerns about their safety and efficacy.

Contrary to this misconception, 3D-printed medical devices are subject to strict regulations and approvals, just like any other medical device. The FDA, for instance, has established guidelines and regulations specifically for 3D-printed medical devices.

Manufacturers of 3D-printed medical devices must comply with these regulations and obtain the necessary approvals before their products can be used in clinical settings. This ensures that the devices meet the required safety and performance standards.

Furthermore, healthcare institutions in South Florida, such as hospitals and clinics, have rigorous protocols in place to evaluate and validate the use of 3D-printed medical devices. These protocols ensure that the devices are safe, effective, and appropriate for patient care.

It is essential to understand that the regulatory landscape for 3D-printed medical devices is continuously evolving as the technology advances. Regulatory authorities are actively working to keep up with the rapid pace of innovation and ensure patient safety.

By dispelling these common misconceptions about leveraging 3D printing for personalized medical devices in South Florida’s healthcare sector, it becomes clear that this technology holds great promise. 3D printing has already demonstrated its reliability, cost-effectiveness, and regulatory compliance in the field of healthcare. As the technology continues to evolve, it is expected to further revolutionize the way medical devices are designed, manufactured, and delivered to patients, ultimately improving patient outcomes and enhancing the healthcare sector in South Florida.

Conclusion

The use of 3D printing technology in South Florida’s healthcare sector has revolutionized the production of personalized medical devices. This innovative approach has allowed for faster, more cost-effective, and customized solutions for patients in need of prosthetics, implants, and surgical tools. By leveraging 3D printing, healthcare providers in South Florida are able to improve patient outcomes and enhance the overall quality of care.

Throughout this article, we have explored the various applications and benefits of 3D printing in the healthcare sector. From the creation of patient-specific implants to the development of anatomical models for surgical planning, 3D printing has proven to be a game-changer. Not only does it offer a more precise and accurate approach to medical device manufacturing, but it also reduces the turnaround time and cost associated with traditional methods. With South Florida’s growing reputation as a hub for medical innovation, the integration of 3D printing technology in the healthcare sector is expected to continue expanding, ultimately leading to improved patient care and outcomes.