The Hidden Treasure Trove: Unveiling the Complexities of Copier Recycling and Unearthing Precious Metals

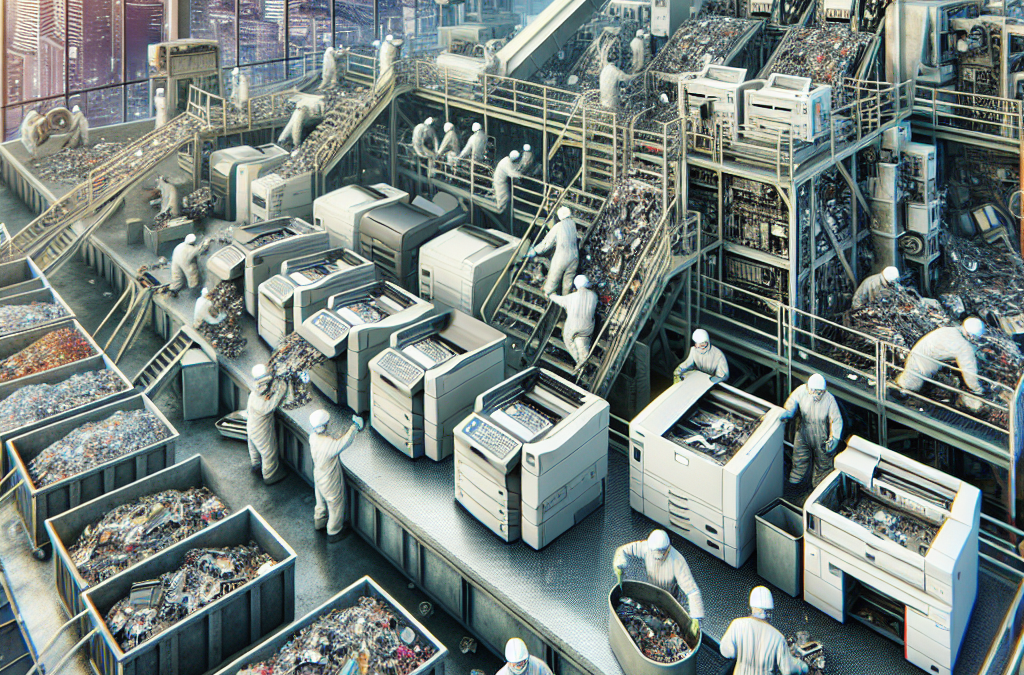

As technology continues to advance at a rapid pace, the lifespan of electronic devices becomes shorter and shorter. This leads to a growing problem of electronic waste, with copiers being one of the major contributors. While recycling these copiers seems like a straightforward solution, the process is not as simple as it seems. In fact, copier recycling poses unique challenges, particularly when it comes to recovering precious metals. In this article, we will delve into the complexities of copier recycling and explore the world of urban mining for precious metal recovery.

Copiers are an essential tool in offices and businesses around the world, but what happens to them when they reach the end of their life cycle? Many end up in landfills, contributing to environmental pollution and wasting valuable resources. Recycling copiers can help mitigate these issues, but it is not without its challenges. One of the primary obstacles in copier recycling is the recovery of precious metals, such as gold, silver, and platinum, which are used in various components of the machines. These metals are not only valuable but also environmentally harmful if not properly disposed of. Urban mining, the process of extracting valuable metals from electronic waste, offers a potential solution, but it comes with its own set of hurdles. In this article, we will explore the complexities of copier recycling and urban mining, discussing the challenges and potential solutions for recovering precious metals and reducing electronic waste.

Key Takeaways:

1. The copier recycling industry faces unique challenges in recovering precious metals due to the complex nature of copier components and the lack of standardized recycling processes.

2. Urban mining, the process of extracting valuable metals from electronic waste, offers a promising solution for copier recycling, as it allows for the recovery of precious metals from discarded copiers.

3. The proper disposal and recycling of copiers is crucial to prevent environmental pollution and reduce the demand for virgin materials, as copiers contain valuable metals such as gold, silver, and platinum.

4. To navigate the challenges of copier recycling and urban mining, collaboration among stakeholders, including manufacturers, recyclers, and government agencies, is essential to develop efficient and sustainable recycling practices.

5. Investing in research and development is crucial to finding innovative solutions for copier recycling, including the development of new technologies and processes that can maximize precious metal recovery and minimize environmental impact.

The Growing Importance of Copier Recycling and Urban Mining in the Precious Metal Recovery Industry

As the demand for electronic devices continues to rise, so does the need for proper disposal and recycling of these products. Copiers, in particular, present a unique challenge due to their complex composition and the presence of valuable precious metals. Navigating the challenges of copier recycling and urban mining for precious metal recovery has become increasingly crucial in the industry. Here, we explore three key insights into this growing trend.

1. The Environmental Impact of Improper Copier Disposal

Improper disposal of copiers can have severe environmental consequences. These machines contain various hazardous materials, including lead, mercury, and cadmium, which can leach into the soil and water if not handled correctly. Additionally, copiers often contain valuable precious metals such as gold, silver, and palladium, which are finite resources. When copiers end up in landfills or are incinerated, these precious metals are lost forever, contributing to resource depletion and environmental degradation.

By focusing on copier recycling and urban mining for precious metal recovery, the industry can mitigate these environmental impacts. Proper recycling processes ensure the safe extraction and reuse of valuable materials while minimizing the release of harmful substances into the environment. This approach not only reduces the need for new mining activities but also helps conserve natural resources and reduce carbon emissions associated with mining and refining processes.

2. The Economic Potential of Precious Metal Recovery from Copiers

While the environmental benefits of copier recycling and urban mining are evident, there is also a significant economic potential in recovering precious metals from these devices. Copiers contain a considerable amount of valuable materials, including gold, silver, platinum, and palladium, which can be extracted and sold to refineries for reuse in various industries.

The global demand for precious metals continues to grow, driven by industries such as electronics, jewelry, and automotive. By adopting efficient recycling practices, companies involved in copier recycling and urban mining can tap into this market and create new revenue streams. Additionally, recycling copiers for precious metal recovery reduces the need for costly and environmentally damaging mining operations, providing a more sustainable and economically viable alternative.

3. Technological Innovations and Challenges in Copier Recycling

Navigating the challenges of copier recycling and urban mining requires technological innovations to ensure efficient and effective processes. Copiers are complex devices with intricate components, making their dismantling and separation a labor-intensive and time-consuming task. Additionally, the presence of hazardous materials necessitates specialized equipment and expertise to handle them safely.

Fortunately, advancements in recycling technologies have made copier recycling more feasible and economically viable. Automated systems, such as robotic disassembly and material separation, have been developed to streamline the recycling process and improve efficiency. These technologies enable the extraction of valuable precious metals with minimal human intervention, reducing costs and increasing overall productivity.

However, challenges still exist in scaling up these technologies and making them accessible to smaller recycling facilities. The high initial investment required for advanced recycling equipment and the need for skilled labor pose barriers to widespread adoption. Overcoming these challenges will be crucial in expanding the capacity for copier recycling and urban mining, ensuring the sustainable recovery of precious metals from these devices.

The challenges of copier recycling and urban mining for precious metal recovery have significant implications for the industry. By addressing the environmental impact of improper disposal, harnessing the economic potential of precious metal recovery, and embracing technological innovations, the industry can navigate these challenges and contribute to a more sustainable and resource-efficient future.

The Importance of Copier Recycling

Copiers are essential office equipment that play a crucial role in day-to-day operations. However, as technology advances and copiers become outdated, the need for proper recycling and disposal becomes increasingly important. Copier recycling helps to mitigate the environmental impact of electronic waste and also offers an opportunity for precious metal recovery. Many copiers contain valuable metals such as gold, silver, and palladium, which can be extracted and reused. In this section, we will explore the importance of copier recycling and the potential benefits it offers.

The Challenges of Copier Recycling

While copier recycling presents numerous benefits, it also comes with its fair share of challenges. One of the primary challenges is the complexity of copier disassembly. Copiers consist of various components, including plastics, circuit boards, and metals, which require careful separation and processing. Additionally, copiers often contain hazardous materials such as lead and mercury, which need to be handled and disposed of properly to prevent environmental contamination. In this section, we will delve into the challenges associated with copier recycling and the strategies employed to overcome them.

Urban Mining: A New Frontier for Precious Metal Recovery

Urban mining, also known as electronic waste recycling, has emerged as a promising solution for precious metal recovery. With the increasing demand for precious metals and the limited availability of natural resources, urban mining provides an alternative source of these valuable materials. Copiers, along with other electronic devices, are rich in precious metals, making them attractive targets for urban mining operations. In this section, we will explore the concept of urban mining and its potential to revolutionize precious metal recovery.

Techniques and Technologies for Precious Metal Recovery

Precious metal recovery from copiers involves a combination of techniques and technologies. These include mechanical processes such as shredding and sorting, as well as chemical processes like leaching and smelting. Each method has its advantages and limitations, and the choice of technique depends on factors such as the composition of the copier and the desired metal recovery rate. In this section, we will discuss the various techniques and technologies used in precious metal recovery from copiers, highlighting their effectiveness and sustainability.

Case Study: Successful Copier Recycling Program

To illustrate the real-world application of copier recycling and precious metal recovery, we will examine a case study of a successful copier recycling program. This case study will delve into the strategies and initiatives implemented by a company or organization to efficiently recycle copiers and recover precious metals. It will highlight the environmental and economic benefits achieved through their recycling efforts and provide insights and lessons learned for other businesses or entities interested in implementing similar programs.

The Role of Legislation and Regulation

Legislation and regulation play a crucial role in promoting copier recycling and ensuring the proper management of electronic waste. Governments around the world have implemented various laws and regulations to encourage responsible recycling practices and discourage improper disposal of copiers. These regulations cover aspects such as the handling of hazardous materials, the establishment of recycling standards, and the enforcement of penalties for non-compliance. In this section, we will explore the role of legislation and regulation in promoting copier recycling and discuss their impact on the industry.

The Future of Copier Recycling and Precious Metal Recovery

The field of copier recycling and precious metal recovery is constantly evolving, driven by advancements in technology and increasing environmental awareness. In this section, we will explore the future prospects of copier recycling, including emerging technologies, innovative approaches, and potential collaborations. We will also discuss the role of stakeholders, such as manufacturers, recyclers, and consumers, in shaping the future of copier recycling and precious metal recovery.

Economic and Environmental Benefits of Copier Recycling

Beyond the recovery of precious metals, copier recycling offers significant economic and environmental benefits. Recycling copiers reduces the need for raw materials, conserves energy, and minimizes greenhouse gas emissions associated with the production of new devices. Additionally, it creates job opportunities in the recycling industry and contributes to the circular economy. In this section, we will explore the economic and environmental benefits of copier recycling, emphasizing its positive impact on both the business sector and the planet.

Collaboration and Partnerships in Copier Recycling

Effective copier recycling requires collaboration and partnerships among various stakeholders. Manufacturers, recyclers, government agencies, and consumers all have a role to play in ensuring the success of recycling initiatives. Collaboration can involve sharing best practices, establishing collection programs, and developing innovative recycling technologies. In this section, we will discuss the importance of collaboration and partnerships in copier recycling and highlight successful examples of industry-wide cooperation.

Copier recycling and urban mining for precious metal recovery present both challenges and opportunities. Proper recycling of copiers not only helps to mitigate the environmental impact of electronic waste but also offers a valuable source of precious metals. By addressing the challenges associated with copier recycling, embracing urban mining, and fostering collaboration among stakeholders, we can navigate the complexities of copier recycling and contribute to a more sustainable and resource-efficient future.

The Origins of Copier Recycling

The practice of recycling copiers and recovering precious metals from them has its roots in the early days of the copier industry. In the 1960s, copiers became increasingly popular in offices and businesses, leading to a growing concern about the environmental impact of disposing of these machines. At the time, copiers contained significant amounts of valuable metals, including gold, silver, and platinum, making them attractive targets for recycling.

However, in the early years, copier recycling was not a well-established industry. There were limited options for recycling and recovering precious metals, and most copiers ended up in landfills, contributing to environmental pollution. The lack of awareness and regulations surrounding electronic waste management meant that copier recycling was largely overlooked.

The Rise of Urban Mining

Urban mining, the process of extracting valuable metals from electronic waste, gained traction in the late 1990s and early 2000s. As the demand for electronic devices increased, so did the need for precious metals used in their production. This led to a shift in focus towards recycling and recovering valuable metals from discarded electronics, including copiers.

Urban mining presented an opportunity to reduce the reliance on traditional mining methods, which are often environmentally destructive. By extracting metals from electronic waste, including copiers, urban mining offered a more sustainable and environmentally friendly alternative. This shift in mindset sparked the development of specialized recycling facilities and processes to handle copiers and other electronic waste.

The Challenges of Copier Recycling

Despite the growing interest in copier recycling, the process was not without its challenges. Copiers are complex machines that contain a wide range of materials, including plastics, metals, and hazardous substances. Disassembling and separating these components in an efficient and environmentally friendly manner proved to be a significant obstacle.

Another challenge was the lack of standardized recycling procedures and regulations. Different copier manufacturers used varying materials and designs, making it difficult to establish consistent recycling practices. Additionally, the lack of awareness among consumers and businesses about the importance of recycling copiers hindered progress in this field.

The Evolution of Copier Recycling

Over time, copier recycling has evolved to address these challenges and meet the growing demand for sustainable waste management practices. The development of advanced recycling technologies and processes has enabled more efficient and effective recovery of precious metals from copiers.

Regulatory bodies have also stepped in to establish guidelines and regulations for electronic waste management, including copier recycling. These regulations have helped standardize recycling practices and ensure the proper handling of hazardous materials present in copiers.

Furthermore, increased awareness and education about the environmental impact of electronic waste have led to a shift in consumer and business behavior. Many organizations now prioritize recycling and seek out certified recycling facilities to dispose of their copiers responsibly.

The Current State of Copier Recycling

Today, copier recycling has become an integral part of the electronic waste management industry. Specialized recycling facilities are equipped with advanced technologies to efficiently disassemble copiers, separate different materials, and recover valuable metals.

The focus on circular economy principles has also influenced copier recycling. Rather than simply extracting precious metals, efforts are being made to reuse and refurbish copier components, extending their lifespan and reducing waste.

However, challenges still remain. The increasing complexity of copiers, with the integration of digital technology and connectivity, poses new obstacles for recycling. The rapid pace of technological advancements also means that copiers become obsolete quickly, leading to a higher turnover rate and a greater need for recycling.

Despite these challenges, copier recycling continues to evolve, driven by the need for sustainable waste management practices and the recognition of the value of urban mining. As technology continues to advance, it is crucial that copier recycling keeps pace to ensure the responsible disposal and recovery of precious metals from these devices.

The Composition of Copiers

Copiers are complex electronic devices that contain a wide range of materials. The main components of a copier include the plastic housing, the glass display panel, the circuit boards, the power supply unit, and various mechanical parts such as gears and rollers. These components are carefully designed and assembled to ensure the smooth functioning of the copier.

Plastic Housing

The plastic housing of a copier is typically made of high-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS). These plastics are chosen for their durability, resistance to heat and chemicals, and ease of molding into complex shapes. The housing provides protection to the internal components and gives the copier its physical structure.

Glass Display Panel

The glass display panel is an essential part of modern copiers, enabling users to interact with the device through a user interface. The glass used in copiers is often treated with a thin layer of indium tin oxide (ITO) to make it conductive and responsive to touch. This allows for the use of touchscreens and other interactive features.

Circuit Boards

The circuit boards in copiers contain a multitude of electronic components, including microprocessors, memory chips, and various integrated circuits. These boards are responsible for controlling the copier’s functions, processing data, and communicating with other devices. The components on the circuit boards are typically soldered onto the board using lead-based solder, although lead-free solder is becoming more common due to environmental concerns.

Power Supply Unit

The power supply unit in a copier converts the incoming electrical power into the appropriate voltage and current required by the copier’s internal components. It usually consists of transformers, capacitors, and voltage regulators. The power supply unit is designed to provide a stable and reliable power source to ensure the copier operates correctly.

Mechanical Parts

Copiers also contain various mechanical parts, such as gears, rollers, and belts, which are responsible for paper feeding, image transfer, and other mechanical operations. These parts are typically made of metal alloys, such as steel or aluminum, chosen for their strength, durability, and resistance to wear and tear.

Urban Mining for Precious Metal Recovery

Urban mining refers to the process of extracting valuable materials from electronic waste, such as copiers. Copiers contain several precious metals that can be recovered through recycling, including gold, silver, palladium, and platinum. These metals are used in various electronic components, such as circuit boards and connectors, due to their excellent conductivity and resistance to corrosion.

Gold Recovery

Gold is one of the most valuable and sought-after metals in copiers. It is primarily found in the circuit boards, where it is used for plating connectors and bonding wires. To recover gold from copiers, the electronic waste is first shredded into small pieces. Then, a combination of mechanical and chemical processes is employed to separate the gold from other materials. This typically involves crushing the shredded waste and using chemicals, such as cyanide or aqua regia, to dissolve the other components while leaving the gold intact.

Silver Recovery

Silver is another precious metal present in copiers, mainly used in electrical contacts and switches. The recovery of silver from copiers follows a similar process to gold recovery, involving shredding, crushing, and chemical extraction. The silver can then be refined and reused in various industries, such as jewelry manufacturing and electronics.

Palladium and Platinum Recovery

Palladium and platinum are less common but still valuable precious metals found in copiers. These metals are typically used in catalytic converters and various electronic components. The recovery process for palladium and platinum involves similar steps to gold and silver recovery, including shredding, chemical extraction, and refining.

Challenges of Copier Recycling

While copier recycling and urban mining offer significant opportunities for precious metal recovery, there are several challenges associated with these processes.

Complex Disassembly

Copiers are intricate devices with numerous components tightly integrated. Disassembling them to extract valuable materials requires specialized knowledge and equipment. The complexity of copiers can make the disassembly process time-consuming and labor-intensive.

Hazardous Materials

Copiers contain hazardous materials, such as lead, mercury, and flame retardants, which can pose risks to human health and the environment if not properly handled. Recycling facilities must adhere to strict regulations and safety protocols to minimize the release of these hazardous substances during the recycling process.

Economic Viability

The economic viability of copier recycling depends on the market prices of the recovered materials. Fluctuations in metal prices can impact the profitability of recycling operations. Additionally, the cost of transportation, processing, and refining further influences the economic feasibility of copier recycling.

E-Waste Management

E-waste management is a significant challenge in copier recycling. The sheer volume of electronic waste generated globally requires efficient collection, sorting, and processing systems. Ensuring that copiers and other electronic devices are properly disposed of and recycled is crucial to minimize the environmental impact of e-waste.

Copiers are intricate electronic devices that contain a wide range of materials, including plastics, glass, circuit boards, power supply units, and mechanical parts. Urban mining techniques can be employed to recover precious metals, such as gold, silver, palladium, and platinum, from copiers. However, copier recycling faces challenges related to complex disassembly, hazardous materials, economic viability, and e-waste management. Addressing these challenges is crucial to ensure the sustainable and efficient recovery of valuable materials from copiers.

Case Study 1: Company A’s Innovative Approach to Copier Recycling

In recent years, Company A, a leading technology company, has been at the forefront of finding sustainable solutions for copier recycling and precious metal recovery. Recognizing the environmental impact of electronic waste, they set out to develop an innovative process that maximizes resource recovery while minimizing harm to the environment.

One key aspect of their approach is the implementation of a closed-loop recycling system. Instead of simply disposing of copiers at the end of their lifecycle, Company A collects them from customers and carefully disassembles them to separate various components. This meticulous process ensures that valuable precious metals, such as gold, silver, and palladium, can be recovered.

Once the copiers are disassembled, the precious metal-containing components are sent to specialized facilities where urban mining techniques are employed. Through a combination of mechanical and chemical processes, the precious metals are extracted from circuit boards, connectors, and other parts. These metals can then be reused in the production of new copiers or other electronic devices, reducing the need for mining raw materials.

Company A’s commitment to sustainable copier recycling has not only reduced the environmental impact of their operations but has also created a new revenue stream. By recovering precious metals, they can sell them to metal refiners, generating additional income while reducing their reliance on virgin materials.

Case Study 2: Organization B’s Community-Based Recycling Initiative

Organization B, a non-profit focused on environmental conservation, has developed a community-based approach to copier recycling and urban mining. Recognizing the potential health and environmental risks associated with informal e-waste recycling practices in many urban areas, they sought to create a safer and more sustainable alternative.

In collaboration with local governments and recycling partners, Organization B established a network of collection centers in urban neighborhoods. These centers serve as drop-off points where individuals can safely dispose of their old copiers. The organization ensures that the collected copiers are then transported to their main facility for further processing.

At the main facility, Organization B employs trained technicians who carefully dismantle the copiers and separate the valuable components. This approach not only ensures the recovery of precious metals but also provides employment opportunities for individuals in the community. By training and hiring local residents, Organization B contributes to the economic development of the area while addressing the issue of unemployment.

Furthermore, Organization B has implemented an educational outreach program to raise awareness about the importance of proper e-waste recycling. They conduct workshops and campaigns in schools, community centers, and local events to inform individuals about the environmental and health risks associated with improper disposal of copiers and other electronic devices. This initiative has not only increased the volume of copiers collected but has also fostered a culture of responsible recycling within the community.

Case Study 3: Manufacturer C’s Circular Economy Approach

Manufacturer C, a global copier manufacturer, has embraced the concept of the circular economy to tackle the challenges of copier recycling and precious metal recovery. They have implemented a comprehensive strategy that focuses on designing copiers for durability, repairability, and recyclability.

One of the key features of Manufacturer C’s copiers is modular design. By incorporating easily replaceable parts and components, they extend the lifespan of their products and reduce the need for complete replacements. This design approach not only reduces electronic waste but also enables efficient recovery of precious metals.

Additionally, Manufacturer C has established a take-back program where customers can return their old copiers at the end of their lifecycle. These copiers are then disassembled at dedicated facilities, and the valuable components are extracted for recycling. The remaining materials are carefully processed to ensure minimal environmental impact.

Furthermore, Manufacturer C has partnered with metal refiners who specialize in urban mining techniques. This collaboration ensures that the precious metals recovered from the copiers are efficiently recycled and reintroduced into the production cycle. By closing the loop and reusing materials, Manufacturer C reduces their reliance on virgin resources and contributes to a more sustainable future.

Manufacturer C’s circular economy approach not only addresses the challenges of copier recycling and urban mining but also sets an example for other manufacturers in the industry. By prioritizing sustainability throughout the product lifecycle, they demonstrate that it is possible to achieve both environmental and economic benefits.

FAQs

1. What is copier recycling?

Copier recycling refers to the process of properly disposing of copiers at the end of their life cycle. It involves dismantling the copiers, separating the different components, and recycling or reusing them.

2. Why is copier recycling important?

Copier recycling is important for several reasons. Firstly, it helps to reduce the amount of electronic waste that ends up in landfills, which can have harmful effects on the environment. Secondly, copiers contain valuable materials, such as precious metals, that can be recovered and reused, reducing the need for mining and preserving natural resources.

3. What are the challenges of copier recycling?

There are several challenges associated with copier recycling. One of the main challenges is the complexity of copier design, which often makes it difficult to disassemble them and separate the different components. Additionally, copiers can contain hazardous materials, such as mercury and lead, which require special handling and disposal.

4. What is urban mining?

Urban mining refers to the process of extracting valuable materials from electronic waste, such as copiers, computers, and smartphones. It involves using specialized techniques to recover precious metals, such as gold, silver, and platinum, from these devices.

5. Why is urban mining important for precious metal recovery?

Urban mining is important for precious metal recovery because it reduces the need for traditional mining, which can have significant environmental and social impacts. By extracting precious metals from electronic waste, we can minimize the demand for new mining operations and conserve natural resources.

6. How are precious metals recovered from copiers?

Precious metals are recovered from copiers through a multi-step process. First, the copiers are disassembled, and the different components are separated. Then, the components containing precious metals, such as circuit boards and connectors, are processed using techniques such as smelting or leaching to extract the valuable metals.

7. What happens to the non-precious metal components of copiers?

The non-precious metal components of copiers are typically recycled or reused. Plastics, for example, can be melted down and used to make new products. Other materials, such as glass and rubber, can also be recycled or repurposed.

8. Are there any regulations or standards for copier recycling?

Yes, there are regulations and standards for copier recycling. In many countries, electronic waste recycling is governed by legislation that requires proper disposal and recycling of copiers and other electronic devices. Additionally, there are industry standards, such as the Responsible Recycling (R2) and e-Stewards certifications, that ensure the responsible and ethical recycling of electronic waste.

9. Can individuals recycle their old copiers?

Yes, individuals can recycle their old copiers. Many municipalities and recycling centers offer electronic waste collection programs where individuals can drop off their old copiers for recycling. Additionally, some manufacturers and retailers have take-back programs that allow customers to return their old copiers for recycling.

10. How can businesses ensure responsible copier recycling?

Businesses can ensure responsible copier recycling by partnering with certified recyclers or electronic waste management companies. These companies have the expertise and infrastructure to properly handle and recycle copiers. It is important for businesses to choose recyclers that adhere to industry standards and have a transparent recycling process.

Concept 1: Copier Recycling

Copier recycling refers to the process of collecting, disassembling, and reusing or disposing of copiers in an environmentally friendly manner. When copiers reach the end of their life cycle or become obsolete, they need to be properly handled to prevent them from ending up in landfills and causing harm to the environment.

During the recycling process, copiers are first collected from various sources such as businesses, organizations, or individuals. They are then disassembled, separating different components like plastic, metal, glass, and circuit boards. These components are sent for further processing to extract valuable materials and ensure that they are reused or recycled properly.

Recycling copiers not only helps in reducing the amount of waste going to landfills but also conserves valuable resources like metals and plastics. It also reduces the energy and raw material requirements for manufacturing new copiers.

Concept 2: Urban Mining

Urban mining is the process of extracting valuable resources from electronic waste (e-waste) and other discarded products. It involves recovering precious metals like gold, silver, and palladium from old electronics, including copiers.

When copiers are recycled, they are sent to specialized facilities where they undergo a process called urban mining. In this process, the copiers are carefully disassembled, and the valuable metals present in their circuit boards and other components are extracted.

Urban mining is an important practice because it allows us to recover valuable resources that would otherwise be lost or require extensive mining operations. By extracting precious metals from e-waste, we can reduce the need for environmentally destructive mining activities and decrease the demand for newly mined metals.

Concept 3: Precious Metal Recovery

Precious metal recovery refers to the process of extracting valuable metals, such as gold, silver, and palladium, from electronic waste or other sources. In the case of copier recycling, precious metal recovery involves extracting these valuable metals from the copier’s circuit boards and other components.

Electronic devices like copiers contain small amounts of precious metals in their circuitry. These metals are used for their excellent conductivity and resistance to corrosion. However, when copiers become obsolete or reach the end of their life cycle, these metals can be recovered and reused.

Precious metal recovery from copiers and other electronic devices is a complex process that involves several steps. First, the copiers are disassembled, and the circuit boards are separated. Then, the boards are crushed into small pieces and treated with chemicals to dissolve the metals. Finally, the dissolved metals are precipitated and purified to obtain pure gold, silver, or palladium.

Precious metal recovery is not only economically beneficial but also environmentally friendly. By reusing these metals, we reduce the need for new mining operations, which can have significant environmental impacts such as deforestation, water pollution, and habitat destruction.

Conclusion

The process of copier recycling and urban mining for precious metal recovery presents numerous challenges that need to be navigated. Firstly, the complex composition of copiers, with their mix of plastic, metal, and electronic components, requires careful dismantling and separation to ensure efficient recycling. Additionally, the presence of precious metals such as gold, silver, and platinum in copiers makes urban mining a viable option for recovering these valuable resources.

However, the challenges lie in the proper management of e-waste and the implementation of sustainable practices. The lack of standardized recycling processes, limited awareness among consumers, and the illegal export of e-waste to developing countries are major obstacles to overcome. Furthermore, the high cost and energy-intensive nature of urban mining require innovative technologies and partnerships between industry, government, and academia.

Despite these challenges, the potential benefits of copier recycling and urban mining are significant. By recovering precious metals from copiers, we can reduce the need for mining and the environmental impact associated with it. Moreover, the recycling of copiers can contribute to the circular economy by promoting resource conservation and minimizing waste. To fully realize these benefits, it is crucial for stakeholders to collaborate and invest in sustainable solutions that address the challenges and promote responsible copier recycling and urban mining practices.