Revolutionizing Technology: The Promising Potential of Thin Film Printing in Printed Electronics

In a world where technology is constantly evolving, the field of printed electronics is pushing boundaries and revolutionizing the way we interact with everyday objects. From flexible displays to smart packaging, printed electronics is transforming traditional manufacturing processes and opening up a world of possibilities. At the forefront of this innovation is thin film printing, a technique that allows for the creation of electronic circuits and devices on a range of materials, including paper, plastic, and even fabric. In this article, we will explore the exciting advancements in printed electronics and delve into how thin film printing is shaping the future of various industries, from healthcare to automotive, and beyond. Get ready to discover the incredible potential of this cutting-edge technology and the impact it will have on our daily lives.

Key Takeaways:

1. Thin film printing is revolutionizing the electronics industry by enabling the production of flexible and lightweight electronic devices. This technology has the potential to reshape various sectors, including healthcare, consumer electronics, and automotive industries.

2. The versatility of thin film printing allows for the creation of complex electronic circuits on flexible substrates, such as plastic or paper. This opens up new possibilities for wearable devices, smart packaging, and even electronic textiles.

3. Printed electronics offer significant cost advantages compared to traditional manufacturing methods. Thin film printing reduces material waste and production time, making it a more sustainable and efficient solution for mass production.

4. The integration of printed electronics with Internet of Things (IoT) technology is driving the development of smart devices and systems. By incorporating sensors and connectivity into printed electronics, we can create a network of intelligent and interconnected objects that enhance our daily lives.

5. Despite its potential, there are still challenges to overcome in the widespread adoption of printed electronics. These include improving the reliability and durability of printed components, as well as scaling up production to meet the demands of the market.

Overall, thin film printing is a game-changer in the electronics industry, offering exciting opportunities for innovation and growth. As more research and development efforts are dedicated to this field, we can expect to see even more groundbreaking applications of printed electronics in the near future.

Insight 1: The Impact of Printed Electronics on the Industry

Printed electronics, specifically thin film printing, is revolutionizing the industry by offering a range of benefits and opportunities. This emerging technology has the potential to disrupt various sectors, including consumer electronics, healthcare, automotive, and energy. Here are some key insights into how printed electronics is shaping the future:

1.1 Enhanced Design Flexibility

One of the most significant advantages of printed electronics is its ability to provide enhanced design flexibility. Traditional electronics manufacturing methods often involve rigid and bulky components, limiting the design possibilities. However, thin film printing allows for the creation of flexible and lightweight electronic devices.

With printed electronics, manufacturers can integrate circuits and sensors onto a wide range of substrates, such as plastics, fabrics, or even paper. This flexibility enables the development of wearable devices, smart packaging, and even electronic textiles. For instance, companies are exploring the use of printed sensors in clothing to monitor vital signs and enhance athletic performance.

The increased design flexibility offered by printed electronics opens up new avenues for product innovation and customization. It allows designers to create devices that seamlessly blend into everyday objects, leading to the development of more intuitive and user-friendly electronics.

1.2 Cost-Effective Manufacturing

Another key impact of printed electronics is its potential to reduce manufacturing costs significantly. Traditional electronics manufacturing processes involve complex and expensive procedures, including photolithography, etching, and assembly. In contrast, thin film printing simplifies the production process, resulting in cost savings.

Printed electronics can be produced using high-volume manufacturing techniques, such as roll-to-roll printing or screen printing. These methods are scalable and can be automated, reducing labor costs and increasing production efficiency. Additionally, the use of low-cost materials, such as organic polymers or metal nanoparticles, further contributes to cost reduction.

The cost-effective nature of printed electronics makes it accessible to a broader range of industries and applications. It enables the production of affordable electronic devices, making technology more accessible to consumers. Moreover, the reduced manufacturing costs open up opportunities for startups and small businesses to enter the electronics market.

1.3 Sustainability and Environmental Benefits

Printed electronics also offers significant sustainability and environmental benefits. Traditional electronics manufacturing processes generate a considerable amount of waste, including toxic chemicals and non-recyclable materials. In contrast, printed electronics has the potential to minimize waste and reduce the environmental impact.

Thin film printing allows for the precise deposition of materials, reducing material waste compared to traditional manufacturing methods. Additionally, the use of organic and biodegradable materials in printed electronics can further enhance its sustainability. For instance, researchers are exploring the use of biodegradable substrates and conductive inks derived from renewable sources.

Furthermore, printed electronics enables the development of energy-efficient devices. The lightweight and flexible nature of printed electronics can lead to reduced energy consumption during operation. For example, flexible displays made possible by printed electronics can be integrated into curved surfaces, reducing the need for bulky and energy-intensive backlighting.

The sustainability and environmental benefits of printed electronics align with the growing global focus on reducing carbon footprints and adopting more eco-friendly technologies. This technology has the potential to revolutionize the electronics industry by providing greener alternatives to traditional manufacturing processes.

Insight 2: Applications of Printed Electronics in Various Sectors

Printed electronics is finding applications in a wide range of sectors, transforming industries and enabling new possibilities. Here are some key insights into how printed electronics is being utilized in different sectors:

2.1 Consumer Electronics

In the consumer electronics sector, printed electronics is driving innovation by enabling the development of flexible displays, touch sensors, and wearable devices. Flexible displays made possible by printed electronics offer enhanced durability, lightweight design, and curved form factors. This technology has the potential to revolutionize the smartphone and tablet industry by introducing foldable and rollable devices.

Printed electronics also plays a crucial role in the development of wearable devices. By integrating sensors and circuits into fabrics or flexible substrates, manufacturers can create smart clothing that monitors vital signs, tracks activity levels, and provides personalized health insights. These wearable devices have applications in healthcare, sports, and fitness industries.

2.2 Healthcare

In the healthcare sector, printed electronics is revolutionizing medical devices and diagnostics. Printed sensors and electrodes can be integrated into wearable patches or smart bandages to monitor patients’ vital signs, such as heart rate, respiration, or blood pressure. These devices offer continuous monitoring, enabling early detection of health issues and remote patient monitoring.

Printed electronics is also being utilized in the development of electronic skin patches that can deliver drugs or monitor glucose levels for diabetes management. These patches offer a non-invasive and convenient alternative to traditional methods, improving patient comfort and compliance.

2.3 Automotive

The automotive industry is leveraging the benefits of printed electronics to enhance vehicle functionality and safety. Printed sensors can be integrated into various components, such as seats, steering wheels, or dashboards, to monitor driver biometrics and provide real-time feedback. This technology has the potential to improve driver safety and enable personalized driving experiences.

Printed electronics is also being utilized in the development of flexible and lightweight lighting solutions for automotive applications. These lighting systems offer improved energy efficiency, design flexibility, and enhanced aesthetics.

Insight 3: Challenges and Future Outlook of Printed Electronics

While printed electronics holds immense potential, there are several challenges that need to be addressed for its widespread adoption. Here are some key insights into the challenges and future outlook of printed electronics:

3.1 Material Development and Performance

One of the primary challenges in printed electronics is the development of high-performance materials. While organic polymers and nanoparticles offer cost and flexibility advantages, they often fall short in terms of electrical conductivity and durability compared to traditional materials. Researchers are actively working on improving the performance of printable materials to meet the requirements of various applications.

3.2 Manufacturing Scalability

To achieve widespread adoption, printed electronics manufacturing processes need to be scalable. Currently, high-volume manufacturing techniques like roll-to-roll printing face challenges in maintaining consistent quality and precision over large areas. Further advancements in manufacturing processes and equipment are required to ensure scalability without compromising quality.

3.3 Integration and Standardization

For printed electronics to become a mainstream technology, integration and standardization across different sectors are crucial. The development of industry-wide standards for materials, processes, and device interfaces would facilitate interoperability and compatibility between printed electronic devices. Collaboration between industry players, researchers, and regulatory bodies is essential to establish these standards.

Looking ahead, the future of printed electronics is promising. As material development progresses, the performance gap between printed and traditional electronics is expected to narrow. The integration of printed electronics into everyday objects will continue to drive innovation and create new market opportunities. With the ongoing focus on sustainability and cost reduction, printed electronics is well-positioned to reshape the future of the electronics industry.

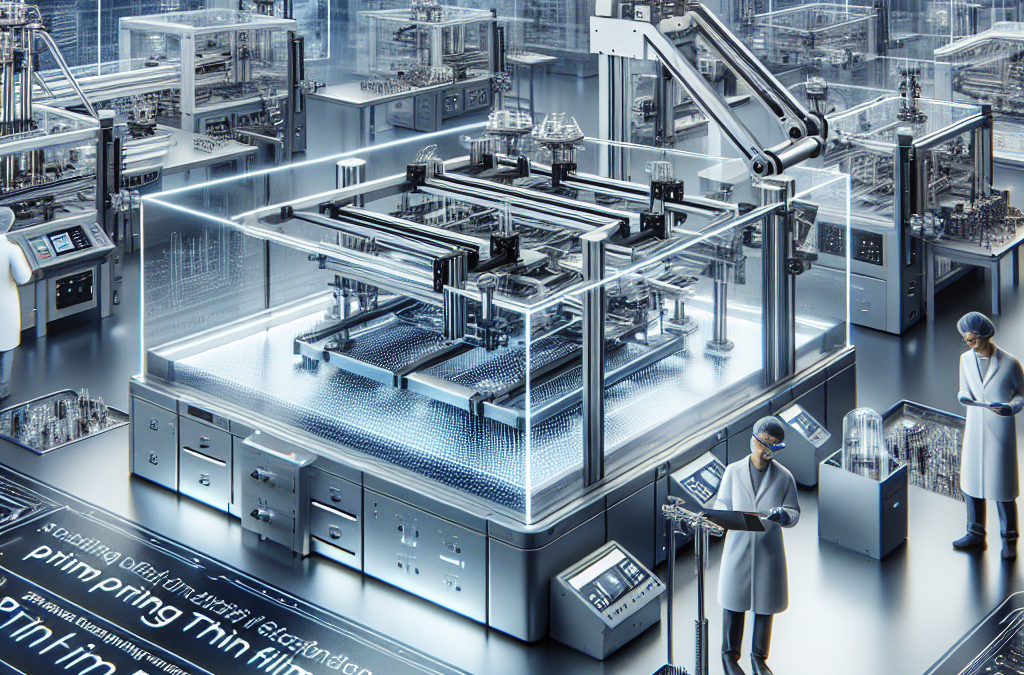

The Rise of Printed Electronics

Printed electronics is revolutionizing the world of technology by enabling the production of flexible, lightweight, and cost-effective electronic devices. This section will explore the growth and potential of printed electronics, highlighting its advantages over traditional manufacturing methods. We will also discuss some notable applications and success stories, such as the development of flexible displays and wearable sensors.

Thin Film Printing Techniques

Thin film printing is a key process in the fabrication of printed electronics. In this section, we will delve into various printing techniques used to deposit thin films, including inkjet printing, screen printing, and gravure printing. We will explore the advantages and limitations of each method, as well as their suitability for different applications. Case studies of companies utilizing these techniques will be examined to provide real-world examples.

Materials for Thin Film Printing

The choice of materials greatly influences the performance and functionality of printed electronic devices. This section will discuss the different types of materials used in thin film printing, such as conductive inks, dielectric materials, and organic semiconductors. We will explore the properties and characteristics of these materials, as well as advancements in material science that have enabled the development of high-performance printed electronics.

Advancements in Thin Film Printing Technology

The field of thin film printing is constantly evolving, with researchers and engineers pushing the boundaries of what is possible. In this section, we will explore the latest advancements in thin film printing technology, such as the development of high-resolution printing techniques, improved ink formulations, and novel deposition methods. We will also discuss the impact of these advancements on the performance and scalability of printed electronic devices.

Applications of Printed Electronics

Printed electronics has found applications in a wide range of industries, from healthcare and automotive to consumer electronics and energy. In this section, we will explore some of the most promising and impactful applications of printed electronics. We will discuss how printed sensors are revolutionizing healthcare monitoring, how flexible displays are transforming the consumer electronics market, and how printed solar cells are paving the way for sustainable energy solutions.

The Future of Printed Electronics

The future of printed electronics looks promising, with ongoing research and development efforts aimed at further improving the performance, reliability, and scalability of printed electronic devices. In this section, we will discuss some of the key areas of focus for future advancements, such as the integration of printed electronics with Internet of Things (IoT) technologies, the development of biodegradable and environmentally friendly materials, and the exploration of new applications in fields like robotics and aerospace.

Challenges and Limitations

While printed electronics offers numerous advantages, it also faces certain challenges and limitations that need to be addressed for widespread adoption. In this section, we will explore some of these challenges, such as the need for improved reliability and durability of printed devices, the scalability of manufacturing processes, and the integration of printed electronics with existing infrastructure. We will also discuss ongoing research and initiatives aimed at overcoming these challenges.

The Role of Printed Electronics in a Sustainable Future

Printed electronics has the potential to contribute significantly to a more sustainable future. This section will discuss how the lightweight and flexible nature of printed electronic devices reduces material consumption and energy requirements during manufacturing. We will also explore how printed electronics can enable the development of energy-efficient devices and promote the circular economy by facilitating the recycling and reuse of electronic components.

Printed electronics, enabled by thin film printing, is shaping the future of technology by offering flexible, lightweight, and cost-effective electronic devices. With advancements in printing techniques, materials, and technology, the field of printed electronics continues to expand, finding applications in various industries. However, challenges such as reliability, scalability, and integration remain to be addressed. Despite these challenges, the potential of printed electronics to contribute to a sustainable future is undeniable. As research and development efforts continue, we can expect to see further advancements and applications of printed electronics in the years to come.

The Origins of Printed Electronics

Printed electronics, also known as organic electronics, is a field that combines traditional printing techniques with electronic components to create flexible, lightweight, and cost-effective devices. The concept of printing electronic circuits dates back to the late 1970s when researchers began exploring the possibility of using conductive inks to print circuits on various substrates.

Early Developments and Challenges

In the early years, researchers faced numerous challenges in developing printed electronics. The conductive inks available at the time had limited conductivity, and the printing processes were not precise enough to create complex circuitry. However, advancements in materials science and printing technology gradually improved the performance and reliability of printed electronic devices.

The Rise of Thin Film Printing

One significant milestone in the evolution of printed electronics was the development of thin film printing techniques. Thin film printing involves depositing a thin layer of material onto a substrate using various printing methods such as inkjet, screen, or gravure printing. This approach allows for the creation of highly precise and intricate patterns, enabling the production of complex electronic devices.

Advancements in Materials

Another crucial factor in the evolution of printed electronics has been the development of new materials specifically designed for printing applications. Initially, conductive inks were made from metals such as silver or copper, but they were expensive and had limited flexibility. Over time, researchers discovered new conductive polymers and carbon-based materials that offered improved performance and flexibility, making them ideal for printed electronics.

Applications in Consumer Electronics

As the performance and reliability of printed electronics improved, they found their way into various consumer electronic devices. One of the earliest applications was in the field of flexible displays, where printed electronic components enabled the creation of bendable and rollable screens. This breakthrough opened up new possibilities for wearable technology, e-readers, and other portable devices.

Advantages for IoT and Smart Packaging

The Internet of Things (IoT) and smart packaging have also benefited from the advancements in printed electronics. Printed sensors and antennas can be integrated into everyday objects, allowing them to collect and transmit data wirelessly. This has led to the development of smart labels, packaging, and even smart clothing, revolutionizing industries such as logistics, healthcare, and retail.

Current State and Future Prospects

Today, printed electronics have become increasingly prevalent in various industries. The technology has matured to the point where it can rival traditional electronic manufacturing methods in terms of performance and cost-effectiveness. Companies are now exploring the potential of printed electronics in areas such as energy harvesting, flexible solar cells, and even printable batteries.

Challenges and Opportunities

While printed electronics offer numerous advantages, there are still challenges to overcome. The scalability of production processes, the integration of multiple functionalities, and the development of more durable materials are areas that require further research and development. However, the potential for printed electronics to revolutionize industries and enable new applications is vast, making it an exciting field for innovation and investment.

The historical evolution of printed electronics has been marked by significant advancements in materials, printing techniques, and applications. From its humble beginnings as a concept in the late 1970s, printed electronics have emerged as a promising technology with a wide range of applications. As further advancements are made, the future of printed electronics looks bright, with the potential to reshape industries and improve the way we interact with electronic devices.

FAQs

1. What are printed electronics?

Printed electronics refer to a set of technologies that enable the printing of electronic components, such as transistors, sensors, and circuits, onto various substrates like plastic, paper, or fabric. This allows for the creation of flexible and lightweight electronic devices.

2. How does thin film printing work?

Thin film printing involves depositing a thin layer of electronic materials, such as conductive inks or semiconducting polymers, onto a substrate using printing techniques like inkjet or screen printing. These materials are formulated to be compatible with the printing process and can form functional electronic components when properly deposited.

3. What are the advantages of printed electronics?

Printed electronics offer several advantages over traditional electronics manufacturing methods. These include lower production costs, faster prototyping, flexibility in design, and the ability to print on a variety of substrates. Additionally, printed electronics can enable the creation of lightweight and flexible devices that can be integrated into everyday objects.

4. What applications can benefit from printed electronics?

Printed electronics have a wide range of potential applications. They can be used in the development of flexible displays, wearable devices, smart packaging, healthcare sensors, and energy harvesting systems, among others. The versatility of printed electronics allows for their integration into various industries, including consumer electronics, healthcare, automotive, and aerospace.

5. Are printed electronics as reliable as traditional electronics?

While printed electronics are still in the early stages of development, significant progress has been made in improving their reliability. Extensive research is being conducted to enhance the performance and stability of printed electronic components. However, it is important to note that the reliability of printed electronics may vary depending on the specific application and the quality of the manufacturing process.

6. Can printed electronics replace traditional silicon-based electronics?

Printed electronics are not intended to replace traditional silicon-based electronics entirely. Instead, they offer an alternative for specific applications where flexibility, low-cost production, and large-area coverage are paramount. Printed electronics can complement traditional electronics by enabling the development of new types of devices and expanding the possibilities for integration into various objects and surfaces.

7. What are the challenges facing printed electronics?

Printed electronics still face several challenges that need to be overcome for widespread adoption. These include improving the performance and reliability of printed components, developing scalable manufacturing processes, ensuring compatibility with existing infrastructure, and addressing environmental concerns related to the disposal of printed electronic devices.

8. How is research contributing to the advancement of printed electronics?

Research plays a crucial role in advancing printed electronics. Scientists and engineers are continuously exploring new materials, printing techniques, and manufacturing processes to improve the performance and reliability of printed electronic components. They are also working on developing new applications and addressing the technical challenges associated with printed electronics.

9. What is the future of printed electronics?

The future of printed electronics looks promising. As research and development efforts continue, we can expect to see further advancements in the performance and reliability of printed electronic components. This will open up new possibilities for integration into everyday objects and surfaces, leading to the widespread adoption of printed electronics in various industries.

10. How can individuals and businesses get involved in printed electronics?

Individuals and businesses interested in printed electronics can get involved in several ways. They can stay updated on the latest developments in the field, participate in conferences and workshops, collaborate with research institutions, or explore partnerships with companies specializing in printed electronics. Additionally, individuals can contribute to the growth of printed electronics by exploring creative applications and supporting the adoption of these technologies in their respective industries.

Misconception 1: Printed Electronics is Limited to Simple Applications

One common misconception about printed electronics is that it is limited to simple applications and cannot compete with traditional electronics in terms of complexity and functionality. However, this is far from the truth.

Printed electronics, also known as thin film printing, is a technology that allows electronic devices to be printed on flexible substrates using various printing techniques. While it is true that printed electronics may not be suitable for all applications, it has made significant advancements in recent years and is now capable of handling complex functionalities.

For example, printed electronics can be used to create flexible displays, sensors, batteries, and even integrated circuits. These devices can be produced at a lower cost and in larger quantities compared to traditional electronics, making them ideal for applications such as wearable technology, smart packaging, and Internet of Things (IoT) devices.

Furthermore, researchers and engineers are continuously working on improving the capabilities of printed electronics. They are exploring new materials, developing advanced printing techniques, and integrating other technologies such as 3D printing and nanotechnology to enhance the performance and functionality of printed electronic devices.

Misconception 2: Printed Electronics is Not Reliable or Durable

Another misconception about printed electronics is that they are not as reliable or durable as traditional electronics. While it is true that printed electronics may have certain limitations in terms of durability, significant progress has been made in this area.

One of the key challenges in printed electronics is ensuring the stability and longevity of the printed components. However, researchers have developed various strategies to enhance the reliability and durability of printed electronic devices.

For instance, advancements in material science have led to the development of new conductive inks and substrates that offer improved stability and resistance to environmental factors such as moisture, temperature, and mechanical stress. Additionally, encapsulation techniques are used to protect the printed components from external factors that could potentially degrade their performance.

Moreover, rigorous testing and quality control processes are implemented during the manufacturing of printed electronic devices to ensure their reliability. These processes involve evaluating the electrical performance, mechanical integrity, and long-term stability of the devices.

While it is true that printed electronics may not have the same level of durability as traditional electronics, they are continuously improving in this aspect and are already suitable for many applications where durability is not a primary concern, such as disposable medical devices, smart packaging, and temporary electronic displays.

Misconception 3: Printed Electronics is Not Environmentally Friendly

There is a misconception that printed electronics is not environmentally friendly and may contribute to electronic waste. However, this is not entirely accurate.

Printed electronics offers several environmental advantages compared to traditional electronics. First and foremost, the manufacturing process of printed electronics requires fewer materials and energy compared to traditional electronics, resulting in a lower carbon footprint.

Moreover, printed electronics can be produced using eco-friendly materials such as organic semiconductors and biodegradable substrates. These materials are less harmful to the environment and can be easily recycled or disposed of without causing significant pollution.

Additionally, printed electronics enable the production of lightweight and flexible devices, which can lead to reduced transportation costs and energy consumption during distribution. This is particularly beneficial for applications such as flexible solar panels and electronic textiles.

Furthermore, printed electronics can enable the development of energy-efficient devices. For example, printed sensors can be used in smart buildings to monitor and optimize energy consumption, leading to significant energy savings.

While it is true that certain challenges remain in terms of recycling and end-of-life management of printed electronic devices, ongoing research and development efforts are focused on addressing these concerns and making printed electronics even more environmentally friendly.

1. Embrace the Power of Flexible Displays

Harness the potential of flexible displays in your daily life. These thin, lightweight, and bendable screens can be used in various applications, such as e-readers, smart clothing, and wearable devices. Stay updated with the latest products and gadgets that utilize flexible displays to enhance your digital experience.

2. Explore the World of E-paper

E-paper, also known as electronic paper, offers the advantage of low power consumption and high visibility in different lighting conditions. Consider using e-paper devices for reading books, newspapers, or even displaying important information like to-do lists or reminders. These devices are easy on the eyes and provide a paper-like reading experience.

3. Opt for Smart Packaging

With printed electronics, packaging can become smarter and more interactive. Look for products with smart packaging that can provide additional information, such as nutritional facts, expiration dates, or even personalized messages. This technology can enhance your shopping experience and help you make informed decisions.

4. Integrate Smart Labels

Smart labels equipped with printed electronics can offer a range of functionalities. These labels can track and monitor various parameters like temperature, humidity, or freshness, ensuring the quality and safety of products. Consider using smart labels for food items, medicines, or even for monitoring the condition of perishable goods during transportation.

5. Embrace the Internet of Things (IoT)

Printed electronics play a crucial role in the development of the Internet of Things (IoT). Explore IoT devices that utilize printed sensors and circuits to connect and automate various aspects of your home or workplace. From smart thermostats to connected appliances, these devices can make your life more convenient and efficient.

6. Wear Smart Clothing

Upgrade your wardrobe with smart clothing that incorporates printed electronics. These garments can monitor your vital signs, track your fitness activities, or even provide haptic feedback. Stay active and connected with the help of smart clothing, which seamlessly integrates technology into your daily life.

7. Enhance Home Decor with Printed Lighting

Printed lighting solutions offer unique design possibilities for your home decor. Look for printed light panels or LED strips that can be easily customized to create different lighting effects. These energy-efficient lighting options can transform the ambiance of any room and add a touch of modernity to your living space.

8. Explore Printed Solar Cells

Consider harnessing the power of the sun with printed solar cells. These lightweight and flexible solar panels can be integrated into various surfaces, such as windows, roofs, or even backpacks, to generate clean energy. Explore the potential of printed solar cells to reduce your carbon footprint and lower your energy bills.

9. Personalize Your Electronics

With printed electronics, personalization becomes easier than ever. Look for customizable gadgets and accessories that allow you to add your own designs or patterns. From smartphone cases to laptop skins, express your creativity and make your devices truly unique.

10. Stay Updated with Emerging Technologies

The field of printed electronics is constantly evolving, with new advancements and applications being developed regularly. Stay informed about the latest trends, products, and research in this field. Follow relevant blogs, attend conferences, and join online communities to stay ahead of the curve and explore new possibilities for incorporating printed electronics into your daily life.

Printed electronics and thin film printing have emerged as revolutionary technologies that are shaping the future in various industries. This article has highlighted the key points and insights related to printed electronics and their impact on different sectors.

Firstly, the article discussed the advantages of printed electronics, such as their flexibility, low cost, and ability to be integrated into various surfaces. This has opened up new possibilities in fields like healthcare, where wearable sensors and smart bandages can monitor vital signs and track healing progress. Additionally, the automotive industry has benefited from printed electronics by incorporating thin film printed sensors into vehicles, enabling advancements in safety and autonomous driving systems.

Furthermore, the article explored the potential of printed electronics in energy generation and storage. Thin film printed solar cells offer a lightweight and cost-effective solution for harnessing solar energy, while printed batteries and supercapacitors hold promise for powering portable devices and electric vehicles. These developments have the potential to revolutionize the renewable energy sector and reduce our dependence on traditional power sources.

In conclusion, the advancements in printed electronics and thin film printing are transforming various industries and opening up new opportunities for innovation. As these technologies continue to evolve, we can expect to see further integration into our daily lives, improving efficiency, sustainability, and functionality across multiple sectors. The future of printed electronics is indeed bright, and it is an exciting time to witness the impact of these technologies on our world.