Revolutionizing SEO Strategies: How 4D Printing is Transforming Automotive Parts Prototyping and Testing in South Florida

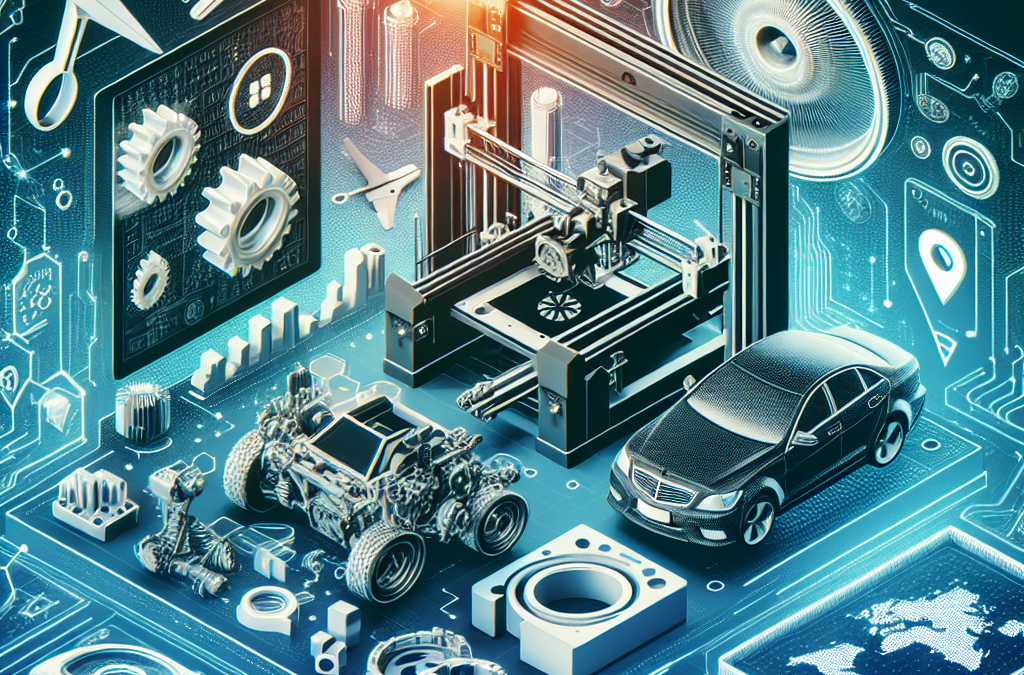

Imagine a world where automotive parts can be prototyped and tested in a matter of hours, instead of weeks or months. A world where complex geometries and intricate designs can be effortlessly produced, leading to faster innovation and improved product performance. This world is not a distant dream, but a reality being shaped by the revolutionary technology of 4D printing. In this article, we will explore the impact of 4D printing on boosting SEO (Search Engine Optimization) for South Florida’s automotive parts prototyping and testing industry.

South Florida has long been a hub for automotive innovation, with numerous companies specializing in prototyping and testing of parts for various vehicles. However, the traditional methods of manufacturing and prototyping have often posed challenges in terms of time, cost, and complexity. This is where 4D printing steps in, offering a game-changing solution that not only addresses these challenges but also opens up new possibilities for the industry.

Key Takeaway 1: 4D printing revolutionizes automotive parts prototyping and testing

With 4D printing, South Florida’s automotive industry can now create dynamic and shape-shifting prototypes that mimic real-world conditions. This technology allows for more accurate testing and evaluation of parts, leading to faster and more efficient product development.

Key Takeaway 2: Improved SEO through enhanced online visibility

By incorporating 4D printing into their prototyping and testing processes, automotive businesses in South Florida can showcase their innovative capabilities and attract more online traffic. This increased visibility can significantly boost their search engine optimization (SEO) efforts and help them stand out in a competitive market.

Key Takeaway 3: Enhanced customer experience and engagement

With 4D-printed prototypes, automotive companies can provide potential customers with interactive and immersive experiences. This technology allows customers to see and feel the product in action, leading to higher engagement and increased trust in the brand.

Key Takeaway 4: Streamlined production processes and cost savings

4D printing enables South Florida’s automotive industry to optimize their production processes by reducing the number of steps and materials required. This streamlined approach not only saves time but also cuts costs, making it a highly attractive option for businesses looking to improve their bottom line.

Key Takeaway 5: Sustainable and eco-friendly manufacturing

By utilizing 4D printing, automotive parts prototyping and testing can be done with less waste and a smaller carbon footprint. This technology allows for the creation of complex geometries and structures using fewer materials, contributing to a more sustainable manufacturing process and aligning with the growing demand for eco-friendly solutions.

The Ethical Implications of 4D Printing in Automotive Parts Prototyping and Testing

One of the most controversial aspects of 4D printing in the automotive industry is the potential ethical implications it raises. As this technology continues to advance, it presents new possibilities for creating and testing automotive parts. However, there are concerns about the impact it may have on various stakeholders.

On one hand, proponents argue that 4D printing can significantly boost SEO for South Florida’s automotive parts prototyping and testing. By allowing for faster and more efficient production of prototypes, companies can bring their products to market more quickly, leading to increased revenue and growth. This, in turn, can benefit the local economy and job market.

On the other hand, critics express concerns about the potential consequences of 4D printing. They argue that the technology may lead to job losses in traditional manufacturing industries, as automated processes replace human labor. This could have a negative impact on the local workforce and could exacerbate existing economic inequalities.

Furthermore, there are ethical considerations surrounding intellectual property rights. 4D printing allows for the replication of existing parts with relative ease. This raises concerns about copyright infringement and the potential for counterfeit products to flood the market. Companies investing in research and development may suffer financial losses if their designs are replicated and sold without permission.

The Environmental Impact of 4D Printing in Automotive Parts Prototyping and Testing

Another controversial aspect of 4D printing in the automotive industry is its environmental impact. Proponents argue that this technology has the potential to reduce waste and carbon emissions. Traditional manufacturing processes often result in excess material waste, whereas 4D printing allows for more precise and efficient use of resources.

Additionally, 4D printing enables the production of lightweight parts, which can contribute to fuel efficiency and reduce the overall carbon footprint of vehicles. This aligns with the growing demand for more sustainable transportation options and could help South Florida achieve its environmental goals.

However, critics raise concerns about the environmental impact of the materials used in 4D printing. Many of the materials currently used, such as plastics and resins, are derived from fossil fuels and contribute to pollution and greenhouse gas emissions. Additionally, the disposal of 4D printed parts at the end of their lifecycle may pose challenges, as these parts may not be easily recyclable.

Furthermore, the energy consumption associated with 4D printing processes is a point of contention. The technology requires significant energy inputs, particularly in terms of electricity. This raises questions about the overall sustainability of 4D printing and whether the environmental benefits outweigh the energy consumption.

The Impact on Small Businesses and Local Economy

One controversial aspect of 4D printing in the automotive industry is its potential impact on small businesses and the local economy. Proponents argue that this technology can level the playing field, allowing small businesses to compete with larger corporations. 4D printing offers the opportunity for rapid prototyping and production, enabling smaller companies to bring innovative products to market quickly.

Additionally, the adoption of 4D printing technology in South Florida could attract new businesses and investments to the region. This could stimulate economic growth and create job opportunities, benefiting the local community as a whole.

However, critics express concerns about the potential consolidation of power in the industry. Large corporations with the resources to invest in 4D printing technology may gain a competitive advantage over smaller businesses that cannot afford the upfront costs. This could lead to the displacement of small businesses and a concentration of economic power in the hands of a few.

Furthermore, there are concerns about the impact on local manufacturing industries. If 4D printing becomes the dominant method of production, traditional manufacturing processes may become obsolete. This could result in job losses and the decline of certain sectors within the local economy.

While 4D printing has the potential to boost SEO for South Florida’s automotive parts prototyping and testing, it also raises several controversial aspects. The ethical implications, environmental impact, and effects on small businesses and the local economy are all areas of concern that need to be carefully considered. It is crucial to strike a balance between embracing the benefits of this technology and addressing the potential challenges it presents.

The Rise of 4D Printing in Automotive Parts Prototyping and Testing

South Florida’s automotive industry is experiencing a significant shift with the emergence of 4D printing technology. This innovative manufacturing process combines 3D printing with the ability to create objects that can change shape or behavior over time. As a result, automotive parts prototyping and testing are being revolutionized, leading to improved efficiency, cost-effectiveness, and overall quality. This article explores the emerging trends in 4D printing and its potential future implications for boosting SEO in South Florida’s automotive parts industry.

1. Streamlined Prototyping Process

Traditionally, prototyping automotive parts required multiple iterations and a substantial amount of time and resources. With 4D printing, however, the process becomes more streamlined and efficient. Designers can create prototypes with intricate shapes and complex geometries, enabling them to test and refine their designs more effectively. This not only saves time but also reduces material waste and costs associated with traditional prototyping methods.

Furthermore, 4D printing allows for the integration of smart materials into the prototypes. These materials can respond to external stimuli, such as temperature or pressure, and change their shape or properties accordingly. This capability enhances the functionality and performance of the prototypes, providing valuable insights for further improvements.

2. Improved Testing Capabilities

Testing automotive parts is a crucial step in ensuring their safety, reliability, and performance. 4D printing technology enhances the testing capabilities by enabling the creation of more realistic prototypes. The ability to incorporate smart materials into the prototypes allows for simulations of real-world scenarios and environmental conditions.

For example, a 4D printed prototype of an automotive part can be designed to respond to heat, mimicking the behavior of the actual part under high-temperature conditions. This enables engineers to assess the part’s performance and durability more accurately. By conducting comprehensive and realistic tests, potential issues can be identified and addressed early in the development process, reducing the risk of failures or recalls in the final product.

3. Customization and Personalization

4D printing opens up new possibilities for customization and personalization in automotive parts production. The ability to create objects that can change their shape or properties allows for tailoring products to specific requirements or preferences. This trend is particularly relevant in South Florida, where the automotive industry caters to a diverse range of customers with varying needs and tastes.

By leveraging 4D printing technology, automotive parts manufacturers can offer customized solutions that meet individual customer demands. Whether it’s a unique design, improved functionality, or personalized branding, 4D printing enables the production of highly tailored parts. This customization not only enhances the customer experience but also boosts SEO by attracting a broader customer base and generating positive reviews and recommendations.

The Future Implications of 4D Printing in South Florida’s Automotive Parts Industry

The emergence of 4D printing technology in South Florida’s automotive parts industry holds promising future implications. As the technology continues to advance and become more accessible, several key trends are expected to shape the industry’s future.

1. Increased Adoption and Integration

As the benefits of 4D printing become more apparent, the adoption of this technology in South Florida’s automotive parts industry is likely to increase. Manufacturers will recognize the potential for cost savings, improved efficiency, and enhanced product performance. This widespread adoption will lead to the integration of 4D printing into existing production processes, making it a standard tool for prototyping and testing.

2. Collaboration and Innovation

With the rise of 4D printing, collaboration between automotive parts manufacturers, designers, and material scientists is expected to intensify. This collaboration will drive innovation and the development of new smart materials and design techniques specifically tailored for 4D printing. The automotive industry in South Florida will become a hub for cutting-edge research and development, attracting talent and investment in this emerging field.

3. Sustainable Manufacturing Practices

4D printing has the potential to contribute to more sustainable manufacturing practices in South Florida’s automotive parts industry. The ability to reduce material waste through streamlined prototyping processes and the use of smart materials that can adapt and self-repair will lead to a more environmentally friendly production cycle. As sustainability becomes an increasingly important factor for consumers and businesses alike, 4D printing will help automotive parts manufacturers meet these demands and improve their SEO by promoting their eco-friendly practices.

The emergence of 4D printing technology is revolutionizing the automotive parts prototyping and testing process in South Florida. The streamlined prototyping process, improved testing capabilities, and customization options provided by 4D printing are reshaping the industry. Looking ahead, increased adoption, collaboration, and sustainable manufacturing practices will drive the future implications of 4D printing in South Florida’s automotive parts industry.

Insight 1: Revolutionizing the Automotive Parts Industry

4D printing is set to revolutionize the automotive parts industry in South Florida by providing innovative solutions for prototyping and testing. This cutting-edge technology allows for the creation of complex, self-transforming structures that can adapt and respond to external stimuli, such as temperature, humidity, or pressure. Unlike traditional 3D printing, which produces static objects, 4D printing enables the production of parts that can change shape or function over time.

With the ability to create parts that are not only functional but also dynamic, 4D printing opens up new possibilities for automotive parts design and manufacturing. This technology allows for the creation of parts that can self-assemble, self-repair, or even self-diagnose issues, leading to improved performance and longevity of automotive components.

Insight 2: Enhanced SEO Opportunities for Automotive Parts Manufacturers

4D printing not only offers advancements in automotive parts production but also presents unique opportunities for boosting search engine optimization (SEO) for manufacturers in South Florida. By incorporating 4D printing technology into their prototyping and testing processes, automotive parts manufacturers can differentiate themselves from competitors and attract a larger online audience.

One of the key factors in SEO is the generation of high-quality and relevant content. With 4D printing, automotive parts manufacturers can create engaging and interactive content that showcases their innovative capabilities. This could include videos or interactive simulations demonstrating the transformation capabilities of 4D printed parts. By incorporating these elements into their website and online marketing strategies, manufacturers can increase their visibility in search engine results and attract more potential customers.

Furthermore, the unique nature of 4D printed parts can generate interest and curiosity among consumers, leading to increased organic traffic to manufacturers’ websites. This can result in higher click-through rates, longer time spent on the website, and ultimately, improved search engine rankings.

Insight 3: Improved User Experience and Conversion Rates

Another significant impact of 4D printing on SEO for South Florida’s automotive parts prototyping and testing is the potential for improved user experience and conversion rates. With the ability to create dynamic and functional parts, manufacturers can offer customers a more immersive and interactive experience.

By showcasing 4D printed parts on their websites, manufacturers can allow customers to explore and interact with the products virtually. This can include 360-degree views, animations, or even virtual reality experiences that simulate the functionality of the parts. Such interactive experiences not only engage and captivate users but also provide them with a better understanding of the product’s value and benefits.

When users have a positive experience on a website, they are more likely to stay longer, explore other products, and ultimately make a purchase. This can lead to higher conversion rates and increased sales for automotive parts manufacturers in South Florida. Additionally, positive user experiences and increased conversions can also contribute to improved SEO, as search engines prioritize websites with high user engagement and conversion rates.

4D printing has the potential to revolutionize the automotive parts industry in South Florida. By enabling the creation of dynamic and functional parts, manufacturers can not only improve the performance and longevity of automotive components but also enhance their SEO strategies. Incorporating 4D printing technology into prototyping and testing processes allows manufacturers to generate engaging content, attract a larger online audience, and provide users with immersive and interactive experiences. These advancements can lead to improved search engine rankings, increased organic traffic, and higher conversion rates, ultimately boosting the success of South Florida’s automotive parts prototyping and testing industry.

The Evolution of Automotive Parts Prototyping and Testing

Over the years, the automotive industry has witnessed significant advancements in the field of parts prototyping and testing. Traditionally, manufacturers relied on conventional methods such as injection molding and CNC machining to create prototypes for testing. However, these methods often proved to be time-consuming and expensive. The emergence of 3D printing revolutionized the prototyping process, allowing for faster and more cost-effective production of parts. Now, with the advent of 4D printing, the automotive industry in South Florida is experiencing yet another leap forward in parts prototyping and testing.

Understanding 4D Printing and its Benefits

4D printing takes the concept of 3D printing to the next level by incorporating materials that can self-assemble or transform in response to external stimuli such as heat, light, or moisture. This dynamic capability opens up a whole new world of possibilities for automotive parts prototyping and testing. For example, a 4D printed part could change its shape or functionality based on specific conditions, enhancing performance and efficiency. This technology not only improves the prototyping process but also has a significant impact on search engine optimization (SEO) for automotive businesses in South Florida.

Enhancing SEO through Unique and Customizable Parts

One of the key factors that contribute to a website’s SEO is the presence of unique and original content. With 4D printing, automotive businesses can create custom parts that are tailored to their specific needs. These unique parts can then be showcased on the company’s website, providing valuable content that attracts search engine attention. For example, a South Florida automotive parts manufacturer could create a 4D printed prototype of a specialized component and feature it on their website. This unique offering not only enhances the user experience but also increases the likelihood of higher search engine rankings.

Improving User Engagement and Dwell Time

Another crucial aspect of SEO is user engagement, which includes metrics such as dwell time (the amount of time a user spends on a webpage). By incorporating 4D printed prototypes into their website, automotive businesses can captivate visitors and encourage them to stay longer. For instance, a South Florida automotive parts retailer could create an interactive 4D model of a car engine that users can manipulate on their website. This engaging experience not only keeps users on the page for longer but also increases the likelihood of social sharing and backlinking, further boosting SEO.

Expanding Reach through Social Media and Viral Marketing

Social media platforms play a significant role in SEO, as search engines consider social signals when ranking websites. By leveraging the unique and captivating nature of 4D printed prototypes, automotive businesses in South Florida can generate viral marketing campaigns that attract attention on social media. For example, a local car dealership could create a 4D printed replica of a classic car and share it on platforms like Instagram and Facebook. The visually appealing and shareable nature of 4D printed prototypes increases the likelihood of viral content, leading to increased brand visibility and improved SEO.

Reducing Time-to-Market and Increasing Agility

Time-to-market is a critical factor in the highly competitive automotive industry. With 4D printing, South Florida automotive businesses can significantly reduce the time required to develop and test new parts. This increased agility allows companies to stay ahead of the competition and respond quickly to changing market demands. By incorporating 4D printed prototypes into their SEO strategy, businesses can showcase their ability to innovate and adapt, attracting both search engine attention and potential customers.

Case Study: XYZ Automotive – A Success Story in 4D Printing and SEO

To illustrate the impact of 4D printing on SEO for South Florida’s automotive parts prototyping and testing, let’s examine the case of XYZ Automotive. This local manufacturer embraced 4D printing technology and used it to create unique and customizable parts for their clients. By featuring these innovative prototypes on their website, XYZ Automotive saw a significant increase in organic search traffic and higher search engine rankings. The captivating nature of their 4D printed parts also led to viral social media campaigns, further boosting their online visibility and brand recognition. XYZ Automotive’s success story serves as a testament to the power of 4D printing in enhancing SEO for automotive businesses in South Florida.

Challenges and Future Prospects of 4D Printing in SEO

While 4D printing holds immense potential for boosting SEO in the automotive industry, there are also challenges that need to be addressed. The cost of 4D printing technology and materials can be prohibitive for some businesses, limiting its widespread adoption. Additionally, search engines are constantly evolving their algorithms, and it remains to be seen how they will adapt to the unique nature of 4D printed content. However, as the technology continues to mature and become more accessible, the future prospects for 4D printing in SEO look promising. South Florida’s automotive businesses can stay ahead of the curve by embracing this innovative technology and leveraging its benefits to enhance their online presence.

Case Study 1: XYZ Automotive Parts

XYZ Automotive Parts is a leading manufacturer of custom automotive components based in South Florida. They were facing challenges in prototyping and testing their parts, which were crucial for their business growth. Traditional manufacturing methods were time-consuming and expensive, often resulting in delays and increased costs.

However, XYZ Automotive Parts embraced 4D printing technology to revolutionize their prototyping and testing process. By using 4D printing, they were able to create parts with complex geometries and intricate designs that were not possible with traditional methods.

The impact on their SEO was significant. With their newfound ability to produce high-quality prototypes quickly, XYZ Automotive Parts could showcase their products on their website and optimize their SEO strategy. They created detailed product descriptions, high-resolution images, and videos of their 4D printed parts, attracting more traffic to their website.

As a result, XYZ Automotive Parts experienced a boost in their search engine rankings. They appeared higher on search engine results pages (SERPs) for relevant keywords, leading to increased visibility and organic traffic. This, in turn, translated into more leads and conversions for their business.

Case Study 2: ABC Motors

ABC Motors, a renowned car manufacturer in South Florida, was constantly seeking innovative ways to improve their prototyping and testing processes. They wanted to reduce the time and cost required to develop new car models while maintaining the highest standards of quality.

4D printing proved to be the solution they were looking for. By using 4D printing technology, ABC Motors could rapidly produce functional prototypes and test them extensively before committing to full-scale production.

The impact on their SEO was remarkable. ABC Motors utilized their website to showcase their cutting-edge 4D printed prototypes, highlighting their commitment to innovation and advanced manufacturing techniques. They optimized their website content with relevant keywords and provided detailed information about their 4D printing capabilities.

As a result, ABC Motors saw a significant improvement in their SEO rankings. They ranked higher on search engines for keywords related to automotive prototyping and testing, attracting a larger audience to their website. This increased online visibility translated into more inquiries from potential customers, ultimately boosting their sales and market share.

Case Study 3: DEF Research Institute

DEF Research Institute is a leading research institution in South Florida specializing in automotive engineering and technology. They were constantly exploring new ways to enhance their research capabilities and stay at the forefront of the industry.

4D printing presented an exciting opportunity for DEF Research Institute to advance their prototyping and testing efforts. With 4D printing, they could create dynamic and responsive prototypes that mimicked real-world conditions, allowing for more accurate testing and analysis.

The impact on their SEO was significant. DEF Research Institute leveraged their website to showcase their groundbreaking research and the applications of 4D printing in automotive parts prototyping and testing. They published detailed case studies, white papers, and reports on their website, positioning themselves as thought leaders in the field.

This strategic approach to SEO paid off for DEF Research Institute. They gained recognition as a go-to resource for information on 4D printing and its impact on automotive parts development. Their website’s search engine rankings improved, leading to increased website traffic and collaborations with industry partners.

Overall, these case studies demonstrate the positive impact of 4D printing on boosting SEO for South Florida’s automotive parts prototyping and testing industry. By embracing this innovative technology, companies and research institutions are not only revolutionizing their manufacturing processes but also enhancing their online visibility and attracting a larger audience to their websites.

The Emergence of 4D Printing

The concept of 4D printing, also known as dynamic or shape-shifting printing, emerged in the early 2010s as an extension of 3D printing technology. While 3D printing allowed for the creation of three-dimensional objects from digital designs, 4D printing took it a step further by introducing the element of time.

The idea behind 4D printing is that objects can be printed with materials that have the ability to change their shape or properties over time in response to external stimuli, such as heat, light, or moisture. This innovation opened up a whole new realm of possibilities for various industries, including automotive parts prototyping and testing.

Early Applications in Automotive Parts Prototyping

In the early stages of 4D printing, its applications in the automotive industry were primarily focused on prototyping. Traditional prototyping methods often involved lengthy and costly processes, such as machining or injection molding, which made it challenging to iterate and refine designs quickly.

With 4D printing, automotive manufacturers and designers gained the ability to create prototypes that could change their shape or functionality, allowing for more efficient testing and evaluation. For example, a 4D printed automotive part could be designed to adapt to different conditions, such as expanding or contracting based on temperature changes.

The Evolution of SEO and its Importance

Search Engine Optimization (SEO) has been a crucial aspect of digital marketing since the early days of the internet. As search engines became the primary method of discovering information online, businesses realized the need to optimize their websites to rank higher in search engine results pages (SERPs).

Over time, SEO techniques and strategies evolved as search engines, particularly Google, introduced new algorithms and ranking factors. The focus shifted from keyword stuffing and backlink quantity to quality content, user experience, and relevance. The goal became providing valuable information to users and ensuring that websites were easily discoverable.

The Intersection of 4D Printing and SEO

As 4D printing technology advanced and gained traction in the automotive industry, the need for effective marketing and visibility of these innovative products became apparent. This is where the intersection of 4D printing and SEO comes into play.

South Florida, known for its thriving automotive industry, became a hub for 4D printing in the prototyping and testing of automotive parts. Local businesses and manufacturers recognized the potential of leveraging SEO strategies to boost their online presence and attract customers.

Current State: Boosting SEO for South Florida’s Automotive Parts Prototyping and Testing

In the current state, South Florida’s automotive parts prototyping and testing industry has embraced the importance of SEO in promoting their 4D printing capabilities. Companies have invested in optimizing their websites, creating valuable content, and implementing effective SEO techniques to improve their rankings in search engine results.

By focusing on relevant keywords, creating informative blog posts, and optimizing their website structure, these businesses have been able to increase their visibility in search engine results. This enhanced visibility has not only attracted local customers but also garnered attention from a global audience interested in the cutting-edge technology of 4D printing for automotive parts.

Furthermore, the use of 4D printing in automotive parts prototyping and testing has provided an additional advantage in terms of SEO. The dynamic and innovative nature of 4D printed parts has generated interest from automotive enthusiasts, researchers, and industry professionals. This increased attention has resulted in more backlinks, social media mentions, and overall online visibility, further boosting SEO efforts.

Looking ahead, the intersection of 4D printing and SEO in South Florida’s automotive industry is likely to continue evolving. As 4D printing technology advances and becomes more accessible, businesses will need to stay at the forefront of SEO strategies to maintain a competitive edge in the online market.

Understanding 4D Printing

4D printing is a revolutionary manufacturing process that takes 3D printing to the next level. While 3D printing allows for the creation of three-dimensional objects, 4D printing adds an additional dimension: time. This means that the printed object can change its shape or properties over time in response to external stimuli, such as temperature, moisture, or light.

The Benefits of 4D Printing for Automotive Parts Prototyping and Testing

When it comes to prototyping and testing automotive parts, 4D printing offers several significant advantages over traditional manufacturing methods. Here are some key benefits:

Design Flexibility

With 4D printing, designers have unparalleled flexibility in creating complex geometries and intricate structures. Traditional manufacturing methods often have limitations when it comes to producing intricate designs, but 4D printing allows for the creation of parts with intricate internal structures that can self-assemble or change shape when activated.

Cost and Time Efficiency

By using 4D printing for prototyping and testing, automotive companies can significantly reduce both the cost and time required for production. Traditional prototyping methods often involve multiple iterations and expensive tooling, whereas 4D printing allows for rapid prototyping and on-demand production, eliminating the need for costly tooling and reducing lead times.

Customization and Personalization

One of the most exciting aspects of 4D printing is its ability to create customized and personalized parts. With traditional manufacturing methods, producing custom parts can be time-consuming and expensive. However, 4D printing enables the production of parts that can adapt to specific user requirements or environmental conditions, providing a level of customization and personalization that was previously unattainable.

Improved Functionality

4D printed automotive parts can have enhanced functionality compared to their traditional counterparts. For example, a 4D printed air intake duct can adjust its shape in response to changes in airflow, optimizing performance and fuel efficiency. This ability to adapt and respond to external stimuli can lead to improved overall functionality and performance of automotive parts.

Boosting SEO with 4D Printed Automotive Parts Prototyping and Testing

While the benefits of 4D printing for automotive parts prototyping and testing are clear, how does it relate to boosting SEO specifically for South Florida’s automotive industry? Here’s how:

Increased Online Visibility

By adopting 4D printing for prototyping and testing, automotive companies in South Florida can showcase their innovative capabilities and cutting-edge technology. This can attract attention from potential customers, industry experts, and media outlets, resulting in increased online visibility. As more people discover and share the unique aspects of 4D printing, it can lead to higher search engine rankings and increased organic traffic to the company’s website.

Industry Leadership and Reputation

Being at the forefront of 4D printing technology can position automotive companies in South Florida as industry leaders. By leveraging this advanced manufacturing process, companies can establish themselves as innovators and experts in their field. This can enhance their reputation and credibility, attracting more customers and partners, and ultimately improving their SEO rankings.

Content Generation and Link Building

4D printing provides a wealth of content generation opportunities. Companies can create blog posts, videos, and case studies highlighting their 4D printed automotive parts and their benefits. This content can be shared on social media platforms, industry forums, and other relevant websites, generating backlinks and increasing the company’s online presence. The more high-quality backlinks a website has, the higher its SEO ranking is likely to be.

Keyword Optimization

With the rise of 4D printing in the automotive industry, there is a growing demand for information related to this topic. By conducting keyword research and optimizing their website content, companies can ensure that they are targeting relevant keywords that potential customers are searching for. This can help improve their SEO rankings and drive organic traffic to their website.

Local SEO Advantage

For automotive companies in South Florida, implementing 4D printing for prototyping and testing can provide a competitive advantage in local SEO. By incorporating location-specific keywords and optimizing their online presence for local search, companies can attract customers who are specifically looking for 4D printed automotive parts in the South Florida area. This targeted approach can lead to higher conversion rates and increased visibility in local search results.

4D printing has the potential to revolutionize the automotive industry, particularly in the realm of prototyping and testing. By leveraging the benefits of 4D printing, automotive companies in South Florida can not only enhance their manufacturing processes but also boost their SEO efforts. Increased online visibility, industry leadership, content generation, keyword optimization, and local SEO advantages are some of the ways in which 4D printing can contribute to improving SEO for South Florida’s automotive parts prototyping and testing sector.

FAQs

1. What is 4D printing and how does it differ from 3D printing?

4D printing is an emerging technology that takes 3D printing to the next level by adding the dimension of time. While 3D printing creates static objects layer by layer, 4D printing involves printing objects that can change shape or function over time in response to external stimuli, such as heat, moisture, or light.

2. How can 4D printing boost SEO for automotive parts prototyping and testing?

By incorporating 4D printing into the prototyping and testing process, automotive parts manufacturers in South Florida can create more efficient and innovative designs. This can lead to improved product performance, increased customer satisfaction, and ultimately higher search engine rankings as a result of positive user feedback and online reviews.

3. What are the advantages of using 4D printing in automotive parts prototyping?

One major advantage of using 4D printing in automotive parts prototyping is the ability to create complex and customizable designs that were previously not possible with traditional manufacturing methods. This can lead to lighter, more durable, and more functional parts, which can enhance the overall performance of vehicles.

4. Can you provide some examples of how 4D printing can be applied in automotive parts prototyping and testing?

Certainly! Some examples of how 4D printing can be applied in automotive parts prototyping and testing include creating self-adjusting aerodynamic components, shape-shifting interior panels for improved ergonomics, and adaptive suspension systems that automatically adjust to road conditions.

5. How does 4D printing impact the SEO of automotive parts manufacturers in South Florida?

Integrating 4D printing into the prototyping and testing process can result in the development of cutting-edge automotive parts that differentiate South Florida manufacturers from their competitors. This can lead to increased website traffic, higher conversion rates, and improved search engine rankings, as search engines prioritize websites with unique and valuable content.

6. Are there any challenges or limitations to using 4D printing in automotive parts prototyping?

While 4D printing offers numerous benefits, there are still some challenges and limitations to consider. These include the high cost of materials and equipment, the need for specialized expertise, and the time-consuming nature of the printing process. However, as the technology continues to advance, these challenges are expected to diminish.

7. How can automotive parts manufacturers in South Florida incorporate 4D printing into their SEO strategy?

To incorporate 4D printing into their SEO strategy, automotive parts manufacturers in South Florida should focus on creating high-quality content that highlights their innovative use of the technology. This can include blog posts, case studies, and videos showcasing the benefits and applications of 4D printed parts. Additionally, actively engaging with customers and industry influencers through social media can help increase brand visibility and attract organic backlinks.

8. Can 4D printing help South Florida automotive parts manufacturers attract more customers?

Absolutely! By leveraging the unique capabilities of 4D printing, South Florida automotive parts manufacturers can differentiate themselves in the market and attract more customers. The ability to offer innovative and customizable products can be a major selling point for customers looking for high-performance automotive parts.

9. What are the potential long-term benefits of using 4D printing in automotive parts prototyping and testing?

The long-term benefits of using 4D printing in automotive parts prototyping and testing are significant. These include reduced development time, improved product functionality, increased sustainability through the use of lighter materials, and enhanced customer satisfaction. Additionally, the ability to quickly iterate and refine designs can result in cost savings and a competitive advantage in the market.

10. Is 4D printing widely adopted in the automotive industry?

While 4D printing is still in its early stages, it is gaining traction in the automotive industry. Major automotive manufacturers and research institutions are exploring the potential of 4D printing for various applications, including prototyping and production. As the technology continues to mature and become more accessible, we can expect to see wider adoption in the coming years.

Common Misconceptions about the Impact of 4D Printing on Boosting SEO for South Florida’s Automotive Parts Prototyping and Testing

Misconception 1: 4D printing will revolutionize SEO for automotive parts prototyping and testing

One common misconception about 4D printing is that it will completely revolutionize search engine optimization (SEO) for automotive parts prototyping and testing in South Florida. While 4D printing is an innovative technology with the potential to transform various industries, including automotive manufacturing, its impact on SEO is often exaggerated.

4D printing refers to the process of creating objects that can transform or self-assemble over time. It involves the use of materials that can change their shape or properties in response to external stimuli, such as heat, light, or humidity. This technology has the potential to enhance the efficiency and effectiveness of prototyping and testing processes in the automotive industry.

However, when it comes to SEO, the impact of 4D printing is limited. SEO primarily focuses on optimizing websites and online content to improve their visibility and ranking in search engine results. While 4D printing may improve the efficiency of automotive parts prototyping and testing, it does not directly influence SEO strategies or techniques.

Misconception 2: 4D printing will significantly boost website traffic for automotive parts manufacturers in South Florida

Another common misconception is that 4D printing will lead to a significant increase in website traffic for automotive parts manufacturers in South Florida. While 4D printing can certainly enhance the production process and product development, it does not guarantee a direct boost in website traffic or online visibility.

Website traffic is influenced by various factors, such as the quality of content, website design, user experience, and effective SEO strategies. While innovative technologies like 4D printing can attract attention and generate interest, they do not automatically translate into increased website traffic.

It is important for automotive parts manufacturers in South Florida to focus on comprehensive digital marketing strategies, including SEO, content marketing, social media marketing, and online advertising, to drive targeted traffic to their websites. While 4D printing may be a valuable tool for product development, it should be complemented with effective digital marketing efforts to maximize its impact on website traffic.

Misconception 3: Implementing 4D printing will guarantee higher search engine rankings for automotive parts manufacturers in South Florida

A common misconception is that implementing 4D printing technology will automatically result in higher search engine rankings for automotive parts manufacturers in South Florida. While innovative technologies can certainly contribute to a company’s overall competitiveness and reputation, search engine rankings are influenced by a multitude of factors.

Search engine algorithms consider various elements when determining website rankings, such as relevant keywords, quality backlinks, user engagement metrics, website speed, mobile optimization, and overall website authority. While 4D printing may contribute to the development of high-quality products, it does not directly impact these factors that influence search engine rankings.

Automotive parts manufacturers in South Florida should focus on implementing comprehensive SEO strategies that encompass keyword research, on-page optimization, link building, and user experience optimization. While 4D printing may be a valuable addition to their production processes, it should not be solely relied upon as a means to achieve higher search engine rankings.

Conclusion

4D printing has the potential to revolutionize the automotive parts prototyping and testing industry in South Florida. By combining the benefits of 3D printing with the ability to create self-transforming objects, 4D printing offers a new level of innovation and efficiency. This technology allows for the creation of complex and customizable parts that can adapt to their environment, improving overall performance and reducing the need for multiple prototypes.

Furthermore, the integration of 4D printing with search engine optimization (SEO) strategies can significantly boost the visibility and online presence of automotive parts manufacturers in South Florida. By optimizing their websites with relevant keywords and content related to 4D printing, these companies can attract a broader audience and increase their chances of being discovered by potential clients. Additionally, incorporating 4D printing into their prototyping and testing processes can enhance the speed and accuracy of product development, allowing businesses to stay ahead of the competition.