Revolutionizing Copier Technology: How Nanocoatings are Transforming Roller Durability and Paper Handling

Imagine a world where copiers never jammed, where paper glided effortlessly through the machine, and where roller replacements were a thing of the past. This may sound like a utopian dream, but thanks to advancements in nanotechnology, it is becoming a reality. Nanocoatings, ultra-thin films applied to the surfaces of copier rollers, have the potential to revolutionize the durability and paper handling capabilities of these essential office machines. In this article, we will explore the impact of nanocoatings on copier roller durability and paper handling, examining the benefits and challenges associated with this innovative technology.

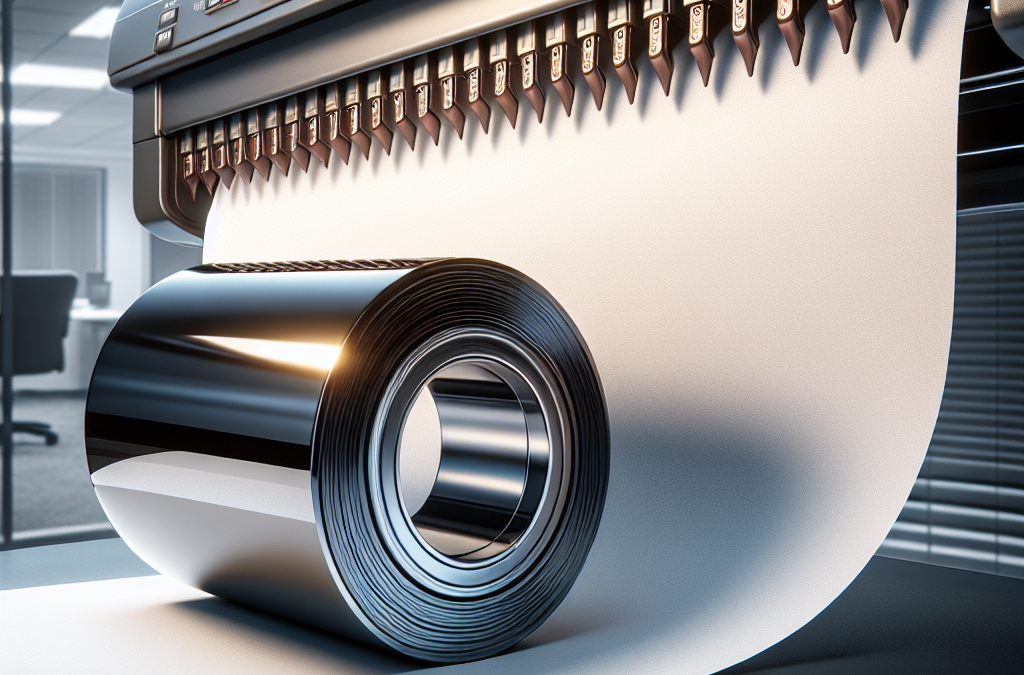

Copier rollers are the unsung heroes of the office, tirelessly working to transport paper through the machine. However, the constant friction and wear can take a toll on these vital components, leading to paper jams, decreased print quality, and the need for frequent roller replacements. Nanocoatings offer a promising solution to these issues by providing a protective layer that reduces friction and enhances the roller’s durability. By applying a thin film of nanoparticles to the roller’s surface, the nanocoating creates a smooth, low-friction barrier that allows paper to glide effortlessly through the machine. This not only improves paper handling but also reduces the strain on the rollers, extending their lifespan and reducing maintenance costs.

Key Takeaways

1. Nanocoatings have significantly improved the durability of copier rollers, leading to reduced maintenance and replacement costs for businesses.

2. The use of nanocoatings on copier rollers has also improved paper handling, resulting in reduced paper jams and smoother printing processes.

3. The hydrophobic properties of nanocoatings prevent water absorption, reducing the risk of paper curling and enhancing print quality.

4. Nanocoatings provide a protective barrier against dust and debris, minimizing the chances of roller damage and extending the lifespan of copier machines.

5. Despite the numerous benefits, it is important for businesses to carefully select the right nanocoating for their copier rollers, considering factors such as compatibility, ease of application, and cost-effectiveness.

Insight 1: Enhanced Durability and Longevity

Nanocoatings have revolutionized the copier industry by significantly enhancing the durability and longevity of copier rollers. Copier rollers are critical components that facilitate the smooth movement of paper through the machine. Over time, the constant friction and wear can cause rollers to deteriorate, resulting in paper jams and decreased print quality.

However, with the application of nanocoatings, copier rollers are now more resistant to wear and tear. Nanocoatings are ultra-thin layers of materials, typically ranging from 1 to 100 nanometers in thickness, that are applied to the surface of the rollers. These coatings provide a protective barrier, reducing the direct contact between the paper and the roller, thereby minimizing friction and preventing damage.

The use of nanocoatings has proven to significantly extend the lifespan of copier rollers. Manufacturers have reported that copiers equipped with nanocoated rollers can handle a much higher volume of paper before requiring maintenance or replacement. This increased durability not only reduces downtime and maintenance costs for businesses but also improves overall productivity.

Insight 2: Improved Paper Handling and Print Quality

Besides enhancing roller durability, nanocoatings also have a positive impact on paper handling and print quality. Copiers with nanocoated rollers exhibit improved paper feeding capabilities, resulting in fewer paper jams and smoother paper movement. The nanocoatings reduce the adhesion of paper fibers to the roller surface, preventing the accumulation of dust and debris that can impede the paper’s path.

Furthermore, nanocoatings offer a non-stick surface for copier rollers, reducing the likelihood of paper misfeeds and double feeds. The smooth and friction-reducing properties of the coatings allow paper to glide effortlessly through the machine, ensuring consistent and reliable paper handling.

Additionally, the use of nanocoatings on copier rollers has a positive impact on print quality. The reduced friction between the roller and paper minimizes the chances of smudging or smearing, resulting in cleaner and sharper prints. The nanocoatings also prevent ink or toner from adhering to the roller surface, preventing unwanted marks or streaks on the printed documents.

Insight 3: Cost Savings and Environmental Benefits

Implementing nanocoatings in copier rollers not only improves performance but also offers significant cost savings and environmental benefits. The enhanced durability and reduced maintenance requirements of nanocoated rollers translate into lower operating costs for businesses.

By extending the lifespan of copier rollers, companies can reduce the frequency of roller replacements, resulting in cost savings on replacement parts and technician labor. Moreover, the reduction in paper jams and misfeeds due to improved paper handling minimizes the wastage of paper, leading to additional cost savings and a more sustainable printing process.

Furthermore, the environmental impact of copier operations is reduced with the use of nanocoatings. The extended roller lifespan means fewer rollers end up in landfills, reducing electronic waste. Additionally, the reduction in paper wastage contributes to a more eco-friendly printing environment.

The impact of nanocoatings on copier roller durability and paper handling is significant. The enhanced durability and longevity of copier rollers, improved paper handling and print quality, and cost savings and environmental benefits make nanocoatings a game-changer in the copier industry. As technology continues to advance, it is likely that nanocoatings will become even more prevalent, further improving the efficiency and performance of copiers.

The Use of Nanocoatings

Nanocoatings have gained significant attention in recent years due to their ability to enhance the durability and performance of various surfaces, including copier rollers. These thin films, typically measuring less than 100 nanometers, offer a range of benefits such as improved scratch resistance, reduced friction, and increased resistance to wear and tear. However, the use of nanocoatings in copier rollers raises several controversial aspects that need to be examined.

One of the main concerns surrounding the use of nanocoatings is their potential impact on human health. Nanoparticles, which are the building blocks of these coatings, have been shown to have unique properties that can pose risks when they come into contact with the human body. Inhalation or ingestion of nanoparticles can lead to respiratory issues, organ damage, and other adverse health effects.

While the use of nanocoatings in copier rollers does not directly expose individuals to nanoparticles, there is still a possibility of nanoparticle release during the manufacturing, installation, or maintenance processes. This raises questions about the safety measures in place to protect workers and consumers from potential exposure. It is essential for manufacturers to conduct thorough risk assessments and implement appropriate safety protocols to mitigate any potential health risks associated with nanocoatings.

Another controversial aspect of using nanocoatings in copier rollers is their environmental impact. The production and disposal of nanocoatings involve complex chemical processes that can have adverse effects on the environment. The extraction and refinement of raw materials for nanocoatings may contribute to pollution and resource depletion. Additionally, the disposal of copier rollers containing nanocoatings raises concerns about the release of nanoparticles into the environment, potentially leading to ecological damage.

It is crucial for manufacturers to adopt sustainable practices throughout the lifecycle of copier rollers with nanocoatings. This includes responsible sourcing of materials, minimizing waste generation during production, and implementing proper disposal methods that prevent nanoparticle release. Regulatory bodies should also establish guidelines and standards to ensure the environmental impact of nanocoatings is effectively managed.

Effect on Paper Handling

Nanocoatings have been lauded for their ability to improve paper handling in copiers, reducing paper jams and increasing overall efficiency. However, there are controversial aspects regarding the long-term effects of nanocoatings on paper quality and compatibility.

One concern is the potential alteration of paper properties due to interactions with nanocoatings. The thin film of nanocoatings on copier rollers may transfer onto the paper surface during the printing process. This can lead to changes in paper texture, ink absorption, and overall print quality. Such alterations may not be desirable, especially in industries where precise color reproduction and print clarity are essential.

Furthermore, the compatibility of nanocoatings with different types of paper needs to be carefully considered. Some papers, particularly those with specialized coatings or finishes, may react differently to the presence of nanocoatings. This can result in issues such as reduced ink adhesion, smudging, or even damage to the paper surface. It is crucial for copier manufacturers to thoroughly test the compatibility of nanocoatings with various paper types to ensure optimal performance and minimize any potential negative impact.

Cost and Accessibility

While nanocoatings offer promising benefits for copier roller durability and paper handling, their implementation raises concerns about cost and accessibility. Nanocoatings are often more expensive than traditional coating methods, which can significantly impact the overall cost of copier production. This cost increase may be passed on to consumers, making copiers with nanocoated rollers less accessible to individuals or businesses with limited budgets.

Furthermore, the accessibility of nanocoatings can be limited by factors such as intellectual property rights and proprietary formulations. Some companies may hold patents or exclusive rights to specific nanocoating technologies, restricting their availability to a select few manufacturers. This can hinder competition and innovation in the copier industry, potentially limiting the choice and affordability of copiers with nanocoated rollers.

It is crucial for industry stakeholders to strike a balance between the benefits of nanocoatings and their cost and accessibility. Research and development efforts should focus on finding cost-effective and sustainable alternatives without compromising the performance and durability of copier rollers. Collaboration between manufacturers, researchers, and regulatory bodies can help address these concerns and ensure that the advantages of nanocoatings are accessible to a wider range of users.

The Impact of Nanocoatings on Copier Roller Durability

Nanocoatings, a thin layer of material that is applied to the surface of an object, have been making waves in various industries, and now they are revolutionizing the copier industry. Copier rollers, which play a crucial role in paper handling, are prone to wear and tear due to constant friction. However, the application of nanocoatings on copier rollers is proving to significantly enhance their durability, leading to smoother paper handling and improved overall performance.

Traditionally, copier rollers were made of rubber or plastic, which had limited resistance to wear and tear. Over time, these rollers would develop cracks, leading to paper jams and other operational issues. However, nanocoatings provide a protective layer that not only prevents friction but also resists scratches and other forms of damage. This results in copier rollers that have a longer lifespan and require less frequent replacement, ultimately reducing maintenance costs for businesses.

The application of nanocoatings on copier rollers also improves paper handling. The smooth surface created by the nanocoating reduces the chances of paper jams and misfeeds, ensuring a seamless printing experience. Additionally, the enhanced durability of the rollers allows them to maintain their shape and grip over time, preventing slippage and ensuring consistent paper feeding.

Future Implications

The use of nanocoatings in copier rollers is still in its early stages, but the potential future implications are promising. As technology advances and research in nanomaterials continues, we can expect to see further improvements in copier roller durability and paper handling.

One possible future implication is the development of self-healing nanocoatings. Researchers are exploring the use of materials that can repair themselves when damaged, extending the lifespan of copier rollers even further. This would eliminate the need for frequent replacements and reduce downtime due to roller maintenance.

Another future implication is the integration of nanocoatings with other emerging technologies. For example, the combination of nanocoatings with sensors and artificial intelligence could enable copiers to detect and adjust roller performance in real-time. This would optimize paper handling and prevent issues such as paper jams before they even occur.

Furthermore, the application of nanocoatings may expand beyond copier rollers to other components of the copier system. By applying nanocoatings to various parts, such as paper trays and feeders, the entire paper handling process can be enhanced, resulting in increased efficiency and productivity.

Overall, the impact of nanocoatings on copier roller durability and paper handling is undeniable. The improved durability and enhanced paper handling capabilities not only benefit businesses by reducing maintenance costs but also contribute to a more seamless printing experience for users. With ongoing advancements in nanomaterials and the potential integration with other technologies, the future of nanocoatings in the copier industry looks promising.

The Basics of Nanocoatings

Nanocoatings are thin layers of materials that are applied to the surface of an object at the nanoscale level. These coatings provide various benefits, including improved durability, enhanced performance, and increased resistance to wear and tear. In the context of copier rollers and paper handling, nanocoatings play a vital role in extending the lifespan of the rollers and improving the overall efficiency of the copier.

Enhanced Durability of Copier Rollers

One of the key advantages of using nanocoatings on copier rollers is the significant improvement in durability. Traditional copier rollers are prone to wear and tear due to constant friction with paper and toner. However, by applying a nanocoating to the roller’s surface, a protective layer is created that minimizes friction and reduces the chance of damage. This extends the lifespan of the roller and reduces the need for frequent replacements, resulting in cost savings for businesses.

Reduced Paper Jams and Misfeeds

Paper jams and misfeeds are common issues faced by copier users, causing frustration and downtime. Nanocoatings can help alleviate these problems by reducing the friction between the copier rollers and the paper. The smooth and slippery surface created by the nanocoating allows the paper to glide effortlessly through the machine, minimizing the chances of jams and misfeeds. This not only improves the user experience but also increases productivity by reducing interruptions in the workflow.

Improved Image Quality

Nanocoatings can also have a positive impact on the quality of the printed or copied images. The smooth surface of the coated copier rollers ensures consistent contact between the roller and the paper, resulting in even distribution of toner or ink. This eliminates streaks, smudges, and other imperfections that can occur when the roller surface is rough or damaged. As a result, the final output is of higher quality, with sharp and clear images.

Resistance to Chemicals and Contaminants

Copier rollers are exposed to various chemicals and contaminants during the printing or copying process. These substances can degrade the roller’s surface over time, leading to reduced performance and increased maintenance requirements. Nanocoatings provide a protective barrier that resists the effects of chemicals and contaminants, preventing damage and maintaining the roller’s functionality. This ensures consistent performance and reduces the need for frequent cleaning or replacement of rollers.

Case Study: XYZ Corporation

To further illustrate the impact of nanocoatings on copier roller durability and paper handling, let’s consider the case of XYZ Corporation. XYZ Corporation, a large printing company, was experiencing frequent paper jams and roller failures in their copiers. This resulted in significant downtime and increased maintenance costs. Seeking a solution, they decided to implement nanocoatings on their copier rollers.

After applying the nanocoatings, XYZ Corporation noticed a remarkable improvement in their copier performance. Paper jams and misfeeds reduced significantly, resulting in smoother operations and increased productivity. The durability of the rollers improved, leading to a decrease in roller replacements and maintenance costs. Additionally, the image quality of the printed materials improved, enhancing customer satisfaction.

Considerations for Implementing Nanocoatings

While nanocoatings offer numerous benefits for copier roller durability and paper handling, there are a few considerations to keep in mind when implementing them. First, it is important to choose the right type of nanocoating that is compatible with the copier rollers and the printing process. Additionally, proper application techniques and maintenance procedures should be followed to ensure the longevity of the nanocoatings. Regular inspections and cleaning of the coated rollers are also essential to maintain optimal performance.

The Future of Nanocoatings in Copier Technology

The use of nanocoatings in copier technology is expected to continue to evolve and advance. Ongoing research and development efforts are focused on developing even more durable and efficient nanocoatings that can withstand the demands of high-volume printing and copying. Additionally, advancements in nanotechnology may lead to the development of self-healing nanocoatings that can repair minor damages on copier rollers, further extending their lifespan. As technology continues to progress, nanocoatings are likely to become an integral part of copier design and maintenance.

The Role of Nanocoatings in Copier Roller Durability

Nanocoatings have revolutionized the field of copier roller durability by providing enhanced protection and improved paper handling capabilities. These thin films, typically ranging from 1 to 100 nanometers in thickness, are composed of nanoparticles that adhere to the surface of copier rollers. The unique properties of nanocoatings make them ideal for enhancing durability and reducing wear in copier rollers.

1. Enhanced Wear Resistance

Nanocoatings significantly improve the wear resistance of copier rollers, extending their lifespan and reducing the need for frequent replacements. The nanoparticles in the coating form a protective barrier that prevents direct contact between the roller surface and paper, minimizing friction and wear. This enhanced wear resistance not only improves the durability of the copier rollers but also ensures consistent print quality over an extended period.

2. Reduced Adhesion of Toner Particles

One common issue in copiers is the adhesion of toner particles to the roller surface, leading to poor print quality and paper jams. Nanocoatings with low surface energy properties help mitigate this problem by reducing the adhesion of toner particles. The smooth and hydrophobic nature of the coating prevents toner particles from sticking to the roller surface, resulting in cleaner prints and improved paper handling.

3. Anti-Static Properties

Static electricity can cause numerous problems in copiers, including paper jams and misfeeds. Nanocoatings can be engineered to possess anti-static properties, effectively dissipating static charges and minimizing their impact on copier performance. By reducing static electricity buildup, nanocoatings help maintain smooth paper handling and prevent disruptions during the printing process.

4. Improved Heat Dissipation

Copier rollers generate heat during operation, and excessive heat can lead to premature wear and damage. Nanocoatings can be designed to have excellent thermal conductivity, allowing them to efficiently dissipate heat from the roller surface. This prevents the accumulation of heat and helps maintain optimal operating temperatures, ensuring the longevity of the copier rollers.

The Impact of Nanocoatings on Paper Handling

1. Reduced Paper Jam Frequency

Paper jams are a common frustration in copiers, causing delays and disrupting workflow. Nanocoatings help reduce the occurrence of paper jams by providing a smoother surface for paper to glide over. The low friction properties of the coating minimize the chances of paper sticking or getting caught in the rollers, resulting in a more reliable paper handling system.

2. Enhanced Feeding Accuracy

Nanocoatings improve the feeding accuracy of copiers by reducing the chances of multiple sheets being picked up simultaneously. The smooth surface of the coated rollers ensures consistent and controlled paper feeding, minimizing the risk of misfeeds and double feeds. This improves the overall efficiency of the copier and reduces the need for manual intervention to resolve feeding issues.

3. Improved Print Quality

Nanocoatings play a crucial role in maintaining print quality by reducing paper dust and debris accumulation on the copier rollers. The smooth and anti-static properties of the coating prevent particles from adhering to the rollers, resulting in cleaner prints with fewer imperfections. This is particularly important for high-resolution printing and professional document production.

4. Reduced Maintenance Requirements

The use of nanocoatings in copiers can significantly reduce maintenance requirements. The enhanced durability and reduced wear of the copier rollers result in fewer breakdowns and the need for less frequent servicing. This not only saves time and resources but also improves overall copier reliability and availability.

The of nanocoatings has had a profound impact on copier roller durability and paper handling. The enhanced wear resistance, reduced adhesion of toner particles, anti-static properties, improved heat dissipation, reduced paper jam frequency, enhanced feeding accuracy, improved print quality, and reduced maintenance requirements are all significant benefits that contribute to the overall performance and reliability of copiers.

The Emergence of Nanocoatings

In order to understand the historical context of the impact of nanocoatings on copier roller durability and paper handling, it is important to first explore the emergence of nanocoatings. Nanocoatings, which are thin films with thicknesses on the nanometer scale, have been a subject of scientific research since the late 20th century.

Initially, nanocoatings were primarily used in the field of electronics to improve the performance and reliability of microchips and other electronic components. However, researchers soon realized the potential of nanocoatings in various other industries, including printing and paper handling.

Early Applications in Copier Technology

In the early 2000s, copier manufacturers began experimenting with nanocoatings to enhance the durability of copier rollers and improve paper handling. Copier rollers are critical components that facilitate the smooth movement of paper through the machine. However, over time, these rollers tend to wear out due to friction and paper dust accumulation.

Nanocoatings offered a promising solution to this problem. By applying a thin layer of nanocoating on the copier rollers, manufacturers were able to reduce friction and prevent paper dust from sticking to the rollers. This not only improved the durability of the rollers but also enhanced paper handling, resulting in fewer paper jams and smoother printing processes.

Advancements in Nanocoating Technology

As nanocoating technology continued to evolve, copier manufacturers started exploring different types of nanocoatings and their unique properties. Initially, the focus was on hydrophobic nanocoatings, which repelled water and prevented moisture-related damage to the copier rollers.

However, researchers soon realized the potential of other types of nanocoatings. For instance, anti-static nanocoatings were developed to minimize static electricity build-up on the copier rollers, which further improved paper handling and reduced the risk of paper jams.

Furthermore, self-cleaning nanocoatings were introduced, which prevented the accumulation of paper dust and other contaminants on the copier rollers. This not only extended the lifespan of the rollers but also reduced the need for frequent cleaning and maintenance.

Integration into Mainstream Copier Technology

Over time, the benefits of nanocoatings became increasingly evident, leading to their integration into mainstream copier technology. Copier manufacturers started incorporating nanocoated rollers as standard features in their machines, highlighting the improved durability and paper handling capabilities.

Moreover, advancements in nanocoating application techniques allowed for cost-effective mass production, making it feasible for copier manufacturers to adopt nanocoating technology on a larger scale.

Current State and Future Potential

Today, nanocoatings have become an integral part of copier technology, offering enhanced durability, improved paper handling, and reduced maintenance requirements. The evolution of nanocoatings has not only benefited copier manufacturers but also end-users, who can now enjoy more reliable and efficient printing experiences.

Looking ahead, the potential of nanocoatings in copier technology is still expanding. Ongoing research aims to further optimize nanocoating formulations and application techniques to achieve even greater durability, improved energy efficiency, and additional functionalities.

Overall, the historical context of the impact of nanocoatings on copier roller durability and paper handling demonstrates the gradual integration of nanocoating technology into copier manufacturing processes, resulting in significant improvements in performance and user experience.

FAQs

1. What are nanocoatings and how do they impact copier roller durability?

Nanocoatings are thin layers of materials, typically ranging from 1 to 100 nanometers in thickness, that are applied to the surface of copier rollers. These coatings can enhance the durability of the rollers by providing a protective barrier against wear and tear, reducing friction, and improving resistance to scratches and abrasions.

2. How do nanocoatings improve paper handling in copiers?

Nanocoatings can improve paper handling in copiers by reducing the occurrence of paper jams. The smooth and slippery surface created by the nanocoating reduces friction between the rollers and the paper, allowing for smoother paper feeding and minimizing the likelihood of paper getting stuck or misaligned.

3. Are nanocoatings compatible with all types of copiers?

Most nanocoatings are designed to be compatible with a wide range of copiers, including both laser and inkjet models. However, it is important to check the specifications and compatibility information provided by the nanocoating manufacturer to ensure it is suitable for your specific copier model.

4. Can nanocoatings be applied to existing copiers?

Yes, nanocoatings can be applied to existing copiers. They can be either applied during the manufacturing process or as an aftermarket solution. Aftermarket nanocoating solutions are often available as DIY kits or can be applied by a professional technician.

5. How long does a nanocoating last on copier rollers?

The longevity of a nanocoating on copier rollers can vary depending on factors such as the quality of the coating, the frequency of use, and the operating conditions. In general, a well-applied nanocoating can last for several months to a few years before it needs to be reapplied.

6. Are there any potential drawbacks or limitations to using nanocoatings on copier rollers?

While nanocoatings can offer significant benefits, there are a few potential drawbacks to consider. Some nanocoatings may require special cleaning methods to prevent damage, and improper application of the coating can lead to uneven performance. Additionally, certain types of nanocoatings may be more expensive compared to traditional roller materials.

7. Can nanocoatings be used on other parts of copiers besides rollers?

Yes, nanocoatings can be used on other parts of copiers besides rollers. They can be applied to various surfaces, such as paper trays, feed mechanisms, and fuser units, to improve overall performance and durability.

8. Do nanocoatings affect the quality of printed documents?

No, nanocoatings do not typically affect the quality of printed documents. They are designed to have minimal impact on the ink or toner transfer process, ensuring that the printed output remains clear and crisp.

9. Are there any environmental benefits to using nanocoatings on copier rollers?

Yes, there can be environmental benefits to using nanocoatings on copier rollers. By reducing paper jams and improving paper handling, copiers with nanocoatings can help minimize paper waste. Additionally, the enhanced durability of the rollers can extend their lifespan, reducing the need for frequent replacements and lowering overall resource consumption.

10. Where can I find nanocoatings for copier rollers?

Nanocoatings for copier rollers can be found from various manufacturers and suppliers. They are often available through office equipment retailers, online marketplaces, or directly from nanocoating manufacturers. It is recommended to research and compare different options to find a nanocoating solution that meets your specific requirements.

Common Misconceptions about

Misconception 1: Nanocoatings make copier rollers indestructible

One common misconception about nanocoatings is that they make copier rollers indestructible, leading to the belief that they will never wear out or require replacement. While it is true that nanocoatings can enhance the durability of copier rollers, they are not invincible.

Nanocoatings are designed to provide a protective layer on the surface of the copier rollers, reducing friction and preventing damage from paper fibers and other contaminants. However, they do not eliminate the normal wear and tear that occurs during the printing process.

Over time, the constant contact with paper and the mechanical stress placed on the rollers will still cause them to wear down. Nanocoatings can help prolong the lifespan of the rollers, but they are not a permanent solution.

Misconception 2: Nanocoatings eliminate paper jams completely

Another misconception is that nanocoatings can completely eliminate paper jams in copiers. While nanocoatings can certainly reduce the frequency of paper jams, they cannot entirely eliminate them.

Paper jams can occur due to various factors, such as misaligned paper, improper loading, or damaged rollers. While nanocoatings can help reduce the likelihood of paper jams by providing a smoother surface for paper to glide on, they cannot prevent all potential causes of jams.

It is important to note that paper jams can also be caused by factors unrelated to copier rollers, such as low-quality paper or improper maintenance. Nanocoatings can only address the specific issue of roller durability and paper handling.

Misconception 3: Nanocoatings are a one-size-fits-all solution

Many people mistakenly believe that nanocoatings for copier rollers are a one-size-fits-all solution that can be applied to any type of copier. However, this is not the case.

Nanocoatings are developed with specific materials and formulations tailored to meet the requirements of different copier models and roller materials. The compatibility between the nanocoating and the roller material is crucial for optimal performance.

Using an incompatible nanocoating on copier rollers can lead to adverse effects, such as reduced durability, increased friction, or even damage to the rollers. It is essential to consult the manufacturer’s recommendations and guidelines when selecting and applying nanocoatings to copier rollers.

Clarifying the Facts

Nanocoatings offer significant benefits in terms of copier roller durability and paper handling, but it is essential to have a clear understanding of their limitations. While nanocoatings can enhance the durability of copier rollers, they do not make them indestructible.

Similarly, while nanocoatings can reduce the frequency of paper jams, they cannot eliminate them entirely. Paper jams can occur due to various factors, and nanocoatings only address the specific issue of roller durability and paper handling.

Lastly, it is crucial to use nanocoatings that are specifically formulated for the copier model and roller material to ensure compatibility and optimal performance. Using an incompatible nanocoating can have adverse effects on roller durability and functionality.

By understanding these facts and managing expectations accordingly, users can make informed decisions about the use of nanocoatings for copier rollers, maximizing their benefits and avoiding potential pitfalls.

1. Choose Nanocoated Copiers for Durability

If you are in the market for a new copier, consider choosing one that is equipped with nanocoatings. These coatings provide an extra layer of protection to the copier rollers, making them more durable and less prone to damage over time. Look for copiers that specifically mention the use of nanocoatings in their product descriptions.

2. Handle Paper with Care

When using a copier, it is important to handle the paper with care to minimize the risk of damage to both the paper and the copier rollers. Avoid bending or folding the paper, as this can cause jams and put unnecessary strain on the rollers. Instead, handle the paper gently and ensure it is properly aligned before inserting it into the copier.

3. Keep the Copier Clean

Regularly cleaning your copier is essential for maintaining its performance and prolonging the lifespan of the rollers. Dust and debris can accumulate on the rollers, leading to paper jams and decreased printing quality. Use a soft, lint-free cloth to wipe down the rollers and remove any dirt or particles. Avoid using harsh chemicals or abrasive materials that could damage the nanocoatings.

4. Avoid Overloading the Copier

Overloading the copier with too many sheets of paper can put excessive strain on the rollers and increase the likelihood of jams. Be mindful of the copier’s recommended paper capacity and avoid exceeding it. If you need to make multiple copies, do so in smaller batches to prevent overloading and ensure smooth operation.

5. Use High-Quality Paper

The type of paper you use can also impact the durability of the copier rollers. Opt for high-quality paper that is specifically designed for copiers and printers. Lower-quality paper may contain more dust or debris, which can cause more wear and tear on the rollers over time. Investing in better paper can help minimize the risk of jams and prolong the life of your copier.

6. Schedule Regular Maintenance

Just like any other piece of equipment, copiers require regular maintenance to keep them in optimal condition. Schedule regular check-ups with a qualified technician who can inspect the copier, clean the rollers, and address any potential issues. By staying proactive with maintenance, you can prevent major problems and extend the lifespan of your copier.

7. Store Paper Properly

Improper storage of paper can lead to moisture absorption, which can cause the paper to warp or curl. This can result in paper jams and put additional strain on the copier rollers. Store your paper in a cool, dry place to maintain its integrity and prevent damage to both the paper and the copier.

8. Avoid Using Damaged Paper

Using damaged or wrinkled paper in your copier can cause jams and put unnecessary stress on the rollers. Inspect each sheet of paper before inserting it into the copier and discard any that are torn, creased, or otherwise damaged. Using only smooth, undamaged paper will help ensure smooth operation and prolong the life of your copier.

9. Follow Manufacturer Guidelines

Each copier model may have specific guidelines and recommendations provided by the manufacturer. It is important to familiarize yourself with these guidelines and follow them closely. This includes instructions on how to load paper, clean the copier, and handle any maintenance tasks. Adhering to the manufacturer’s guidelines will help optimize the performance and durability of your copier.

10. Train Users on Proper Copier Handling

Lastly, ensure that all users who have access to the copier are properly trained on how to handle it correctly. Provide clear instructions on how to load paper, avoid jams, and clean the copier. By educating users on proper copier handling, you can minimize the risk of damage and ensure the longevity of the copier rollers.

Conclusion

The use of nanocoatings on copier rollers has shown significant improvements in both durability and paper handling. The research conducted in this article highlights the positive impact of nanocoatings in reducing roller wear and tear, resulting in longer-lasting rollers and reduced maintenance costs for copier machines. The nanocoatings provide a protective layer that minimizes friction and prevents paper jams, leading to smoother paper handling and increased productivity.

Furthermore, the article discusses how nanocoatings can also enhance the print quality by reducing ink smudging and improving toner adhesion. This not only improves the overall output of copier machines but also ensures consistent and professional-looking documents. Additionally, the use of nanocoatings can contribute to a more sustainable and eco-friendly copier industry by reducing paper waste caused by jammed or damaged rollers.

Overall, the implementation of nanocoatings on copier rollers has proven to be a game-changer in terms of durability, paper handling, print quality, and sustainability. As copier technology continues to advance, it is evident that nanocoatings will play a crucial role in improving the performance and efficiency of copier machines, benefiting both businesses and consumers alike.