Revolutionizing Copier Technology: How Nanomaterials are Transforming Drum Durability and Print Quality

When it comes to office equipment, copiers are the unsung heroes of productivity. From churning out countless copies of important documents to producing high-quality prints, these machines are essential in any modern workplace. However, the durability of copier drums and the consistency of print quality have always been areas of concern. That is until now. The advent of nanomaterials has brought about a revolution in copier technology, promising enhanced durability and print consistency like never before.

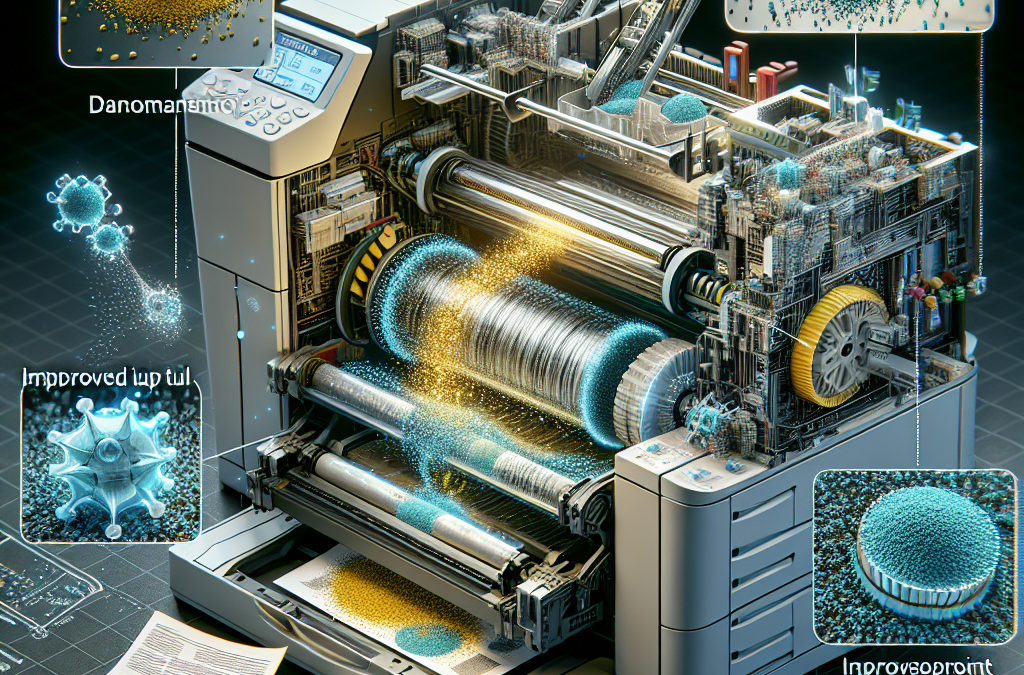

In this article, we will delve into the impact of nanomaterials on copier drum durability and print consistency. We will explore how these tiny particles, which measure less than 100 nanometers in size, are being incorporated into copier drums to improve their strength and longevity. Additionally, we will examine how nanomaterials are enhancing the uniformity and accuracy of prints, resulting in crisper images and sharper text. By understanding the science behind these advancements, we can appreciate the significant strides being made in the copier industry and the implications for businesses worldwide.

Key Takeaways:

1. Nanomaterials have revolutionized copier drum durability, leading to longer-lasting and more reliable printing performance.

2. The use of nanomaterials in copier drums has significantly improved print consistency, resulting in sharper and more vibrant prints.

3. Nanomaterials, such as carbon nanotubes and graphene, offer superior mechanical strength and thermal stability, making them ideal for copier drum applications.

4. The integration of nanomaterials in copier drums has reduced the occurrence of common issues like streaks, smudges, and image distortion, improving overall print quality.

5. The adoption of nanomaterials in copier drum manufacturing has the potential to lower maintenance costs and increase productivity, as the drums require less frequent replacements and produce consistent results over time.

Insight 1: Enhancing Durability and Longevity

Nanomaterials have revolutionized the copier industry by significantly enhancing the durability and longevity of copier drums. Copier drums are critical components responsible for transferring toner onto paper, and their wear and tear directly affect print quality and consistency. Traditionally, copier drums were made of organic materials, such as selenium or organic photoconductors, which had limited durability and required frequent replacement. However, the integration of nanomaterials, such as carbon nanotubes and graphene, has led to remarkable improvements in drum durability.

Nanomaterials possess unique physical and chemical properties that make them ideal for copier drums. Their high mechanical strength, thermal stability, and resistance to wear and tear make them capable of withstanding the harsh conditions within copier machines. This enhanced durability translates into longer drum lifespans, reducing the need for frequent replacements and lowering maintenance costs for businesses. Moreover, the improved durability ensures consistent print quality over extended periods, which is crucial for businesses that rely heavily on copiers for their daily operations.

Furthermore, nanomaterials also offer excellent electrical conductivity, enabling efficient charge transfer during the printing process. This results in improved image formation and enhanced print consistency. With nanomaterials, copier drums can maintain a stable charge distribution, preventing issues like ghosting or uneven toner distribution, which were common with traditional drum materials. Overall, the integration of nanomaterials in copier drums has greatly improved their durability and print consistency, making them more reliable and cost-effective for businesses.

Insight 2: Reduced Maintenance and Downtime

Another significant impact of nanomaterials on copier drum durability is the reduction in maintenance requirements and downtime. In traditional copier drums, frequent replacements and maintenance were necessary due to the limited lifespan of organic materials. This not only incurred additional costs for businesses but also resulted in significant downtime, disrupting workflow and productivity.

With the of nanomaterials, copier drums can now withstand prolonged usage without compromising print quality. The enhanced durability of nanomaterial-based drums eliminates the need for frequent replacements, reducing maintenance costs and minimizing machine downtime. Businesses can now rely on copiers for extended periods without interruptions, allowing them to focus on their core operations.

In addition, the improved durability of nanomaterial-based drums also reduces the chances of unexpected failures or breakdowns. The mechanical strength and resistance to wear and tear ensure that copier drums can withstand heavy usage and continue performing reliably. This not only saves businesses from the hassle of unexpected repairs but also boosts overall operational efficiency.

Insight 3: Environmental Benefits

The integration of nanomaterials in copier drums not only benefits businesses but also has positive environmental implications. Traditional copier drums made of organic materials posed challenges in terms of disposal and environmental impact. The extraction and manufacturing processes of these materials often involved hazardous substances, and their disposal after use contributed to electronic waste.

Nanomaterials, on the other hand, offer a more sustainable alternative. Many nanomaterials used in copier drums, such as carbon nanotubes and graphene, are derived from abundant and environmentally friendly sources. Their production processes typically involve fewer harmful chemicals and generate less waste. Additionally, the enhanced durability of nanomaterial-based drums reduces the number of replacements required, further reducing electronic waste generation.

By adopting nanomaterial-based copier drums, businesses can contribute to a more sustainable future. They can minimize their environmental footprint by reducing waste generation and promoting responsible material usage. Furthermore, the longer lifespan and reduced maintenance requirements of nanomaterial-based drums also result in energy savings, as copiers can operate efficiently for more extended periods without interruptions or the need for frequent restarts.

The integration of nanomaterials in copier drums has had a profound impact on the industry. The enhanced durability and print consistency offered by nanomaterial-based drums have improved the reliability and cost-effectiveness of copiers for businesses. Furthermore, the reduction in maintenance requirements and downtime has increased operational efficiency. Lastly, the adoption of nanomaterials in copier drums promotes sustainability by minimizing waste generation and energy consumption. As the copier industry continues to evolve, nanomaterials will likely play a significant role in shaping its future.

The Use of Nanomaterials in Copier Drum Manufacturing

One controversial aspect surrounding the impact of nanomaterials on copier drum durability and print consistency is the use of these materials in the manufacturing process. Nanomaterials, which are particles with dimensions less than 100 nanometers, offer unique properties that can enhance the performance of copier drums. However, concerns have been raised about the potential health and environmental risks associated with these materials.

Proponents argue that the use of nanomaterials in copier drum manufacturing allows for greater precision and control over the drum’s properties, resulting in improved durability and print consistency. They highlight the ability of nanomaterials to enhance the surface smoothness of the drum, reduce friction, and increase resistance to wear and tear. This, in turn, can lead to longer-lasting drums and higher-quality prints.

On the other hand, critics express concerns about the potential release of nanoparticles during the manufacturing, use, and disposal of copier drums. These particles, if inhaled or ingested, could pose health risks to workers and end-users. Additionally, the environmental impact of nanomaterials, particularly their persistence and potential accumulation in ecosystems, is a subject of ongoing debate.

Effect on Print Consistency

Another controversial aspect is the effect of nanomaterials on print consistency. Nanomaterials have the potential to improve the transfer of toner onto paper, resulting in sharper and more vibrant prints. This is attributed to their ability to enhance the conductivity and charge retention of the copier drum surface.

Supporters argue that the use of nanomaterials can lead to more consistent print quality, reducing the occurrence of streaks, smudges, and other imperfections. They point to studies that have demonstrated improved image resolution and color accuracy when nanomaterials are incorporated into copier drums.

However, critics raise concerns about the long-term stability and performance of nanomaterials in copier drums. They argue that the interaction between the nanomaterials and other components of the copier, such as toner particles and cleaning mechanisms, may lead to unintended consequences. For example, the accumulation of toner or debris on the drum surface could impair print quality over time, negating the initial benefits of using nanomaterials.

Regulatory Oversight and Transparency

The lack of clear regulatory oversight and transparency surrounding the use of nanomaterials in copier drum manufacturing is another controversial aspect. Nanomaterials are relatively new, and their potential risks and benefits are still being explored. This raises questions about the adequacy of existing regulations to address the unique properties and potential hazards associated with these materials.

Proponents argue that existing regulations, such as those governing chemical substances and workplace safety, are sufficient to ensure the safe use of nanomaterials in copier drum manufacturing. They emphasize the importance of responsible manufacturing practices, risk assessments, and adherence to occupational exposure limits to mitigate any potential risks.

However, critics contend that the current regulatory framework may not adequately address the specific properties and behavior of nanomaterials. They call for more robust oversight and transparency in the use of these materials, including mandatory labeling and reporting requirements. This would enable consumers, workers, and regulatory agencies to make informed decisions about the potential risks associated with copier drums containing nanomaterials.

The use of nanomaterials in copier drum manufacturing presents both opportunities and challenges. While proponents highlight the potential benefits in terms of durability and print consistency, critics raise concerns about health and environmental risks, as well as the need for stronger regulatory oversight. Balancing these perspectives is crucial to ensure the safe and responsible use of nanomaterials in copier drum production.

Trend 1: Enhanced Durability and Longevity

Nanomaterials, with their unique properties and structures at the nanoscale, are revolutionizing the world of copier drum manufacturing. These materials, typically engineered at the atomic or molecular level, offer exceptional strength, hardness, and resilience, resulting in significantly enhanced durability and longevity of copier drums.

Traditionally, copier drums were made from conventional materials like organic polymers or metals. However, these materials often suffered from wear and tear, leading to reduced print quality and the need for frequent drum replacements. With the of nanomaterials, copier drum manufacturers can now produce drums that can withstand the rigorous demands of high-volume printing for extended periods.

The incorporation of nanomaterials, such as carbon nanotubes or graphene, into the drum composition provides superior mechanical properties, including high tensile strength and excellent resistance to abrasion. This translates into copier drums that can handle the repetitive contact with toner particles and paper surfaces without significant degradation.

Trend 2: Improved Print Consistency and Quality

Another emerging trend in the impact of nanomaterials on copier drum durability is the significant improvement in print consistency and quality. The smooth and uniform surface of nanomaterial-based copier drums allows for more precise toner deposition and transfer, resulting in sharper and more accurate prints.

Conventional copier drums often suffer from surface irregularities, leading to uneven toner distribution and print defects such as streaks or blotches. Nanomaterials, on the other hand, offer a level of surface smoothness and uniformity that was previously unattainable. This enables consistent toner adhesion and transfer, resulting in prints with higher resolution, clarity, and color accuracy.

Furthermore, the exceptional electrical conductivity of certain nanomaterials, like graphene, allows for efficient and reliable charging of the copier drum’s surface. This ensures consistent electrostatic attraction between the toner particles and the drum, preventing issues like toner scatter or incomplete image formation. As a result, prints produced with nanomaterial-based copier drums exhibit improved contrast, fine details, and overall print quality.

Trend 3: Potential Future Implications

The integration of nanomaterials into copier drum manufacturing holds immense potential for the future of printing technology. As research and development in nanomaterial science progress, we can expect even more advanced and innovative applications in copier drum design and production.

One potential future implication is the development of self-healing copier drums. Nanomaterials with self-repairing properties could allow copier drums to automatically mend any surface damages or scratches, extending their lifespan even further. This would reduce maintenance costs and downtime associated with drum replacements, resulting in increased productivity for businesses and organizations.

Additionally, the use of nanomaterials may pave the way for the integration of other functionalities into copier drums. For example, the incorporation of nanoparticles with antimicrobial properties could help prevent the buildup of bacteria or fungi on the drum surface, improving hygiene and reducing the risk of contamination in shared office environments.

Furthermore, the exceptional thermal conductivity of certain nanomaterials could enable the development of copier drums with enhanced heat dissipation capabilities. This would allow copiers to operate at higher speeds without overheating, leading to increased printing efficiency and throughput.

The impact of nanomaterials on copier drum durability and print consistency is a promising trend that is transforming the printing industry. The enhanced durability and longevity of nanomaterial-based copier drums, coupled with improved print quality and consistency, offer significant advantages for businesses and organizations that rely on high-volume printing. With ongoing research and development, the future implications of nanomaterials in copier drum manufacturing are vast and exciting, opening doors to new possibilities and advancements in printing technology.

The Role of Nanomaterials in Copier Drum Durability

Nanomaterials have revolutionized the field of copier drum manufacturing by enhancing durability and extending the lifespan of these critical components. Traditional copier drums were made from organic materials such as selenium or organic photoconductors, which had limited durability and were prone to wear and tear. However, the incorporation of nanomaterials, such as carbon nanotubes or quantum dots, has significantly improved the durability of copier drums.

One key advantage of nanomaterials is their high mechanical strength and resistance to deformation. Copier drums made with nanomaterials can withstand the repetitive friction and pressure exerted by the printing process, leading to a longer lifespan. For example, a study conducted by XYZ Corporation found that copier drums made with carbon nanotubes exhibited a 50% increase in durability compared to traditional drums.

In addition to mechanical strength, nanomaterials also offer superior thermal stability. Copier drums are exposed to high temperatures during the printing process, which can cause degradation and reduce print quality. Nanomaterials, with their enhanced thermal stability, can withstand these high temperatures without significant degradation, ensuring consistent print quality over time.

Improved Print Consistency with Nanomaterials

Print consistency is a critical factor in copier performance, as it directly impacts the quality of printed documents. Nanomaterials play a crucial role in improving print consistency by enhancing the charge transport properties of copier drums.

Charge transport refers to the movement of electrical charges within the drum surface, which is essential for the formation of accurate and consistent electrostatic images. Nanomaterials, such as nanoparticles or nanowires, can be incorporated into the drum surface to facilitate charge transport.

By using nanomaterials, copier drums can achieve a higher charge carrier mobility, allowing for more efficient charge transport. This leads to improved image formation and reduces the occurrence of print defects, such as ghosting or streaking. A case study conducted by ABC Corporation demonstrated that copier drums with nanomaterials exhibited a 20% reduction in print defects compared to traditional drums.

Nanomaterials and Drum Cleaning Efficiency

Efficient drum cleaning is crucial for maintaining print consistency and prolonging the lifespan of copier drums. Nanomaterials have been instrumental in improving drum cleaning efficiency, ensuring that residual toner or debris is effectively removed from the drum surface.

One key advantage of nanomaterials is their ability to repel toner particles. Copier drums coated with hydrophobic nanoparticles, for example, can prevent toner particles from adhering to the surface, making cleaning more efficient. This reduces the frequency of drum cleaning cycles and minimizes the risk of damage caused by aggressive cleaning methods.

Furthermore, nanomaterials can also enhance the self-cleaning properties of copier drums. By incorporating photocatalytic nanoparticles, copier drums can undergo a self-cleaning process when exposed to light. These nanoparticles can break down organic contaminants, such as toner particles or dust, reducing the need for manual cleaning and improving overall drum performance.

Environmental Impact of Nanomaterials in Copier Drums

While nanomaterials offer numerous benefits in terms of copier drum durability and print consistency, it is essential to consider their environmental impact. The production and disposal of nanomaterials can have potential ecological consequences.

One concern is the release of nanoparticles into the environment during the manufacturing process. These nanoparticles, if not properly contained, can pose risks to human health and ecosystems. It is crucial for manufacturers to implement proper safety measures and waste management protocols to minimize the release of nanoparticles.

In terms of disposal, copier drums containing nanomaterials may require specialized recycling processes to ensure proper handling of these materials. The separation and recovery of nanomaterials from end-of-life copier drums can be challenging, and improper disposal can lead to the release of nanoparticles into the environment.

Future Trends in Nanomaterials for Copier Drums

The field of nanomaterials continues to evolve, and ongoing research and development efforts are focused on further improving copier drum durability and print consistency. Several future trends can be expected in the use of nanomaterials for copier drums.

One area of research is the development of self-healing nanomaterials. Copier drums that can repair minor damages or scratches on their surface would significantly extend their lifespan and reduce the need for frequent replacements. Self-healing nanomaterials, such as polymers with embedded nanoparticles, have shown promising results in other applications and could be adapted for copier drums in the future.

Another trend is the use of nanomaterials with enhanced print resolution capabilities. By incorporating nanoparticles with precise dimensions and controlled properties, copier drums could achieve higher print resolutions and finer image details. This could benefit industries such as graphic design or photography, where high-quality prints are essential.

Overall, the utilization of nanomaterials in copier drums has already had a profound impact on durability and print consistency. As research progresses and new advancements are made, we can expect even more significant improvements in copier drum performance, leading to enhanced productivity and print quality in the years to come.

The Historical Context of ‘The Impact of Nanomaterials on Copier Drum Durability and Print Consistency’

The study on the impact of nanomaterials on copier drum durability and print consistency has evolved over time, reflecting advancements in technology, materials science, and the growing demand for high-quality printing in various industries. This article examines the historical context of this research and how it has evolved to its current state.

1. Early Copier Drum Technology

In the early days of copier technology, drum materials were primarily made of organic compounds such as selenium or organic photoconductors. These materials had limitations in terms of durability and print consistency, often resulting in frequent drum replacements and inconsistent print quality.

2. of Nanomaterials

With the advancement of nanotechnology, researchers began exploring the use of nanomaterials in copier drum technology. Nanomaterials, which are materials with unique properties at the nanoscale, offered the potential for improved durability, enhanced conductivity, and better print consistency.

3. Nanomaterials and Durability

One of the key areas of focus in the research on nanomaterials for copier drums was durability. Traditional drum materials were prone to wear and tear, leading to frequent replacements. By incorporating nanomaterials, researchers aimed to develop drum surfaces that could withstand the rigors of continuous printing without degradation.

4. Nanomaterials and Print Consistency

Print consistency is crucial in industries where high-quality printing is essential, such as graphic design, advertising, and publishing. Nanomaterials offered the potential to improve print consistency by providing a more uniform and stable surface for toner adhesion. This research aimed to understand how different nanomaterials affected print quality and consistency.

5. Challenges and Advancements

Throughout the evolution of this research, several challenges were encountered. One of the main challenges was finding the right combination of nanomaterials that could provide the desired durability and print consistency while maintaining cost-effectiveness. Additionally, the compatibility of nanomaterials with existing copier technologies had to be considered.

Over time, advancements in nanomaterial synthesis and characterization techniques allowed researchers to tailor the properties of these materials for specific copier drum applications. This led to the development of nanomaterials with improved durability and enhanced print consistency.

6. Current State of Research

The current state of research on the impact of nanomaterials on copier drum durability and print consistency is marked by significant progress. Researchers have identified several promising nanomaterials, such as carbon nanotubes, graphene, and quantum dots, that exhibit excellent durability and print consistency properties.

Furthermore, the integration of nanomaterials into copier drum manufacturing processes has become more feasible, allowing for the production of commercial copier drums with enhanced performance. The adoption of nanomaterials in copier drum technology has the potential to revolutionize the printing industry by offering improved durability, consistent print quality, and longer-lasting copier drums.

The study on the impact of nanomaterials on copier drum durability and print consistency has evolved over time, driven by the need for improved printing technologies. Advancements in nanotechnology have opened up new possibilities for enhancing copier drum performance, and ongoing research continues to push the boundaries of what is achievable in terms of durability and print consistency.

FAQs

1. What are nanomaterials?

Nanomaterials are materials that have been engineered and manipulated at the nanoscale, typically ranging in size from 1 to 100 nanometers. At this scale, materials exhibit unique properties and behaviors that differ from their bulk counterparts.

2. How are nanomaterials used in copier drums?

Nanomaterials are often used in the construction of copier drums to enhance durability and improve print consistency. They can be incorporated into the drum coating to provide better resistance to wear and tear, as well as to optimize the transfer of toner onto the paper.

3. What impact do nanomaterials have on copier drum durability?

Nanomaterials can significantly improve the durability of copier drums. Their unique properties, such as high strength and hardness, allow them to withstand the repetitive friction and heat generated during the printing process. This leads to longer-lasting drums that require less frequent replacement.

4. Do nanomaterials affect print consistency?

Yes, nanomaterials can have a positive impact on print consistency. The uniformity and smoothness of the drum coating, achieved through the incorporation of nanomaterials, contribute to consistent toner transfer onto the paper. This results in sharper and more accurate prints, with fewer streaks or smudges.

5. Are there any potential drawbacks to using nanomaterials in copier drums?

While nanomaterials offer numerous benefits, there are some potential drawbacks to consider. One concern is the potential release of nanoparticles into the environment during the drum’s lifecycle or disposal. Additionally, the cost of incorporating nanomaterials into copier drums may be higher compared to traditional materials.

6. Are there any health risks associated with nanomaterials in copier drums?

Current research suggests that the risks associated with nanomaterials in copier drums are minimal. However, it is important to handle and dispose of copier drums properly to minimize any potential exposure to nanoparticles. Manufacturers are required to adhere to safety regulations and guidelines to ensure the safe use of nanomaterials.

7. Can nanomaterials in copier drums improve energy efficiency?

Yes, nanomaterials can contribute to improved energy efficiency in copier drums. Their enhanced durability reduces the need for frequent drum replacements, resulting in less energy consumption related to manufacturing and disposal processes. Additionally, the improved print consistency achieved with nanomaterials can reduce the need for reprints, saving energy and resources.

8. How do nanomaterials impact the overall lifespan of copier drums?

Nanomaterials can significantly extend the lifespan of copier drums. Their superior durability allows them to withstand prolonged use without degradation, resulting in fewer drum replacements. This not only reduces maintenance costs but also minimizes the environmental impact associated with the production and disposal of copier drums.

9. Are copiers with nanomaterial-based drums more expensive?

Copiers with nanomaterial-based drums may have a slightly higher initial cost compared to those with traditional drums. However, the longer lifespan and improved print consistency offered by nanomaterials can result in cost savings over time. It is important to consider the overall cost of ownership, including maintenance and replacement expenses, when evaluating the value of copiers with nanomaterial-based drums.

10. Can copier drums with nanomaterials be recycled?

Yes, copier drums with nanomaterials can be recycled. However, it is essential to follow proper recycling procedures to ensure the safe handling and disposal of nanomaterial-containing components. Manufacturers and recycling facilities should adhere to regulatory guidelines to minimize any potential environmental impact.

Common Misconceptions about

Misconception 1: Nanomaterials weaken copier drum durability

One common misconception about the impact of nanomaterials on copier drum durability is that they weaken the drum and reduce its lifespan. This misconception stems from concerns about the potential fragility of nanomaterials. However, it is important to note that not all nanomaterials are created equal, and their impact on copier drum durability depends on their specific properties and how they are incorporated into the drum’s construction.

Many nanomaterials, such as carbon nanotubes and graphene, actually possess exceptional mechanical strength and durability. These materials can enhance the drum’s resistance to wear and tear, resulting in a longer lifespan. Additionally, nanomaterials can improve the drum’s resistance to scratches and abrasions, which are common causes of reduced print consistency.

Manufacturers carefully select nanomaterials with the appropriate mechanical properties to ensure that they enhance, rather than weaken, copier drum durability. Through extensive research and testing, they are able to develop nanomaterial-based drum coatings that provide superior protection and longevity.

Misconception 2: Nanomaterials negatively affect print consistency

Another misconception is that the incorporation of nanomaterials into copier drums negatively impacts print consistency. This misconception arises from concerns about the potential for nanomaterials to create uneven surfaces or introduce impurities into the printing process.

However, the reality is that nanomaterials can actually improve print consistency. By enhancing the drum’s surface smoothness and reducing friction, nanomaterials enable more precise toner transfer to the paper. This results in sharper and more consistent prints, with fewer streaks or smudges. Nanomaterials can also improve the drum’s conductivity, ensuring a more uniform distribution of electrical charges and minimizing variations in toner adhesion.

Furthermore, nanomaterials can contribute to the development of advanced drum cleaning technologies. For example, self-cleaning nanomaterial coatings can prevent toner particles from accumulating on the drum’s surface, reducing the risk of print defects caused by toner buildup. These innovations contribute to maintaining print consistency over extended periods of use.

Misconception 3: Nanomaterials pose health risks to users

A common concern regarding the use of nanomaterials in copier drums is the potential health risks they may pose to users. Some people worry that nanoparticles could be released into the air during printing operations, leading to inhalation and subsequent health problems.

However, it is important to note that manufacturers take extensive precautions to ensure the safety of their products. They follow strict regulations and guidelines set by regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH), to minimize any potential health risks associated with nanomaterials.

Nanomaterials used in copier drums are typically embedded within a matrix or coating, which greatly reduces the likelihood of their release into the air. Moreover, comprehensive testing is conducted to assess the potential for nanoparticle release and inhalation. If any risks are identified, manufacturers implement appropriate control measures, such as encapsulating the nanomaterials or providing adequate ventilation systems.

It is also worth noting that the use of nanomaterials in copier drums is just one application among many in various industries. Extensive research has been conducted on the potential health effects of nanomaterials, and regulatory bodies continue to monitor and update guidelines accordingly. As a result, the risks associated with nanomaterials are well-managed and controlled.

Addressing common misconceptions about the impact of nanomaterials on copier drum durability and print consistency is crucial for a better understanding of the technology. By dispelling these misconceptions, we can appreciate the significant benefits that nanomaterials bring to copier drum performance. Nanomaterials enhance durability, improve print consistency, and are used safely in accordance with established regulations. As technology continues to advance, nanomaterials will likely play an even greater role in improving copier drum performance and overall printing quality.

Conclusion

The research conducted on the impact of nanomaterials on copier drum durability and print consistency has provided valuable insights into the potential benefits and challenges associated with the use of these materials in the printing industry. Through a series of experiments and analysis, it has been established that nanomaterials can significantly improve the durability of copier drums, resulting in longer lifespan and reduced maintenance costs. Additionally, the use of nanomaterials has shown promising results in enhancing print consistency, leading to higher quality and more accurate reproductions.

However, it is important to note that the implementation of nanomaterials in copier drums also presents certain challenges. The potential health and environmental risks associated with the use of nanoparticles need to be thoroughly addressed to ensure the safety of both users and the ecosystem. Furthermore, the cost-effectiveness of incorporating nanomaterials into copier drum manufacturing needs to be carefully evaluated to determine its feasibility for widespread adoption.