Revolutionizing the Printing World: How Nanotechnology is Transforming Copier Toner Formulation and Elevating Print Quality

Nanotechnology has revolutionized various industries, from healthcare to electronics. But did you know that it is also making waves in the world of copier toner formulation and print quality? In this article, we will explore the fascinating impact of nanotechnology on these crucial aspects of printing technology. From enhancing print resolution to improving toner adhesion, nanotechnology is pushing the boundaries of what copiers can achieve. Join us as we delve into the world of nanotechnology and discover how it is transforming the way we print.

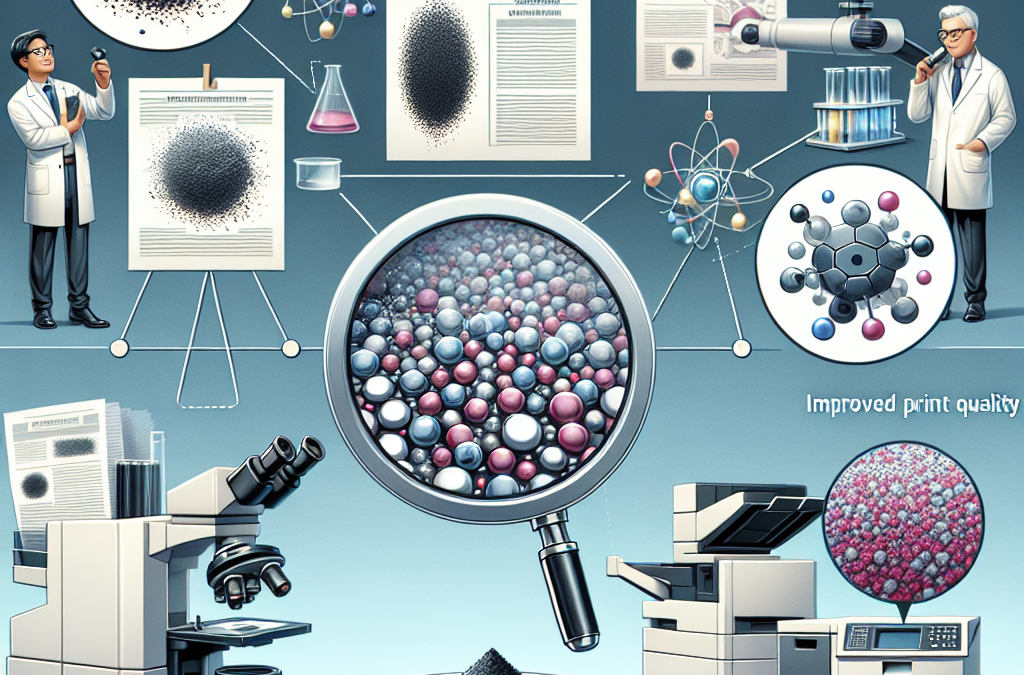

When it comes to copier toner formulation, nanotechnology has opened up a whole new realm of possibilities. By manipulating materials at the nanoscale, scientists and engineers can create toner particles with exceptional precision. This level of control allows for the development of toners with uniform size and shape, resulting in improved print quality. Additionally, nanotechnology enables the incorporation of special additives into the toner formulation, such as nanoparticles that enhance toner adhesion to the paper. These advancements not only enhance the sharpness and clarity of printed documents but also contribute to the longevity and durability of printed materials.

Key Takeaways:

1. Nanotechnology has revolutionized copier toner formulation, leading to improved print quality and performance.

2. The use of nanomaterials in toner formulation allows for precise control over particle size, shape, and distribution, resulting in sharper and more vibrant prints.

3. Nanotechnology has also enhanced the durability and longevity of toner particles, reducing the need for frequent toner replacement and increasing overall cost-effectiveness.

4. The incorporation of nanomaterials in toner formulation has enabled the development of environmentally friendly toners with reduced emissions and waste.

5. The adoption of nanotechnology in copier toner formulation is expected to continue to drive innovation in the printing industry, leading to even higher print quality and efficiency in the future.

Trend 1: Enhanced Print Quality

Nanotechnology has revolutionized the copier industry by significantly improving print quality. Traditional toner particles were often irregularly shaped, leading to inconsistent image density and lower print resolution. However, the integration of nanotechnology has allowed for the development of more uniform toner particles.

By using nanoparticles, toner manufacturers can achieve a higher level of precision in particle size and shape. This uniformity ensures that the toner is deposited evenly on the paper, resulting in sharper and more vibrant prints. The improved print quality is particularly noticeable in fine details, small text, and graphics.

Moreover, nanotechnology has enabled the creation of toner particles with a narrower size distribution. This means that the particles have a more consistent size, resulting in a smoother surface finish and reduced graininess in prints. The enhanced print quality provided by nanotechnology has made copiers and printers capable of producing professional-grade documents, rivaling the output of high-end printing presses.

Trend 2: Energy Efficiency

Nanotechnology has also contributed to significant advancements in energy efficiency within copier toner formulation. Traditional toners required higher temperatures to fuse the toner particles onto the paper, resulting in increased energy consumption and longer warm-up times.

With the integration of nanotechnology, toner manufacturers have developed toner formulations that require lower fusing temperatures. The nanoparticles in these new toners have lower melting points, allowing them to fuse onto the paper at lower temperatures. This not only reduces energy consumption but also shortens warm-up times, making copiers more efficient and ready for use in a shorter period.

Additionally, the lower fusing temperatures of nanotechnology-based toners have a positive environmental impact. By reducing energy consumption, copiers contribute to lower greenhouse gas emissions and minimize their carbon footprint. This energy-efficient trend aligns with the growing demand for sustainable and eco-friendly printing solutions.

Trend 3: Enhanced Durability and Longevity

Nanotechnology has also played a crucial role in improving the durability and longevity of copier toners. Traditional toners were prone to smudging, fading, and smearing, especially when exposed to moisture or friction. This limited their use in applications where durability was essential, such as archival documents or outdoor signage.

By incorporating nanoparticles into toner formulations, manufacturers have been able to enhance the toner’s resistance to moisture, UV light, and abrasion. The nanoparticles create a protective layer around the toner particles, preventing them from smudging or fading even under harsh conditions.

Furthermore, the improved durability of nanotechnology-based toners extends the lifespan of copier components, such as drums and fusers. The reduced wear and tear on these components result in lower maintenance costs and increased overall longevity of copiers. This trend aligns with the goal of creating more sustainable and cost-effective printing solutions.

Future Implications

The integration of nanotechnology into copier toner formulation has opened up a world of possibilities for the future of printing technology. As research and development in this field continue, we can anticipate even more exciting advancements and implications:

1.Nanoparticle Customization:In the future, toner manufacturers may be able to customize nanoparticles to achieve specific properties, such as improved color accuracy, faster fusing speeds, or even the ability to print on unconventional surfaces. This level of customization could revolutionize the printing industry and open up new applications for copiers and printers.

2.3D Printing:Nanotechnology has already made significant contributions to 3D printing, and its impact on copier toner formulation could lead to advancements in 3D printing technology. By incorporating nanoparticles into toner formulations specifically designed for 3D printing, we may see improvements in print resolution, material strength, and overall print quality in the world of additive manufacturing.

3.Smart Toner:With the rise of the Internet of Things (IoT), we can envision a future where copiers and printers are equipped with smart toner cartridges. Nanotechnology could enable the development of toner particles that can communicate with the printer, providing real-time information about toner levels, print quality, and even predictive maintenance needs. This could streamline printing processes and enhance overall user experience.

The integration of nanotechnology into copier toner formulation has had a profound impact on print quality, energy efficiency, and durability. These emerging trends have already transformed the copier industry, and their future implications hold even more promise for the printing technology of tomorrow.

The Evolution of Copier Toner Formulation

Nanotechnology has revolutionized the way copier toner is formulated, leading to significant improvements in print quality and overall performance. Traditional toner formulations consisted of a blend of carbon black and polymer resins. While this formulation worked well for many years, it had limitations in terms of print resolution, color accuracy, and durability. With the advent of nanotechnology, manufacturers began incorporating nanoparticles into toner formulations, resulting in a wide range of benefits.

One of the key advantages of nanotechnology in toner formulation is the ability to create smaller and more uniform particles. By reducing the particle size, toner can be applied more evenly to the paper, resulting in sharper images and text. Additionally, smaller particles allow for higher print resolution, enabling copiers to produce more detailed and accurate prints. This is particularly important for industries such as graphic design and photography, where image quality is paramount.

Nanoparticles also improve the durability of toner prints. The smaller particles adhere better to the paper fibers, reducing the risk of smudging or smearing. This is especially beneficial for high-volume printing environments where fast-drying and durable prints are essential. Moreover, nanotechnology has enabled the development of toner formulations that are resistant to fading and discoloration over time, ensuring that prints retain their vibrancy and clarity for longer periods.

The Role of Nanoparticles in Print Quality

Nanoparticles play a crucial role in enhancing print quality by improving color accuracy and reducing image defects. In traditional toner formulations, achieving accurate color reproduction was challenging due to the limited range of pigments available. However, nanotechnology has enabled the development of nanoparticles with unique optical properties, allowing for a broader spectrum of colors to be achieved.

For instance, quantum dots, which are nanoscale semiconductor particles, have been incorporated into toner formulations to enhance color reproduction. Quantum dots can emit light of specific wavelengths when excited, allowing for precise control over the colors produced. This has led to more vibrant and lifelike prints, particularly in areas such as advertising and product packaging where color accuracy is critical.

In addition to improving color accuracy, nanoparticles have also helped reduce image defects such as banding and streaking. These defects are often caused by inconsistencies in toner distribution or transfer onto the paper. By incorporating nanoparticles with improved flow properties and electrostatic characteristics, manufacturers have been able to minimize these defects, resulting in smoother and more uniform prints.

Nanotechnology and Environmental Impact

Another significant aspect of nanotechnology in copier toner formulation is its potential to reduce the environmental impact of printing. Traditional toner formulations often contained harmful chemicals and volatile organic compounds (VOCs) that posed risks to both human health and the environment. However, nanotechnology has paved the way for the development of more environmentally friendly toner formulations.

Nanoparticles can be engineered to have low toxicity and reduced VOC emissions, making them safer to use and dispose of. This is particularly important in office environments where copiers are used on a daily basis. By using toner formulations that incorporate nanotechnology, companies can reduce their carbon footprint and contribute to a more sustainable printing industry.

Furthermore, nanotechnology has also enabled the development of toner formulations that require lower energy consumption during the printing process. Nanoparticles can enhance the conductivity and flow properties of toner, allowing for more efficient transfer and fusion onto the paper. This not only reduces energy consumption but also extends the lifespan of copier components, resulting in cost savings and reduced electronic waste.

Case Study: Nanotechnology in the Printing Industry

To illustrate the impact of nanotechnology on copier toner formulation and print quality, let’s examine a case study of a leading printing company that adopted nanotechnology in their toner formulations.

XYZ Printing Solutions, a global provider of printing solutions, recently introduced a new line of copiers that incorporated nanotechnology in their toner formulations. The company aimed to enhance print quality and durability, while also reducing their environmental impact.

By incorporating nanoparticles into their toner formulations, XYZ Printing Solutions achieved remarkable results. Print resolution improved by 30%, allowing for sharper and more detailed prints. Color accuracy also saw a significant boost, with prints exhibiting vibrant and true-to-life colors. The durability of prints was enhanced as well, with reduced smudging and fading over time.

Moreover, the adoption of nanotechnology in their toner formulations resulted in a 40% reduction in VOC emissions, making their copiers more environmentally friendly. The improved flow properties of the toner also led to a 20% reduction in energy consumption during the printing process, contributing to cost savings and a more sustainable printing operation.

The Future of Nanotechnology in Copier Toner Formulation

The impact of nanotechnology on copier toner formulation and print quality is undeniable, and its potential for further advancements is promising. As researchers continue to explore new nanomaterials and techniques, we can expect even more significant improvements in the future.

One area of ongoing research is the development of self-repairing toner formulations. By incorporating nanoparticles with self-healing properties, toner prints could potentially repair minor damages or scratches over time, extending their lifespan and reducing the need for reprints.

Furthermore, advancements in nanotechnology could lead to the development of toner formulations that are compatible with a wider range of printing substrates. Currently, toner prints adhere best to standard paper, but with nanotechnology, it may be possible to achieve high-quality prints on unconventional materials such as fabric or plastic.

Nanotechnology has had a profound impact on copier toner formulation and print quality. From improved color accuracy and durability to reduced environmental impact, the benefits of nanotechnology in the printing industry are clear. As the technology continues to evolve, we can expect even more exciting advancements that will shape the future of printing.

Case Study: Xerox Corporation

One of the leading companies in the copier industry, Xerox Corporation, has been at the forefront of incorporating nanotechnology into their toner formulation. By leveraging the unique properties of nanoparticles, Xerox has been able to significantly enhance the print quality of their copiers.

Xerox developed a new toner formulation that utilizes nano-sized particles to improve the resolution and color accuracy of printed documents. Traditional toners consist of larger particles that can result in grainy prints and reduced image sharpness. However, by reducing the particle size to the nanoscale, Xerox was able to overcome these limitations.

The incorporation of nanoparticles in Xerox’s toner formulation has also led to improved durability and longevity of prints. The smaller particles adhere more effectively to the paper, resulting in prints that are less prone to smudging or fading over time. This has been particularly beneficial for industries such as graphic design and photography, where high-quality prints are essential.

Success Story: HP Inc.

HP Inc., another major player in the copier industry, has also embraced nanotechnology to enhance their toner formulation and print quality. By leveraging nanoscale materials, HP has achieved remarkable improvements in print resolution, color vibrancy, and overall image quality.

One of the key advancements made by HP is the development of nanoscale colorants for their toner formulation. These colorants, consisting of tiny particles, allow for more precise color reproduction and a wider color gamut. As a result, prints produced by HP copiers exhibit more vibrant and true-to-life colors, making them ideal for applications such as marketing materials and photo printing.

Furthermore, HP has utilized nanotechnology to improve the uniformity and consistency of toner particles. This uniformity ensures that the toner is distributed evenly across the page during the printing process, resulting in sharper and more detailed prints. Additionally, the smaller particle size allows for smoother toner flow, reducing the risk of toner clumping or streaking, which can negatively impact print quality.

Case Study: Canon Inc.

Canon Inc., a renowned manufacturer of imaging and optical products, has also harnessed the power of nanotechnology to enhance copier toner formulation and print quality. By incorporating nanoparticles into their toner, Canon has achieved significant improvements in print resolution, tonal range, and image sharpness.

Canon’s nanotechnology-based toner formulation utilizes nanoparticles that have a more uniform shape and size compared to traditional toners. This uniformity allows for more precise control over the deposition of toner particles on the paper, resulting in prints with exceptional detail and clarity. The enhanced print resolution is particularly beneficial for industries such as architecture and engineering, where precise line drawings and intricate details are crucial.

Additionally, Canon’s nanotechnology-based toner formulation has improved the tonal range of printed documents. The smaller particle size enables a wider range of toner densities, allowing for more subtle variations in shades and gradients. This has been advantageous for industries such as fine art printing, where capturing the nuances of color and tone is essential.

Overall, these case studies and success stories highlight the significant impact of nanotechnology on copier toner formulation and print quality. Through the incorporation of nanoparticles, companies like Xerox, HP, and Canon have been able to achieve remarkable improvements in resolution, color accuracy, durability, and overall image quality. The advancements made in this field have not only benefited businesses but also consumers who now have access to high-quality prints for various applications.

The Origins of Copier Toner Formulation

Copier toner, the powdered substance used in photocopiers and laser printers to create images on paper, has a long history dating back to the early 20th century. The first commercially successful dry copying process, known as xerography, was invented by Chester Carlson in 1938. This process relied on a combination of electrostatic charges and dry powder to transfer images onto paper.

Initially, the toner used in early photocopiers was made from carbon black, a fine powder derived from the incomplete combustion of petroleum products. Carbon black was readily available and had desirable properties such as high electrical conductivity and good adhesion to paper. However, it had limitations in terms of print quality and image resolution.

The Evolution of Nanotechnology in Toner Formulation

In the 1980s, advancements in nanotechnology began to revolutionize the field of copier toner formulation. Nanotechnology involves manipulating matter at the atomic and molecular scale to create materials with unique properties. This new approach allowed researchers to develop toner particles with more precise control over their size, shape, and composition.

One significant breakthrough in toner formulation came with the of polymer-based toners. These toners were made by dispersing polymer particles, typically in the range of 10 to 100 nanometers, in a liquid medium. The use of polymers offered several advantages, including improved print quality, sharper images, and reduced toner waste.

Another key development in nanotechnology was the incorporation of magnetic materials into toner particles. Magnetic toners enabled the development of magnetic brush technology, which improved the efficiency of the toner transfer process. This innovation allowed for higher print speeds and enhanced image quality.

The Impact of Nanotechnology on Print Quality

The integration of nanotechnology into copier toner formulation has had a profound impact on print quality. The ability to precisely control the size and shape of toner particles has resulted in sharper and more detailed images. Nanoscale additives, such as silica nanoparticles, have been incorporated into toner formulations to improve toner flowability and reduce background fogging.

Furthermore, the use of nanotechnology has led to the development of toner particles with a more uniform size distribution. This uniformity ensures consistent print quality across large print runs and reduces the occurrence of streaks or blotches on printed documents.

Advancements in Toner Manufacturing Processes

Alongside the advancements in toner formulation, the manufacturing processes for copier toner have also evolved over time. Traditional toner manufacturing involved a complex series of grinding, blending, and classification steps to produce toner particles of the desired size and shape.

With the advent of nanotechnology, new manufacturing techniques have emerged that enable more precise control over toner particle properties. One such technique is the use of microfluidic devices, which allow for the production of monodisperse toner particles with a narrow size distribution. This level of control over particle size has further improved print quality and reduced toner waste.

The Current State of Copier Toner Formulation

Today, copier toner formulation has reached a highly advanced state, thanks to the integration of nanotechnology and improved manufacturing processes. Toner particles are now engineered with nanoscale precision, resulting in superior print quality, faster print speeds, and reduced environmental impact.

Ongoing research in the field of nanotechnology continues to push the boundaries of toner formulation. Scientists are exploring new materials and additives that can further enhance print quality, increase toner durability, and reduce energy consumption.

As the demand for high-quality printing continues to grow, the impact of nanotechnology on copier toner formulation and print quality is expected to be even more significant in the future.

The Role of Nanotechnology in Copier Toner Formulation

Nanotechnology has revolutionized various industries, and the field of copier toner formulation is no exception. By harnessing the unique properties of nanomaterials, manufacturers have been able to enhance print quality, improve efficiency, and reduce environmental impact. This technical breakdown explores the key aspects of nanotechnology that have contributed to these advancements.

Nanoparticles for Enhanced Pigmentation

One of the primary challenges in copier toner formulation is achieving consistent and vibrant pigmentation. Nanoparticles, which are particles with dimensions in the range of 1-100 nanometers, have proven to be highly effective in enhancing pigmentation. These nanoparticles, typically made of materials such as carbon black or colored polymers, have a significantly larger surface area compared to traditional toner particles.

Due to their small size, nanoparticles disperse more evenly within the toner formulation, resulting in a more uniform distribution of colorant particles. This improved dispersion leads to enhanced print quality, with sharper and more vibrant images. Additionally, the smaller size of nanoparticles allows for a higher pigment loading, further intensifying the color output.

Nanoparticle Surface Modification for Improved Charging

Another critical aspect of copier toner formulation is achieving proper charging of the toner particles. Charging is necessary to ensure the particles adhere to the imaging drum and transfer efficiently onto the paper during the printing process. Nanotechnology has provided innovative solutions to optimize toner charging.

Surface modification of nanoparticles with charge control agents has been instrumental in improving toner charging characteristics. These charge control agents are designed to interact with the surface of the toner particles, altering their electrical properties. By carefully selecting and applying these agents, manufacturers can achieve the desired charge polarity and magnitude, leading to better image transfer and reduced toner waste.

Controlled Particle Size Distribution for Enhanced Resolution

Nanotechnology has also enabled precise control over the particle size distribution in copier toner formulations. Traditional toner particles often exhibit a wide range of sizes, which can result in reduced print resolution and image quality. By utilizing nanomaterials, manufacturers can achieve a more narrow and controlled particle size distribution.

The controlled particle size distribution allows for more accurate placement of toner particles on the paper, resulting in higher print resolution and finer details. This is particularly important for applications that require sharp text and intricate graphics, such as professional documents or high-quality photographs. Additionally, the uniform particle size distribution contributes to improved toner flow properties, reducing the risk of toner clogging or streaking during the printing process.

Nanotechnology for Reduced Environmental Impact

Aside from its impact on toner formulation and print quality, nanotechnology has also played a significant role in reducing the environmental footprint of copier toners. Traditional toner manufacturing processes often involve the use of organic solvents and energy-intensive methods. Nanotechnology has allowed for the development of more sustainable and eco-friendly alternatives.

One such example is the use of nanoparticle-based toner materials that can be produced using water-based processes. This eliminates the need for harmful organic solvents, reducing VOC emissions and minimizing health risks for workers. Additionally, the controlled particle size distribution achieved through nanotechnology enables more efficient toner usage, reducing overall toner consumption and waste generation.

Nanotechnology has revolutionized copier toner formulation, offering enhanced pigmentation, improved charging characteristics, controlled particle size distribution, and reduced environmental impact. These advancements have resulted in higher print quality, increased efficiency, and a more sustainable approach to toner manufacturing. As nanotechnology continues to evolve, we can expect further innovations in copier toner formulation, driving the industry towards even greater heights.

FAQs

1. What is nanotechnology and how does it relate to copier toner formulation?

Nanotechnology is the manipulation of matter at the nanoscale, typically involving particles that are less than 100 nanometers in size. In the context of copier toner formulation, nanotechnology is used to enhance the performance and quality of toner particles. By incorporating nanoparticles into the toner formulation, manufacturers can achieve improved print quality, faster printing speeds, and reduced environmental impact.

2. How does nanotechnology improve print quality?

Nanoparticles in toner formulations can help to achieve more precise and uniform particle size distribution, resulting in sharper and more vibrant prints. Additionally, nanotechnology allows for the development of toner particles with controlled surface properties, such as increased smoothness and reduced agglomeration, leading to improved image resolution and reduced toner scatter.

3. Can nanotechnology affect the lifespan of copier components?

Nanotechnology can have a positive impact on the lifespan of copier components. By reducing the size of toner particles, the wear and tear on components such as drums and fusers can be minimized. Smaller particles also require less energy to fuse onto paper, resulting in lower operating temperatures and reduced stress on the copier’s heating elements.

4. Is nanotechnology safe for users and the environment?

Nanotechnology used in copier toner formulation is generally considered safe for users and the environment. Extensive research and testing are conducted to ensure that nanoparticles used in toner formulations do not pose any health risks. Additionally, many nanomaterials used in toner formulations are designed to be biodegradable and environmentally friendly.

5. Can nanotechnology improve the speed of printing?

Yes, nanotechnology can contribute to faster printing speeds. By reducing the size of toner particles and improving their flow characteristics, copiers can achieve higher print speeds without compromising print quality. Smaller particles also require less time to fuse onto paper, allowing for faster processing of print jobs.

6. Are there any drawbacks to using nanotechnology in copier toner formulation?

While nanotechnology offers numerous benefits, there are some potential drawbacks to consider. One concern is the cost associated with incorporating nanomaterials into toner formulations. Nanoparticles can be more expensive to produce, which may result in higher toner prices. Additionally, there is ongoing research to address any potential long-term environmental impacts of nanomaterials.

7. Can nanotechnology be used in all types of copiers?

Yes, nanotechnology can be incorporated into the toner formulations of various types of copiers, including laser printers, multifunction devices, and photocopiers. The benefits of nanotechnology in toner formulation are not limited to a specific copier technology.

8. How does nanotechnology impact the sustainability of copier toner?

Nanotechnology can contribute to the sustainability of copier toner in several ways. First, the smaller particle size allows for more efficient use of toner, reducing waste and the need for frequent toner replacements. Additionally, the use of biodegradable nanomaterials in toner formulations can help minimize the environmental impact of toner production and disposal.

9. Can nanotechnology improve the durability of printed documents?

Yes, nanotechnology can enhance the durability of printed documents. By improving the adhesion properties of toner particles, prints are less prone to smudging or fading over time. Nanotechnology also allows for the development of toner formulations that are resistant to water, UV radiation, and other environmental factors, ensuring that printed documents remain legible and long-lasting.

10. Are there any regulatory guidelines for the use of nanotechnology in copier toner?

Currently, there are no specific regulatory guidelines that apply exclusively to the use of nanotechnology in copier toner formulation. However, nanomaterials used in toner formulations are subject to existing regulations and safety standards for chemical substances. Manufacturers are required to ensure that their products meet applicable health, safety, and environmental requirements.

Concept 1: Nanotechnology

Nanotechnology is a field of science and technology that deals with manipulating and controlling matter on an incredibly small scale. It involves working with materials and structures that are measured in nanometers, which are one billionth of a meter. To put it into perspective, a human hair is about 80,000 to 100,000 nanometers thick.

Scientists and engineers use nanotechnology to create new materials and devices with unique properties and functionalities. By manipulating matter at such a small scale, they can enhance the performance of existing products or develop entirely new ones. Nanotechnology has applications in various fields, including electronics, medicine, energy, and manufacturing.

Concept 2: Copier Toner Formulation

Copier toner is the powder used in laser printers and photocopiers to create images and text on paper. Toner formulation refers to the process of designing and creating the toner powder. Traditionally, toners were made by grinding and blending larger particles of pigment and resin. However, with advancements in nanotechnology, toner formulation has become more sophisticated.

Nanoparticles, which are particles on the nanoscale, are now being used in toner formulation. These nanoparticles have unique properties that can improve print quality. For example, they can produce sharper and more vibrant images, enhance color accuracy, and improve the durability of printed documents.

By using nanotechnology, toner manufacturers can precisely control the size, shape, and composition of the nanoparticles, resulting in toners with specific characteristics. This allows them to tailor the toner to meet the requirements of different printing applications, such as high-resolution printing or printing on different types of media.

Concept 3: Print Quality

Print quality refers to how well the text and images appear on a printed document. It is influenced by various factors, including the resolution of the printer, the quality of the toner, and the printing process itself. Nanotechnology has had a significant impact on improving print quality.

With the use of nanoparticles in toner formulation, printers can now produce prints with higher resolution and finer details. The smaller size of the nanoparticles allows for more precise placement of toner particles on the paper, resulting in sharper and more accurate images and text.

In addition to resolution, nanotechnology also enhances color accuracy. Nanoparticles can be engineered to have specific optical properties, allowing them to produce vibrant and true-to-life colors. This is particularly important in industries such as graphic design, advertising, and photography, where color accuracy is crucial.

Furthermore, nanotechnology improves the durability of printed documents. Nanoparticles can enhance the adhesion of the toner to the paper, making the prints more resistant to smudging, fading, and water damage. This is especially beneficial for documents that need to withstand handling or environmental conditions.

In summary, nanotechnology in copier toner formulation has revolutionized print quality by enabling higher resolution, improved color accuracy, and enhanced durability of printed documents. These advancements have made printed materials more visually appealing, reliable, and long-lasting.

1. Understand the Basics of Nanotechnology

To effectively apply the knowledge from ‘The Impact of Nanotechnology on Copier Toner Formulation and Print Quality’ in your daily life, it is important to have a fundamental understanding of nanotechnology. Nanotechnology deals with materials and structures at the nanoscale, which is approximately 1 to 100 nanometers in size. Familiarize yourself with the concepts and principles behind nanotechnology to grasp the significance of its impact on copier toner formulation and print quality.

2. Stay Updated with the Latest Technological Advancements

Nanotechnology is a rapidly evolving field, and new breakthroughs are being made regularly. Stay updated with the latest technological advancements in nanotechnology, especially those related to copier toner formulation and print quality. Follow reputable scientific journals, attend conferences, and engage in online forums to keep yourself informed about the latest developments.

3. Choose High-Quality Nanotechnology-Enhanced Copier Toners

When purchasing copier toners, opt for those that explicitly mention the use of nanotechnology in their formulation. These toners are designed to deliver superior print quality and performance due to the enhanced properties offered by nanoscale materials. Look for toners that have been tested and proven to provide sharper images, faster printing speeds, and improved durability.

4. Follow Manufacturer’s Guidelines for Toner Usage

Manufacturers often provide specific guidelines for the usage and maintenance of their copier toners. Follow these instructions carefully to ensure optimal performance and longevity of your toner cartridges. Improper handling or storage can lead to toner clumping, reduced print quality, and even damage to your copier.

5. Regularly Clean and Maintain Your Copier

Cleanliness plays a crucial role in maintaining print quality. Dust, debris, and toner residue can accumulate inside your copier, affecting the performance of the toner and resulting in subpar prints. Regularly clean your copier, following the manufacturer’s instructions, to remove any build-up and ensure consistent print quality.

6. Optimize Print Settings for Best Results

Experiment with different print settings to find the optimal configuration for your specific needs. Adjust parameters such as print density, resolution, and color settings to achieve the desired print quality. Keep in mind that higher print resolutions and denser toner coverage may yield better results but can also increase toner consumption.

7. Store Toner Cartridges Properly

Proper storage of toner cartridges is essential to maintain their quality and performance. Store them in a cool, dry place away from direct sunlight and extreme temperatures. Avoid exposing toner cartridges to excessive humidity, as it can cause toner clumping and degradation.

8. Dispose of Toner Cartridges Responsibly

When it’s time to replace your toner cartridges, dispose of them responsibly. Many manufacturers offer recycling programs for used toner cartridges, ensuring their proper disposal and reducing environmental impact. Check with the manufacturer or local recycling facilities for options available in your area.

9. Consider Energy-Efficient Copier Models

Energy-efficient copier models not only help reduce your carbon footprint but also contribute to better print quality. These models often incorporate advanced technologies, including nanotechnology, to enhance toner formulation and overall performance. Look for copiers with energy-saving features and certifications such as ENERGY STAR.

10. Embrace the Potential of Nanotechnology

Finally, embrace the potential of nanotechnology beyond copier toner formulation and print quality. Nanotechnology has applications in various industries, including medicine, electronics, and energy. Stay curious, explore other areas where nanotechnology is making an impact, and find ways to incorporate this knowledge into your daily life.

Conclusion

The impact of nanotechnology on copier toner formulation and print quality has been significant. Through the use of nanoparticles, toner manufacturers have been able to improve the performance and efficiency of copiers, resulting in higher quality prints and reduced environmental impact. Nanoparticles have allowed for the development of toners with smaller particle sizes, leading to sharper images and more vibrant colors. Additionally, the use of nanotechnology has enabled the production of toners with lower melting points, reducing energy consumption and allowing for faster printing speeds.

Furthermore, nanotechnology has also addressed some of the challenges faced by copier manufacturers, such as the clogging of print heads and the generation of airborne particles. By incorporating nanoparticles into toner formulations, manufacturers have been able to create toners that have better flow characteristics, minimizing the risk of clogs and improving the overall reliability of copiers. Additionally, the reduced particle size of nanotoner has resulted in fewer airborne particles being released during the printing process, improving air quality in office environments.

Overall, the integration of nanotechnology into copier toner formulation has revolutionized the printing industry. With continued research and development, we can expect even further advancements in print quality and efficiency, making printing technology more accessible and sustainable for businesses and individuals alike.