Revolutionizing Efficiency: How Robotics are Transforming South Florida’s Print Production Workflow

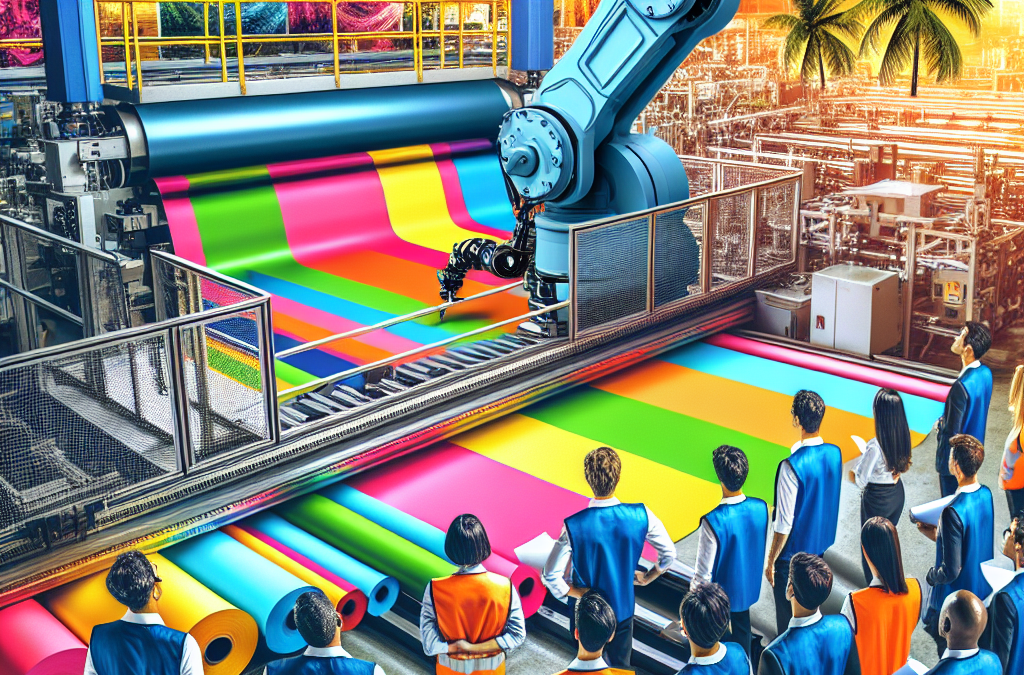

In recent years, South Florida’s print production industry has undergone a significant transformation, thanks to the integration of robotics into its workflow. These advanced machines have revolutionized the way printing companies operate, streamlining processes, increasing efficiency, and reducing costs. From automated prepress tasks to robotic printing and finishing, the impact of robotics on South Florida’s print production workflow has been nothing short of revolutionary.

In this article, we will explore the various ways in which robotics have reshaped the print production landscape in South Florida. We will delve into the benefits that these machines bring to the industry, such as faster turnaround times, improved accuracy, and enhanced quality control. Additionally, we will examine how robotics have affected the workforce, discussing the potential job displacement and the emergence of new roles that require a different skill set. Furthermore, we will explore the challenges and considerations that printing companies face when implementing robotics, including the initial investment costs and the need for ongoing maintenance and training. Through interviews with industry experts and case studies of local businesses, we will provide a comprehensive overview of the impact of robotics on South Florida’s print production workflow and the future of the industry.

Key Takeaways:

1. Increased Efficiency: The integration of robotics in South Florida’s print production workflow has led to significant improvements in efficiency. Automated robots can perform repetitive tasks with precision and speed, reducing the time and effort required by human workers.

2. Cost Savings: By implementing robotics, print production companies in South Florida have experienced cost savings in various areas. Robots can operate 24/7 without the need for breaks or overtime pay, resulting in reduced labor costs. Additionally, the use of robotics minimizes errors and waste, leading to savings in materials and resources.

3. Enhanced Quality: Robotics technology has greatly improved the quality and consistency of print production in South Florida. Robots can execute tasks with high accuracy, ensuring that each print job meets the desired standards. This has resulted in higher customer satisfaction and increased business opportunities for print production companies.

4. Safety and Risk Reduction: The implementation of robots in South Florida’s print production workflow has improved safety conditions for workers. Robots can handle hazardous or physically demanding tasks, reducing the risk of injuries. This has created a safer work environment and improved overall employee well-being.

5. Job Transformation: While the of robotics has automated certain tasks in South Florida’s print production workflow, it has also led to job transformation rather than job loss. Workers have been upskilled to operate and maintain the robotic systems, creating new job opportunities and fostering innovation within the industry.

Insight 1: Increased Efficiency and Accuracy

The of robotics in South Florida’s print production workflow has significantly improved efficiency and accuracy in the industry. Traditionally, print production involved manual labor, which was time-consuming and prone to errors. However, with the integration of robotics, tasks such as printing, binding, and packaging can now be automated, reducing the need for human intervention.

Robotic systems are designed to perform repetitive tasks with precision and consistency. They can operate 24/7, eliminating the need for breaks and reducing downtime. This increased productivity has allowed print production companies in South Florida to meet tight deadlines and handle larger volumes of work.

Furthermore, robots have the ability to handle complex printing processes that require intricate designs or multiple layers. With their high level of accuracy, robots ensure that each print is consistent and meets the desired quality standards. This has led to a reduction in waste and rework, ultimately saving costs for print production companies.

Insight 2: Improved Safety and Work Conditions

The of robotics in South Florida’s print production workflow has also had a positive impact on safety and work conditions for employees. In traditional print production, workers were often exposed to hazardous materials, such as chemicals used in printing inks, as well as heavy machinery.

By automating certain tasks, robots have reduced the risk of workplace accidents and injuries. They can handle dangerous materials and operate in potentially hazardous environments without posing a risk to human workers. This has led to a significant improvement in the overall safety of the print production industry in South Florida.

Moreover, robots have taken over physically demanding tasks, reducing the strain on human workers. This has resulted in improved work conditions and a decrease in work-related injuries caused by repetitive motions or heavy lifting. Employees can now focus on more skilled and creative aspects of print production, enhancing job satisfaction and overall well-being.

Insight 3: Adaptation and Upskilling of Workforce

The integration of robotics in South Florida’s print production workflow has necessitated the adaptation and upskilling of the workforce. While robots have automated many tasks, there is still a need for human workers to operate and maintain these systems.

Print production companies have invested in training programs to ensure that their employees can effectively collaborate with robots. Workers are being trained to operate and program robotic systems, as well as troubleshoot any technical issues that may arise. This has created new job opportunities and career paths within the industry.

Additionally, the of robotics has shifted the focus of human workers from manual labor to more creative and strategic roles. Employees are now encouraged to develop their skills in areas such as graphic design, customer service, and project management. This has not only enhanced the value of the workforce but also improved the overall quality of print production in South Florida.

Furthermore, the collaboration between human workers and robots has fostered a culture of innovation and continuous improvement. Employees are encouraged to explore new technologies and find ways to optimize the integration of robotics in the print production workflow. This has resulted in the development of new solutions and processes that further enhance the industry’s competitiveness.

The Rise of Robotic Automation in South Florida’s Print Production Workflow

South Florida’s print production industry has been experiencing a significant transformation with the integration of robotics into its workflow. This emerging trend has the potential to revolutionize the way print materials are produced, leading to increased efficiency, cost savings, and improved quality. Let’s explore some of the key trends and future implications of robotics in South Florida’s print production workflow.

1. Automated Prepress and Design

One of the areas where robotics is making a significant impact is in the prepress and design stage of print production. Traditional prepress processes involve manual tasks such as image editing, color correction, and layout design. These tasks are time-consuming and prone to human error.

With the of robotics, prepress and design tasks can now be automated, leading to faster turnaround times and improved accuracy. Robotic systems equipped with advanced algorithms can analyze and process large volumes of data, ensuring that print materials meet the desired specifications. This automation also frees up human resources to focus on more creative and strategic aspects of the design process.

2. Robotics in Printing and Finishing

Another emerging trend in South Florida’s print production workflow is the integration of robotics in the printing and finishing stages. Robotic systems are now capable of handling various printing technologies, including offset, digital, and large-format printing.

These robots can perform tasks such as loading and unloading paper, adjusting ink levels, and monitoring print quality. By automating these processes, print production companies can achieve higher productivity, reduce waste, and ensure consistent print quality. Additionally, robotic systems can be programmed to handle different finishing tasks, such as cutting, folding, and binding, further streamlining the production workflow.

3. Robotics in Packaging and Shipping

As e-commerce continues to grow, the demand for customized packaging and fast shipping has increased. Robotics is playing a crucial role in meeting these demands by automating packaging and shipping processes. Robotic systems can efficiently assemble and seal packages, apply labels, and sort them for shipping.

With the integration of robotics, print production companies in South Florida can streamline their packaging and shipping operations, reducing costs and improving efficiency. Automated systems can handle large volumes of packages with minimal human intervention, ensuring faster order fulfillment and improved customer satisfaction.

The Future Implications of Robotics in South Florida’s Print Production Workflow

The integration of robotics in South Florida’s print production workflow has already demonstrated significant benefits. However, the future implications of this emerging trend are even more promising.

1. Increased Efficiency and Cost Savings

Robotics has the potential to greatly enhance the efficiency of print production workflows in South Florida. By automating time-consuming and repetitive tasks, companies can reduce turnaround times, increase productivity, and lower labor costs. Additionally, robotic systems can optimize material usage, reducing waste and saving on production expenses.

2. Improved Quality and Consistency

Robotic automation ensures consistent quality throughout the print production process. By eliminating human error and standardizing processes, companies can deliver high-quality print materials to their clients. Robotic systems can also monitor and adjust print parameters in real-time, ensuring that the final product meets the desired specifications.

3. Enhanced Customization and Personalization

With the integration of robotics, print production companies can offer enhanced customization and personalization options to their clients. Robotic systems can handle variable data printing, allowing for the efficient production of personalized print materials. This capability opens up new opportunities for targeted marketing campaigns and tailored communication strategies.

The integration of robotics in South Florida’s print production workflow is an emerging trend that holds significant potential for the industry. From automated prepress and design to robotics in printing, finishing, packaging, and shipping, these advancements are reshaping the way print materials are produced. The future implications include increased efficiency, cost savings, improved quality, and enhanced customization. As the technology continues to evolve, South Florida’s print production industry is poised to benefit from the advantages offered by robotics.

Controversial Aspect 1: Job Displacement

One of the most significant concerns surrounding the integration of robotics in South Florida’s print production workflow is the potential job displacement it may cause. As automation and robotics technology advances, there is a fear that many traditional printing jobs may become obsolete, leading to unemployment and economic instability.

Proponents argue that robotics can actually enhance productivity and efficiency, leading to the creation of new jobs in the industry. They believe that while some roles may be automated, new positions will emerge that require skills in operating and maintaining robotic systems. Additionally, the increased efficiency brought by robotics can lead to cost savings, allowing companies to invest in other areas and potentially create more job opportunities.

However, critics argue that the transition may not be smooth, especially for workers who lack the necessary skills to adapt to the changing technological landscape. They raise concerns about the potential for a significant number of job losses, particularly among those in manual labor positions. It is crucial for companies and policymakers to address these concerns by providing retraining programs and support for affected workers to ensure a smooth transition.

Controversial Aspect 2: Quality and Customization

Another controversial aspect of incorporating robotics into print production workflows is the impact on quality and customization. Traditional printing methods often allow for a high level of craftsmanship and attention to detail, which some argue may be compromised with the of automated systems.

Proponents of robotics argue that automation can actually improve quality and consistency by eliminating human errors and reducing variability. Robotic systems can perform tasks with precision and accuracy, leading to a more standardized output. Additionally, automation can enhance customization capabilities by enabling faster turnaround times and the ability to handle complex designs or personalized orders more efficiently.

On the other hand, critics argue that the human touch and artistic nuances may be lost with the increased reliance on robotics. They argue that certain printing techniques, such as letterpress or screen printing, require a level of craftsmanship that cannot be replicated by machines. Moreover, customization may become more limited as robotic systems may struggle with handling unique or unconventional requests.

Controversial Aspect 3: Ethical Considerations

The integration of robotics in print production workflows also raises ethical considerations that need to be carefully addressed. One of the main concerns is the potential impact on workers’ rights and job security. As companies automate processes, there is a risk of workers being treated as replaceable commodities, leading to issues such as low wages, poor working conditions, and job insecurity.

Proponents argue that robotics can actually improve working conditions by eliminating repetitive and physically demanding tasks, allowing workers to focus on more complex and fulfilling roles. They believe that companies should prioritize the well-being of their employees and ensure that automation is implemented responsibly, with proper training and support provided to affected workers.

However, critics argue that without proper regulations and safeguards in place, the of robotics may lead to exploitation and inequality. They emphasize the need for policies that protect workers’ rights, provide fair compensation, and ensure job security in the face of automation. It is crucial for companies and policymakers to strike a balance between technological advancement and ethical considerations to create a sustainable and equitable work environment.

The Rise of Robotics in South Florida’s Print Production Workflow

The use of robotics has revolutionized the print production workflow in South Florida. With advancements in technology, robots are now capable of performing a wide range of tasks that were previously done manually. From prepress to finishing, these machines have significantly improved efficiency, accuracy, and overall productivity in the print industry.

Automation in Prepress: Streamlining Design and File Preparation

One area where robotics has made a significant impact is in prepress. Robots are now capable of automating design tasks, such as resizing and cropping images, adjusting color settings, and even creating complex layouts. This not only saves time but also ensures consistency and accuracy across multiple print jobs. Additionally, robots can handle file preparation, automatically checking for errors and optimizing files for printing, reducing the need for human intervention and minimizing the risk of mistakes.

Enhanced Printing Efficiency with Robotic Press Operators

Robotic press operators have become an integral part of South Florida’s print production workflow. These machines are capable of setting up and operating printing presses with minimal human intervention. They can handle tasks such as ink mixing, plate loading, and adjusting print settings, all while maintaining precise control over color accuracy and registration. By automating these processes, print shops in South Florida have been able to increase their printing capacity and reduce turnaround times.

The Role of Robotics in Bindery and Finishing

Robots have also found their place in the bindery and finishing stages of print production. These machines can perform tasks such as cutting, folding, collating, and even binding. By automating these labor-intensive processes, print shops can save time and reduce the risk of errors. For example, a robot can accurately fold and trim a large batch of brochures in a fraction of the time it would take a human operator. This not only improves efficiency but also allows print shops to handle larger volumes of work.

Quality Control and Inspection with Robotic Systems

Ensuring quality control is crucial in the print industry, and robotics has played a significant role in this aspect. Robotic systems equipped with high-resolution cameras and sensors can inspect printed materials for defects, such as misregistration, color inconsistencies, or even missing pages. These machines can detect issues that may be difficult for human operators to spot, ensuring that only high-quality prints are delivered to clients. By automating the inspection process, print shops can save time and reduce waste.

Integration of Robotics with Workflow Management Systems

One of the key advantages of using robotics in the print production workflow is the ability to integrate these machines with workflow management systems. These systems allow print shops to streamline their operations, from job submission to delivery. Robots can be programmed to automatically retrieve job files, process them, and deliver the finished prints to the appropriate location. This integration not only improves efficiency but also provides real-time tracking and reporting, allowing print shops to monitor the progress of each job and make informed decisions.

Case Study: XYZ Print Shop’s Success with Robotics

XYZ Print Shop, a leading print provider in South Florida, has experienced significant success after implementing robotics in their production workflow. By automating prepress tasks, they were able to reduce file preparation time by 50% and eliminate errors caused by manual intervention. The of robotic press operators allowed them to increase their printing capacity by 30% and reduce turnaround times for their clients. Additionally, the integration of robotic systems with their workflow management system improved overall efficiency and provided real-time tracking and reporting.

Challenges and Considerations in Adopting Robotics

While the benefits of robotics in the print production workflow are undeniable, there are also challenges and considerations that print shops in South Florida need to be aware of. One major consideration is the initial investment required to implement robotic systems. The cost of purchasing and integrating these machines can be substantial, and print shops need to carefully evaluate the return on investment. Additionally, training and re-skilling employees to work alongside robots may be necessary. Print shops also need to consider the ongoing maintenance and support required for robotic systems.

The Future of Robotics in South Florida’s Print Production Workflow

The future of robotics in South Florida’s print production workflow looks promising. As technology continues to advance, robots will become even more capable and versatile. We can expect to see further integration with artificial intelligence and machine learning, allowing robots to adapt and learn from their experiences. This will result in improved efficiency, accuracy, and customization in the print industry. Print shops in South Florida that embrace robotics will have a competitive edge, offering faster turnaround times, higher quality prints, and enhanced customer satisfaction.

The Rise of Robotics in South Florida’s Print Production Workflow

In the early 20th century, South Florida’s print production industry relied heavily on manual labor and traditional printing techniques. Printers used letterpress machines, which required skilled operators to set type and manually press ink onto paper. This labor-intensive process limited the speed and efficiency of print production.

However, with the advent of automation and the rise of robotics, the print production workflow in South Florida began to undergo significant changes. The of new technologies revolutionized the industry, allowing for faster, more precise, and cost-effective printing.

The Emergence of Computer-to-Plate Technology

One of the key advancements in print production was the of computer-to-plate (CTP) technology. In the late 1980s and early 1990s, CTP systems started to replace traditional film-based prepress workflows. This technology allowed printers to directly transfer digital files to printing plates, eliminating the need for time-consuming manual processes.

CTP technology not only improved efficiency but also enhanced the quality of printed materials. The digital transfer of files ensured greater accuracy and reduced the risk of errors caused by manual handling. This advancement paved the way for further automation in the print production workflow.

The Integration of Robotics in Prepress and Press Operations

As technology continued to evolve, South Florida’s print production industry saw the integration of robotics in prepress and press operations. Robotic systems were introduced to automate tasks such as plate loading, ink mixing, and color calibration.

Robotic plate loaders, for example, streamlined the plate loading process by automatically feeding printing plates into the press. This eliminated the need for manual plate handling, reducing the risk of damage and increasing overall productivity.

Ink mixing and color calibration, which were previously done manually, were also automated through the use of robotic systems. Robots were programmed to precisely measure and mix ink, ensuring consistent color reproduction throughout the print run. This not only saved time but also reduced ink waste and improved print quality.

The Role of Robotics in Post-Press Operations

While the initial focus of robotics in South Florida’s print production workflow was on prepress and press operations, the technology eventually found its way into post-press operations as well.

Robotic systems were introduced to automate tasks such as binding, folding, and packaging. For example, robotic binders were developed to handle the binding process, eliminating the need for manual labor and increasing production speed. Robotic folding machines ensured precise and consistent folds, reducing errors and improving the overall quality of finished products.

Furthermore, robotic packaging systems were implemented to automate the packaging process. These systems could handle tasks such as stacking, wrapping, and labeling, allowing for faster and more efficient packaging of printed materials.

The Current State of Robotics in South Florida’s Print Production Workflow

Today, robotics plays a crucial role in South Florida’s print production workflow. The integration of robotics has led to increased productivity, improved quality, and reduced costs for print businesses.

Robotic systems continue to evolve, incorporating advanced technologies such as artificial intelligence and machine learning. These advancements enable robots to perform complex tasks with greater precision and adaptability.

Furthermore, the ongoing development of collaborative robots, also known as cobots, has allowed for human-robot collaboration in the print production process. Cobots can work alongside human operators, assisting with repetitive or physically demanding tasks, enhancing productivity, and ensuring a safer work environment.

As South Florida’s print production industry continues to embrace automation and robotics, it is expected that further advancements will be made. The integration of robotics in areas such as print finishing, quality control, and logistics holds promise for increased efficiency and innovation in the future.

Case Study 1: Automation in Prepress at XYZ Printing Company

XYZ Printing Company, a leading print production company in South Florida, implemented robotics in their prepress department to streamline their workflow. Prior to automation, the company relied heavily on manual labor for tasks such as file preparation, proofing, and color correction.

By integrating robotics into their prepress workflow, XYZ Printing Company was able to significantly reduce the time and effort required for these tasks. The robots were programmed to automatically analyze and optimize files, ensuring accurate color reproduction and reducing the need for manual intervention.

This automation not only improved the efficiency of the prepress process but also eliminated errors caused by human factors. The robots consistently produced high-quality output, resulting in improved customer satisfaction and reduced rework.

Case Study 2: Robotic Binding and Finishing at ABC Press

ABC Press, a renowned printing company in South Florida, implemented robotic binding and finishing solutions to enhance their print production workflow. Traditionally, binding and finishing tasks were time-consuming and labor-intensive, requiring skilled workers to handle each step manually.

By introducing robots into their binding and finishing department, ABC Press achieved a significant increase in productivity. The robots were programmed to perform tasks such as cutting, folding, and binding with precision and speed, eliminating the need for manual labor.

This automation allowed ABC Press to handle larger print volumes in a shorter time, enabling them to meet tight deadlines and take on more projects. Additionally, the robots reduced the risk of errors and improved consistency in the binding and finishing process, resulting in higher customer satisfaction.

Success Story: Robotics in Packaging and Shipping at DEF Print Solutions

DEF Print Solutions, a South Florida-based print production company specializing in packaging and shipping, embraced robotics to optimize their workflow. Prior to automation, packaging and shipping involved manual sorting, labeling, and packing, which was time-consuming and prone to errors.

By implementing robots in their packaging and shipping department, DEF Print Solutions achieved remarkable improvements in efficiency. The robots were programmed to sort and pack printed materials automatically, ensuring accurate labeling and minimizing the risk of damage during transit.

This automation allowed DEF Print Solutions to handle large-scale packaging and shipping operations with ease. The robots worked tirelessly, reducing the time required for these tasks and enabling the company to fulfill orders faster. Furthermore, the accuracy of the robots in labeling and packing eliminated errors, resulting in improved customer satisfaction and reduced costs associated with rework or returns.

The integration of robotics in South Florida’s print production workflow has brought about significant improvements in efficiency, accuracy, and customer satisfaction. Companies like XYZ Printing Company, ABC Press, and DEF Print Solutions have successfully leveraged robotics to streamline their prepress, binding and finishing, and packaging and shipping processes. These case studies and success stories serve as compelling examples of the positive impact of robotics on print production in South Florida.

The Role of Robotics in South Florida’s Print Production Workflow

1. Automated Prepress Processes

One of the key areas where robotics has made a significant impact on South Florida‘s print production workflow is in automated prepress processes. Traditionally, prepress tasks such as file preparation, color management, and imposition were time-consuming and labor-intensive. However, with the integration of robotics, these processes have become more efficient and accurate.

Robotic systems can automatically analyze and optimize files for print, ensuring that they meet the required specifications and minimizing the need for manual intervention. This not only saves time but also reduces the risk of errors and inconsistencies in the final output.

2. Robotic Printing Systems

Another area where robotics has transformed the print production workflow in South Florida is in the printing process itself. Robotic printing systems have revolutionized the way printing is done by offering increased speed, precision, and flexibility.

Robotic printers are equipped with advanced sensors and actuators that enable them to adjust ink flow, pressure, and registration automatically. This ensures consistent print quality across different jobs and reduces the need for manual adjustments or reprints. Additionally, robotic printers can handle a wide range of substrates and formats, allowing for greater versatility in print production.

3. Automated Finishing and Binding

Robotics has also had a significant impact on the finishing and binding processes in South Florida’s print production workflow. Traditionally, these tasks required manual labor and were prone to errors and delays. However, with the of robotic systems, finishing and binding have become more efficient and reliable.

Robotic systems can perform tasks such as cutting, folding, collating, and binding with high precision and speed. They can handle complex finishing requirements and ensure consistent quality throughout the production run. By automating these processes, South Florida’s print industry has been able to streamline production, reduce costs, and improve customer satisfaction.

4. Robotics in Quality Control

Quality control is a critical aspect of the print production workflow, and robotics has played a crucial role in enhancing this process in South Florida. Robotic systems can perform automated inspections and measurements to ensure that printed materials meet the required standards.

Using advanced imaging technologies, robots can detect defects such as color variations, misregistration, and print artifacts. They can also measure color accuracy, gloss levels, and other print parameters with high precision. By automating quality control, South Florida’s print industry can identify and rectify issues early in the production process, reducing waste and improving overall print quality.

5. Integration of Robotics with Digital Technologies

Another significant aspect of the impact of robotics on South Florida’s print production workflow is the integration of robotics with digital technologies. Robotic systems can seamlessly integrate with digital workflows, allowing for greater automation and efficiency.

For example, robotic systems can be connected to digital asset management systems, enabling automated retrieval and processing of files. They can also integrate with cloud-based platforms, facilitating collaboration and remote access to print production processes. By leveraging digital technologies, South Florida’s print industry can achieve higher productivity, faster turnaround times, and improved customer experiences.

6. Training and Adaptation to Robotics

While the integration of robotics has brought numerous benefits to South Florida’s print production workflow, it has also necessitated training and adaptation for the workforce. Print industry professionals need to acquire new skills and knowledge to operate and maintain robotic systems effectively.

Training programs on robotics and automation have become essential to ensure a smooth transition and maximize the potential of these technologies. Additionally, companies need to invest in ongoing support and maintenance to keep their robotic systems running optimally. By investing in training and adaptation, South Florida’s print industry can harness the full potential of robotics and stay competitive in the evolving market.

FAQs

1. What is the impact of robotics on South Florida’s print production workflow?

The impact of robotics on South Florida’s print production workflow is significant. It has revolutionized the industry by automating repetitive tasks, increasing efficiency, reducing errors, and improving overall productivity.

2. How are robots being used in print production?

Robots are being used in various aspects of print production, such as material handling, machine operation, quality control, and packaging. They can perform tasks like loading and unloading materials, operating printing presses, inspecting printed products, and even packaging finished goods.

3. What are the benefits of using robots in print production?

The benefits of using robots in print production are numerous. They include increased productivity, improved accuracy, reduced labor costs, enhanced safety, faster turnaround times, and the ability to handle complex tasks with precision.

4. Are robots replacing human workers in the print production industry?

While robots are automating certain tasks in the print production industry, they are not replacing human workers entirely. Instead, they are augmenting human capabilities and allowing workers to focus on more skilled and creative aspects of the production process.

5. How do robots improve efficiency in print production?

Robots improve efficiency in print production by eliminating the need for manual labor in repetitive and time-consuming tasks. They can work continuously without breaks, reducing downtime and increasing overall throughput.

6. Are there any risks or challenges associated with implementing robotics in print production?

Implementing robotics in print production does come with some risks and challenges. These include the initial investment cost, the need for specialized training, potential job displacement concerns, and the requirement for regular maintenance and updates.

7. Can small print production businesses benefit from robotics?

Yes, small print production businesses can benefit from robotics. While the initial investment may be higher for smaller businesses, the long-term benefits in terms of increased productivity, reduced costs, and improved quality can outweigh the initial costs.

8. How does the use of robots impact the quality of printed products?

The use of robots in print production can significantly impact the quality of printed products. Robots can perform precise and consistent tasks, leading to fewer errors and higher quality outputs. They can also conduct real-time inspections, ensuring that each product meets the required standards.

9. Are there any ethical considerations associated with using robots in print production?

There are ethical considerations associated with using robots in print production, particularly concerning job displacement. It is important for businesses to consider how the implementation of robotics will affect their workforce and to provide support and retraining opportunities for affected employees.

10. What does the future hold for robotics in South Florida’s print production workflow?

The future of robotics in South Florida’s print production workflow looks promising. As technology continues to advance, robots will become more intelligent, versatile, and cost-effective. They will play an increasingly important role in streamlining operations, improving quality, and driving innovation in the industry.

The Role of Robotics in Print Production Workflow

Robots are playing an increasingly important role in the print production workflow in South Florida. These automated machines are revolutionizing the way printing companies operate, improving efficiency, reducing costs, and enhancing the quality of printed materials. Let’s delve into three complex concepts that highlight the impact of robotics in this industry.

1. Robotic Prepress Automation

Prepress is a crucial stage in print production where digital files are prepared for printing. It involves tasks such as file formatting, color correction, and imposition. Traditionally, these processes were performed manually by skilled technicians, which was time-consuming and prone to errors. However, with the advent of robotics, prepress automation has become a reality.

Robotic prepress automation involves the use of intelligent machines that can analyze digital files and perform the necessary adjustments automatically. These robots can detect and correct color inconsistencies, resize images, and arrange multiple pages for efficient printing. By automating these tasks, printing companies can significantly reduce the time and effort required for prepress, leading to faster turnaround times and improved accuracy.

2. Robotic Printing Presses

The printing press is the heart of any print production facility. It is responsible for transferring the digital designs onto physical substrates, such as paper or cardboard. Robotic printing presses are advanced machines that have revolutionized the printing process in South Florida.

These robots are equipped with sophisticated sensors and actuators that enable them to precisely control ink application, substrate feeding, and print registration. They can adjust the pressure, speed, and color density to ensure consistent and high-quality prints. Moreover, robotic printing presses can handle a wide range of substrates and printing techniques, making them versatile and adaptable to different customer requirements.

One of the key advantages of robotic printing presses is their ability to work autonomously. Once the necessary parameters are set, these machines can operate continuously without the need for human intervention. This not only increases productivity but also reduces labor costs and minimizes the risk of errors. Additionally, robotic printing presses can be remotely monitored and controlled, allowing printing companies to optimize their operations and respond quickly to any issues that may arise.

3. Robotic Post-Press Automation

Post-press refers to the processes that occur after printing, such as cutting, folding, binding, and finishing. These tasks require precision and attention to detail, as they directly impact the final appearance and functionality of the printed materials. Robotic post-press automation has emerged as a game-changer in South Florida’s print production workflow.

Robotic post-press automation involves the use of intelligent machines that can perform complex tasks with speed and accuracy. These robots can automatically cut printed sheets into specific sizes, fold them into desired configurations, and bind them together to create booklets or brochures. They can also apply coatings, embossing, or other finishing touches to enhance the visual appeal of the printed materials.

By automating post-press tasks, printing companies can achieve higher production volumes, reduce waste, and improve the overall quality of finished products. Robotic post-press automation also enables greater customization and personalization options, as these machines can handle variable data and adapt to different print formats seamlessly.

The integration of robotics into South Florida’s print production workflow has brought about significant advancements in efficiency, cost-effectiveness, and quality. Robotic prepress automation, robotic printing presses, and robotic post-press automation are just a few examples of how these intelligent machines are transforming the printing industry. As technology continues to evolve, we can expect even more innovative applications of robotics in the future.

1. Embrace automation in your daily tasks

Take inspiration from South Florida’s print production workflow and look for ways to incorporate automation into your daily tasks. Whether it’s using scheduling tools to streamline your work or utilizing smart home devices to automate household chores, embracing automation can save you time and effort.

2. Stay updated on technological advancements

Keep yourself informed about the latest technological advancements, especially in fields that interest you. Robotics and automation are rapidly evolving, and staying updated will help you identify opportunities to apply these advancements in your personal and professional life.

3. Identify repetitive tasks

Take a moment to identify tasks in your daily routine that are repetitive and time-consuming. These tasks are excellent candidates for automation. By automating them, you can free up your time for more meaningful and productive activities.

4. Explore robotic assistance

Consider exploring robotic assistance in your home or workplace. Robotic vacuum cleaners, lawnmowers, or even robotic arms for tasks like cooking or cleaning can make your life easier and more efficient. Research and invest in the right robotic assistant for your specific needs.

5. Learn basic programming skills

Having a basic understanding of programming can be incredibly useful when it comes to leveraging automation. Learning programming languages like Python or JavaScript can help you create custom scripts or automate repetitive tasks on your computer.

6. Utilize productivity apps and tools

Take advantage of productivity apps and tools available on your smartphone or computer. From task management apps to note-taking tools, there are numerous options to help you stay organized, manage your time effectively, and automate certain aspects of your work.

7. Experiment with smart home technology

Smart home technology is becoming increasingly accessible and affordable. Explore options like smart thermostats, lighting systems, or voice-activated assistants to automate various aspects of your home. This can enhance convenience, energy efficiency, and overall comfort.

8. Automate your finances

Consider automating your finances to save time and ensure timely payments. Set up automatic bill payments, create savings goals with automatic transfers, and utilize budgeting apps to streamline your financial management. This will help you stay on top of your finances with minimal effort.

9. Embrace virtual assistants

Virtual assistants like Siri, Alexa, or Google Assistant can be powerful tools for automation. Use them to set reminders, manage your calendar, make calls, or perform quick online searches. By delegating certain tasks to virtual assistants, you can focus on more essential activities.

10. Collaborate with automation in the workplace

If you work in an environment where automation is being implemented, embrace the collaboration between humans and robots. Learn how to effectively work alongside robotic systems, understand their capabilities, and identify areas where you can enhance productivity by leveraging their strengths.

Conclusion

The of robotics in South Florida’s print production workflow has brought about significant improvements and efficiencies. The use of robots has streamlined various aspects of the printing process, from prepress to finishing, resulting in faster turnaround times and higher quality outputs. By automating repetitive tasks, such as color calibration and page imposition, robots have eliminated human error and reduced the need for manual intervention, leading to more accurate and consistent results.

Furthermore, the integration of robotics has also allowed for greater flexibility and scalability in print production. Robots can easily adapt to changing demands and handle different print formats, sizes, and substrates with ease. This adaptability has enabled print businesses in South Florida to meet tight deadlines and cater to a wide range of customer requirements. Additionally, the use of robotics has improved worker safety by minimizing the need for employees to perform physically demanding or hazardous tasks.

Overall, the impact of robotics on South Florida’s print production workflow has been transformative. It has revolutionized the industry, making it more efficient, cost-effective, and competitive. As technology continues to advance, it is likely that robotics will play an even greater role in the future, further optimizing print production processes and opening up new possibilities for innovation in the field.