From Dot-Matrix to High-Resolution: The Remarkable Transformation of Digital Printing Technology

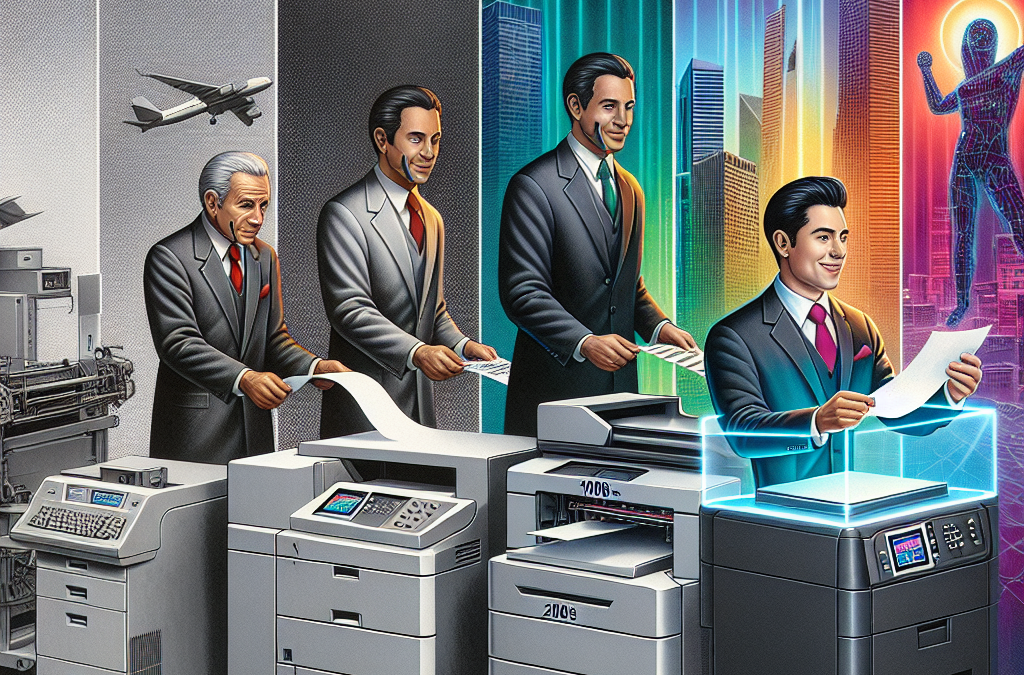

The world of printing has undergone a remarkable transformation over the past few decades, thanks to the rapid advancements in digital technology. Gone are the days of laboriously setting up metal type and painstakingly aligning ink rollers. Today, we find ourselves in the era of digital printing, where a few clicks of a button can produce vibrant, high-quality prints in a matter of seconds. But how did we get here? In this article, we will delve into the fascinating evolution of digital printing technology, exploring its origins, milestones, and the incredible impact it has had on various industries.

From its humble beginnings in the 1950s with the advent of dot matrix printers, digital printing has come a long way. Early digital printers used a matrix of pins to strike an inked ribbon against the paper, creating tiny dots that formed characters and images. While these printers were slow and produced low-resolution prints, they laid the foundation for the future of digital printing. The 1980s saw the rise of laser printers, which utilized a laser beam to transfer toner onto the paper, resulting in sharper and more precise prints. This breakthrough technology revolutionized the printing industry, making it more accessible and affordable for businesses and individuals alike. As the years went by, digital printing continued to evolve, with advancements in inkjet technology leading to faster printing speeds, higher resolutions, and a wider range of color options. Today, digital printing has become the go-to choice for many industries, including advertising, packaging, textiles, and even 3D printing. Its flexibility, cost-effectiveness, and ability to produce customized prints on demand have made it an indispensable tool for businesses worldwide. In this article, we will explore the key milestones in the evolution of digital printing technology, highlighting the game-changing innovations that have shaped the industry and examining the exciting possibilities that lie ahead.

Key Takeaways:

1. Digital printing technology has revolutionized the printing industry, offering numerous benefits such as faster turnaround times, cost-effectiveness, and customization options.

2. The evolution of digital printing technology has seen significant advancements in print quality, with high-resolution prints that rival traditional offset printing.

3. Variable data printing is a game-changer, allowing for personalized and targeted marketing materials, resulting in higher response rates and customer engagement.

4. The rise of digital printing has opened up new opportunities for small businesses and individuals, enabling them to produce professional-quality prints without the need for large print runs.

5. The integration of digital printing technology with other technologies, such as augmented reality and 3D printing, is pushing the boundaries of what can be achieved in the printing industry, creating exciting possibilities for the future.

Overall, the article will delve into the transformative impact of digital printing technology, exploring its evolution, benefits, and future prospects. Readers will gain a deeper understanding of how digital printing has changed the industry and how it continues to shape the way we produce printed materials.

: Emerging Trends and Future Highlights

Trend 1: High-Speed and High-Quality Printing

In recent years, one of the most significant advancements in digital printing technology has been the development of high-speed and high-quality printing capabilities. Traditional printing methods often struggled to keep up with the demands of modern businesses and consumers, but digital printing has changed the game.

With the of advanced inkjet and laser technologies, digital printers can now produce high-resolution prints at incredible speeds. This has revolutionized industries such as publishing, packaging, and advertising, where quick turnaround times and top-notch quality are crucial.

The implications of this trend are far-reaching. Faster printing speeds mean that businesses can meet tight deadlines and respond to market demands more efficiently. Additionally, high-quality prints allow for more vibrant colors, sharper images, and finer details, resulting in visually stunning products.

As digital printing technology continues to evolve, we can expect even faster printing speeds and higher print resolutions. This will open up new possibilities for industries that require large-scale production, such as textiles and signage. Furthermore, the combination of speed and quality will enable businesses to create personalized and customized prints on a mass scale, catering to the individual preferences of their customers.

Trend 2: Variable Data Printing

Another emerging trend in digital printing technology is variable data printing (VDP). VDP allows for the customization of each printed piece by incorporating unique data, such as names, addresses, or images, into the design. This technology has proven to be particularly valuable in direct marketing and personalized communication.

Traditionally, personalization was limited to pre-printed templates that required manual customization, resulting in higher costs and longer production times. However, with VDP, businesses can now automate the process, making it more efficient and cost-effective.

The implications of VDP are significant for businesses looking to enhance their marketing strategies. By tailoring printed materials to specific individuals or target audiences, companies can achieve higher response rates and improve customer engagement. For example, a direct mail campaign that includes personalized offers based on a recipient’s purchase history is more likely to generate interest and conversions.

Looking ahead, VDP is expected to become even more sophisticated. Advancements in data analytics and artificial intelligence will enable businesses to gather and analyze customer data more effectively, allowing for highly targeted and personalized printing. This trend has the potential to revolutionize the way businesses communicate with their customers, creating more meaningful and impactful interactions.

Trend 3: Sustainability and Eco-Friendly Printing

As environmental concerns continue to grow, the printing industry is shifting towards more sustainable and eco-friendly practices. Digital printing technology is playing a crucial role in this transition.

Unlike traditional printing methods that often involve toxic chemicals and excessive waste, digital printing offers a more environmentally friendly alternative. Digital printers use fewer resources, such as ink and paper, and produce less waste during the printing process. Additionally, the ability to print on demand reduces the need for large print runs, minimizing excess inventory and reducing carbon emissions associated with transportation.

The implications of this trend are significant for both businesses and the environment. By adopting digital printing technology, companies can reduce their ecological footprint and align with sustainable practices. This not only appeals to environmentally conscious customers but also helps businesses save costs by minimizing waste and optimizing resources.

Looking forward, the focus on sustainability in digital printing technology is expected to intensify. Manufacturers are investing in research and development to create more eco-friendly inks and substrates. Furthermore, advancements in recycling and waste management systems will further enhance the industry’s sustainability efforts.

The evolution of digital printing technology is driving significant changes across various industries. the emergence of high-speed and high-quality printing capabilities allows for faster production and superior print quality. variable data printing enables businesses to personalize their communication and marketing efforts, leading to increased engagement and response rates. lastly, the focus on sustainability and eco-friendly practices is transforming the printing industry, making it more environmentally responsible. as technology continues to advance, we can expect these trends to shape the future of digital printing, opening up new possibilities and opportunities for businesses worldwide.

The Rise of Digital Printing

Digital printing technology has revolutionized the printing industry by providing faster, more efficient, and cost-effective solutions. Unlike traditional printing methods, such as offset printing, digital printing eliminates the need for plates and allows for on-demand printing. This has opened up new possibilities for businesses and individuals alike, enabling them to print small quantities or even a single copy of a document or image. The rise of digital printing can be attributed to several key factors, including advancements in technology, the demand for personalized and customized products, and the need for quick turnaround times.

The Advantages of Digital Printing

Digital printing offers numerous advantages over traditional printing methods. One of the main advantages is the ability to produce high-quality prints with vibrant colors and sharp details. Digital printing also allows for variable data printing, which means that each print can be personalized with unique information, such as names or addresses. This is particularly useful for direct mail campaigns or targeted marketing materials. Additionally, digital printing is more environmentally friendly than traditional printing methods, as it generates less waste and requires fewer chemicals.

The Evolution of Inkjet Technology

Inkjet printing has played a significant role in the evolution of digital printing technology. Early inkjet printers were limited in terms of speed and quality, but advancements in technology have led to significant improvements. Today, inkjet printers can produce prints with resolutions of up to 2400 dpi, rivaling the quality of offset printing. The of new ink formulations, such as UV-curable and latex inks, has also expanded the range of applications for inkjet printing. These inks offer improved durability, scratch resistance, and color gamut, making them suitable for outdoor signage, vehicle wraps, and even textiles.

The Impact of Digital Printing on Marketing

Digital printing has had a profound impact on the field of marketing. It has allowed businesses to create personalized and targeted marketing materials that resonate with their target audience. For example, variable data printing enables companies to send direct mail pieces with customized offers based on the recipient’s preferences or purchase history. This level of personalization has been shown to significantly increase response rates and ROI. Digital printing has also made it easier for businesses to experiment with different designs and messages, as small print runs are more affordable and can be produced quickly.

The Role of Digital Printing in Packaging

Digital printing has transformed the packaging industry by offering shorter production runs, faster turnaround times, and greater flexibility in design. In the past, packaging was often produced in large quantities to justify the cost of offset printing. However, digital printing has made it possible to produce small batches of packaging, allowing businesses to test new products or designs without committing to a large print run. Furthermore, digital printing enables the customization of packaging, making it easier to create unique and eye-catching designs that stand out on store shelves.

The Future of Digital Printing

As technology continues to advance, the future of digital printing looks promising. One area of development is 3D printing, which has the potential to revolutionize manufacturing and prototyping. 3D printers can create three-dimensional objects by building up layers of material, offering endless possibilities in various industries, including healthcare, aerospace, and automotive. Another area of growth is the integration of digital printing with other technologies, such as augmented reality. Imagine being able to print a physical object and then use your smartphone or tablet to interact with it in a virtual environment. These advancements will continue to push the boundaries of what is possible with digital printing.

Case Study: The Impact of Digital Printing in the Publishing Industry

The publishing industry has experienced significant changes with the advent of digital printing. Traditional publishing methods often required large print runs, resulting in high upfront costs and the risk of unsold inventory. However, digital printing has allowed publishers to print books on-demand, reducing costs and eliminating the need for warehousing. Print-on-demand services, such as Amazon’s Kindle Direct Publishing, have made it easier for authors to self-publish their work and reach a global audience. This democratization of the publishing industry has led to a proliferation of new voices and genres, as well as increased accessibility for readers.

Case Study: Digital Printing in the Fashion Industry

Digital printing has also made a significant impact on the fashion industry. Traditionally, fabric printing involved lengthy and expensive processes, such as screen printing or heat transfer. However, digital textile printing has revolutionized the way fabrics are printed, allowing for greater creativity and customization. Designers can now create intricate patterns and vibrant colors directly on fabric, resulting in unique and eye-catching garments. Digital printing has also enabled the production of small quantities or even one-off pieces, catering to the growing demand for sustainable and ethically produced fashion.

The evolution of digital printing technology has transformed various industries, from marketing and packaging to publishing and fashion. Advancements in inkjet technology, the rise of on-demand printing, and the ability to personalize prints have opened up new possibilities for businesses and individuals alike. As technology continues to advance, we can expect further innovations in digital printing, including the integration of 3D printing and augmented reality. The future of digital printing is bright, and it will continue to shape the way we create, communicate, and consume printed materials.

Early Beginnings: The Emergence of Digital Printing

The history of digital printing can be traced back to the early 1950s when the first computer-driven printer, known as the IBM 3800, was introduced. This machine utilized a laser beam to create high-quality printed documents. However, it was not until the 1970s that digital printing technology began to gain traction.

The Rise of Laser Printing

In 1971, Xerox Corporation introduced the Xerox 9700, a high-speed laser printer that revolutionized the printing industry. This printer utilized laser technology to produce sharp, precise images and text. It marked a significant milestone in the development of digital printing technology, as it offered faster printing speeds and superior print quality compared to traditional printing methods.

Advancements in Inkjet Printing

While laser printing was gaining popularity, inkjet printing technology was also making significant strides. In the late 1970s, companies like Canon and Hewlett-Packard (HP) began developing inkjet printers for the consumer market. These printers used tiny droplets of ink sprayed onto the paper to create images and text.

Throughout the 1980s and 1990s, inkjet printers became more affordable and widely available, leading to their widespread adoption. The of color inkjet printers further expanded the capabilities of digital printing, allowing for the production of vibrant and realistic color prints.

The Digital Printing Revolution

The 1990s marked a turning point in the evolution of digital printing technology. Advancements in computer processing power and software development enabled the creation of more sophisticated printing systems. Digital printing became increasingly popular in commercial printing, as it offered cost-effective solutions for short-run printing and variable data printing.

One notable breakthrough during this period was the of the Indigo E-Print 1000, the first digital offset press. Developed by Indigo, this press combined the benefits of digital printing with the quality and versatility of offset printing. It allowed for high-quality prints on a wide range of substrates, opening up new possibilities for digital printing applications.

Continued Innovations: On-Demand Printing and Wide-Format Printing

In the early 2000s, on-demand printing emerged as a major trend in the printing industry. Digital printing technology enabled businesses to print materials as needed, eliminating the need for large print runs and reducing waste. This shift towards on-demand printing revolutionized the publishing industry, as books, magazines, and other printed materials could be produced quickly and cost-effectively.

Another significant development in digital printing technology was the advancement of wide-format printing. Wide-format printers, also known as large-format printers, allowed for the printing of oversized materials such as banners, posters, and signage. These printers employed advanced inkjet technology and specialized inks to produce high-quality, durable prints on a variety of media.

The Present State: Digital Printing in the Digital Age

Today, digital printing technology has become an integral part of various industries, including advertising, packaging, and textiles. The advancements in digital printing have led to faster printing speeds, improved print quality, and enhanced color accuracy. Furthermore, the integration of digital printing with web-to-print platforms and variable data printing has opened up new opportunities for personalized and targeted marketing campaigns.

Moreover, the development of 3D printing technology has expanded the capabilities of digital printing even further. 3D printers can create three-dimensional objects by layering materials such as plastic, metal, or even human tissue. This technology has revolutionized industries such as manufacturing, healthcare, and architecture, allowing for the production of complex and customized products.

The Future of Digital Printing

As technology continues to advance, the future of digital printing looks promising. The integration of artificial intelligence (AI) and machine learning algorithms is expected to enhance the efficiency and accuracy of digital printing processes. Additionally, the development of new materials and inks will enable the printing of more diverse and specialized products.

The evolution of digital printing technology has come a long way since its early beginnings. from the emergence of laser and inkjet printing to the of digital offset presses, on-demand printing, and wide-format printing, digital printing has transformed the way we produce printed materials. with ongoing innovations and advancements, digital printing is poised to play an even more significant role in the digital age and beyond.

: Case Studies and Success Stories

Case Study 1: HP Indigo’s Impact on the Printing Industry

In the late 1990s, the printing industry underwent a significant transformation with the of the HP Indigo digital press. This case study highlights the impact of HP Indigo’s technology on the industry and its continued evolution.

The HP Indigo press revolutionized the printing landscape by combining the quality of offset printing with the flexibility of digital technology. It employed electroink technology, which uses liquid ink instead of toner, resulting in vibrant and high-resolution prints. This innovation allowed for shorter print runs, faster turnaround times, and customization options that were previously unimaginable.

One success story that exemplifies the impact of HP Indigo is the collaboration between the fashion brand Burberry and HP. Burberry wanted to create personalized packaging for their iconic trench coats, and traditional printing methods were not cost-effective for such a small-scale project. With the HP Indigo press, Burberry was able to produce customized packaging for each coat, incorporating individual customer names and unique designs. This not only enhanced the brand’s image but also created a memorable and personalized experience for customers.

Furthermore, the HP Indigo press enabled businesses to adopt just-in-time printing, reducing inventory costs and waste. This was exemplified by the success of Moo.com, an online printing company. Moo.com utilized the HP Indigo press to offer customers the ability to print custom business cards, postcards, and other marketing materials in small quantities. This approach allowed businesses to order only what they needed, eliminating excess inventory and reducing their environmental footprint.

The success of the HP Indigo press paved the way for further advancements in digital printing technology, such as improved print quality, faster printing speeds, and expanded media options. Today, digital printing technology continues to evolve, offering even more possibilities for businesses across various industries.

Case Study 2: Xerox’s Versatility in Digital Printing

Xerox, a renowned name in the printing industry, has been at the forefront of digital printing technology for decades. This case study focuses on Xerox’s versatile digital printing solutions and their impact on businesses.

One success story that showcases Xerox’s versatility is their collaboration with the publishing industry. Traditional book printing required large print runs, making it challenging for authors and publishers to test the market or cater to niche audiences. Xerox’s digital printing technology changed this paradigm by enabling print-on-demand services. Authors could now have their books printed in small quantities or even one copy at a time, reducing costs and minimizing inventory risks. This approach opened up new opportunities for self-publishing and niche markets, empowering authors and small publishers to bring their works to a wider audience.

Another success story is Xerox’s work with direct mail marketing companies. Direct mail campaigns have always been effective in reaching target audiences, but traditional printing methods limited personalization options and made it difficult to track campaign performance. Xerox’s digital printing solutions allowed for variable data printing, enabling companies to personalize each piece of direct mail with customer-specific information. This level of customization significantly increased response rates and campaign effectiveness. Additionally, the digital printing technology provided real-time tracking and analytics, allowing businesses to measure the success of their campaigns and make data-driven decisions for future marketing efforts.

Xerox’s commitment to continuous innovation has resulted in advancements such as high-speed inkjet printing and the integration of digital and offset printing technologies. These developments have further expanded the possibilities of digital printing, making it a versatile and reliable solution for businesses across industries.

Case Study 3: 3D Printing Revolutionizes Manufacturing

The evolution of digital printing technology goes beyond traditional 2D printing. 3D printing, also known as additive manufacturing, has emerged as a game-changer in various industries, from aerospace to healthcare. This case study explores the impact of 3D printing on manufacturing processes and its transformative potential.

One notable success story in the field of 3D printing is the partnership between General Electric (GE) and Concept Laser, a leading provider of metal 3D printing solutions. GE recognized the potential of 3D printing to revolutionize the production of complex components for their jet engines. By utilizing Concept Laser’s technology, GE was able to print intricate parts that were lighter, more durable, and more efficient than their traditionally manufactured counterparts. This not only reduced the weight of the engines, resulting in fuel savings, but also simplified the production process, reducing lead times and costs.

Another industry that has benefited from 3D printing is healthcare. In 2014, a baby born with a rare condition called tracheobronchomalacia faced severe respiratory challenges. Traditional treatment options were limited, and surgery carried significant risks. However, using 3D printing technology, surgeons at the University of Michigan were able to create a custom-designed splint to support the baby’s airway. This innovative solution saved the baby’s life and demonstrated the potential of 3D printing in personalized medicine.

The success of 3D printing in these case studies highlights its ability to transform manufacturing processes, enabling greater design freedom, cost savings, and improved product performance. As the technology continues to evolve, it holds immense potential for disrupting traditional manufacturing methods and unlocking new possibilities in various industries.

Digital printing technology has revolutionized the printing industry, enabling faster, more versatile, and cost-effective printing solutions. Over the years, this technology has evolved significantly, pushing the boundaries of what is possible in terms of quality, speed, and customization. In this article, we will explore the key aspects of the evolution of digital printing technology.

1. Inkjet Printing

Inkjet printing is one of the most common digital printing technologies used today. It works by propelling tiny droplets of ink onto the printing substrate. Early inkjet printers used thermal or piezoelectric mechanisms to control the droplet ejection. However, modern inkjet printers have evolved to incorporate advanced printhead technologies, such as Micro-Electro-Mechanical Systems (MEMS), which enable higher resolution, faster printing speeds, and better color accuracy.

1.1 Continuous Inkjet (CIJ)

Continuous inkjet printing is the oldest form of inkjet technology. It involves a continuous stream of ink droplets being generated, with only the desired droplets being deflected onto the substrate. This technology is ideal for high-speed printing applications, such as industrial coding and marking.

1.2 Drop-on-Demand (DOD)

Drop-on-demand inkjet printing is the most widely used inkjet technology today. It works by ejecting ink droplets only when needed, resulting in precise control and minimal ink wastage. DOD inkjet printers can be further classified into thermal and piezoelectric inkjet technologies.

1.2.1 Thermal Inkjet (TIJ)

Thermal inkjet technology uses tiny resistors to heat the ink, creating a vapor bubble that forces the ink droplet onto the substrate. TIJ printers are known for their high resolution and excellent color reproduction, making them popular for photo printing and graphic arts applications.

1.2.2 Piezoelectric Inkjet

Piezoelectric inkjet technology relies on piezoelectric materials that change shape when an electric field is applied. These materials control the ink droplet ejection by applying pressure to the ink chamber. Piezoelectric inkjet printers offer greater flexibility in terms of ink compatibility and are commonly used in industrial printing, textile printing, and 3D printing.

2. Electrophotography (Laser Printing)

Electrophotography, commonly known as laser printing, is another significant digital printing technology. It uses a combination of electrostatic charges and toner to create an image on the substrate. Laser printers have evolved to become faster, more efficient, and capable of higher print resolutions.

2.1 Photoreceptor

The photoreceptor, typically a drum or a belt, plays a crucial role in laser printing. It is coated with a photoconductive material that holds an electrostatic charge. The photoreceptor is exposed to a laser beam or LED array, which selectively discharges the areas where the image will be formed.

2.2 Charging

After the photoreceptor is exposed to the laser, it passes through a charging unit that applies a uniform electrostatic charge to the surface. This charge prepares the photoreceptor for the next step in the process.

2.3 Developing

In the developing stage, toner particles are attracted to the areas of the photoreceptor that have been discharged by the laser. The toner is transferred from the developer unit onto the photoreceptor, forming the image.

2.4 Transfer

Once the image is formed on the photoreceptor, it is transferred onto the substrate, typically a sheet of paper or other media. This transfer is achieved by applying an opposite charge to the back of the paper, attracting the toner particles away from the photoreceptor.

2.5 Fusing

The final step in laser printing is the fusing process, where heat and pressure are applied to the toner particles to melt and bond them to the substrate. This ensures a permanent and durable image.

3. Digital Offset Printing

Digital offset printing combines the best aspects of traditional offset printing with the advantages of digital technology. It involves transferring the image from a digital file directly onto a printing plate, which is then used to transfer the image onto the substrate.

3.1 Computer-to-Plate (CTP)

Computer-to-plate technology eliminates the need for film negatives by directly imaging the printing plate using lasers or LEDs. This process improves accuracy, reduces setup time, and allows for greater flexibility in printing variable data.

3.2 Plate Imaging

In digital offset printing, the printing plate is imaged using a laser or LED array that selectively exposes the plate’s photosensitive layer. The exposed areas become hydrophilic, attracting the ink, while the unexposed areas remain hydrophobic, repelling the ink.

3.3 Offset Printing Process

Once the plate is imaged, it goes through the traditional offset printing process. The ink is transferred from the plate to a rubber blanket cylinder and then onto the substrate. This process allows for high-quality printing on a variety of substrates, including paper, cardboard, and plastic.

The evolution of digital printing technology has transformed the printing industry, enabling faster turnaround times, high-quality prints, and greater customization options. From the early days of inkjet printing to the advanced digital offset printing techniques, each technology has its unique advantages and applications. As technology continues to advance, we can expect further innovations in digital printing, pushing the boundaries of what is possible in the world of print.

FAQs about the Evolution of Digital Printing Technology

1. What is digital printing technology?

Digital printing technology refers to the process of printing digital images or documents directly onto various substrates, such as paper, fabric, plastic, or metal, using computer-controlled machines. It eliminates the need for traditional printing plates or screens, allowing for quick and efficient printing.

2. How has digital printing technology evolved over the years?

Initially, digital printing was limited to small-scale applications and low-quality outputs. However, advancements in technology have led to significant improvements in print quality, speed, and versatility. Today, digital printing can produce high-resolution prints with vibrant colors, and it can handle a wide range of materials and finishes.

3. What are the advantages of digital printing over traditional printing methods?

Digital printing offers several advantages over traditional printing methods, including:

- Quick turnaround times: Digital printing allows for on-demand printing, eliminating the need for lengthy setup times.

- Cost-effective for small print runs: Unlike traditional printing, digital printing does not require expensive setup costs, making it more affordable for small print quantities.

- Variable data printing: Digital printing enables the customization of each printed piece, making it ideal for personalized marketing materials.

- High-quality output: With advancements in technology, digital printing can now produce prints with exceptional image quality and color accuracy.

4. Can digital printing be used for large-scale printing?

Yes, digital printing can be used for large-scale printing. While it may not be as cost-effective as traditional printing methods for very large print runs, digital printing technology has improved to handle larger quantities efficiently. Many commercial printers now offer digital printing services for both small and large-scale projects.

5. What are some common applications of digital printing?

Digital printing is widely used in various industries and applications, including:

- Marketing and advertising materials, such as brochures, flyers, and banners

- Labels and packaging

- Photographic prints and fine art reproductions

- Textile printing for apparel, home decor, and signage

- Variable data printing for personalized direct mail campaigns

6. Are there any limitations to digital printing?

While digital printing technology has come a long way, it still has some limitations. These include:

- Color matching: Achieving precise color accuracy can be challenging, especially when matching specific Pantone colors.

- Limited range of substrates: Although digital printing can handle a wide range of materials, certain specialty substrates may not be compatible.

- Print size limitations: Digital printers have size limitations compared to traditional printing methods, which can affect large-format printing.

7. How eco-friendly is digital printing compared to traditional printing?

Digital printing is generally considered more eco-friendly than traditional printing methods. It produces less waste as it does not require setup materials like plates or screens. Additionally, digital printing allows for on-demand printing, reducing excess inventory and minimizing paper waste. However, the environmental impact can vary depending on factors such as ink usage and disposal practices.

8. What is the future of digital printing technology?

The future of digital printing technology looks promising. Advancements in inkjet and toner technologies continue to improve print quality and speed. Additionally, developments in 3D printing are expanding the possibilities of digital printing beyond flat surfaces. As technology evolves, we can expect digital printing to become even more versatile, efficient, and accessible.

9. Can I print my own digital designs at home?

Yes, you can print your own digital designs at home using a desktop inkjet or laser printer. These printers are affordable and easy to use, making them suitable for small-scale printing needs. However, it’s important to note that the print quality and color accuracy may not be on par with commercial digital printing services.

10. How can I find a reliable digital printing service provider?

When looking for a digital printing service provider, consider the following factors:

- Experience and reputation: Look for a company with a proven track record in digital printing and positive customer reviews.

- Capabilities: Ensure that the service provider has the necessary equipment and expertise to handle your specific printing requirements.

- Sample prints: Request samples of their previous work to assess the print quality and color accuracy.

- Customer service: Choose a provider that offers excellent customer service and is responsive to your inquiries and concerns.

- Pricing: Compare quotes from different providers to ensure you are getting a fair price for the services offered.

Concept 1: Inkjet Printing

Inkjet printing is a method of printing where tiny droplets of ink are sprayed onto paper to create an image or text. It has evolved significantly over the years and is now widely used in homes, offices, and commercial printing.

Initially, inkjet printers used a single color cartridge, which limited the quality and range of colors that could be produced. However, advancements in technology led to the development of printers with multiple color cartridges, allowing for more accurate color reproduction.

Another important development in inkjet printing is the improvement in print resolution. Print resolution refers to the number of dots per inch (dpi) that a printer can produce. Higher dpi means more dots, resulting in sharper and more detailed prints.

Moreover, the of photo inkjet printers revolutionized the printing of photographs. These printers use additional colors, such as light cyan and light magenta, to produce more vibrant and realistic photo prints.

Furthermore, the size of inkjet printers has also reduced significantly. Compact and portable inkjet printers are now available, making it easier for people to print on the go.

Concept 2: Laser Printing

Laser printing is another important advancement in digital printing technology. It uses a laser beam to create an electrostatic image on a drum, which is then transferred onto paper using toner.

One of the key advantages of laser printing is its speed. Laser printers can produce prints at a much faster rate compared to inkjet printers. This makes them ideal for high-volume printing in offices and commercial settings.

Additionally, laser printers offer superior print quality, especially when it comes to text documents. The laser technology allows for precise and sharp text, making it easier to read.

Laser printers also have the ability to print on a variety of media, including envelopes, labels, and transparencies. This versatility makes them suitable for a wide range of printing needs.

Furthermore, laser printers have become more affordable over time, making them accessible to a larger audience. This has contributed to their widespread adoption in both personal and professional settings.

Concept 3: 3D Printing

3D printing is a revolutionary technology that allows the creation of three-dimensional objects from digital files. It has the potential to transform various industries, including manufacturing, healthcare, and even fashion.

The process of 3D printing involves creating a digital design using computer-aided design (CAD) software. The design is then sliced into thin layers, and the 3D printer builds the object layer by layer.

One of the key advantages of 3D printing is its ability to create complex and intricate structures that would be difficult or impossible to produce using traditional manufacturing methods. This opens up new possibilities for design and innovation.

Moreover, 3D printing allows for customization and personalization. It enables individuals to create unique products tailored to their specific needs and preferences. For example, in healthcare, 3D printing has been used to create personalized prosthetics and implants.

Furthermore, 3D printing is more sustainable compared to traditional manufacturing processes. It reduces waste as objects are built only using the necessary materials. Additionally, it has the potential to reduce transportation and storage costs as objects can be printed on-demand, eliminating the need for large inventories.

However, it’s important to note that 3D printing is still evolving, and there are challenges to overcome, such as the limited range of materials that can be used and the time it takes to print complex objects. Nonetheless, as technology continues to advance, 3D printing holds great promise for the future.

The evolution of digital printing technology has revolutionized the way we print and create objects. inkjet printing has improved in terms of color accuracy, resolution, and portability. laser printing offers faster speed, superior print quality, and versatility. 3d printing has the potential to transform industries by enabling the creation of complex and customized objects. these advancements have made printing more accessible, efficient, and innovative.

1. Stay updated on the latest digital printing technology

Keeping yourself informed about the latest advancements in digital printing technology is essential if you want to apply this knowledge in your daily life. Follow industry news, subscribe to relevant blogs or newsletters, and attend conferences or webinars to stay up-to-date with the latest trends and innovations in the field.

2. Understand the different types of digital printing

Digital printing encompasses various techniques, including inkjet, laser, and 3D printing. Take the time to understand the strengths and limitations of each method to determine which one suits your specific needs. This knowledge will help you make informed decisions when it comes to printing documents, photographs, or even creating 3D models.

3. Explore personal printing options

Investigate personal digital printing options that can enhance your daily life. Home printers equipped with high-quality photo printing capabilities allow you to print your own photographs, create personalized greeting cards, or design custom labels for various purposes. Consider the features and cost-effectiveness of different printers before making a purchase.

4. Utilize digital printing for artistic expression

Digital printing technology provides artists with new avenues for creative expression. Experiment with printing your artwork on different mediums, such as canvas or specialty papers, to create unique and visually striking pieces. Explore the possibilities of combining digital printing with traditional art techniques to push the boundaries of your creativity.

5. Customize your home decor

Digital printing technology allows you to personalize your home decor by printing custom wallpapers, wall decals, or even fabric patterns. Consider using digital printing to create unique and eye-catching designs that reflect your personal style. You can also print custom artwork or photographs to display as wall art.

6. Enhance your business marketing materials

If you own a business, digital printing technology can greatly enhance your marketing efforts. Use high-quality digital printing to create professional business cards, brochures, flyers, or banners. The ability to print on-demand allows for easy customization and quick turnaround, ensuring that your marketing materials are always up-to-date and impactful.

7. Explore digital textile printing

Digital printing has revolutionized the textile industry, allowing for the production of vibrant and intricate designs on fabrics. Consider exploring digital textile printing to create custom clothing, accessories, or home textiles. This technology also enables small-scale production, making it ideal for independent designers or entrepreneurs looking to start their own fashion or home decor business.

8. Embrace sustainable printing practices

Digital printing technology offers several sustainability advantages over traditional printing methods. It produces less waste, uses fewer chemicals, and allows for more precise ink usage. When applicable, choose digital printing to reduce your environmental footprint. Additionally, opt for eco-friendly paper and ink options to further minimize your impact on the environment.

9. Collaborate with printing professionals

If you have complex printing needs or require professional-quality results, consider partnering with printing professionals who specialize in digital printing. They can provide guidance on the best printing techniques, materials, and finishes to achieve your desired outcome. Collaborating with experts can save you time, money, and ensure optimal results.

10. Experiment and have fun!

Digital printing technology offers endless possibilities for experimentation and fun. Don’t be afraid to explore different techniques, materials, and designs. Use digital printing to unleash your creativity and bring your ideas to life. Whether it’s creating personalized gifts, designing unique clothing, or printing your own artwork, embrace the joy of experimenting with digital printing technology.

Remember, the evolution of digital printing technology continues to push boundaries and open new doors for innovation. By staying informed, exploring different applications, and embracing your creativity, you can harness the power of digital printing to enhance your daily life in countless ways.

: Debunking Common Misconceptions

Misconception 1: Digital printing is inferior to traditional printing methods

Digital printing has often been seen as a less prestigious alternative to traditional printing methods such as offset printing. However, this perception is outdated and fails to recognize the significant advancements made in digital printing technology over the years.

One of the main reasons for this misconception is the assumption that digital printing cannot match the quality and color accuracy of traditional methods. While it is true that early digital printers had limitations in terms of color gamut and resolution, modern digital printers have closed the gap considerably.

Today, digital printing technology has reached a level where it can produce prints of exceptional quality and color accuracy. High-end digital printers use advanced color management systems and sophisticated inkjet technology to achieve results that rival or even surpass those of traditional methods. Furthermore, digital printing allows for more precise control over color consistency, making it ideal for projects that require accurate color reproduction.

Another aspect where digital printing has made significant strides is in its ability to handle a wide range of substrates. While traditional printing methods are often limited to paper and certain types of materials, digital printers can handle various surfaces, including fabrics, plastics, metals, and even ceramics. This versatility opens up new possibilities for personalized and customized printing applications.

Misconception 2: Digital printing is only suitable for short print runs

One common misconception is that digital printing is primarily suited for short print runs, while traditional methods are better for large-scale production. While it is true that digital printing offers advantages in terms of cost and turnaround time for short runs, it is not limited to small-scale projects.

Advancements in digital printing technology have significantly improved its efficiency and productivity, making it a viable option for medium to large print runs as well. Modern digital printers can handle high volumes of print jobs without compromising quality or speed. Additionally, digital printing eliminates the need for time-consuming setup processes, allowing for quicker turnaround times compared to traditional methods.

Moreover, digital printing offers the advantage of variable data printing (VDP), which allows for the customization of each printed piece within a single print run. This capability is particularly useful for targeted marketing campaigns, personalized direct mail, and other applications that require individualized content. Traditional printing methods would require separate plates or setups for each version, making it less efficient and cost-effective for such projects.

Misconception 3: Digital printing is environmentally unfriendly

Many people assume that digital printing is less eco-friendly than traditional printing methods due to the use of toners and inks. However, this is a misconception that fails to consider the overall environmental impact of both methods.

Traditional printing methods often involve more waste and resource consumption. Offset printing, for example, requires the creation of metal plates, which can generate significant waste during the setup process. Additionally, the use of chemical solvents for plate cleaning and ink drying contributes to air and water pollution.

In contrast, digital printing significantly reduces waste by eliminating the need for plates and minimizing setup time. It enables on-demand printing, reducing excess inventory and the risk of obsolescence. Moreover, digital printers consume less energy during operation and produce fewer emissions compared to traditional printing presses.

Furthermore, advancements in digital printing technology have led to the development of more sustainable ink formulations. Many manufacturers now offer environmentally friendly options such as vegetable-based inks, low VOC (volatile organic compound) inks, and water-based inks. These alternatives reduce the environmental impact without compromising print quality.

It is important to dispel these common misconceptions about the evolution of digital printing technology. digital printing has come a long way and is now capable of producing high-quality prints, handling large print runs, and offering environmentally friendly options. embracing digital printing can provide numerous benefits for businesses and individuals looking for efficient, versatile, and sustainable printing solutions.

In conclusion, the evolution of digital printing technology has revolutionized the printing industry in numerous ways. The shift from traditional printing methods to digital printing has brought about increased efficiency, cost-effectiveness, and improved quality.

One key point discussed is the advent of high-speed digital printers, which have significantly reduced production time and allowed for on-demand printing. This has enabled businesses to meet customer demands more effectively and efficiently, resulting in reduced inventory costs and improved customer satisfaction. Additionally, the advancements in digital printing technology have led to the development of variable data printing, allowing for personalized and targeted marketing materials. This has proven to be highly effective in increasing customer engagement and response rates.

Furthermore, the integration of digital printing technology with other digital platforms, such as online ordering systems and web-to-print solutions, has streamlined the printing process and made it more accessible to a wider range of users. This has opened up new opportunities for small businesses and individuals to create professional-quality printed materials without the need for large investments in printing equipment.

Overall, the evolution of digital printing technology has transformed the printing industry, providing numerous benefits such as increased efficiency, cost-effectiveness, improved quality, and expanded opportunities for businesses and individuals alike. As technology continues to advance, it is exciting to anticipate what further developments will emerge and how they will continue to shape the future of printing.