Revolutionizing Copier Maintenance: Harnessing the Power of Digital Twins for Unparalleled Efficiency

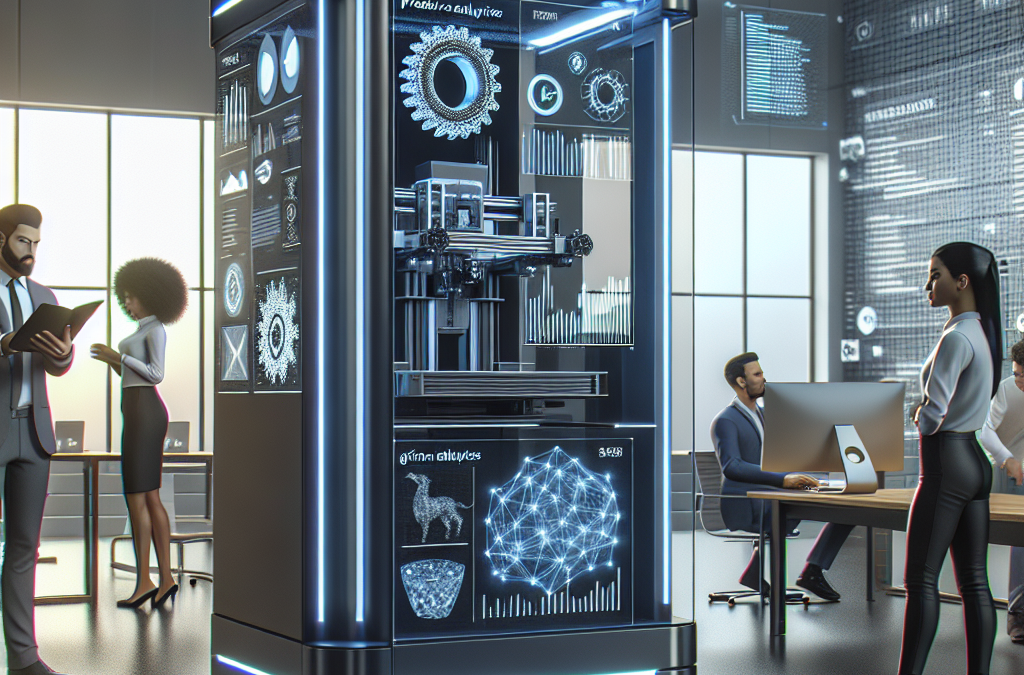

In today’s fast-paced business world, copiers play a crucial role in maintaining productivity and efficiency. However, when these machines break down unexpectedly, it can lead to costly delays and frustration. To combat this issue, companies are now turning to the power of digital twins for predictive copier maintenance and optimization. By creating virtual replicas of their physical copiers, businesses can gain valuable insights into their machines’ health, detect potential issues before they occur, and optimize performance to ensure smooth operations.

In this article, we will explore the concept of digital twins and how they are revolutionizing copier maintenance. We will delve into the benefits of leveraging digital twins for predictive maintenance, such as reducing downtime, minimizing repair costs, and improving overall copier performance. Additionally, we will discuss the technologies and tools used to create and monitor digital twins, as well as the challenges and considerations businesses need to address when implementing this innovative approach. With the help of digital twins, companies can proactively manage their copiers, maximize uptime, and optimize their printing infrastructure for enhanced productivity.

Key Takeaways:

1. Digital twins offer a revolutionary approach to copier maintenance and optimization, allowing businesses to predict and prevent breakdowns before they occur.

2. By creating a virtual replica of a copier, businesses can monitor its performance in real-time, identify potential issues, and take proactive measures to ensure optimal functionality.

3. Leveraging digital twins enables copier manufacturers and service providers to offer more efficient and cost-effective maintenance solutions, reducing downtime and improving customer satisfaction.

4. Predictive maintenance powered by digital twins can significantly extend the lifespan of copiers, saving businesses money on costly repairs and replacements.

5. The data collected from digital twins can be used to optimize copier performance, identify usage patterns, and make informed decisions about fleet management and future investments.

Overall, digital twins are revolutionizing copier maintenance and optimization by providing businesses with valuable insights and predictive capabilities. By harnessing the power of digital twins, businesses can reduce maintenance costs, improve copier performance, and enhance overall productivity.

The Ethics of Data Collection and Privacy Concerns

One of the most controversial aspects of leveraging digital twins for predictive copier maintenance and optimization is the ethics of data collection and the privacy concerns associated with it. Digital twins require a vast amount of data to accurately simulate and predict copier performance, which raises questions about the extent to which individuals’ personal information is being collected and utilized.

On one hand, proponents argue that the collection of data is necessary for improving copier performance and reducing downtime. By analyzing user behavior, machine usage patterns, and environmental conditions, manufacturers can identify potential issues before they occur, resulting in more efficient maintenance and optimization processes. This can lead to cost savings for businesses and a better user experience.

However, critics argue that the extensive data collection required for digital twins raises serious privacy concerns. Users may feel uncomfortable knowing that their copier usage data is being monitored and analyzed, potentially revealing sensitive information about their work habits or personal activities. There is also the risk of data breaches, where unauthorized individuals could gain access to this data and misuse it for malicious purposes.

It is important to strike a balance between utilizing data for improving copier performance and respecting individuals’ privacy rights. Manufacturers should be transparent about the data they collect, how it is used, and provide users with clear options to opt-out if they do not wish to participate. Implementing robust security measures to protect data from unauthorized access is also crucial to address privacy concerns.

Implications for Job Security and Employment

Another controversial aspect of leveraging digital twins for predictive copier maintenance and optimization is the potential implications for job security and employment in the copier industry. As digital twins become more sophisticated and capable of autonomously diagnosing and resolving issues, the need for manual intervention and on-site technicians may decrease.

Advocates argue that digital twins can enhance the efficiency of copier maintenance and optimization processes, leading to reduced downtime and cost savings for businesses. By automating routine tasks, technicians can focus on more complex and specialized tasks, improving overall service quality. This can also create new job opportunities in areas such as data analysis and software development, as digital twins require skilled professionals to develop and maintain them.

However, critics express concerns about the potential job displacement caused by the adoption of digital twins. If copier maintenance and optimization become largely automated, the demand for on-site technicians may decrease, leading to job losses in the industry. This raises questions about the social and economic implications of technological advancements and the responsibility of manufacturers to ensure a just transition for workers.

It is important for manufacturers to consider the potential impact on employment and develop strategies to mitigate any negative consequences. This could include reskilling and upskilling programs to support technicians in adapting to new roles and technologies. Collaboration between manufacturers, trade unions, and policymakers is essential to ensure that the adoption of digital twins does not disproportionately harm workers and that the benefits are shared equitably.

Reliability and Accuracy of Predictive Models

The reliability and accuracy of predictive models used in digital twins for copier maintenance and optimization is another controversial aspect. Digital twins rely on complex algorithms and machine learning techniques to analyze copier data and make predictions about potential issues. However, there are concerns about the accuracy and reliability of these models, particularly in real-world scenarios.

Proponents argue that predictive models can significantly improve copier maintenance and optimization by identifying potential issues before they cause major disruptions. By continuously analyzing copier data and comparing it to historical patterns, digital twins can detect anomalies and provide early warnings, allowing for proactive maintenance. This can result in increased copier uptime and improved overall performance.

On the other hand, critics raise concerns about the limitations and potential biases of predictive models. Machine learning algorithms are only as good as the data they are trained on, and if the data used to develop the models is incomplete or biased, it can lead to inaccurate predictions. There is also the challenge of accounting for unpredictable factors that may impact copier performance, such as environmental conditions or user behavior that cannot be easily captured by data.

Manufacturers must invest in rigorous testing and validation processes to ensure the reliability and accuracy of predictive models. Transparency in the development and implementation of these models is also crucial, allowing users and independent experts to scrutinize the algorithms and identify potential biases or limitations. Ongoing monitoring and refinement of the models based on real-world feedback can help improve their performance over time.

Digital twins revolutionize copier maintenance and optimization

Digital twins have emerged as a game-changing technology in the copier industry, enabling businesses to improve maintenance and optimize copier performance like never before. By creating a virtual replica of physical copiers, digital twins offer real-time insights and predictive analytics that help identify potential issues, streamline maintenance processes, and enhance overall operational efficiency. This article explores three key insights into how leveraging digital twins can revolutionize copier maintenance and optimization.

Insight 1: Proactive maintenance reduces downtime and costs

One of the most significant advantages of digital twins in copier maintenance is the ability to proactively identify and address potential issues before they cause major disruptions. Traditional maintenance practices often rely on reactive measures, waiting for copiers to break down before taking action. This approach not only leads to costly downtime but also increases the risk of more extensive damage and expensive repairs.

With digital twins, copier manufacturers and service providers can continuously monitor the performance of virtual replicas in real-time. By analyzing data from various sensors and IoT devices embedded in the copiers, they can detect early warning signs of potential failures or malfunctions. This proactive approach allows for timely intervention, preventing breakdowns and minimizing downtime.

Moreover, digital twins enable predictive analytics, leveraging historical data and machine learning algorithms to forecast when specific components might fail or require maintenance. By accurately predicting maintenance needs, businesses can schedule proactive servicing during planned downtime, minimizing disruption to operations and reducing overall maintenance costs.

Insight 2: Optimizing copier performance enhances productivity

Digital twins not only enable proactive maintenance but also provide valuable insights for optimizing copier performance. By analyzing data collected from the virtual replicas, businesses can identify patterns, trends, and inefficiencies that impact copier productivity.

For instance, digital twins can monitor factors such as paper jams, ink or toner consumption, and printing speeds. By analyzing this data, businesses can identify bottlenecks or recurring issues that hamper copier performance. They can then make informed decisions to optimize workflows, improve paper handling systems, or implement software updates that enhance overall copier efficiency.

Furthermore, digital twins allow for scenario modeling and simulation, enabling businesses to test different settings, configurations, or upgrades virtually. By simulating changes in the virtual environment, businesses can evaluate the potential impact on copier performance before implementing them in the physical world. This not only reduces the risk of costly mistakes but also ensures that any modifications or optimizations are tailored to the specific needs of the copiers and the business.

Insight 3: Remote monitoring and support increase customer satisfaction

Another significant advantage of digital twins in copier maintenance is the ability to provide remote monitoring and support to customers. Traditionally, copier service providers relied on manual inspections and customer reports to identify issues and provide support. This often led to delays in addressing problems and increased customer frustration.

With digital twins, copier manufacturers and service providers can remotely monitor the performance of copiers in real-time. By analyzing data from the virtual replicas, they can identify potential issues even before customers notice them. This allows for proactive support, with service providers reaching out to customers to resolve problems or schedule maintenance before they become major concerns.

Moreover, digital twins enable remote troubleshooting and diagnostics. Service technicians can access the virtual replicas to analyze copier data, identify the root causes of issues, and provide remote assistance to customers. This reduces the need for on-site visits, saving time and costs for both the service provider and the customer. Additionally, remote support improves customer satisfaction by minimizing copier downtime and resolving issues more efficiently.

Digital twins have the potential to revolutionize copier maintenance and optimization in the industry. By enabling proactive maintenance, optimizing copier performance, and providing remote monitoring and support, businesses can enhance operational efficiency, reduce downtime and costs, and increase customer satisfaction. As this technology continues to evolve, copier manufacturers and service providers should embrace digital twins to stay ahead of the competition and deliver superior copier solutions to their customers.

Emerging Trend: Integration of IoT Sensors

One of the emerging trends in the field of copier maintenance and optimization is the integration of Internet of Things (IoT) sensors with digital twin technology. IoT sensors are small devices that can be embedded in copiers to collect real-time data about their performance, usage, and condition. This data is then transmitted to a central system where it is analyzed and used to create a digital twin of the copier.

The digital twin is a virtual replica of the physical copier, which is continuously updated with the latest data from the IoT sensors. By analyzing the data collected by the sensors, the digital twin can provide insights into the copier’s performance, identify potential issues or failures, and even predict when maintenance or repairs will be needed.

This integration of IoT sensors with digital twin technology has several benefits for copier maintenance and optimization. Firstly, it allows for proactive maintenance, where potential issues can be identified and addressed before they cause any major problems. This not only reduces downtime but also extends the lifespan of the copier, saving costs on repairs and replacements.

Secondly, the data collected by the IoT sensors can be used to optimize the copier’s performance. By analyzing usage patterns and identifying areas for improvement, the digital twin can suggest changes to settings or workflows that can increase efficiency and productivity.

Overall, the integration of IoT sensors with digital twin technology is revolutionizing copier maintenance and optimization by enabling proactive maintenance and performance optimization.

Emerging Trend: Machine Learning and Artificial Intelligence

Another emerging trend in the field of copier maintenance and optimization is the use of machine learning and artificial intelligence (AI) algorithms to analyze the data collected by digital twins. Machine learning algorithms are able to learn from the data and make predictions or recommendations based on patterns and trends.

By applying machine learning and AI algorithms to the data collected by digital twins, copier maintenance and optimization can be taken to the next level. These algorithms can analyze large amounts of data quickly and accurately, identifying patterns and anomalies that may not be immediately apparent to human operators.

For example, machine learning algorithms can identify patterns in copier usage data that indicate a specific part is likely to fail in the near future. This allows for proactive maintenance, where the part can be replaced before it causes any major issues. Similarly, machine learning algorithms can analyze usage data to identify areas where the copier’s performance can be optimized, such as adjusting settings or workflows.

The use of machine learning and AI algorithms in copier maintenance and optimization not only improves efficiency and reduces downtime but also enables predictive maintenance, where potential issues can be identified and addressed before they occur.

Future Implications: Remote Monitoring and Management

Looking ahead, the integration of digital twins, IoT sensors, and machine learning algorithms has the potential to enable remote monitoring and management of copiers. With the ability to collect real-time data about copier performance and condition, and analyze it using machine learning algorithms, copier maintenance and optimization can be done remotely, without the need for physical inspections or interventions.

This has several implications for the future of copier maintenance and optimization. Firstly, it allows for more efficient and cost-effective maintenance. Instead of sending technicians to inspect and service copiers on-site, remote monitoring and management can be done from a central location, reducing travel time and costs.

Secondly, remote monitoring and management enable faster response times. With real-time data and machine learning algorithms, potential issues can be identified and addressed immediately, reducing downtime and improving productivity.

Finally, remote monitoring and management also open up possibilities for predictive maintenance and optimization. By continuously collecting and analyzing data, digital twins can predict when maintenance or repairs will be needed and recommend actions to optimize copier performance.

The integration of digital twins, IoT sensors, and machine learning algorithms is transforming copier maintenance and optimization. This emerging trend allows for proactive maintenance, performance optimization, and has the potential to enable remote monitoring and management in the future.

The Concept of Digital Twins

Digital twins are virtual replicas of physical objects or systems that can be used for various purposes, including maintenance and optimization. In the context of copier machines, a digital twin is a virtual representation of a physical copier that mimics its behavior, performance, and characteristics. It is created by combining real-time data from sensors and other sources with advanced analytics and modeling techniques.

By leveraging digital twins, organizations can gain a deeper understanding of their copier machines’ performance, identify potential issues before they occur, and optimize their maintenance processes. The digital twin acts as a bridge between the physical copier and the digital world, allowing for real-time monitoring, analysis, and decision-making.

Real-Time Monitoring and Predictive Maintenance

One of the key benefits of using digital twins for copier maintenance is the ability to monitor the machine’s performance in real-time. Sensors embedded within the copier continuously collect data on various parameters such as temperature, humidity, paper jams, and ink levels. This data is then transmitted to the digital twin, where it is analyzed to identify any anomalies or potential issues.

By analyzing the data collected from the copier’s sensors, organizations can predict when maintenance or repairs will be required. For example, if the digital twin detects a sudden increase in temperature or a decrease in ink levels, it can alert the maintenance team to take action before the copier breaks down. This proactive approach to maintenance helps minimize downtime, reduce repair costs, and ensure optimal copier performance.

Optimizing Copier Performance

In addition to predictive maintenance, digital twins can also be used to optimize the performance of copier machines. By analyzing the copier’s data, organizations can identify patterns and trends that can help improve efficiency and productivity.

For example, the digital twin may reveal that certain types of documents or printing settings lead to higher ink consumption or more frequent paper jams. Armed with this information, organizations can make informed decisions to optimize their copier usage, such as adjusting printing settings or providing additional training to users.

Case Study: XYZ Corporation

XYZ Corporation, a large multinational company, has successfully implemented digital twins for predictive copier maintenance and optimization. They have deployed sensors on their copier machines across multiple office locations and integrated the data with a centralized digital twin platform.

By leveraging the digital twins, XYZ Corporation has achieved significant improvements in copier maintenance and performance. The real-time monitoring capabilities have allowed them to detect and address issues proactively, resulting in a 30% reduction in copier downtime and a 20% decrease in repair costs.

Furthermore, the insights gained from the digital twins have enabled XYZ Corporation to optimize their copier usage. They have identified specific document types and printing settings that were leading to excessive ink consumption and adjusted their processes accordingly. As a result, they have achieved a 15% reduction in ink usage without compromising print quality.

Integration with Service Management Systems

To fully leverage the benefits of digital twins for copier maintenance and optimization, integration with existing service management systems is crucial. By integrating the digital twin platform with service management systems, organizations can streamline their maintenance processes and ensure seamless communication between the digital twin and the maintenance team.

For example, when the digital twin detects a potential issue, it can automatically generate a work order in the service management system, assign it to the appropriate technician, and provide them with all the necessary information to address the problem. This integration eliminates manual intervention, reduces response times, and improves overall maintenance efficiency.

Challenges and Considerations

While digital twins offer significant benefits for copier maintenance and optimization, there are also challenges and considerations that organizations need to be aware of.

Firstly, implementing digital twins requires a robust infrastructure, including sensors, data collection mechanisms, and analytics capabilities. Organizations need to invest in the necessary technology and ensure that their copier machines are equipped with the required sensors.

Secondly, data privacy and security are critical considerations when implementing digital twins. The copier’s data contains sensitive information, such as documents and user details, which must be protected from unauthorized access or breaches.

Lastly, organizations should also consider the scalability and interoperability of their digital twin platforms. As they expand their copier fleet or integrate with other systems, the digital twin platform should be able to handle the increased data volume and seamlessly communicate with other systems.

The Future of Copier Maintenance and Optimization

The use of digital twins for copier maintenance and optimization is still in its early stages, but the potential is immense. As technology continues to advance, we can expect to see further improvements in the accuracy and capabilities of digital twins.

In the future, digital twins may incorporate artificial intelligence and machine learning algorithms to provide more accurate predictions and recommendations. They may also be integrated with other smart office devices and systems to create a holistic approach to facility management.

Overall, leveraging digital twins for predictive copier maintenance and optimization has the potential to revolutionize the way organizations manage their copier fleet. By combining real-time monitoring, predictive analytics, and optimization strategies, organizations can ensure optimal copier performance, minimize downtime, and reduce maintenance costs.

Case Study 1: Improving Copier Performance with Predictive Maintenance

In this case study, a large printing company utilized digital twins to optimize the maintenance and performance of their copier fleet. By implementing predictive maintenance strategies, they were able to minimize downtime and reduce overall maintenance costs.

The company started by creating digital twins of each copier in their fleet. These digital twins were virtual replicas that included real-time data on copier performance, such as ink levels, paper jams, and error codes. By continuously monitoring this data, the company could identify potential issues before they caused a breakdown.

Through machine learning algorithms, the digital twins analyzed historical data to predict when maintenance was required. For example, if a specific copier tended to have paper jams after a certain number of prints, the digital twin would alert the maintenance team to schedule preventive maintenance before the issue occurred.

By leveraging digital twins for predictive maintenance, the company experienced a significant reduction in copier downtime. They were able to proactively address maintenance issues, preventing costly breakdowns and minimizing the impact on production schedules.

Furthermore, the digital twins allowed the company to optimize maintenance schedules. Instead of performing routine maintenance on all copiers at fixed intervals, they could prioritize maintenance based on actual usage and performance data. This approach not only reduced unnecessary maintenance but also extended the lifespan of the copiers.

Case Study 2: Enhancing Efficiency through Copier Optimization

In this case study, a medium-sized office implemented digital twins to optimize the performance and efficiency of their copiers. By analyzing data from the digital twins, they identified opportunities to streamline workflows and reduce waste.

The office created digital twins for each copier, which provided real-time data on usage patterns, energy consumption, and paper waste. By analyzing this data, they discovered that certain copiers were underutilized, while others experienced high demand during peak hours.

With this insight, the office implemented a copier sharing system, where employees were encouraged to use copiers that were underutilized. They also adjusted the copier settings to default to double-sided printing, reducing paper waste. These changes were communicated to employees through a digital dashboard that displayed real-time copier usage and efficiency metrics.

As a result of these optimizations, the office saw a significant reduction in paper waste and energy consumption. They were able to achieve cost savings by consolidating copier usage and reducing the number of copiers required. Additionally, employees appreciated the transparency provided by the digital dashboard, which encouraged them to adopt more sustainable printing practices.

Case Study 3: Remote Monitoring and Troubleshooting for Copier Maintenance

In this case study, a global copier manufacturer leveraged digital twins to remotely monitor and troubleshoot copiers, improving maintenance efficiency and customer satisfaction.

The manufacturer equipped their copiers with sensors that collected real-time data on performance, including temperature, humidity, and ink levels. This data was transmitted to a cloud-based digital twin, allowing the manufacturer to monitor copier health and performance from a centralized location.

When a copier experienced an issue, the digital twin would alert the manufacturer’s support team, who could remotely diagnose and troubleshoot the problem. In many cases, issues could be resolved remotely, eliminating the need for on-site visits and reducing downtime for customers.

The digital twins also allowed the manufacturer to proactively address potential issues. By analyzing historical data, they could identify patterns and trends that indicated impending failures. This enabled them to notify customers in advance and schedule preventive maintenance, minimizing disruptions to their operations.

By implementing remote monitoring and troubleshooting through digital twins, the copier manufacturer significantly improved their maintenance efficiency. They were able to resolve issues faster, reduce the need for on-site visits, and provide a higher level of customer service.

In the modern era, businesses heavily rely on copiers for their document management needs. These machines are critical for maintaining productivity and efficiency within an organization. However, copiers are prone to wear and tear, leading to unexpected breakdowns and costly repairs. To address this challenge, the concept of digital twins has emerged as a powerful tool for predictive maintenance and optimization of copiers.

What are Digital Twins?

Digital twins are virtual replicas or simulations of physical assets, processes, or systems. They leverage real-time data, analytics, and modeling techniques to provide insights into the performance, behavior, and condition of the physical counterpart. In the case of copiers, a digital twin represents a virtual copy of the machine, capturing its operational data and simulating its behavior.

Data Collection and Integration

The first step in leveraging digital twins for copier maintenance and optimization is data collection. Various sensors and monitoring devices are installed within the copier to capture real-time information such as temperature, humidity, vibration, ink levels, and paper jams. This data is then integrated into a central database or cloud platform, where it can be analyzed and used to develop the digital twin model.

Model Development and Calibration

Once the data is collected, it is used to develop a digital twin model that accurately represents the behavior and characteristics of the physical copier. This involves creating mathematical algorithms and simulations that mimic the copier’s operational processes. The model is then calibrated and validated using historical data and real-world observations to ensure its accuracy and reliability.

Predictive Analytics and Maintenance

With the digital twin model in place, predictive analytics techniques can be applied to forecast potential issues and optimize copier performance. Machine learning algorithms analyze the copier’s operational data in real-time, identifying patterns and anomalies that may indicate impending failures or maintenance needs. By leveraging these insights, maintenance teams can proactively address issues before they lead to downtime or costly repairs.

Optimization and Performance Enhancement

Digital twins also offer opportunities for optimizing copier performance and enhancing efficiency. By simulating different operating scenarios and configurations, the digital twin can identify the most efficient settings for specific tasks or usage patterns. This helps businesses maximize productivity, reduce energy consumption, and extend the lifespan of the copier.

Remote Monitoring and Control

One of the key advantages of digital twins is the ability to remotely monitor and control copiers. Through a connected platform, maintenance teams can access real-time data from the digital twin, enabling them to remotely diagnose issues, adjust settings, and perform maintenance tasks. This eliminates the need for physical inspections and allows for faster response times, minimizing downtime and improving overall copier performance.

Continuous Improvement and Machine Learning

As copiers generate more data and the digital twin model evolves, machine learning algorithms can be applied to continuously improve the accuracy and effectiveness of predictive maintenance and optimization. By learning from historical data and real-time observations, the digital twin becomes more adept at identifying patterns, predicting failures, and suggesting optimal operating parameters.

Leveraging digital twins for predictive copier maintenance and optimization offers significant benefits for businesses. By capturing real-time data, developing accurate models, and applying predictive analytics, organizations can proactively address maintenance needs, optimize copier performance, and reduce costs. As technology continues to advance, digital twins will play an increasingly vital role in ensuring the reliability and efficiency of copiers and other critical assets.

FAQs

1. What is a digital twin?

A digital twin is a virtual replica of a physical object, system, or process. It is created by collecting and analyzing real-time data from sensors, machines, and other sources to create a digital representation that mirrors the physical object or system.

2. How can digital twins be used for copier maintenance?

Digital twins can be used for copier maintenance by continuously monitoring the performance and condition of the copier in real-time. The digital twin can provide insights into the copier’s health, detect potential issues before they occur, and enable predictive maintenance to optimize performance and reduce downtime.

3. What data is collected to create a digital twin for a copier?

Data collected to create a digital twin for a copier can include information such as temperature, humidity, usage patterns, error codes, and other relevant operational parameters. This data is collected from sensors embedded in the copier and other connected devices.

4. How does predictive maintenance work with digital twins?

Predictive maintenance with digital twins involves using the data collected from the digital twin to analyze the copier’s performance and detect patterns or anomalies that may indicate potential issues. By analyzing this data, maintenance teams can predict when maintenance is needed and proactively address any problems before they cause downtime.

5. Can digital twins optimize copier performance?

Yes, digital twins can optimize copier performance by providing real-time insights into the copier’s operation. By monitoring key performance indicators and analyzing data, digital twins can identify opportunities for improvement, optimize processes, and suggest adjustments to enhance overall copier performance.

6. Are digital twins only useful for large copier fleets?

No, digital twins can be useful for both small and large copier fleets. While larger fleets may benefit from the scalability and centralized management offered by digital twins, even a single copier can benefit from predictive maintenance and optimization using a digital twin.

7. How can digital twins reduce copier downtime?

Digital twins can reduce copier downtime by enabling predictive maintenance. By continuously monitoring the copier’s performance and detecting potential issues in advance, maintenance teams can schedule proactive maintenance and address problems before they cause downtime.

8. Is creating a digital twin for a copier complex?

Creating a digital twin for a copier can be complex, depending on the level of detail and integration required. It involves collecting and analyzing data from multiple sources, including sensors, machines, and other connected devices. However, with the right expertise and technology, creating a digital twin can be a manageable process.

9. Are there any privacy concerns with digital twins?

Privacy concerns with digital twins can arise if personal or sensitive data is collected and stored. It is important to ensure that data collection and storage practices comply with relevant privacy regulations. Additionally, data anonymization techniques can be employed to protect individual privacy while still enabling effective maintenance and optimization.

10. What are the potential cost savings of leveraging digital twins for copier maintenance?

The potential cost savings of leveraging digital twins for copier maintenance can be significant. By enabling predictive maintenance, digital twins can reduce unplanned downtime, minimize repair costs, and optimize copier performance. Additionally, by identifying inefficiencies and suggesting optimizations, digital twins can help reduce overall operational costs associated with copier maintenance.

Concept 1: Digital Twins

Imagine having an exact replica of a physical object, but in the digital world. That’s what a digital twin is. It’s a virtual model that simulates the behavior and characteristics of a real object or system. In the case of copiers, a digital twin would mimic the copier’s functions, performance, and even its maintenance needs.

By creating a digital twin of a copier, technicians can monitor its operation in real-time and gather valuable data. This data can include things like the number of pages printed, the temperature inside the copier, or any error messages that may occur. This information is then used to analyze the copier’s performance and predict when maintenance or repairs may be needed.

Concept 2: Predictive Maintenance

Have you ever had a copier break down unexpectedly, causing delays and frustration? Predictive maintenance aims to prevent such situations by using data from the digital twin to anticipate and address potential issues before they happen.

By analyzing the copier’s data, sophisticated algorithms can identify patterns and anomalies that may indicate a future problem. For example, if the digital twin shows that the copier’s temperature is consistently higher than usual, it could be a sign of a malfunctioning cooling system. The system can then alert technicians to investigate and fix the issue before it causes a breakdown.

This proactive approach to maintenance not only reduces the risk of unexpected downtime but also saves money by preventing major repairs or replacements. It also allows technicians to schedule maintenance tasks more efficiently, avoiding unnecessary disruptions to your work.

Concept 3: Optimization

Optimization is all about making things work better and more efficiently. In the context of copiers, leveraging digital twins can help optimize their performance and productivity.

By closely monitoring the copier’s data, technicians can identify areas where improvements can be made. For example, the digital twin might reveal that certain printing settings are causing excessive ink or toner usage. By adjusting these settings, the copier can be optimized to reduce waste and save costs.

Additionally, the digital twin can help identify bottlenecks or inefficiencies in the copier’s workflow. For instance, if the data shows that the copier frequently experiences jams in a particular tray, technicians can investigate and address the issue. This optimization process ensures that the copier operates at its best, maximizing productivity and minimizing disruptions.

By leveraging digital twins, copier maintenance and optimization can be taken to a whole new level. The virtual models provide valuable insights into the copier’s performance and enable technicians to predict and prevent issues before they occur. This proactive approach not only saves time and money but also ensures that your copier operates at its best, keeping your office running smoothly.

Common Misconceptions about

Misconception 1: Digital twins are only useful for complex industrial systems

One common misconception about digital twins is that they are only applicable to large-scale, complex industrial systems. However, this is not the case when it comes to leveraging digital twins for predictive copier maintenance and optimization.

Digital twins are virtual replicas of physical objects or processes that can be used to monitor, analyze, and optimize their performance. While they are indeed used extensively in industries such as manufacturing, energy, and healthcare, digital twins can also be effective tools for managing and maintaining copiers.

By creating a digital twin of a copier, technicians and service providers can gain valuable insights into its performance, identify potential issues before they occur, and optimize its operation for better efficiency. This technology allows for real-time monitoring of copier metrics, such as paper jams, toner levels, and maintenance requirements, enabling proactive maintenance and reducing downtime.

Misconception 2: Digital twins are expensive and difficult to implement

Another misconception is that leveraging digital twins for copier maintenance and optimization is a costly and complex endeavor. While implementing a digital twin solution may require an initial investment, the long-term benefits outweigh the costs.

Advancements in technology have made digital twin solutions more accessible and affordable. Copier manufacturers and service providers are increasingly integrating digital twin capabilities into their offerings, making it easier for businesses to adopt this technology.

Additionally, the implementation process has become more streamlined, with user-friendly interfaces and intuitive software tools. Copier technicians and service providers can quickly create digital twins, connect them to the physical copiers, and start monitoring and optimizing their performance.

By investing in digital twin technology, businesses can reduce maintenance costs, extend the lifespan of their copiers, and improve overall operational efficiency. The predictive capabilities of digital twins help prevent unexpected breakdowns, minimize downtime, and optimize resource allocation.

Misconception 3: Digital twins replace the need for human expertise

A common misconception is that digital twins eliminate the need for human expertise in copier maintenance and optimization. While digital twins provide valuable data and insights, human expertise remains crucial in interpreting and acting upon that information.

Digital twins serve as powerful tools that augment human capabilities, rather than replacing them. Copier technicians and service providers can leverage the data generated by digital twins to make informed decisions and take proactive actions.

For example, when a digital twin detects a potential issue with a copier, it can alert the technician, providing detailed information about the problem. The technician can then use their expertise to diagnose the issue, determine the appropriate course of action, and perform the necessary maintenance or repairs.

Furthermore, digital twins enable technicians to optimize copier performance by analyzing data trends and identifying areas for improvement. By combining their expertise with the insights provided by digital twins, technicians can fine-tune copier settings, implement preventive maintenance measures, and optimize resource allocation.

In summary, digital twins enhance human expertise in copier maintenance and optimization by providing real-time data, predictive capabilities, and optimization insights. They are not a substitute for human involvement but rather a valuable tool that empowers technicians to make informed decisions and optimize copier performance.

1. Understand the concept of digital twins

Before leveraging digital twins for predictive copier maintenance and optimization, it’s crucial to understand the concept. A digital twin is a virtual representation of a physical object or system, such as a copier. It collects real-time data and simulates its behavior, allowing for predictive analysis and optimization.

2. Choose the right digital twin platform

When applying digital twins to your daily life, it’s essential to select the right platform. Look for a platform that offers features like data collection, visualization, and predictive analytics specifically tailored to your needs. Consider factors such as ease of use, scalability, and compatibility with your existing devices.

3. Collect relevant data

To make the most of digital twins, you need to collect relevant data from your copier or any other system you want to optimize. This data can include information about usage patterns, maintenance history, and performance metrics. Ensure that the data collected is accurate, reliable, and covers a sufficient period to enable accurate predictions.

4. Implement real-time monitoring

Real-time monitoring is crucial for leveraging digital twins effectively. Set up sensors or monitoring devices that can capture data from your copier continuously. This will provide you with up-to-date information about its performance, enabling you to identify potential issues and take proactive measures to prevent breakdowns.

5. Analyze and interpret data

Once you have collected the data, it’s time to analyze and interpret it. Use analytics tools or software to gain insights into the copier’s behavior, identify patterns, and predict potential maintenance needs. This analysis will help you optimize the copier’s performance and minimize downtime.

6. Take proactive maintenance measures

Based on the insights gained from data analysis, take proactive maintenance measures to prevent issues before they occur. Schedule regular maintenance checks, replace worn-out parts, and address any potential problems identified through the digital twin. This approach will help prolong the copier’s lifespan and reduce unexpected breakdowns.

7. Optimize copier performance

Digital twins can also be used to optimize copier performance. By analyzing data, you can identify areas where the copier may be underperforming or consuming excess resources. Adjust settings, fine-tune operations, or implement software updates to improve efficiency and reduce costs.

8. Monitor energy consumption

Energy consumption is a significant aspect of copier maintenance and optimization. Use your digital twin to monitor energy usage patterns and identify areas where the copier may be consuming excessive energy. By optimizing energy consumption, you can reduce costs and contribute to environmental sustainability.

9. Stay updated with technology advancements

Technology is constantly evolving, and new advancements can enhance the capabilities of digital twins. Stay updated with the latest developments in digital twin technology, such as improved data analytics algorithms or new sensor technologies. This will ensure that you can leverage the most advanced tools for copier maintenance and optimization.

10. Share and collaborate

If you are part of a community or organization that utilizes digital twins for copier maintenance and optimization, share your experiences and collaborate with others. By exchanging knowledge and best practices, you can collectively improve the effectiveness of digital twin applications and drive innovation in this field.

Conclusion

Leveraging digital twins for predictive copier maintenance and optimization offers numerous benefits for businesses and organizations. By creating a virtual replica of physical copiers, companies can gain real-time insights into their performance, identify potential issues before they occur, and optimize maintenance schedules to ensure maximum uptime. This technology enables proactive maintenance, reducing the risk of unexpected breakdowns and minimizing costly repairs.

Furthermore, digital twins allow for data-driven decision-making and optimization. By analyzing the copiers’ performance data, businesses can identify patterns, trends, and potential areas for improvement. This information can be used to optimize copier settings, reduce energy consumption, and enhance overall efficiency. Additionally, digital twins enable remote monitoring and troubleshooting, saving time and resources by minimizing the need for on-site visits.

Overall, leveraging digital twins for predictive copier maintenance and optimization is a game-changer for businesses. It empowers companies to take a proactive approach to maintenance, improve copier performance, and optimize resource allocation. As technology continues to advance, we can expect digital twins to become an integral part of copier management, revolutionizing the way businesses maintain and optimize their printing infrastructure.