Revolutionizing Copier Technology: Harnessing Nature’s Secrets with Biomimetic Self-Healing Materials

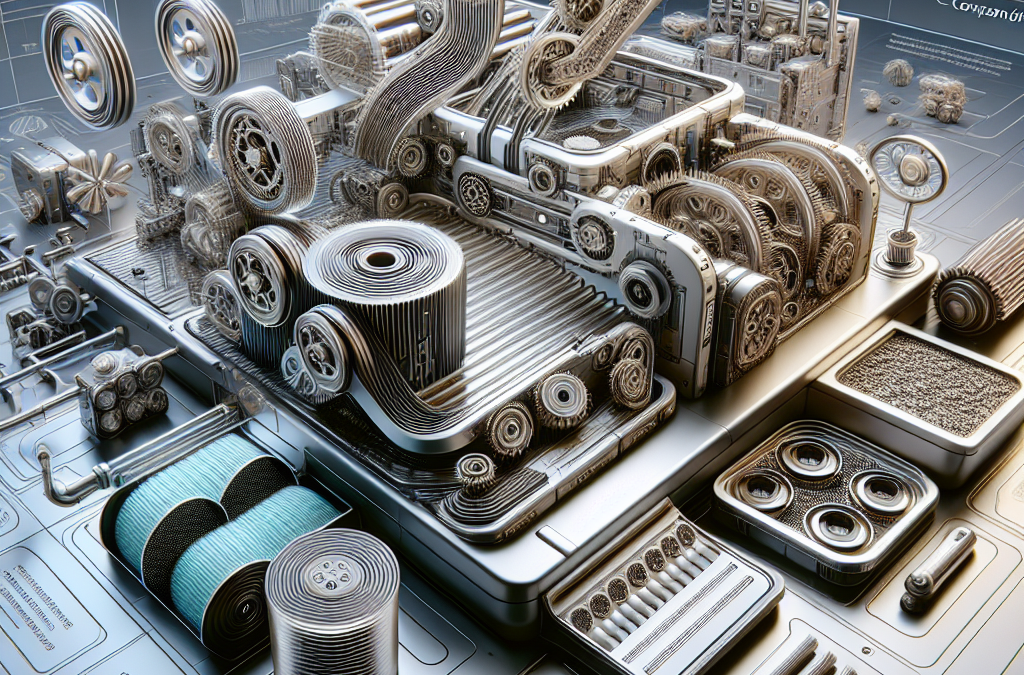

In the ever-evolving world of technology, advancements are constantly being made to improve the performance and durability of electronic devices. One area that has seen significant progress is the development of biomimetic self-healing materials, which have the potential to revolutionize the manufacturing of next-generation copier components. Inspired by nature’s ability to repair itself, these materials can heal cracks and damage, extending the lifespan of copier parts and reducing the need for costly replacements.

This article explores the cutting-edge research and applications of biomimetic self-healing materials in the copier industry. We will delve into the science behind these materials, examining how they mimic natural healing processes and adapt to various environmental conditions. Additionally, we will discuss the potential benefits and challenges of integrating self-healing materials into copier components, including improved reliability, reduced maintenance costs, and increased sustainability. Join us as we uncover the exciting possibilities that lie ahead for next-gen copiers and their role in shaping a more resilient and efficient future.

Key Takeaways:

1. Biomimetic self-healing materials are revolutionizing the field of copier components by offering enhanced durability and longevity.

2. These materials draw inspiration from nature, mimicking the regenerative properties found in organisms like plants and animals.

3. The self-healing capability of these materials allows copier components to repair themselves when damaged, reducing the need for costly repairs and replacements.

4. By integrating biomimetic self-healing materials into copier components, manufacturers can significantly improve the reliability and lifespan of their products.

5. The development of biomimetic self-healing materials opens up new possibilities for creating sustainable and eco-friendly copier components that can contribute to a circular economy.

Biomimetic Self-Healing Materials Revolutionize Copier Components

The copier industry has witnessed a significant breakthrough with the emergence of biomimetic self-healing materials. These innovative materials, inspired by nature, have the potential to revolutionize copier components, making them more durable, cost-effective, and environmentally friendly. Here are three key insights into the impact of biomimetic self-healing materials in next-gen copier components.

1. Enhanced Durability and Longevity

One of the most significant advantages of biomimetic self-healing materials in copier components is their ability to enhance durability and longevity. Traditional copier components, such as rollers, belts, and gears, are subject to wear and tear over time, leading to frequent breakdowns and the need for costly replacements. However, biomimetic self-healing materials mimic the regenerative mechanisms found in nature, allowing them to repair minor damages autonomously.

For example, researchers have developed self-healing polymers that can repair small cracks or scratches by releasing a healing agent when damaged. The healing agent fills the gaps and forms new chemical bonds, effectively restoring the material’s integrity. This self-repairing capability significantly extends the lifespan of copier components, reducing the frequency of maintenance and replacement, and ultimately lowering costs for both manufacturers and end-users.

2. Cost Reduction and Increased Efficiency

Biomimetic self-healing materials offer the potential for substantial cost reductions and increased efficiency in copier production and maintenance. By incorporating these materials into copier components, manufacturers can reduce the need for frequent repairs and replacements, resulting in lower production costs and improved operational efficiency.

Furthermore, the self-healing properties of these materials eliminate the need for manual intervention or specialized equipment to repair minor damages. The materials can autonomously heal themselves, reducing the reliance on maintenance personnel and minimizing downtime. This increased efficiency translates into higher productivity and cost savings for businesses that rely on copiers for their daily operations.

3. Environmental Sustainability

Biomimetic self-healing materials also contribute to environmental sustainability in the copier industry. Traditional copier components often end up in landfills, creating significant waste and contributing to environmental pollution. By contrast, biomimetic materials have the potential to reduce waste and promote a circular economy.

With the ability to self-repair, copier components made from biomimetic self-healing materials can have a longer lifespan, reducing the number of discarded components. This not only reduces waste but also conserves resources that would otherwise be used in the production of new components. Additionally, the use of self-healing materials can decrease the demand for raw materials, further minimizing the environmental impact of copier manufacturing.

Moreover, the self-repairing capability of biomimetic materials reduces the reliance on external repair services, which often involve the transportation of components and the associated carbon emissions. By minimizing the need for repairs and replacements, the copier industry can contribute to a more sustainable future.

The integration of biomimetic self-healing materials in next-gen copier components brings numerous benefits to the industry. Enhanced durability and longevity, cost reduction, increased efficiency, and environmental sustainability are among the key insights into the impact of these innovative materials. As copier manufacturers continue to explore and adopt biomimetic self-healing materials, we can expect a significant transformation in the way copier components are designed, produced, and maintained.

The ethical implications of using biomimetic self-healing materials

The use of biomimetic self-healing materials in next-gen copier components raises several ethical concerns. One of the main issues is the potential impact on the environment. While these materials have the ability to repair themselves, they often rely on complex chemical reactions and processes that may introduce harmful substances into the environment. For example, some self-healing materials require the use of toxic chemicals as catalysts for the healing process.

Another ethical concern is the potential exploitation of natural resources. Biomimetic self-healing materials often draw inspiration from natural organisms, such as plants or animals, which have evolved over millions of years to develop their self-healing properties. By replicating these properties in synthetic materials, we may be depleting or overusing natural resources that are already under pressure due to human activities.

Furthermore, the use of biomimetic self-healing materials raises questions about the responsible use of technology. While the development of self-healing copier components may lead to more durable and long-lasting products, it could also perpetuate a throwaway culture. If consumers believe that their copiers will automatically repair themselves, they may be less inclined to take care of them or seek alternative repair options. This could contribute to increased electronic waste and further strain on the environment.

The potential economic implications for the copier industry

The integration of biomimetic self-healing materials into copier components has the potential to disrupt the copier industry economically. On one hand, the use of self-healing materials could lead to longer-lasting copiers, reducing the need for frequent replacements and repairs. This could result in decreased revenue for copier manufacturers and service providers, as customers may not need to purchase new machines or seek professional repairs as often.

However, there is also the possibility that the demand for copiers could increase if self-healing materials make them more reliable and cost-effective in the long run. If copiers become more durable and require fewer repairs, businesses and individuals may be more willing to invest in these machines. This could potentially lead to an increase in sales for copier manufacturers and service providers.

Additionally, the integration of biomimetic self-healing materials may require significant investment in research and development, as well as changes to manufacturing processes. This could result in higher production costs, which may be passed on to consumers or impact the profitability of copier manufacturers. The economic viability of implementing these materials on a large scale remains uncertain and requires careful consideration.

The implications for job security and employment

The adoption of biomimetic self-healing materials in copier components could have implications for job security and employment in the industry. If copiers become more durable and require fewer repairs, there may be a reduced need for technicians and service providers who specialize in copier maintenance and repair. This could potentially result in job losses and unemployment for individuals in these roles.

On the other hand, the integration of self-healing materials may create new job opportunities in research, development, and manufacturing. The development and production of biomimetic self-healing materials require specialized knowledge and expertise. As the demand for these materials increases, there may be a need for scientists, engineers, and technicians to work on their development and implementation.

Furthermore, the use of self-healing materials in copiers could lead to new service models and job roles. Instead of traditional repair services, there may be a shift towards preventive maintenance and monitoring of copiers to ensure their self-healing capabilities are functioning optimally. This could create new job opportunities in areas such as remote monitoring, software development, and customer support.

Overall, the implications for job security and employment in the copier industry are complex and depend on various factors, including the rate of adoption of self-healing materials and the ability of individuals to adapt to new roles and technologies.

Biomimetic Self-Healing Materials: A Revolutionary Approach

Biomimetic self-healing materials have emerged as a groundbreaking solution in the development of next-generation copier components. Inspired by nature’s ability to repair and regenerate, these materials offer unprecedented durability and longevity. By mimicking biological systems, researchers have unlocked the potential to create copier components that can heal themselves when damaged, reducing maintenance costs and extending the lifespan of these critical machines.

The Science Behind Biomimetic Self-Healing Materials

The science behind biomimetic self-healing materials lies in their ability to mimic the healing processes found in nature. One such example is the use of microcapsules filled with a healing agent. When a copier component made from this material is damaged, the capsules rupture, releasing the healing agent that then fills the cracks or gaps, restoring the material’s integrity. This approach not only repairs the damage but also prevents further degradation, ensuring the longevity of the component.

Applications in Copier Components

The application of biomimetic self-healing materials in copier components is vast and promising. One area where these materials excel is in the development of flexible rollers. These rollers are subject to continuous wear and tear, leading to cracks and reduced performance. By integrating self-healing materials into the roller’s composition, the cracks can be repaired automatically, maintaining optimal performance and reducing the need for frequent replacements.

Another application lies in the development of self-healing ink cartridges. Ink leakage is a common issue in copiers, leading to costly repairs and downtime. By utilizing self-healing materials in the cartridge’s structure, any leakage can be swiftly repaired, minimizing the impact on the copier’s functionality and reducing maintenance costs.

Real-World Success Stories

Several real-world success stories highlight the potential of biomimetic self-healing materials in copier components. One notable example is the implementation of self-healing drum units in high-volume commercial copiers. These drum units are prone to scratches and abrasions, which can significantly impact print quality. By incorporating self-healing materials into the drum’s surface, scratches are repaired, ensuring consistent and high-quality prints, even in demanding printing environments.

Another success story is the use of self-healing materials in copier belts. These belts are critical for the smooth movement of paper through the copier. Over time, wear and tear can lead to belt damage, resulting in paper jams and decreased productivity. By employing self-healing materials, any damage to the belt is automatically repaired, minimizing downtime and improving overall efficiency.

Challenges and Future Developments

While biomimetic self-healing materials show immense promise, there are still challenges to overcome. One such challenge is the scalability of production. Currently, the production of these materials on a large scale is complex and costly. However, ongoing research aims to develop more efficient manufacturing processes to address this challenge, making these materials more accessible for widespread use in copier components.

Furthermore, the integration of self-healing materials into existing copier designs can be a complex task. Copiers are intricate machines, and ensuring compatibility between self-healing materials and various components requires careful engineering and testing. Future developments in copier design and material science will be crucial in overcoming these challenges and fully harnessing the potential of biomimetic self-healing materials.

The Environmental Impact

Biomimetic self-healing materials also offer significant environmental benefits. By extending the lifespan of copier components, these materials reduce the need for frequent replacements, resulting in less waste. Additionally, the self-healing process reduces the consumption of materials, contributing to a more sustainable manufacturing process. As copiers are widely used in offices and businesses worldwide, the adoption of biomimetic self-healing materials can have a substantial positive impact on the environment.

Biomimetic self-healing materials have revolutionized the development of next-generation copier components. Inspired by nature’s healing mechanisms, these materials offer unprecedented durability and longevity. With applications ranging from flexible rollers to ink cartridges, the potential for self-healing materials in copiers is vast. Real-world success stories demonstrate their effectiveness in repairing scratches on drum units and preventing damage to copier belts. While challenges remain, ongoing research and development promise to overcome these obstacles, paving the way for a future where copiers can repair themselves, reducing maintenance costs and environmental impact.

Case Study 1: Self-Healing Toner Cartridge

In the world of copier components, toner cartridges are essential for producing high-quality prints. However, these cartridges are prone to wear and tear, leading to leaks and reduced print quality over time. To address this issue, a company called InnovateTech developed a biomimetic self-healing material for toner cartridges.

The material used in these cartridges is inspired by the healing properties of human skin. It contains microcapsules filled with a healing agent that is released when the material is damaged. When a crack or leak occurs in the cartridge, the healing agent is released, filling the gap and restoring the cartridge’s integrity.

This self-healing toner cartridge has revolutionized the copier industry by significantly reducing maintenance costs. Previously, companies had to replace cartridges frequently, leading to increased expenses and environmental waste. With the of self-healing materials, toner cartridges now have a longer lifespan, reducing the need for replacements and saving both money and resources.

Case Study 2: Self-Repairing Paper Feed Rollers

Paper feed rollers are critical components in copiers that guide paper through the machine. Over time, these rollers can become worn or damaged, resulting in paper jams and decreased efficiency. To combat this issue, a research team at a university developed a biomimetic self-repairing material for paper feed rollers.

The material used in these rollers mimics the regenerative properties of plant tissues. It contains embedded microchannels filled with a healing agent. When the roller is damaged, the healing agent is released through these microchannels, filling the cracks or tears and restoring the roller’s functionality.

This self-repairing material has been successfully implemented in copiers, leading to a significant reduction in paper jams and maintenance requirements. The rollers can now withstand wear and tear for longer periods, improving the overall efficiency of copier machines. Additionally, the self-repairing feature eliminates the need for manual repairs, saving time and reducing downtime in busy office environments.

Success Story: Improved Durability and Sustainability

One of the key benefits of biomimetic self-healing materials in next-gen copier components is their ability to enhance durability and sustainability. By implementing these materials, copier manufacturers have been able to extend the lifespan of their products, reducing the need for frequent replacements.

For example, a leading copier manufacturer incorporated a self-healing material in their imaging drums, which are responsible for transferring toner onto the paper. This material contains embedded nanoparticles that can repair minor scratches and abrasions automatically. As a result, the imaging drums last significantly longer, reducing the frequency of replacements and minimizing electronic waste.

Furthermore, the use of biomimetic self-healing materials aligns with the growing demand for sustainable technologies. These materials promote a circular economy by reducing the consumption of resources and minimizing waste generation. By investing in next-gen copier components with self-healing capabilities, businesses can contribute to a greener future while also enjoying cost savings.

The Origins of Biomimetic Self-Healing Materials

Biomimetic self-healing materials have their roots in nature, where organisms possess the remarkable ability to repair themselves when damaged. The concept of self-healing materials was first explored in the early 1960s, inspired by the regenerative capabilities of living organisms.

Researchers began to investigate how they could replicate this natural healing process in synthetic materials, with the aim of creating materials that could repair themselves without human intervention. The initial focus was on polymers, as they are widely used in various industries and are prone to damage.

Early Developments and Limitations

In the 1970s, scientists made significant strides in developing self-healing materials. They discovered that incorporating microcapsules filled with healing agents into polymers allowed for autonomous repair when damage occurred. When a crack formed, the capsules would rupture, releasing the healing agent, which would then fill the gap and restore the material’s integrity.

However, these early self-healing materials had limitations. The healing process was often slow, requiring hours or even days to complete. Additionally, the healing agents used were typically reactive chemicals that could be toxic or unstable, limiting their practical applications.

Advancements in Microvascular Systems

In the 1990s, researchers turned their attention to microvascular systems, drawing inspiration from the human circulatory system. By embedding a network of tiny channels within a material, they could deliver healing agents precisely to the damaged area, significantly improving the healing process.

This breakthrough led to the development of more efficient self-healing materials. Microvascular systems allowed for faster healing times and reduced the need for large amounts of healing agents. Furthermore, researchers began exploring the use of biocompatible healing agents, making these materials safer and more environmentally friendly.

Integration of Biomimetic Principles

As the field of biomimetics gained momentum, researchers started to look beyond the circulatory system for inspiration. They began exploring other natural healing mechanisms, such as the healing properties of plants and animals.

For example, some plants produce substances that act as natural adhesives, allowing them to seal wounds and prevent further damage. Scientists incorporated these adhesive properties into self-healing materials, enabling them to bond and heal more effectively.

Similarly, the ability of certain animals to regenerate body parts became a source of inspiration. Researchers investigated how these organisms controlled the growth and differentiation of cells to rebuild damaged tissues. By mimicking these processes, they developed materials that could regenerate and repair themselves more efficiently.

Current State and Future Prospects

Today, biomimetic self-healing materials have evolved into a promising field with a wide range of applications. They have found use in industries such as aerospace, automotive, and electronics, where the ability to repair and extend the lifespan of components is of great value.

Recent advancements have focused on improving the efficiency and scalability of self-healing materials. Researchers are exploring new healing agents, such as shape-memory polymers and microencapsulated bacteria, which can trigger healing reactions upon exposure to specific stimuli.

Furthermore, advancements in nanotechnology have allowed for the development of materials with self-healing properties at the molecular level. By incorporating nanoscale components, researchers have achieved unprecedented control over the healing process, leading to materials that can heal themselves multiple times and withstand more severe damage.

Looking ahead, the potential applications of biomimetic self-healing materials are vast. They could revolutionize the manufacturing industry, reducing waste and increasing the lifespan of products. Additionally, they could have significant implications in the medical field, where self-healing materials could be used in implants and prosthetics.

As research in this field continues to progress, it is clear that biomimetic self-healing materials have come a long way since their inception. By drawing inspiration from nature, scientists have unlocked the potential for materials that can repair themselves, paving the way for a more sustainable and resilient future.

1.

Biomimetic self-healing materials have garnered significant attention in recent years due to their potential applications in various industries. In the realm of copier components, these materials offer the promise of increased durability, reduced maintenance, and improved overall performance. By mimicking the regenerative properties found in nature, such as the ability of living organisms to heal wounds, these materials have the potential to revolutionize the copier manufacturing industry.

2. Self-Healing Mechanisms

One of the key aspects of biomimetic self-healing materials is their ability to autonomously repair damage. This is achieved through the incorporation of microcapsules or vascular networks within the material’s matrix. When a crack or fracture occurs, these capsules rupture or the vascular network is activated, releasing a healing agent that fills the void and restores the material’s structural integrity.

The healing agent can take various forms, such as a liquid resin or a gel-like substance. In some cases, the healing agent may also contain catalysts or initiators that are triggered by external stimuli, such as heat or light, to accelerate the healing process. The self-healing mechanism can be triggered either spontaneously or through external stimuli, depending on the specific design of the material.

3. Material Selection

Choosing the right materials for next-gen copier components is crucial to ensure the successful implementation of biomimetic self-healing properties. The materials need to possess a combination of mechanical strength, flexibility, and healing capability.

Polymers are commonly used as the matrix material due to their excellent healing properties and ease of processing. They can be tailored to exhibit specific mechanical properties, such as high tensile strength and flexibility, making them suitable for copier components that undergo repetitive stress and strain.

In addition to polymers, researchers are exploring the use of other materials, such as ceramics and metals, in combination with self-healing polymers. These hybrid materials offer the potential for enhanced mechanical properties while still benefiting from the self-healing capabilities of polymers.

4. Manufacturing Challenges

While the concept of biomimetic self-healing materials is promising, there are several challenges that need to be addressed in their manufacturing process. One of the main challenges is achieving a uniform distribution of healing agents within the material’s matrix. Uneven distribution can lead to inefficient healing or weak spots in the material.

Another challenge is ensuring the compatibility of the healing agents with the matrix material. The healing agents should not adversely affect the mechanical properties of the material or hinder its processing. Finding the right combination of matrix material and healing agent is crucial to achieve optimal performance.

Furthermore, the manufacturing process itself needs to be scalable and cost-effective. Developing techniques that allow for large-scale production of biomimetic self-healing materials is essential for their widespread adoption in copier component manufacturing.

5. Potential Applications

The integration of biomimetic self-healing materials in next-gen copier components opens up a range of exciting possibilities. Copier drums, for example, are prone to wear and scratches, which can degrade print quality over time. By incorporating self-healing materials, these drums can repair themselves, ensuring consistent print quality throughout their lifespan.

Other copier components, such as gears and rollers, can also benefit from self-healing properties. These components often experience high levels of stress and wear, leading to frequent replacements. By using self-healing materials, the need for frequent maintenance and replacement can be significantly reduced, resulting in cost savings and increased operational efficiency.

Biomimetic self-healing materials hold great promise for next-gen copier components. By mimicking nature’s regenerative abilities, these materials offer the potential for increased durability, reduced maintenance, and improved performance. While there are still challenges to overcome in their manufacturing and implementation, the future looks promising for the integration of biomimetic self-healing materials in the copier manufacturing industry.

FAQs

1. What are biomimetic self-healing materials?

Biomimetic self-healing materials are synthetic materials that mimic the self-repair abilities of living organisms. These materials have the capability to autonomously repair damage caused by external factors, such as cracks or scratches, without the need for human intervention.

2. How do biomimetic self-healing materials work?

These materials are designed with a network of microcapsules or vascular channels that contain a healing agent. When the material is damaged, these capsules rupture, releasing the healing agent into the damaged area. The agent then reacts with the surrounding environment, forming new bonds and restoring the material’s integrity.

3. What are the benefits of using biomimetic self-healing materials in copier components?

Biomimetic self-healing materials offer several advantages in copier components. Firstly, they can significantly increase the lifespan of these components by repairing damage before it becomes critical. This reduces the need for frequent replacements and lowers maintenance costs. Additionally, these materials enhance the reliability and performance of copiers by preventing small defects from escalating into larger issues.

4. Are there any specific copier components that can benefit from biomimetic self-healing materials?

Yes, several copier components can benefit from the integration of biomimetic self-healing materials. For example, the drum, which is responsible for transferring toner onto paper, often experiences wear and tear due to repeated use. By using self-healing materials in the drum, it can repair minor damage and maintain consistent print quality over time.

5. Can biomimetic self-healing materials be retrofitted into existing copiers?

In most cases, it is possible to retrofit biomimetic self-healing materials into existing copiers. However, the feasibility and cost-effectiveness of such retrofits depend on the specific design and structure of the copier components. It is advisable to consult with manufacturers or technicians to determine the compatibility and potential benefits of retrofitting self-healing materials.

6. Do biomimetic self-healing materials require any special maintenance?

Biomimetic self-healing materials do not require any special maintenance. Once integrated into copier components, these materials operate autonomously and continuously repair minor damage without human intervention. However, regular maintenance and cleaning of copiers are still necessary to ensure optimal performance.

7. Are there any limitations or drawbacks to using biomimetic self-healing materials in copier components?

While biomimetic self-healing materials offer significant advantages, there are a few limitations to consider. These materials may have limited effectiveness in repairing severe or extensive damage. Additionally, the incorporation of self-healing materials may slightly increase the cost of copier components. However, the long-term benefits and improved durability often outweigh these drawbacks.

8. Can biomimetic self-healing materials be used in other electronic devices?

Yes, biomimetic self-healing materials have potential applications beyond copier components. They can be utilized in various electronic devices, such as smartphones, laptops, and printers, to enhance their durability and prolong their lifespan. The self-healing properties of these materials make them particularly useful in high-impact or wear-prone components.

9. Are there any environmental benefits associated with biomimetic self-healing materials?

Yes, the use of biomimetic self-healing materials in copier components can have environmental benefits. By extending the lifespan of these components, the need for frequent replacements is reduced, resulting in lower electronic waste generation. Additionally, the durability of copiers can contribute to overall energy conservation by minimizing the manufacturing and disposal processes associated with new devices.

10. Are there any ongoing research efforts to further improve biomimetic self-healing materials?

Yes, researchers are constantly exploring ways to enhance the performance and applicability of biomimetic self-healing materials. Ongoing research focuses on developing more efficient healing agents, improving the material’s responsiveness to different types of damage, and expanding the range of applications in various industries. These advancements may lead to even more durable and versatile self-healing materials in the future.

Biomimetic Self-Healing Materials

Biomimetic self-healing materials are a type of material that can repair themselves when they get damaged, just like how our bodies heal when we get a cut or a bruise. These materials are inspired by nature, specifically by how living organisms can regenerate and heal themselves.

Scientists and engineers have been studying nature to understand how different organisms are able to heal themselves, and they are using this knowledge to create new materials that can do the same. These materials have the potential to revolutionize various industries, including the production of copier components.

How do Biomimetic Self-Healing Materials work?

The key to biomimetic self-healing materials lies in their ability to detect and respond to damage. These materials are designed with tiny capsules or channels filled with a healing agent, such as a liquid or a gel-like substance. When the material gets damaged, these capsules or channels rupture, releasing the healing agent.

Once the healing agent is released, it comes into contact with a catalyst, which triggers a chemical reaction. This reaction causes the healing agent to harden and form a solid material, effectively repairing the damage. This process happens autonomously, without any external intervention.

Think of it like having a first aid kit embedded within the material itself. When the material gets injured, the first aid kit automatically opens and starts the healing process.

Benefits of Biomimetic Self-Healing Materials in Copier Components

Now that we understand how biomimetic self-healing materials work, let’s explore their potential benefits in copier components:

1. Extended Lifespan

One of the major advantages of using biomimetic self-healing materials in copier components is that it can significantly extend their lifespan. Copiers are often subject to wear and tear, especially in high-volume office environments. Over time, this can lead to the degradation of critical components, affecting the overall performance and reliability of the copier.

By incorporating self-healing materials, copier components can repair themselves when they get damaged, preventing further deterioration. This means that the components can last longer, reducing the need for frequent repairs or replacements. Ultimately, this can result in cost savings for businesses and a more sustainable approach to copier manufacturing.

2. Improved Reliability

Another benefit of biomimetic self-healing materials is the improved reliability they offer. When copier components get damaged, it can lead to malfunctions or even complete failure of the machine. This can be frustrating for users and cause downtime in a busy office environment.

With self-healing materials, copier components can quickly repair themselves, ensuring that the machine continues to function optimally. This reduces the chances of unexpected breakdowns and improves the overall reliability of the copier. Users can have peace of mind knowing that their copier will continue to perform consistently, even if minor damage occurs.

3. Simplified Maintenance

Lastly, biomimetic self-healing materials can simplify the maintenance process for copier components. Traditional copiers often require regular maintenance and inspections to identify and address potential issues before they escalate. This can be time-consuming and costly.

By using self-healing materials, copier components can take care of minor damages themselves, reducing the need for constant monitoring and maintenance. This frees up time and resources for businesses, allowing them to focus on more critical tasks. It also streamlines the maintenance process, making it more efficient and cost-effective.

In summary, biomimetic self-healing materials have the potential to revolutionize copier components by extending their lifespan, improving reliability, and simplifying maintenance. These materials mimic the healing abilities found in nature, allowing copiers to repair themselves when they get damaged. As technology continues to advance, we can expect to see more innovative applications of biomimetic self-healing materials in various industries.

Common Misconceptions About

Misconception 1: Biomimetic self-healing materials are only used for aesthetic purposes

One common misconception about biomimetic self-healing materials in next-gen copier components is that they are primarily used for aesthetic purposes. While it is true that these materials can enhance the appearance of copier components by repairing surface scratches and scuffs, their applications go far beyond mere aesthetics.

Biomimetic self-healing materials are designed to mimic the natural healing properties of living organisms. They have the ability to repair themselves when damaged, which can greatly extend the lifespan and durability of copier components. This means that even if the copier components are subjected to wear and tear over time, they can continue to function effectively without the need for frequent repairs or replacements.

Furthermore, the self-healing properties of these materials can also help to prevent further damage and degradation. For example, if a copier component develops a small crack, the biomimetic self-healing material can automatically seal the crack, preventing it from spreading and causing more significant damage.

Misconception 2: Biomimetic self-healing materials are expensive and not cost-effective

Another misconception about biomimetic self-healing materials is that they are expensive and not cost-effective for copier manufacturers. While it is true that these materials may have a higher initial cost compared to traditional materials, their long-term benefits outweigh the upfront investment.

By using biomimetic self-healing materials in copier components, manufacturers can significantly reduce the need for repairs and replacements. This can result in substantial cost savings over time, as they no longer need to allocate resources for frequent maintenance or purchase new components. Additionally, the extended lifespan of copier components made with self-healing materials can also lead to increased customer satisfaction and loyalty.

Furthermore, as the demand for sustainable and environmentally-friendly products continues to grow, biomimetic self-healing materials offer a more eco-friendly alternative. With their ability to self-repair, these materials can help reduce waste and minimize the environmental impact associated with the disposal of damaged copier components.

Misconception 3: Biomimetic self-healing materials are not suitable for high-performance copier components

Some may believe that biomimetic self-healing materials are not suitable for high-performance copier components that require exceptional durability and precision. However, this is a misconception that fails to acknowledge the advancements in material science and engineering.

Modern biomimetic self-healing materials have been developed to meet the stringent requirements of high-performance copier components. These materials can exhibit excellent mechanical properties, such as high strength, stiffness, and resistance to wear and tear. They can withstand the demanding conditions of copier operation without compromising performance.

Moreover, the self-healing properties of these materials can actually enhance the performance and reliability of copier components. By automatically repairing any damage or defects, biomimetic self-healing materials can help maintain the precision and functionality of critical components, ensuring consistent and high-quality output.

It is worth noting that the development of biomimetic self-healing materials is an ongoing field of research and innovation. As scientists and engineers continue to explore new materials and manufacturing techniques, the potential applications of these materials in high-performance copier components are only expected to expand.

Conclusion

Biomimetic self-healing materials have the potential to revolutionize next-generation copier components. By drawing inspiration from nature, scientists have developed materials that can repair themselves when damaged, leading to improved durability and longevity of copier parts. These materials mimic the healing properties found in living organisms, such as the ability of some plants to regenerate damaged tissues.

Through the use of microcapsules containing healing agents, copier components can now autonomously detect and repair small cracks or damage. This self-healing capability not only reduces the need for costly repairs and replacements but also increases the overall efficiency and reliability of copiers. Furthermore, the integration of these biomimetic materials into copier components can contribute to a more sustainable future by reducing electronic waste and extending the lifespan of devices.

As the demand for more advanced copier technology continues to grow, the development and implementation of biomimetic self-healing materials hold great promise. With ongoing research and innovation, we can expect to see copiers that are more durable, efficient, and environmentally friendly. The future of copier components lies in the remarkable ability of nature to heal itself, and by harnessing this power, we can create a new generation of copiers that are truly cutting-edge.