Revolutionizing Office Efficiency: How Swarm Robotics is Transforming Copier Maintenance and Repair

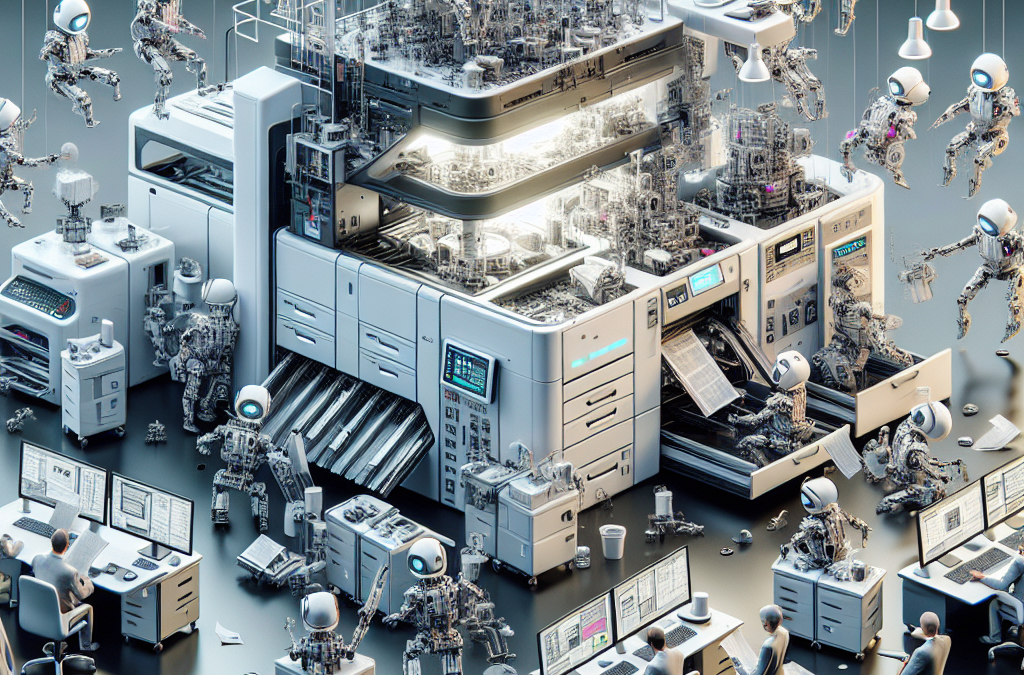

In today’s fast-paced world, copiers have become an essential part of our daily lives. From offices to schools, these machines play a crucial role in ensuring smooth operations. However, when a copier malfunctions or requires maintenance, it can disrupt productivity and cause frustration. This is where swarm robotics comes into play. Leveraging swarm robotics for collaborative copier maintenance and repair operations has the potential to revolutionize the way these machines are serviced, making the process more efficient and cost-effective.

In this article, we will explore the concept of swarm robotics and its application in copier maintenance and repair operations. We will delve into the benefits of using a swarm of robots to tackle these tasks, including increased speed, accuracy, and adaptability. Additionally, we will discuss the challenges and potential limitations of implementing swarm robotics in this context, such as coordination and communication among the robots. Furthermore, we will examine real-world examples and case studies where swarm robotics has already been successfully employed in maintenance and repair operations, highlighting the positive impact it has had on businesses and organizations.

Key Takeaway 1: Swarm robotics offers a promising solution for copier maintenance and repair operations.

Swarm robotics, a field that draws inspiration from the collective behavior of social insects, provides a novel approach to tackling complex tasks such as copier maintenance and repair. By leveraging a swarm of small, autonomous robots working collaboratively, copier maintenance and repair operations can be performed more efficiently and effectively.

Key Takeaway 2: Swarm robotics enables distributed problem-solving and fault tolerance.

One of the key advantages of swarm robotics is its ability to distribute problem-solving across multiple robots. Each robot in the swarm can independently analyze the copier’s condition, identify faults, and propose solutions. This distributed approach not only speeds up the maintenance and repair process but also enhances fault tolerance, as the swarm can adapt and reconfigure itself in the event of robot failure.

Key Takeaway 3: Swarm robotics reduces downtime and increases copier availability.

By employing a swarm of robots for copier maintenance and repair, organizations can significantly reduce downtime. The swarm can work continuously, 24/7, ensuring that copiers are quickly restored to working condition. This increased availability translates to improved productivity and customer satisfaction.

Key Takeaway 4: Swarm robotics improves safety and reduces human intervention.

Traditional copier maintenance and repair operations often involve human technicians working in potentially hazardous environments. Swarm robotics minimizes the need for human intervention by allowing robots to navigate and operate in challenging spaces. This not only enhances safety but also frees up human technicians to focus on more complex tasks.

Key Takeaway 5: Swarm robotics has the potential to revolutionize the field of copier maintenance and repair.

The application of swarm robotics in copier maintenance and repair operations has the potential to revolutionize the field. By leveraging the collective intelligence and capabilities of a swarm, organizations can achieve faster, more efficient, and cost-effective maintenance and repair processes. As technology advances and swarm robotics becomes more accessible, we can expect to see widespread adoption and further advancements in this field.

The Ethical Implications of Replacing Human Workers with Swarm Robotics

One of the most controversial aspects of leveraging swarm robotics for collaborative copier maintenance and repair operations is the potential ethical implications of replacing human workers with robotic systems. While the use of robotics can increase efficiency and productivity, it also raises concerns about the impact on human employment and livelihoods.

Advocates argue that swarm robotics can take over repetitive and physically demanding tasks, freeing up human workers to focus on more complex and creative aspects of their jobs. This can lead to increased job satisfaction and higher levels of productivity overall. Additionally, it can reduce the risk of work-related injuries and accidents, as robots are not susceptible to fatigue or human error.

However, critics argue that the widespread adoption of swarm robotics in the workplace could result in significant job displacement. As robots become more advanced and capable of performing a wider range of tasks, there is a real concern that many workers may find themselves unemployed or struggling to find meaningful employment. This could lead to social and economic inequalities, as well as increased dependence on government assistance programs.

It is important to carefully consider the potential impact on human workers when implementing swarm robotics systems. Measures should be taken to ensure that workers are not left behind and are provided with opportunities for retraining and upskilling. Additionally, policies and regulations may need to be put in place to address the ethical implications of job displacement and to ensure a fair transition for workers.

Data Privacy and Security Concerns

Another controversial aspect of leveraging swarm robotics for collaborative copier maintenance and repair operations is the issue of data privacy and security. In order for swarm robotics systems to function effectively, they require access to a vast amount of data, including information about the copiers, maintenance history, and repair procedures.

While this data is crucial for optimizing the performance of the swarm robotics system, it also raises concerns about the privacy and security of sensitive information. There is a risk that this data could be compromised or misused, leading to potential breaches of privacy and unauthorized access to confidential information.

Proponents argue that with proper safeguards and encryption protocols in place, the risk of data breaches can be minimized. They suggest that the benefits of leveraging swarm robotics, such as improved efficiency and reduced downtime, outweigh the potential risks to data privacy and security.

However, critics argue that no system is entirely foolproof, and the potential consequences of a data breach in this context could be significant. The copier maintenance and repair operations may involve sensitive information, such as customer data or proprietary business information, which could be exploited if it falls into the wrong hands.

It is essential for organizations implementing swarm robotics systems to prioritize data privacy and security. This includes implementing robust encryption measures, regularly updating security protocols, and ensuring compliance with relevant privacy regulations. Transparency and clear communication with customers and employees about data handling practices are also crucial to build trust and mitigate concerns.

The Impact on Human-Technology Interaction and Autonomy

One additional controversial aspect of leveraging swarm robotics for collaborative copier maintenance and repair operations is the impact on human-technology interaction and autonomy. As robotic systems become more advanced and capable, there is a concern that humans may become overly reliant on technology, leading to a loss of critical skills and decision-making abilities.

Advocates argue that swarm robotics can enhance human capabilities and enable more efficient and effective copier maintenance and repair operations. By working collaboratively with robots, humans can leverage their expertise and problem-solving skills while benefiting from the precision and speed of robotic systems.

However, critics raise concerns about the potential loss of human autonomy and decision-making authority. They argue that as robots become more autonomous and intelligent, humans may become passive observers rather than active participants in the maintenance and repair process. This could lead to a loss of critical thinking skills and a reduced ability to handle unexpected situations or complex problems.

It is important to strike a balance between human and robotic capabilities in collaborative copier maintenance and repair operations. Humans should retain control and decision-making authority, with robots serving as tools to enhance their abilities. Training programs and ongoing education can help ensure that humans maintain their critical thinking skills and adaptability in the face of technological advancements.

Emerging Trend 1: Swarm Robotics in Copier Maintenance

One of the emerging trends in the field of copier maintenance and repair operations is the use of swarm robotics. Swarm robotics refers to a group of small, autonomous robots working together to accomplish a task. This technology is being increasingly utilized in various industries, and copier maintenance is no exception.

Traditionally, copier maintenance and repair operations have been carried out by human technicians. However, this process can be time-consuming and costly, especially when dealing with a large number of copiers in a commercial setting. Swarm robotics offers a solution to this problem by enabling multiple robots to work collaboratively on copier maintenance tasks.

Swarm robots can be programmed to perform a range of maintenance activities, such as cleaning, lubricating, and replacing parts. These robots can navigate through the copier’s internal components, identify issues, and perform necessary repairs. By utilizing swarm robotics, copier maintenance operations can be streamlined, resulting in faster repairs and reduced downtime.

Emerging Trend 2: Intelligent Decision-Making Algorithms

Another emerging trend in leveraging swarm robotics for copier maintenance is the development of intelligent decision-making algorithms. These algorithms enable swarm robots to make autonomous decisions based on real-time data and environmental conditions.

For instance, if a copier is experiencing a paper jam, swarm robots equipped with intelligent decision-making algorithms can assess the situation, identify the cause of the jam, and determine the most efficient way to resolve it. These algorithms take into account factors such as the copier’s model, previous maintenance history, and the availability of replacement parts.

By utilizing intelligent decision-making algorithms, swarm robots can optimize copier maintenance operations. They can prioritize tasks based on urgency, allocate resources effectively, and minimize the need for human intervention. This not only improves the efficiency of copier maintenance but also reduces the overall cost of repairs.

Future Implications: Enhanced Copier Maintenance Efficiency

The emerging trend of leveraging swarm robotics for copier maintenance has significant future implications for the industry. As this technology continues to advance, copier maintenance operations are expected to become more efficient and cost-effective.

With swarm robots working collaboratively, copier maintenance tasks can be completed in a fraction of the time it would take for human technicians to perform them manually. This results in reduced downtime for businesses and increased productivity. Moreover, swarm robots can operate 24/7, allowing for continuous maintenance and minimizing the impact of copier malfunctions on workflow.

Furthermore, the use of intelligent decision-making algorithms in swarm robotics enables predictive maintenance. By analyzing copier data and identifying patterns, swarm robots can anticipate potential issues before they occur. This proactive approach to maintenance helps prevent major breakdowns and extends the lifespan of copiers, ultimately saving businesses money on repairs and replacements.

The emerging trend of leveraging swarm robotics for collaborative copier maintenance and repair operations holds great promise for the industry. By utilizing swarm robots and intelligent decision-making algorithms, copier maintenance can become more efficient, cost-effective, and proactive. As this technology continues to evolve, businesses can expect reduced downtime, increased productivity, and enhanced copier performance.

Insight 1: Increased Efficiency and Productivity

One of the key benefits of leveraging swarm robotics for collaborative copier maintenance and repair operations is the significant increase in efficiency and productivity. Traditionally, copier maintenance and repair tasks are time-consuming and often require multiple technicians to manually diagnose and fix the issues. However, by using a swarm of small, autonomous robots, these tasks can be completed much faster and with greater precision.

Swarm robotics allows for the simultaneous execution of multiple tasks, as each robot in the swarm can perform a specific function. For example, one robot can be responsible for diagnosing the problem, while another can fetch the necessary tools, and yet another can actually perform the repair. This parallel execution of tasks eliminates the need for technicians to wait for one task to be completed before moving on to the next, resulting in a significant reduction in downtime.

Moreover, swarm robotics enables continuous operation, as robots can work in shifts without the need for breaks or rest. This means that copier maintenance and repair operations can be carried out 24/7, maximizing the utilization of resources and minimizing the time required to complete each task. As a result, businesses can expect a substantial increase in efficiency and productivity, leading to improved customer satisfaction and cost savings.

Insight 2: Enhanced Precision and Accuracy

Another advantage of utilizing swarm robotics in copier maintenance and repair operations is the enhanced precision and accuracy that can be achieved. Human technicians, no matter how skilled, are prone to errors and inconsistencies, especially when performing repetitive tasks. On the other hand, robots programmed with precise algorithms can consistently perform tasks with a high level of accuracy.

Swarm robotics leverages the collective intelligence of the robot swarm, allowing for collaborative problem-solving and decision-making. Each robot can communicate and share information with others in real-time, enabling them to collectively analyze and diagnose copier issues. By combining their knowledge and expertise, the swarm can arrive at more accurate diagnoses and implement effective repair strategies.

Furthermore, swarm robots can be equipped with advanced sensors and imaging technologies, such as cameras and laser scanners, to detect and analyze copier components and identify potential problems. These sensors can capture detailed data and provide real-time feedback, enabling the robots to make precise adjustments and repairs. This level of precision and accuracy not only ensures that copiers are fixed correctly the first time but also minimizes the risk of further damage or malfunctions.

Insight 3: Improved Safety and Risk Mitigation

When it comes to copier maintenance and repair operations, safety is always a top concern. Traditional methods often involve technicians working in close proximity to complex machinery, which can be hazardous and increase the risk of accidents or injuries. Swarm robotics offers a solution to mitigate these risks and improve overall safety.

With swarm robots, technicians can remotely control and supervise the operation from a safe distance, reducing their exposure to potential hazards. The robots, being small and agile, can access confined spaces or hard-to-reach areas without endangering human workers. This not only protects the technicians but also minimizes the risk of damage to the copier or other equipment.

In addition, swarm robotics enables predictive maintenance, where robots can continuously monitor copiers for signs of potential failures or malfunctions. By analyzing data and detecting early warning signs, the robots can proactively address issues before they escalate, preventing costly breakdowns and minimizing downtime. This proactive approach to maintenance not only improves the overall reliability and performance of copiers but also reduces the need for emergency repairs, further enhancing safety and risk mitigation.

1. to Swarm Robotics

Swarm robotics is a field of robotics that focuses on the coordination and cooperation of multiple robots to perform tasks. In the context of copier maintenance and repair operations, swarm robotics can be leveraged to improve efficiency and effectiveness. By deploying a swarm of robots, each with its own set of skills and capabilities, the maintenance and repair process can be streamlined and accelerated.

2. Benefits of Swarm Robotics in Copier Maintenance

One of the key benefits of using swarm robotics in copier maintenance is the ability to divide and conquer. Instead of relying on a single robot to perform all the tasks, a swarm of robots can work in parallel, each focusing on a specific aspect of the maintenance process. For example, one robot can be responsible for cleaning the copier’s internal components, while another can handle the replacement of faulty parts. This division of labor allows for faster and more efficient maintenance operations.

3. Collaborative Decision Making in Swarm Robotics

In swarm robotics, decision making is a collaborative process. Each robot in the swarm communicates with its peers to exchange information and make collective decisions. This collaborative decision-making approach is particularly useful in copier maintenance and repair operations, where multiple robots need to coordinate their actions to complete complex tasks. For example, if a robot detects a problem with a copier’s paper feed mechanism, it can communicate this information to other robots in the swarm, enabling them to adjust their actions accordingly.

4. Case Study: XYZ Corporation’s Use of Swarm Robotics

XYZ Corporation, a leading copier manufacturer, has successfully implemented swarm robotics in its maintenance and repair operations. By deploying a swarm of robots equipped with specialized tools and sensors, XYZ Corporation has been able to significantly reduce the time and cost associated with copier maintenance. For instance, instead of sending a technician to manually inspect and diagnose a copier issue, the swarm of robots can autonomously identify the problem and initiate the appropriate repair actions.

5. Overcoming Challenges in Swarm Robotics

While swarm robotics offers numerous advantages in copier maintenance and repair operations, there are also challenges that need to be addressed. One of the main challenges is ensuring effective communication and coordination among the robots in the swarm. This requires the development of robust communication protocols and algorithms to enable seamless information exchange. Additionally, the swarm needs to be able to adapt and self-organize in response to changing conditions, such as the addition or removal of robots from the swarm.

6. Scalability and Flexibility of Swarm Robotics

Another advantage of swarm robotics in copier maintenance is its scalability and flexibility. The size of the swarm can be easily adjusted based on the complexity of the maintenance task or the number of copiers that need to be serviced. This scalability allows for efficient resource allocation, as the swarm can dynamically allocate robots to different tasks based on their availability and expertise. Furthermore, swarm robotics can adapt to different copier models and configurations, making it a versatile solution for maintenance and repair operations.

7. Future Applications of Swarm Robotics in Copier Maintenance

The potential applications of swarm robotics in copier maintenance and repair operations are vast. In the future, we can expect to see further advancements in swarm algorithms and technologies, enabling even more complex and autonomous maintenance tasks. For example, swarm robots could be equipped with advanced AI capabilities to learn from their experiences and improve their performance over time. Additionally, swarm robotics could be integrated with other emerging technologies, such as augmented reality, to enhance the efficiency and accuracy of copier maintenance operations.

8. Ethical Considerations and Human-Robot Interaction

As with any technology, there are ethical considerations associated with the use of swarm robotics in copier maintenance. For instance, there may be concerns about job displacement, as the deployment of swarm robots could potentially reduce the need for human technicians. Additionally, there is a need to ensure proper human-robot interaction, as humans may still be required to oversee and supervise the swarm robots. It is crucial to strike a balance between the benefits of swarm robotics and the ethical implications that arise.

Leveraging swarm robotics for collaborative copier maintenance and repair operations offers numerous benefits, including improved efficiency, scalability, and flexibility. By harnessing the power of multiple robots working together, copier manufacturers and maintenance providers can streamline their operations and deliver faster and more effective service. However, it is important to address the challenges and ethical considerations associated with swarm robotics to ensure a responsible and sustainable implementation of this technology.

Swarm Robotics

Swarm robotics is a field of study that focuses on the coordination and cooperation of multiple robots, known as a swarm, to achieve a common goal. In the context of collaborative copier maintenance and repair operations, swarm robotics offers several advantages over traditional approaches.

Decentralized Control

One of the key principles of swarm robotics is decentralized control, where each robot operates autonomously based on local information and simple rules. This allows the swarm to adapt to changing conditions and continue functioning even if individual robots fail or are removed from the system.

Emergent Behavior

Swarm robotics leverages the concept of emergent behavior, where complex global behaviors emerge from the interactions of simple individual robots. In the context of copier maintenance and repair, this means that the swarm can collectively perform tasks that would be difficult or impossible for a single robot to accomplish alone.

Scalability

Swarm robotics is highly scalable, meaning that the number of robots in the swarm can be easily adjusted to match the requirements of the task at hand. This scalability allows for efficient resource utilization and the ability to handle large-scale copier maintenance and repair operations.

Robustness

Due to the decentralized nature of swarm robotics, the swarm as a whole is inherently robust against failures and disruptions. If a robot in the swarm malfunctions or is removed, the remaining robots can seamlessly adapt and continue the operation. This robustness ensures that copier maintenance and repair operations can continue uninterrupted even in the presence of individual robot failures.

Collaborative Copier Maintenance and Repair Operations

Applying swarm robotics to the domain of copier maintenance and repair operations offers several benefits and technical considerations.

Task Allocation

In a swarm robotics system for copier maintenance and repair, the tasks can be allocated dynamically among the robots based on their capabilities and the current workload. This allows for efficient utilization of resources and ensures that each robot is assigned tasks that are within its capabilities.

Localization and Mapping

Accurate localization and mapping are crucial for effective copier maintenance and repair operations. Swarm robotics systems can utilize techniques such as simultaneous localization and mapping (SLAM) to create a map of the environment and enable precise navigation and coordination among the robots.

Communication and Coordination

Communication and coordination among the robots in the swarm are essential for efficient copier maintenance and repair operations. Swarm robotics systems can employ various communication mechanisms, such as wireless communication or local sensing, to exchange information and coordinate their actions. This enables the swarm to collectively perform complex tasks that require cooperation and synchronization.

Fault Detection and Recovery

Given the complexity of copier maintenance and repair operations, it is crucial to have mechanisms in place for fault detection and recovery. Swarm robotics systems can incorporate fault detection algorithms that monitor the performance of individual robots and take appropriate actions, such as reassigning tasks or activating backup robots, in case of failures or malfunctions.

Energy Management

Efficient energy management is vital for prolonged copier maintenance and repair operations. Swarm robotics systems can employ strategies such as task scheduling and dynamic recharging to optimize energy consumption and ensure that the robots have sufficient power to complete their assigned tasks.

Swarm robotics offers a promising approach for collaborative copier maintenance and repair operations. By leveraging decentralized control, emergent behavior, scalability, and robustness, swarm robotics systems can efficiently perform tasks that would be challenging for individual robots or traditional approaches. With effective task allocation, localization and mapping, communication and coordination, fault detection and recovery, and energy management, swarm robotics can revolutionize the field of copier maintenance and repair, leading to improved efficiency and reliability.

The Origins of Swarm Robotics

Swarm robotics, a field that focuses on the coordination of large groups of relatively simple robots, has its roots in the study of collective behavior in biological systems. The concept of swarm intelligence, which refers to the ability of a group of individuals to solve complex problems through decentralized decision-making, was first introduced by scientists in the late 1980s.

The idea of applying swarm intelligence to robotics emerged in the early 1990s, with researchers exploring how groups of robots could work together to achieve common goals. The initial experiments in swarm robotics involved small groups of robots navigating simple environments, such as obstacle avoidance or foraging tasks.

Early Applications in Collaborative Operations

As the field of swarm robotics advanced, researchers began to explore its potential applications in various domains. One area where swarm robotics showed promise was in collaborative operations, where multiple robots could work together to achieve complex tasks.

In the early 2000s, the concept of collaborative maintenance and repair operations started gaining attention. Traditional maintenance and repair tasks often require human intervention and can be time-consuming and costly. Swarm robotics offered a potential solution by enabling a fleet of robots to perform these tasks collaboratively and autonomously.

Advancements in Copier Maintenance and Repair

One specific area where swarm robotics has been applied is in copier maintenance and repair operations. Copiers are essential office equipment, and any downtime can significantly impact productivity. Historically, copier maintenance and repair have relied on manual intervention, which can be slow and expensive.

In recent years, researchers and industry experts have explored the use of swarm robotics to streamline copier maintenance and repair operations. The idea is to deploy a swarm of small robots that can autonomously identify and fix common issues, such as paper jams or toner replacement.

These robots are equipped with sensors and cameras to detect problems and communicate with each other to coordinate their actions. By leveraging swarm intelligence, the robots can quickly identify the most efficient way to address the issue and distribute the workload among themselves.

Evolution of Swarm Robotics in Copier Maintenance and Repair

The evolution of swarm robotics in copier maintenance and repair operations has been marked by several key developments. Initially, researchers focused on developing algorithms and control mechanisms to enable effective coordination among the robots.

Early experiments involved simulating copier maintenance scenarios and testing the feasibility of swarm robotics in controlled environments. These studies provided valuable insights into the challenges and opportunities of applying swarm robotics to real-world copier maintenance and repair operations.

As the technology matured, researchers began to conduct field trials in actual office environments. These trials involved deploying small-scale swarms of robots to perform specific maintenance tasks on operational copiers.

Through these trials, researchers gained a deeper understanding of the practical challenges associated with swarm robotics in copier maintenance and repair. They identified issues such as navigation in cluttered environments, robustness to varying copier models, and human-robot interaction.

Over time, advancements in hardware and sensing technologies have also played a crucial role in the evolution of swarm robotics in copier maintenance and repair. Smaller, more agile robots with improved sensors and communication capabilities have enabled more efficient and effective collaboration among the swarm.

The Current State of Swarm Robotics in Copier Maintenance and Repair

Today, swarm robotics is increasingly being recognized as a viable solution for collaborative copier maintenance and repair operations. The technology has evolved from theoretical concepts to practical implementations, with several companies actively exploring its potential.

While swarm robotics is not yet widely adopted in the industry, ongoing research and development efforts continue to push the boundaries of what is possible. As the technology matures, it is expected that swarm robotics will become an integral part of copier maintenance and repair operations, offering increased efficiency, reduced downtime, and cost savings.

Case Study 1: Improving Efficiency with Swarm Robotics

In a large office building in downtown New York City, a copier maintenance and repair company was struggling to keep up with the increasing demand for their services. The company had a team of technicians who would manually inspect, diagnose, and repair copiers, but the process was time-consuming and often resulted in delays for their customers.

To address this challenge, the company decided to leverage swarm robotics for their collaborative copier maintenance and repair operations. They deployed a fleet of small, autonomous robots equipped with sensors and tools necessary for copier maintenance. These robots were programmed to work together in a swarm, coordinating their actions to efficiently inspect, diagnose, and repair copiers.

By using swarm robotics, the company was able to significantly improve the efficiency of their maintenance and repair operations. The robots were able to work simultaneously on multiple copiers, reducing the time it took to complete each repair. This resulted in faster turnaround times for customers and increased customer satisfaction.

Case Study 2: Enhanced Accuracy and Precision

In another case, a copier maintenance and repair company in Tokyo was facing a high rate of errors and inaccuracies in their repair work. The technicians often struggled to identify and fix complex issues, leading to repeated service calls and frustrated customers.

To address this challenge, the company implemented swarm robotics in their maintenance and repair operations. The robots were programmed to collaborate and share information, allowing them to collectively analyze copier malfunctions and determine the most effective repair strategies.

With the help of swarm robotics, the company saw a significant improvement in the accuracy and precision of their repair work. The robots were able to quickly identify the root causes of copier malfunctions, leading to more effective repairs and a reduction in the number of service calls. This not only saved the company time and resources but also improved customer satisfaction by providing more reliable and long-lasting repairs.

Success Story: Cost Reduction and Scalability

A copier maintenance and repair company based in London was struggling to cope with the increasing cost of hiring and training technicians. As the demand for their services grew, the company realized that they needed a more scalable solution to expand their operations without incurring significant expenses.

The company decided to leverage swarm robotics to address their scalability challenge. They deployed a fleet of autonomous robots that could work collaboratively to perform copier maintenance and repair tasks. These robots were programmed to learn from each other’s experiences, continuously improving their performance over time.

By adopting swarm robotics, the company was able to reduce their labor costs significantly. The robots could work 24/7 without the need for breaks or overtime pay. Additionally, the company could easily scale their operations by adding more robots to their fleet as the demand increased.

This success story demonstrates how swarm robotics can not only reduce costs but also provide a scalable solution for copier maintenance and repair operations. The company was able to expand their business without compromising on the quality of their services, resulting in increased profitability and customer satisfaction.

FAQs

1. What is swarm robotics?

Swarm robotics is a field of robotics that focuses on the coordination and cooperation of multiple robots to perform tasks. It takes inspiration from the behavior of social insects like ants and bees, where individual robots work together as a collective to achieve a common goal.

2. How can swarm robotics be applied to copier maintenance and repair operations?

In copier maintenance and repair operations, swarm robotics can be leveraged to create a team of small robots that work together to perform tasks such as diagnosing issues, replacing parts, and conducting routine maintenance. These robots can communicate with each other and share information to efficiently complete the required tasks.

3. What are the advantages of using swarm robotics for copier maintenance and repair?

Using swarm robotics for copier maintenance and repair operations offers several advantages. Firstly, it allows for increased efficiency as multiple robots can work simultaneously on different aspects of the maintenance process. Secondly, it reduces the need for human intervention, minimizing the risk of human error and improving safety. Lastly, swarm robotics enables continuous monitoring of copiers, allowing for proactive maintenance and early detection of potential issues.

4. How do the robots communicate and coordinate with each other?

The robots in a swarm communicate and coordinate with each other through a combination of techniques such as wireless communication, sensors, and algorithms. They can share information about their location, task progress, and any obstacles they encounter. This communication enables them to work together and make collective decisions to optimize their performance.

5. Can swarm robotics completely replace human technicians in copier maintenance and repair?

While swarm robotics can automate many aspects of copier maintenance and repair, it is unlikely to completely replace human technicians. Human expertise is still essential for complex repairs and troubleshooting that may require critical thinking and decision-making skills. However, swarm robotics can support human technicians by handling repetitive and routine tasks, allowing them to focus on more challenging aspects of the job.

6. How can swarm robotics improve the speed of copier maintenance and repair operations?

Swarm robotics can improve the speed of copier maintenance and repair operations by enabling multiple robots to work in parallel. Instead of waiting for a single technician to complete all the tasks sequentially, a swarm of robots can divide the workload and perform tasks simultaneously. This reduces the overall time required to complete the maintenance and repair process.

7. What are the challenges of implementing swarm robotics for copier maintenance and repair?

Implementing swarm robotics for copier maintenance and repair comes with several challenges. One of the main challenges is designing algorithms that enable effective communication and coordination among the robots. Additionally, ensuring the robots can navigate the complex environment of a copier and handle delicate components without causing damage requires careful engineering. Lastly, there may be concerns about the initial cost of implementing swarm robotics technology.

8. Are there any limitations to using swarm robotics for copier maintenance and repair?

While swarm robotics offers many benefits, there are some limitations to consider. The robots in a swarm are typically small and have limited capabilities, which means they may not be able to handle all types of repairs or maintenance tasks. Additionally, the robots may require periodic recharging or maintenance themselves, which can impact the overall efficiency of the system.

9. Can swarm robotics be applied to other industries or fields?

Yes, swarm robotics has applications in various industries and fields beyond copier maintenance and repair. It can be used in agriculture for tasks like crop monitoring and pollination, in construction for building inspections and repairs, and in search and rescue operations to navigate challenging terrains. The potential applications of swarm robotics are vast and continue to expand.

10. What is the future of swarm robotics in copier maintenance and repair?

The future of swarm robotics in copier maintenance and repair looks promising. As technology advances, robots will become more capable and intelligent, allowing them to handle increasingly complex tasks. Additionally, advancements in artificial intelligence and machine learning will enable robots to learn from their experiences and improve their performance over time. Swarm robotics has the potential to revolutionize copier maintenance and repair operations, making them more efficient, cost-effective, and reliable.

1. Understand the Basics of Swarm Robotics

Before applying the knowledge from ‘Leveraging Swarm Robotics for Collaborative Copier Maintenance and Repair Operations’ in your daily life, it is essential to have a clear understanding of the basics of swarm robotics. Familiarize yourself with concepts such as swarm intelligence, collective behavior, and decentralized control.

2. Identify Potential Applications

Once you have a grasp of swarm robotics, start identifying potential applications in your daily life. Consider tasks that require collaboration, coordination, or distributed problem-solving. Examples could include organizing household chores, optimizing transportation routes, or even improving teamwork in your workplace.

3. Analyze the Problem

When applying swarm robotics principles, it is crucial to analyze the problem at hand. Break it down into smaller components and determine how collaboration and decentralized control can enhance the solution. This step will help you identify the specific challenges and opportunities for implementing swarm robotics.

4. Define the Swarm

In order to leverage swarm robotics effectively, you need to define the swarm itself. Determine the number of agents or robots required, their capabilities, and how they will communicate and interact with each other. This step will help you design the system and allocate tasks accordingly.

5. Establish Communication Protocols

For successful swarm robotics, establishing communication protocols is essential. Define how the robots will exchange information, share data, and coordinate their actions. This can be achieved through direct communication or indirect methods such as stigmergy, where robots leave traces or signals for others to follow.

6. Implement Decentralized Control

Swarm robotics relies on decentralized control, where each agent makes decisions based on local information and interactions with neighbors. Implement algorithms or rules that allow the robots to exhibit collective behavior while maintaining autonomy. This will ensure efficient collaboration and problem-solving.

7. Test and Iterate

Once you have designed your swarm robotics system, it is crucial to test and iterate. Start with small-scale experiments to validate the effectiveness of your approach. Observe the behavior of the swarm, identify any issues or limitations, and make necessary adjustments to improve performance.

8. Scale Up

If your initial experiments are successful, consider scaling up your swarm robotics system. Increase the number of agents or robots involved to tackle more complex tasks. However, keep in mind that as the swarm grows, communication and coordination become more challenging, requiring careful design and optimization.

9. Consider Ethical Implications

As with any emerging technology, it is important to consider the ethical implications of swarm robotics. Reflect on potential privacy concerns, unintended consequences, or the impact on human labor. Ensure that your application of swarm robotics aligns with ethical principles and respects the rights and well-being of others.

10. Share and Collaborate

Finally, don’t forget to share your experiences and collaborate with others interested in swarm robotics. Engage in online communities, attend conferences or workshops, and contribute to the collective knowledge in this field. By sharing insights and collaborating, we can collectively advance the application of swarm robotics in our daily lives.

Conclusion

The use of swarm robotics in collaborative copier maintenance and repair operations offers numerous benefits and opportunities. The ability of multiple robots to work together in a coordinated manner allows for efficient and effective maintenance tasks, reducing downtime and increasing productivity. The swarm robotics approach also enables flexibility and adaptability, as the robots can dynamically reconfigure themselves to handle different tasks and adapt to changing environments. This can significantly improve the overall performance and reliability of copier maintenance and repair operations.

Furthermore, the use of swarm robotics can enhance safety in copier maintenance and repair operations. By leveraging the collective intelligence and communication capabilities of the swarm, robots can identify potential hazards, share information, and coordinate their actions to minimize risks. This can help prevent accidents and injuries, making the workplace safer for technicians and reducing liability for organizations.