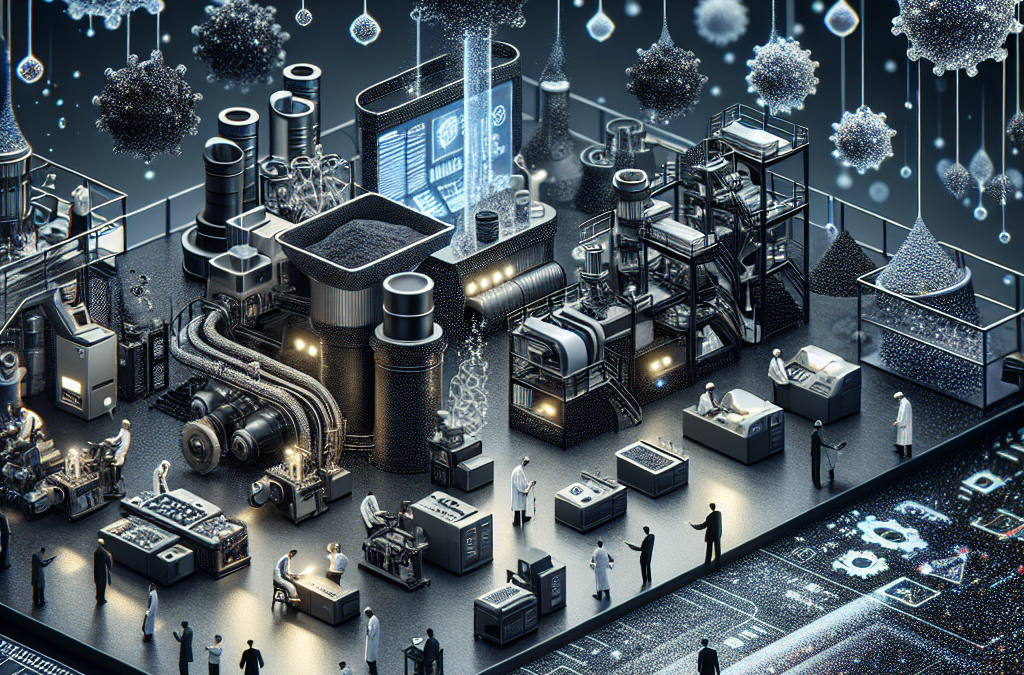

Revolutionizing Printing: How Nanotechnology is Transforming Toner Production

Nanotechnology has revolutionized various industries, and now it is making its mark in the world of printing. The use of nanotechnology in toner production has led to significant advancements in print quality and efficiency, transforming the way we print documents. This article explores the latest developments in nanotechnology and how they are enhancing the printing process, from sharper images and vibrant colors to faster printing speeds and reduced environmental impact.

Traditionally, toner particles were created through a process called pulverization, which resulted in irregularly shaped particles that affected print quality. However, with the integration of nanotechnology, toner particles can now be engineered at the nanoscale, allowing for precise control over their size and shape. This level of precision ensures uniform distribution of toner particles on the page, resulting in crisper text and images. Additionally, nanotechnology enables the creation of toner particles with enhanced color pigments, leading to more vibrant and accurate color reproduction.

Key Takeaways:

1. Nanotechnology is revolutionizing the toner production industry, leading to significant advancements in print quality and efficiency.

2. The use of nanomaterials in toner formulations allows for precise control over particle size, shape, and distribution, resulting in sharper and more vibrant prints.

3. Nanotechnology-enhanced toners have improved durability, with prints that are resistant to smudging, fading, and water damage.

4. The incorporation of nanomaterials in toner production has also led to increased efficiency, as smaller particle sizes allow for faster melting and fusing, reducing energy consumption and printer downtime.

5. Nanotechnology has the potential to revolutionize the printing industry, with the development of new toner materials that offer enhanced functionalities such as conductive or magnetic properties, opening up possibilities for applications in flexible electronics and security printing.

Nanoparticles in Toner: Enhancing Print Quality and Efficiency

Nanotechnology has been making significant strides in various industries, and the field of toner production is no exception. By incorporating nanoparticles into toner formulations, manufacturers are able to achieve improved print quality and efficiency. This emerging trend in nanotechnology is revolutionizing the printing industry and has the potential to reshape the future of printing technology.

1. Enhanced Print Quality

One of the key advantages of using nanoparticles in toner production is the significant improvement in print quality. Traditional toners consist of larger particles that can lead to grainy or blurry prints, especially when dealing with small fonts or intricate details. However, by reducing the particle size to the nanoscale, toner manufacturers can achieve much sharper and more vibrant prints.

The smaller size of the nanoparticles allows for a higher resolution, resulting in crisper text and more detailed images. This is particularly beneficial for industries such as graphic design, advertising, and photography, where print quality is of utmost importance. The use of nanotechnology in toner production ensures that the final prints accurately capture the nuances and intricacies of the original digital content.

2. Improved Efficiency and Cost Savings

In addition to enhancing print quality, nanotechnology in toner production also offers improved efficiency and cost savings. Traditional toners often require multiple passes to achieve the desired print density, resulting in longer print times and higher energy consumption. However, by utilizing nanoparticles, toner manufacturers can create formulations that require fewer passes, thereby reducing printing time and energy usage.

The smaller particle size of nanotechnology-based toners also allows for a more even distribution of toner on the page. This means that less toner is required to achieve the same print density, resulting in cost savings for both consumers and manufacturers. Additionally, the improved efficiency of nanotechnology-based toners translates to increased productivity in printing environments, as faster print speeds can be achieved without compromising print quality.

3. Environmental Benefits

Another significant advantage of incorporating nanotechnology into toner production is the potential for environmental benefits. Traditional toners often contain harmful chemicals and heavy metals that can pose risks to human health and the environment. However, nanotechnology-based toners have the potential to reduce or eliminate the need for these hazardous materials.

Nanoparticles can be engineered to have specific properties that enhance toner performance without the need for toxic additives. For example, nanoparticles with magnetic properties can be used to improve the efficiency of the printing process without relying on magnetic toners that contain heavy metals. By reducing the use of hazardous materials, nanotechnology in toner production contributes to a cleaner and more sustainable printing industry.

The Future of Nanotechnology in Toner Production

The emerging trend of incorporating nanotechnology into toner production holds great promise for the future of printing technology. As research and development in this field continue to advance, we can expect to see further improvements in print quality, efficiency, and environmental sustainability.

One area of future development is the use of nanotechnology to create toners with specialized properties. For example, researchers are exploring the use of nanoparticles that can change color depending on external factors such as temperature or humidity. This could lead to the development of toners that are more responsive and adaptable to different printing conditions.

Furthermore, nanotechnology has the potential to enable the production of toners that are more environmentally friendly throughout their lifecycle. From the sourcing of raw materials to the disposal of used toner cartridges, nanotechnology can offer solutions that minimize the environmental impact of printing.

The incorporation of nanoparticles into toner production is an emerging trend that is revolutionizing the printing industry. By enhancing print quality, improving efficiency and cost savings, and providing environmental benefits, nanotechnology is reshaping the future of printing technology. As research and development in this field continue, we can anticipate even more exciting advancements that will further propel the printing industry into the future.

Nanotechnology Enhances Print Quality

Nanotechnology has revolutionized toner production, leading to significant advancements in print quality. By incorporating nanoparticles into toner formulations, manufacturers have been able to achieve sharper, more vibrant prints with enhanced details and color accuracy. This is particularly beneficial for industries that rely heavily on high-quality printed materials, such as graphic design, advertising, and photography.

The use of nanoparticles in toner production allows for precise control over particle size and distribution. This level of control ensures that the toner particles are uniform, resulting in consistent print quality across the entire page. Additionally, the reduced particle size enables better toner adhesion to the paper, resulting in crisper text and images.

Furthermore, nanotechnology has enabled the development of toners with improved resistance to smudging and fading. The nanoparticles create a protective layer around the toner particles, preventing them from smearing or smudging during the printing process. This is especially important for documents that require frequent handling or exposure to environmental factors.

Increased Efficiency in Toner Consumption

Another key impact of nanotechnology in toner production is the increased efficiency in toner consumption. Traditional toners often suffer from excessive waste due to inefficient transfer to the paper and residual toner left in the cartridge. However, nanotechnology has addressed these issues, resulting in reduced toner waste and improved cost-effectiveness.

Nanoparticles in toner formulations enhance the transfer efficiency of toner particles from the cartridge to the paper. The smaller particle size allows for better adhesion to the paper, minimizing the amount of toner that remains in the cartridge. This not only reduces waste but also extends the lifespan of the toner cartridge, resulting in cost savings for businesses and individuals.

In addition, nanotechnology has enabled the development of toners with lower melting points. This means that less energy is required to fuse the toner particles onto the paper during the printing process. As a result, printers equipped with nanotechnology-based toners consume less power, reducing energy costs and making printing more environmentally friendly.

Advancements in Sustainable Toner Production

With the growing emphasis on sustainability, the use of nanotechnology in toner production has also contributed to advancements in sustainable manufacturing practices. Nanoparticles offer several environmental benefits, making them a viable alternative to traditional toner production methods.

Firstly, the use of nanoparticles in toner production reduces the reliance on petroleum-based materials. Traditional toners are typically derived from fossil fuels, which contribute to greenhouse gas emissions and environmental degradation. Nanotechnology-based toners, on the other hand, utilize alternative materials that are more sustainable and have a lower environmental impact.

Moreover, nanotechnology enables the development of toners with improved recyclability. The smaller particle size of nanotechnology-based toners allows for easier separation of toner particles from the paper during recycling processes. This facilitates the efficient recovery of toner materials, reducing the amount of waste sent to landfills and promoting a circular economy.

Furthermore, the enhanced print quality achieved through nanotechnology reduces the need for reprints, minimizing paper waste. By producing high-quality prints on the first attempt, businesses can reduce their paper consumption and contribute to a more sustainable printing industry.

The Environmental Impact of Nanotechnology in Toner Production

One of the most controversial aspects of nanotechnology in toner production is its potential environmental impact. While nanotechnology offers numerous benefits, such as improved print quality and efficiency, there are concerns about the release of nanoparticles into the environment during the manufacturing process and disposal of toner cartridges.

Proponents argue that nanotechnology can reduce the overall environmental footprint of toner production. By using nanoparticles, manufacturers can achieve higher levels of precision, resulting in less waste and energy consumption. Additionally, nanotechnology enables the development of toner materials that are more biodegradable, reducing the long-term impact on ecosystems.

However, critics argue that the potential risks associated with nanoparticles are not yet fully understood. There are concerns that these tiny particles could accumulate in the environment and pose a threat to human health and ecosystems. Studies have shown that certain nanoparticles can have toxic effects on living organisms, raising questions about the long-term consequences of their use in toner production.

It is essential to strike a balance between reaping the benefits of nanotechnology in toner production and minimizing its potential environmental impact. Further research and regulation are needed to ensure that the use of nanoparticles in toner production is safe for both humans and the environment.

Health and Safety Risks for Workers

Another controversial aspect of nanotechnology in toner production is the potential health and safety risks for workers involved in the manufacturing process. Nanoparticles are incredibly small, measuring at the nanoscale, which means they can easily penetrate the skin and respiratory system.

Proponents argue that with proper safety measures in place, the risks can be mitigated. Manufacturers can implement strict protocols to minimize exposure, such as using engineering controls, personal protective equipment, and proper ventilation systems. Additionally, advancements in nanotechnology can lead to the development of safer nanoparticles that are less harmful to human health.

However, critics express concerns about the adequacy of current safety regulations and the lack of comprehensive studies on the long-term health effects of nanoparticles. Some studies have suggested that certain nanoparticles may have adverse effects on the respiratory system, potentially leading to respiratory diseases or even cancer.

It is crucial to prioritize the health and safety of workers in the toner production industry. Strict regulations and guidelines should be in place to protect workers from potential exposure to nanoparticles. Additionally, further research is needed to fully understand the long-term health effects of nanoparticles and develop safer alternatives if necessary.

Social and Economic Implications

Nanotechnology in toner production also raises social and economic implications. The adoption of nanotechnology often requires significant investment in research and development, as well as the acquisition of specialized equipment and expertise. This can create barriers to entry for smaller companies, potentially leading to market consolidation and reduced competition.

Proponents argue that the advancements in print quality and efficiency brought about by nanotechnology can lead to cost savings for consumers and businesses. Improved printing capabilities can result in higher productivity and reduced printing costs in the long run. Additionally, the development of nanotechnology in toner production can drive innovation and create new job opportunities in the industry.

However, critics raise concerns about the potential concentration of power in the hands of a few large corporations. Market consolidation may lead to monopolistic practices, limiting consumer choice and potentially driving up prices. Smaller companies may struggle to compete with larger players who have the resources to invest in nanotechnology research and development.

It is essential to strike a balance between the benefits of nanotechnology in toner production and ensuring a fair and competitive market. Regulatory measures should be in place to prevent monopolistic practices and promote fair competition. Additionally, governments and industry stakeholders should work together to provide support and incentives for smaller companies to adopt and benefit from nanotechnology.

The Role of Nanotechnology in Toner Production

Nanotechnology has revolutionized various industries, and the printing industry is no exception. In toner production, nanotechnology has played a significant role in enhancing print quality and efficiency. By manipulating materials at the nanoscale level, toner manufacturers have been able to create toner particles with superior properties. These advancements have resulted in sharper images, vibrant colors, and improved overall print quality.

Nanoparticles in Toner Formulation

One of the key areas where nanotechnology has made a difference in toner production is in the formulation of toner particles. Traditional toner particles were typically irregularly shaped and had a wide size distribution, leading to inconsistent print quality. However, with the of nanoparticles, toner particles can now be precisely engineered to have uniform shapes and sizes, resulting in more consistent printouts.

For instance, by using nanoparticles of different materials such as polymers, pigments, and magnetic particles, toner manufacturers can tailor the properties of the toner particles to meet specific printing requirements. This level of control allows for improved image resolution, color accuracy, and toner adhesion to the paper surface.

Advancements in Toner Manufacturing Processes

Nanotechnology has also brought advancements in toner manufacturing processes, leading to increased efficiency and productivity. One such advancement is the use of nanoemulsion technology in toner production. Nanoemulsion involves the creation of a stable colloidal suspension of nanoparticles in a liquid medium.

This technology allows for the precise control of particle size and distribution, resulting in toner particles with consistent properties. Additionally, nanoemulsion-based toner production processes are more environmentally friendly compared to traditional methods, as they require fewer chemicals and produce less waste.

Improved Print Speed and Energy Efficiency

Another benefit of nanotechnology in toner production is the improvement in print speed and energy efficiency. With the use of nanoscale materials, toner particles can be designed to have lower melting points, allowing for faster fusing during the printing process.

This means that printers can operate at higher speeds without compromising print quality. Additionally, the lower melting points of nanoscale toner particles require less energy for fusing, resulting in energy savings and reduced carbon emissions.

Enhanced Toner Durability and Longevity

Nanotechnology has also contributed to the enhanced durability and longevity of toner particles. By incorporating nanoscale additives, such as silica or metal oxide nanoparticles, into the toner formulation, manufacturers can improve the resistance of toner particles to abrasion and fading.

This means that printouts produced with nanotechnology-based toner are less prone to smudging, fading, or deterioration over time. This is particularly important for industries that require long-lasting and archival-quality prints, such as photography, graphic design, and document preservation.

Case Study: Nanotechnology in High-Volume Printing

A notable case study showcasing the benefits of nanotechnology in toner production is its application in high-volume printing. In large-scale printing operations, such as commercial printing presses or print-on-demand services, the efficiency and quality of toner play a crucial role.

By using toner particles engineered at the nanoscale, these high-volume printers can achieve faster print speeds, reduced downtime due to toner replacement, and improved print quality. The precise control over toner particle size and shape ensures consistent results, even during prolonged printing runs.

Future Prospects and Challenges

While nanotechnology has already made significant advancements in toner production, the field continues to evolve, presenting new prospects and challenges. Researchers are exploring the use of nanomaterials with unique properties, such as quantum dots, to further enhance print quality and color accuracy.

However, challenges remain in terms of cost-effectiveness and scalability. Nanotechnology-based toner production processes can be more expensive compared to traditional methods, and scaling up production while maintaining quality standards can be a complex task.

Nanotechnology has undoubtedly transformed toner production, leading to advancements in print quality, efficiency, and durability. With the ability to precisely engineer toner particles at the nanoscale, manufacturers can achieve sharper images, vibrant colors, and faster print speeds. As the field continues to evolve, the future holds even more exciting possibilities for nanotechnology in toner production.

Nanoparticle Size and Distribution

Nanotechnology has revolutionized toner production by allowing manufacturers to create toner particles with precise sizes and distributions. In traditional toner production, particles are typically irregularly shaped and vary in size, leading to inconsistencies in print quality. However, with the advent of nanotechnology, toner particles can now be engineered to have uniform shapes and sizes.

The size of toner particles plays a crucial role in print quality. Smaller particles result in sharper images and finer details, while larger particles can lead to grainy prints. Nanotechnology enables the production of toner particles in the nanoscale range, typically between 1 and 100 nanometers. These smaller particles allow for higher resolution prints with enhanced clarity and sharpness.

Furthermore, nanotechnology also enables the precise control of particle size distribution. In traditional toner production, particle size distribution can be quite broad, resulting in inconsistent print quality. However, with nanotechnology, manufacturers can achieve a narrow particle size distribution, ensuring consistent print quality across all prints.

Surface Modification and Charge Control

Another significant advancement in toner production brought about by nanotechnology is the ability to modify the surface properties of toner particles. Surface modification allows for better control of toner charge, which is essential for achieving optimal print quality and efficiency.

In traditional toner production, charge control agents are added to toner particles to ensure they acquire the appropriate electrical charge. However, these agents can sometimes lead to unwanted side effects, such as increased toner consumption or reduced print quality. With nanotechnology, manufacturers can modify the surface of toner particles at the nanoscale, allowing for precise control of charge properties without the need for additional agents.

Nanotechnology enables the creation of toner particles with tailored surface chemistries. By carefully selecting the materials and surface treatments, manufacturers can optimize the charge properties of toner particles. This results in improved print quality, reduced toner consumption, and enhanced overall efficiency.

Improved Fusing and Energy Efficiency

Fusing is a critical step in the printing process where toner particles are melted and bonded to the paper. Nanotechnology has led to advancements in fusing technology, resulting in improved print quality and energy efficiency.

One of the key challenges in fusing is achieving uniform heat distribution across the printed page. In traditional fusing systems, heat is typically applied uniformly to the entire page, which can lead to uneven fusing and potential image distortion. Nanotechnology has enabled the development of fusing systems with precise control over heat distribution. By incorporating nanoscale heating elements or using nanomaterial-based fusing belts, manufacturers can ensure uniform heat distribution, resulting in high-quality prints without any distortion.

Additionally, nanotechnology has also contributed to improved energy efficiency in toner production. By using nanomaterials with high thermal conductivity, fusing systems can transfer heat more efficiently, reducing energy consumption. This not only benefits the environment but also reduces operational costs for printing companies.

Environmental Impact and Sustainability

Nanotechnology in toner production has also addressed environmental concerns associated with traditional toner manufacturing processes. Traditional toner production often involves the use of hazardous chemicals and generates significant waste. Nanotechnology offers more sustainable alternatives.

With the precise control over particle size and distribution, nanotechnology allows for the reduction of toner consumption. Smaller toner particles enable higher print resolution, reducing the amount of toner required for each print. This leads to lower toner consumption, resulting in less waste and reduced environmental impact.

Furthermore, nanotechnology enables the development of toner materials with improved biodegradability. Traditional toner materials can persist in the environment for extended periods, contributing to pollution. Nanomaterial-based toners can be designed to degrade more rapidly, minimizing their environmental footprint.

Overall, nanotechnology in toner production has brought significant advancements in print quality, efficiency, and sustainability. By leveraging nanoscale engineering and surface modification techniques, manufacturers can produce toner particles with precise sizes, controlled charge properties, and improved fusing characteristics. These advancements not only benefit the printing industry but also contribute to a more sustainable and environmentally friendly approach to toner production.

The Origins of Toner Production

The history of toner production can be traced back to the early days of printing, when ink was first used to transfer images onto paper. In the early 19th century, the advent of the printing press revolutionized the way information was disseminated, leading to an increased demand for faster and more efficient printing methods.

Initially, ink was made from natural substances such as plant dyes and carbon black, which were mixed with various solvents to create a liquid ink. However, this liquid ink had several limitations, including a longer drying time and a tendency to smudge. As a result, researchers began to explore alternative methods of printing that would overcome these drawbacks.

The Rise of Dry Toner

In the 1940s, the concept of dry toner was introduced as a solution to the problems associated with liquid ink. Dry toner is a powdered substance that consists of tiny particles, typically made from a combination of plastic resins and pigments. Unlike liquid ink, dry toner does not require a drying time and is less prone to smudging, making it a more efficient and reliable option for printing.

Early dry toners were produced using a mechanical grinding process, which resulted in particles of varying sizes. This inconsistency in particle size led to issues with print quality and image resolution. However, advancements in manufacturing techniques and the of electrostatic toner production in the 1950s addressed these concerns, paving the way for the mass production of high-quality dry toners.

The Emergence of Nanotechnology in Toner Production

In the late 20th century, nanotechnology began to revolutionize various industries, including printing. Nanotechnology involves manipulating materials at the atomic and molecular level, allowing for the creation of new materials with enhanced properties.

In the context of toner production, nanotechnology enabled the development of toner particles with more uniform size and shape, resulting in improved print quality and efficiency. By controlling the particle size and shape at the nanoscale, manufacturers were able to achieve sharper images, finer details, and more consistent color reproduction.

Nanotechnology also brought about advancements in toner composition. Traditional toners were composed of a mixture of plastic resins and pigments. However, with the integration of nanomaterials, toners could now incorporate additional functionalities. For example, nanoparticles of certain metals could be added to toner particles to enhance their magnetic properties, allowing for better image transfer and fixing during the printing process.

Current State of Nanotechnology in Toner Production

Today, nanotechnology plays a critical role in toner production, with manufacturers continually pushing the boundaries of what is possible. The use of nanomaterials in toner formulation has resulted in significant improvements in print quality, efficiency, and environmental sustainability.

One of the key advancements in recent years is the development of polymer-based toners. These toners utilize nanoscale polymers that offer superior performance compared to traditional toners. The smaller size of the polymer particles allows for better toner flow, resulting in more precise and consistent image reproduction. Additionally, polymer-based toners have lower melting points, leading to energy savings during the printing process.

Another area of innovation is the incorporation of nanocarriers in toner particles. Nanocarriers are microscopic capsules that can encapsulate and deliver functional materials, such as colorants or additives, to the printing surface. This technology allows for improved color gamut, increased toner yield, and enhanced durability of printed images.

Furthermore, nanotechnology has also contributed to the development of more sustainable toner production processes. By utilizing nanomaterials, manufacturers can reduce the amount of raw materials required, minimize waste generation, and improve the recyclability of toner cartridges.

The historical evolution of toner production from liquid ink to dry toner and the integration of nanotechnology has significantly transformed the printing industry. Nanotechnology has enabled the production of toners with enhanced print quality, efficiency, and sustainability. As technology continues to advance, we can expect further innovations in toner production, pushing the boundaries of what is possible in the world of printing.

Case Study 1: Improved Print Quality with Nanotechnology

In recent years, nanotechnology has revolutionized the toner production industry, leading to significant advancements in print quality. One notable case study is the collaboration between a leading printer manufacturer and a nanotechnology research institute.

The printer manufacturer was struggling to meet customer demands for high-resolution prints with vibrant colors. Traditional toner particles were limited in their ability to deliver sharp images and accurate color reproduction. Recognizing the potential of nanotechnology, the manufacturer partnered with the research institute to develop a new type of toner.

Through meticulous research and experimentation, the team successfully engineered nanoscale toner particles with enhanced color dispersion properties. These nanoparticles had a uniform size distribution, allowing for precise control over the printing process. The result was a toner that produced prints with exceptional clarity and color accuracy.

Customers who tested the new toner reported a noticeable improvement in print quality. Fine details were rendered with greater precision, and colors appeared more vibrant and true to life. This case study demonstrates how nanotechnology can elevate print quality to new heights, satisfying the demands of even the most discerning customers.

Case Study 2: Increased Efficiency through Nanoparticle Coating

Another compelling case study showcases how nanotechnology has improved the efficiency of toner production. A major toner manufacturer faced challenges in achieving consistent toner performance and reducing waste during the manufacturing process.

By incorporating nanotechnology, the manufacturer developed a novel method of coating toner particles with a thin layer of nanoparticles. This nanoparticle coating acted as a protective barrier, preventing clumping and agglomeration of the toner particles. It also enhanced the flowability of the toner, ensuring smooth operation within printers.

The implementation of nanoparticle coating resulted in several benefits. Firstly, the coated toner particles exhibited improved stability, reducing the likelihood of toner clumping and clogging printer components. This led to a significant decrease in printer downtime and maintenance costs.

Secondly, the nanoparticle coating improved the flowability of the toner, enabling faster and more efficient printing. The smooth flow of toner particles through the printer mechanism resulted in higher printing speeds and increased productivity.

Overall, this case study demonstrates how nanotechnology can optimize toner production processes, leading to improved efficiency, reduced waste, and enhanced printer performance.

Success Story: Sustainable Toner Production with Nanotechnology

Nanotechnology has also played a crucial role in promoting sustainability in toner production. One success story highlights the efforts of a small-scale toner manufacturer to develop eco-friendly toner using nanotechnology.

Traditionally, toner production involved the use of harmful solvents and chemicals, posing environmental risks during manufacturing and disposal. The manufacturer recognized the need for a greener alternative and turned to nanotechnology for a solution.

By employing nanoscale materials, the manufacturer developed a toner formulation that eliminated the need for hazardous solvents. The nanoparticles used in the toner were derived from sustainable sources and had minimal impact on the environment.

Furthermore, the nanoscale toner particles exhibited superior adhesion properties, requiring less toner to achieve the desired print quality. This reduced the overall consumption of toner and minimized waste generation.

The success of this sustainable toner was evident in its market reception. Customers were increasingly drawn to the environmentally friendly aspect of the product, leading to a surge in demand for the manufacturer’s toner.

This success story highlights the positive impact of nanotechnology in toner production, enabling the development of sustainable and eco-friendly products that meet the needs of environmentally conscious consumers.

FAQs on

1. What is nanotechnology and how does it relate to toner production?

Nanotechnology is the science, engineering, and application of materials at the nanoscale level, which is about 1 to 100 nanometers in size. In toner production, nanotechnology is used to manipulate and control the properties of toner particles, resulting in improved print quality and efficiency.

2. How does nanotechnology improve print quality?

Nanotechnology allows for the precise control of toner particle size, shape, and composition. This enables the production of toner particles with uniform characteristics, resulting in sharper and more vibrant prints. Additionally, nanotechnology can enhance the dispersion of toner particles, reducing graininess and improving image resolution.

3. What are the benefits of nanotechnology in toner production?

Some of the key benefits of nanotechnology in toner production include:

- Improved print quality with sharper and more vibrant prints

- Enhanced image resolution and reduced graininess

- Increased efficiency and productivity in printing processes

- Reduced toner consumption and waste

- Compatibility with a wide range of printing technologies and substrates

4. Does nanotechnology in toner production have any environmental benefits?

Yes, nanotechnology in toner production can have environmental benefits. By improving print quality and efficiency, it reduces the need for reprints and minimizes toner waste. Additionally, advancements in nanotechnology have led to the development of toners with lower energy requirements during the printing process, resulting in reduced carbon emissions.

5. Are there any health risks associated with nanotechnology in toner production?

Extensive research has been conducted to assess the health risks of nanotechnology in toner production. Current evidence suggests that when handled and used properly, the risks are minimal. However, it is important for manufacturers and users to follow appropriate safety guidelines to minimize exposure to nanoparticles.

6. Can nanotechnology be used in all types of printers?

Yes, nanotechnology can be applied to various types of printers, including laser printers, inkjet printers, and even 3D printers. The advancements in toner production using nanotechnology have made it compatible with a wide range of printing technologies.

7. Does nanotechnology increase the cost of toner production?

While the initial investment in nanotechnology research and development may increase the cost of toner production, the long-term benefits outweigh the costs. Improved print quality, efficiency, and reduced toner waste can result in cost savings for both manufacturers and end-users.

8. Can nanotechnology improve the speed of printing processes?

Yes, nanotechnology can contribute to faster printing processes. By controlling the properties of toner particles, such as size and shape, it enables better flow and dispersion, leading to improved transfer and fixation speeds. This can result in increased printing productivity and efficiency.

9. Are there any limitations or challenges in using nanotechnology in toner production?

While nanotechnology offers significant advancements in toner production, there are some limitations and challenges to consider. These include the need for specialized equipment and expertise, potential compatibility issues with certain substrates, and the ongoing research required to ensure the safety and environmental impact of nanomaterials.

10. What does the future hold for nanotechnology in toner production?

The future of nanotechnology in toner production looks promising. Continued research and development are expected to lead to further improvements in print quality, efficiency, and environmental sustainability. Additionally, advancements in nanomaterials and printing technologies may open up new possibilities for applications in areas such as flexible electronics and 3D printing.

1. Choose toner cartridges with nanotechnology

When purchasing toner cartridges for your printer, look for ones that specifically mention the use of nanotechnology. These cartridges are designed to provide improved print quality and efficiency, thanks to the incorporation of nanoparticles.

2. Opt for printers compatible with nanotechnology toner

Not all printers are compatible with nanotechnology toner. To fully benefit from the advancements in print quality and efficiency, ensure that your printer is compatible with these specialized cartridges. Check the printer specifications or consult with the manufacturer if you are unsure.

3. Adjust print settings for optimal results

To make the most of nanotechnology toner, adjust your printer’s settings accordingly. Experiment with different print modes, such as “Best” or “High Quality,” to achieve sharper and more vibrant prints. These settings are often optimized for the use of advanced toner technologies.

4. Regularly clean your printer

Keeping your printer clean is crucial for maintaining print quality and efficiency, especially when using nanotechnology toner. Follow the manufacturer’s instructions for cleaning your printer, paying extra attention to areas where toner residue may accumulate. A clean printer ensures consistent and reliable printing results.

5. Store toner cartridges properly

Nanotechnology toner cartridges should be stored in a cool and dry environment to maintain their effectiveness. Avoid exposing them to extreme temperatures or direct sunlight, as this can degrade the toner particles. Additionally, make sure to seal the cartridges tightly to prevent moisture or air from entering.

6. Use high-quality paper

The benefits of nanotechnology toner can be fully realized when printing on high-quality paper. Invest in paper that is specifically designed for laser printers and has a smooth surface. This type of paper allows the toner particles to adhere better, resulting in sharper and more vibrant prints.

7. Avoid unnecessary printing

Reducing unnecessary printing not only helps to conserve resources but also prolongs the lifespan of your toner cartridges. Before hitting the print button, ask yourself if the document truly needs to be printed. Whenever possible, opt for digital formats or use print preview to ensure the document is correctly formatted before printing.

8. Recycle toner cartridges responsibly

Dispose of used toner cartridges responsibly by recycling them. Many manufacturers and office supply stores offer recycling programs for toner cartridges. By recycling, you contribute to reducing electronic waste and promote a more sustainable approach to printing.

9. Stay updated with advancements in nanotechnology

Nanotechnology is a rapidly evolving field, and new advancements are constantly being made. Stay informed about the latest developments in nanotechnology and how they relate to toner production. This knowledge can help you make informed decisions when purchasing toner cartridges and understanding the potential benefits they offer.

10. Share your experiences

If you have successfully implemented nanotechnology toner in your daily printing routine, share your experiences with others. Whether it’s through online reviews, social media, or word of mouth, your insights can help others make informed decisions and benefit from the advancements in print quality and efficiency.

Common Misconceptions About Nanotechnology in Toner Production

Misconception 1: Nanotechnology in toner production is harmful to the environment

One common misconception about nanotechnology in toner production is that it is harmful to the environment. Many people believe that the use of nanoparticles in toner manufacturing can lead to pollution and ecological damage. However, this belief is not entirely accurate.

Nanotechnology in toner production actually offers several environmental benefits. Firstly, the use of nanoparticles allows for more precise control over the composition and properties of toner particles. This means that manufacturers can reduce the amount of toner required to produce high-quality prints, resulting in less waste.

Additionally, nanotechnology enables the development of toner particles with improved durability and resistance to fading. This means that prints produced with nanotechnology-based toners have a longer lifespan, reducing the need for reprinting and ultimately saving resources.

Moreover, the manufacturing processes used in nanotechnology-based toner production are often more energy-efficient compared to traditional methods. This leads to a lower carbon footprint and reduced energy consumption.

It is important to note that, like any manufacturing process, the responsible use of nanotechnology in toner production is crucial. Manufacturers must adhere to strict regulations and guidelines to ensure the safe handling and disposal of nanoparticles. By doing so, the environmental impact of nanotechnology in toner production can be minimized.

Misconception 2: Nanotechnology-based toners are more expensive

Another misconception surrounding nanotechnology in toner production is that it leads to higher costs. Many people assume that the use of advanced technologies and materials in toner manufacturing automatically translates to a more expensive end product. However, this is not necessarily the case.

While it is true that the initial investment in research and development of nanotechnology-based toners may be higher, the long-term cost benefits can outweigh the upfront expenses. As mentioned earlier, nanotechnology allows for the production of toner particles with enhanced durability and print quality. This means that prints produced with nanotechnology-based toners are less likely to fade or smudge, reducing the need for reprints and saving both time and money.

In addition, the improved efficiency of nanotechnology-based toners can lead to cost savings in terms of energy consumption. By requiring less toner to achieve high-quality prints, businesses can reduce their toner usage and subsequently lower their printing costs.

Furthermore, the increased precision in toner particle composition made possible by nanotechnology can result in a more consistent and reliable printing process. This reduces the likelihood of print defects and the associated costs of reprinting and waste.

While the initial price of nanotechnology-based toners may be slightly higher than traditional toners, the long-term cost savings and improved print quality make them a viable and cost-effective option for many businesses.

Misconception 3: Nanotechnology in toner production is only beneficial for high-volume printing

Many people believe that the benefits of nanotechnology in toner production are only applicable to high-volume printing environments, such as commercial printing presses. However, this is a misconception that overlooks the advantages that nanotechnology can bring to all types of printing.

Nanotechnology-based toners offer improved print quality and efficiency, regardless of the volume of printing. The precise control over toner particle composition and properties allows for sharper and more vibrant prints, even at lower print volumes.

In addition, the durability and resistance to fading offered by nanotechnology-based toners are beneficial for any printing application. Whether it is a high-volume commercial print job or a single-page document, prints produced with nanotechnology-based toners will maintain their quality over time.

Furthermore, the energy efficiency of nanotechnology-based toner production can benefit businesses of all sizes. By reducing energy consumption, businesses can lower their environmental impact and operating costs, regardless of their printing volume.

It is important to recognize that nanotechnology in toner production has the potential to improve print quality and efficiency for all users, not just those in high-volume printing environments.

Nanoparticles in Toner: Making Colors Pop

Nanotechnology plays a crucial role in improving the print quality of toner. One of the main advancements in toner production is the use of nanoparticles. These are incredibly tiny particles, much smaller than the width of a human hair. By incorporating nanoparticles into toner, manufacturers are able to achieve more vibrant and accurate colors in printed documents.

Traditional toner particles are larger and tend to scatter light, resulting in a dull and less precise image. Nanoparticles, on the other hand, have unique optical properties that allow them to absorb and emit light in a much more controlled manner. This means that when you print a document using toner with nanoparticles, the colors appear more vivid and true to life.

Furthermore, nanoparticles also enhance the durability of printed documents. Due to their small size, they can penetrate the tiny crevices of paper fibers, creating a stronger bond between the toner and the paper. This makes the printed image less prone to smudging or fading over time.

Nanotechnology and Efficiency: Smaller is Better

Another important aspect of nanotechnology in toner production is its contribution to increased efficiency. One way this is achieved is through the use of smaller toner particles. When toner particles are smaller, they can be distributed more evenly on the paper, resulting in a smoother and more precise image.

Smaller toner particles also require less energy to fuse onto the paper. In traditional printing processes, toner is melted and fused onto the paper using heat. By reducing the size of the toner particles, less heat is required to achieve the same level of fusion. This not only saves energy but also reduces the time it takes for the printed document to be ready.

Furthermore, the use of nanotechnology allows for the development of toner with a narrower particle size distribution. This means that the majority of toner particles have a similar size, resulting in a more consistent print quality. With less variation in particle size, the printer can accurately deposit the toner onto the paper, minimizing wastage and ensuring a higher yield of printed pages.

Nanoparticle Coating: Improving Toner Performance

In addition to incorporating nanoparticles directly into toner particles, nanotechnology is also used to enhance the performance of toner through nanoparticle coatings. These coatings can provide several benefits, including improved adhesion, reduced friction, and anti-static properties.

Adhesion refers to how well the toner sticks to the paper. Nanoparticle coatings can be designed to have strong adhesive properties, ensuring that the toner stays firmly attached to the paper surface. This is particularly important for high-speed printing, where the toner needs to adhere quickly and securely to prevent smudging or smearing.

Friction between the toner and other printer components can cause wear and tear, leading to reduced print quality and printer malfunctions. Nanoparticle coatings can reduce friction, allowing the toner to flow smoothly through the printing process. This not only improves print quality but also extends the lifespan of the printer.

Lastly, static electricity can be a common issue in printing, causing toner particles to clump together or stick to surfaces they shouldn’t. Nanoparticle coatings can provide anti-static properties, preventing the accumulation of static charge and ensuring that the toner behaves as intended during the printing process.

Conclusion

Nanotechnology has revolutionized toner production, leading to significant advancements in print quality and efficiency. Through the use of nanoparticles, toner particles have become smaller and more uniform, resulting in sharper and more vibrant prints. The precise control over particle size and shape has also improved the flow properties of toner, reducing clogging and enhancing the overall printing process.

Furthermore, nanotechnology has enabled the development of new toner materials with enhanced properties, such as increased durability and resistance to fading. This has extended the lifespan of printed documents and reduced the need for reprints, ultimately saving both time and resources. Additionally, the incorporation of nanomaterials in toner production has allowed for the development of environmentally friendly toners, reducing the environmental impact of printing.

Overall, the integration of nanotechnology in toner production has brought about numerous benefits to the printing industry. The advancements in print quality and efficiency have not only improved the end-user experience but also have had positive implications for businesses and the environment. As nanotechnology continues to evolve, we can expect further innovations in toner production, leading to even more remarkable improvements in the future.