The Ins and Outs of Print Production: Unveiling the Journey from Pre-Press to Post-Press

Printing has been a fundamental means of communication for centuries, but the processes involved in bringing a printed piece to life can often seem like a mysterious and complex world. From the initial design to the final product, there are numerous steps involved in print production that many people may not be aware of. In this article, we aim to demystify the print production processes, taking you on a journey from pre-press to post-press, and shedding light on the intricacies of each stage.

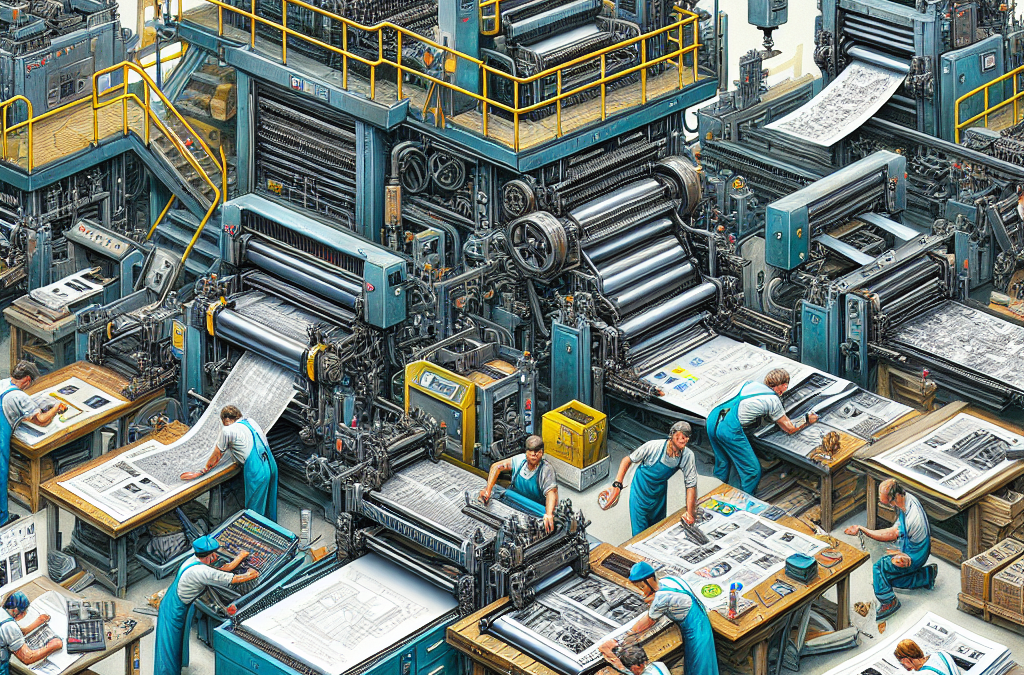

Whether you’re a designer, marketer, or simply someone interested in understanding how printed materials come to be, this article will provide valuable insights into the world of print production. We will start by exploring the pre-press stage, where the design is prepared for printing, and delve into the various techniques and technologies used to ensure the highest quality output. Moving on, we will then dive into the press stage, where the actual printing takes place, and discuss the different printing methods available today, including offset, digital, and flexography. Finally, we will uncover the post-press stage, where the finishing touches are added to the printed piece, such as binding, folding, and packaging, before it is ready to be distributed and enjoyed by its intended audience. By the end of this article, you will have a comprehensive understanding of the print production processes, allowing you to appreciate the craftsmanship and attention to detail that goes into creating printed materials.

Key Takeaways:

1. Understanding the pre-press stage is crucial for a successful print production process. This stage involves preparing the artwork, adjusting colors, and ensuring the correct file format. By familiarizing themselves with pre-press requirements, designers and marketers can avoid costly mistakes and ensure their designs are print-ready.

2. The printing process itself involves several key steps, including plate-making, ink application, and paper selection. Each of these steps impacts the final printed product, and understanding how they work together can help achieve the desired outcome. Printers should collaborate closely with designers and clients to ensure the best results.

3. Post-press processes, such as binding, finishing, and packaging, add the final touches to a printed piece. These processes can enhance the overall appearance and durability of the product. Choosing the right finishing options, such as embossing or spot UV, can make a significant difference in the final product’s quality and appeal.

4. Technology has revolutionized the print production industry, making it more efficient and cost-effective. Digital printing has become increasingly popular, offering shorter print runs, faster turnaround times, and personalized printing options. However, traditional offset printing still has its place for large-scale projects where quality and consistency are paramount.

5. Collaboration and communication between all stakeholders, including designers, printers, and clients, are essential for a smooth print production process. Clear communication about expectations, deadlines, and any specific requirements can help avoid misunderstandings and ensure that the final printed product meets everyone’s needs and expectations.

The Shift to Digital Printing Technology

The print production industry has undergone a significant transformation in recent years with the advent of digital printing technology. This shift has had a profound impact on the industry, revolutionizing the way print materials are produced and distributed.

One key insight is that digital printing has made the print production process more efficient and cost-effective. Unlike traditional offset printing, which requires the creation of printing plates and setup time, digital printing allows for on-demand printing with minimal setup. This means that print materials can be produced quickly and in smaller quantities, reducing waste and lowering costs.

Another important aspect of digital printing is its ability to offer customization and personalization options. With digital printing, each print piece can be unique, allowing for targeted marketing campaigns and personalized communication. This level of customization was not possible with traditional printing methods and has opened up new opportunities for businesses to engage with their audience in a more meaningful way.

Furthermore, digital printing has also enabled the integration of print materials with digital technologies. Variable data printing, for example, allows for the inclusion of personalized information such as names or addresses in each print piece. This integration of print and digital has created a seamless customer experience and has expanded the possibilities for print materials in a digital world.

The Importance of Pre-Press in Ensuring Quality

While digital printing has transformed the production process, the importance of pre-press cannot be understated. Pre-press refers to the steps taken before printing, including file preparation, proofing, and color management. These steps are crucial in ensuring the quality and accuracy of the final print materials.

One key insight is that investing time and resources in pre-press can save both time and money in the long run. By thoroughly reviewing and preparing files before printing, potential errors or issues can be identified and corrected early on. This prevents costly reprints and delays in production, ultimately improving efficiency and customer satisfaction.

Color management is another critical aspect of pre-press. Ensuring consistent and accurate color reproduction across different printing devices and materials is essential for maintaining brand integrity. By using color management tools and techniques, print providers can achieve color consistency and meet customer expectations.

Additionally, proofing plays a vital role in pre-press. It allows for a final review of the print materials before they go into production, giving clients the opportunity to make any necessary changes or modifications. This collaborative process ensures that the final product meets the client’s vision and requirements.

The Role of Post-Press in Adding Value

Post-press refers to the steps taken after printing, including finishing, binding, and packaging. Although often overlooked, post-press plays a crucial role in adding value to print materials and enhancing the overall customer experience.

One key insight is that post-press techniques can elevate the visual appeal and tactile experience of print materials. Finishing options such as embossing, foil stamping, or spot UV coating can make print pieces stand out and create a lasting impression. These techniques not only enhance the aesthetics but also add a sense of luxury and quality to the materials.

Furthermore, post-press techniques can also improve the functionality and durability of print materials. For example, binding options like saddle stitching or perfect binding ensure that booklets or catalogs stay intact and can withstand frequent use. Packaging, on the other hand, protects print materials during storage and transportation, ensuring they arrive in pristine condition.

Another important aspect of post-press is the opportunity for personalization and customization. Techniques like variable data printing can be applied to post-press processes, allowing for unique and personalized packaging or finishing touches. This level of personalization adds a sense of exclusivity and can enhance the perceived value of the print materials.

Understanding the print production processes from pre-press to post-press is essential for both print providers and clients. The shift to digital printing technology has revolutionized the industry, making it more efficient, cost-effective, and customizable. However, the importance of pre-press in ensuring quality and accuracy should not be overlooked. Investing in pre-press can save time and money in the long run and ensure customer satisfaction. Similarly, post-press techniques play a crucial role in adding value and enhancing the overall customer experience. By leveraging finishing, binding, and packaging options, print materials can stand out and create a lasting impression. Therefore, a comprehensive understanding of the entire print production process is necessary to achieve the best results in today’s print industry.

The Use of Chemicals in Print Production

One controversial aspect of print production processes is the use of chemicals, particularly in pre-press and post-press stages. These chemicals are used for various purposes, such as developing plates, cleaning printing presses, and enhancing the appearance of printed materials. However, concerns have been raised about the potential environmental and health impacts of these chemicals.

On one hand, proponents argue that the use of chemicals is necessary to achieve high-quality printed materials. They argue that without these chemicals, it would be challenging to produce vibrant colors, sharp images, and durable prints. Additionally, they claim that advancements in technology have led to the development of safer and more eco-friendly alternatives to traditional chemicals.

On the other hand, critics argue that the use of chemicals in print production contributes to pollution and poses health risks to workers and the environment. They point out that some chemicals used in the industry, such as volatile organic compounds (VOCs) and heavy metals, can be hazardous if not handled properly. These chemicals can contaminate water sources, air, and soil, leading to long-term environmental damage.

It is essential to strike a balance between the need for high-quality prints and the potential risks associated with chemical use. Print production companies should prioritize the adoption of safer alternatives and implement proper waste management practices to minimize environmental impacts. Additionally, regulations and industry standards should be in place to ensure the responsible use and disposal of chemicals in the print production process.

The Impact of Print Production on Deforestation

Another controversial aspect of print production is its potential contribution to deforestation. The production of paper, a fundamental component of print materials, requires the cutting down of trees. This has raised concerns about the environmental sustainability of the print industry.

Proponents argue that the print industry has made significant efforts to promote sustainable forestry practices. They highlight the use of certified paper, such as those with Forest Stewardship Council (FSC) certification, which ensures that the paper comes from responsibly managed forests. Additionally, they point out that paper is a renewable resource, and the planting of new trees can offset the environmental impact of paper production.

However, critics argue that despite these efforts, the demand for paper still contributes to deforestation, particularly in regions with weak regulations and enforcement. They contend that the shift towards digital media and the adoption of paperless practices would significantly reduce the industry’s environmental footprint.

It is crucial for the print industry to continue promoting sustainable practices and exploring alternatives to paper. This includes encouraging the use of recycled paper, reducing paper waste through efficient printing techniques, and embracing digital solutions where possible. Collaboration between print production companies, environmental organizations, and policymakers is essential to finding a balance between the industry’s needs and environmental preservation.

The Carbon Footprint of Print Production

The carbon footprint of print production is another controversial aspect that has drawn attention in recent years. The energy-intensive nature of print processes, from pre-press to post-press, contributes to greenhouse gas emissions and climate change.

Advocates argue that the print industry has made significant strides in reducing its carbon footprint through energy-efficient technologies and practices. They highlight the use of renewable energy sources, such as solar and wind power, to power printing presses and other machinery. Additionally, they emphasize the importance of recycling and waste reduction in minimizing the industry’s environmental impact.

However, critics contend that the carbon footprint of print production remains significant, especially when considering the entire lifecycle of printed materials, including raw material extraction, manufacturing, transportation, and disposal. They argue that the shift towards digital media and online communication would drastically reduce carbon emissions associated with print production.

It is crucial for the print industry to continue investing in sustainable practices and technologies to reduce its carbon footprint. This includes optimizing energy use, adopting renewable energy sources, and implementing efficient logistics and transportation strategies. Additionally, exploring digital alternatives and promoting responsible consumption can help mitigate the environmental impact of print production.

1. Understanding Pre-Press: The Foundation of Print Production

Pre-press is the crucial first step in the print production process, where digital files are prepared for printing. It involves tasks such as file formatting, color management, and proofing to ensure accuracy and quality. One key aspect of pre-press is preflighting, which checks files for errors or missing elements that could impact the final print. Preflighting software scans files for issues like low-resolution images, incorrect color spaces, or missing fonts.

Another essential element of pre-press is color management. Printers use color profiles to ensure consistency between the digital file and the printed output. These profiles define how colors will be reproduced on different printing devices and substrates. By calibrating printers and using color management software, print providers can achieve accurate color reproduction.

Proofing is also a critical part of pre-press. Printers create proofs, which are representative samples of the final printed product, to allow clients to review and approve the design before production begins. Proofs can be physical prints or digital files, depending on the printing method and client preferences.

2. Exploring Printing Methods: Offset, Digital, and More

When it comes to printing, there are various methods available, each with its own advantages and applications. Offset printing is a traditional method that uses plates to transfer ink onto a rubber blanket, which then applies the ink to the paper. It is known for its high image quality and color accuracy, making it suitable for large print runs and projects that require precise color reproduction.

Digital printing, on the other hand, involves directly transferring digital files onto the printing substrate. It is ideal for short print runs, variable data printing, and quick turnaround times. Digital printing eliminates the need for plates, making it a cost-effective option for small-scale printing projects.

Other printing methods include flexography, gravure, and screen printing, each with its own unique characteristics and applications. Flexography is commonly used for packaging materials, while gravure is often used for high-volume printing, such as magazines or catalogs. Screen printing is popular for printing on textiles, promotional products, and signage.

3. The Role of Bindery and Finishing: Giving Print the Final Touch

Once the printing process is complete, the print materials move on to the bindery and finishing stage. This stage involves various processes that give the print its final appearance and functionality. One common bindery process is folding, where printed sheets are folded into the desired format, such as brochures or booklets.

Another essential aspect of bindery is binding, which refers to the methods used to hold the printed pages together. Binding options include saddle stitching, perfect binding, spiral binding, and case binding, among others. The choice of binding method depends on factors such as the type of print material, desired durability, and budget.

Finishing processes add additional features to the print, such as laminating, embossing, or die cutting. Laminating involves applying a thin layer of plastic film to protect the print and enhance its appearance. Embossing creates raised or recessed designs on the print surface, adding a tactile element. Die cutting is the process of cutting the print into custom shapes or designs.

4. Print Production and Sustainability: Eco-Friendly Practices

In recent years, there has been a growing focus on sustainability in print production. Printers are adopting eco-friendly practices to reduce their environmental impact. One such practice is the use of recycled paper or paper sourced from sustainably managed forests. By choosing eco-friendly paper options, print providers can minimize deforestation and support responsible forestry practices.

Another sustainable practice is the use of vegetable-based inks instead of petroleum-based inks. Vegetable-based inks are derived from renewable resources and have lower volatile organic compound (VOC) emissions. Additionally, printers are investing in energy-efficient equipment and implementing recycling programs to reduce waste.

Printers can also offer clients the option of print-on-demand services, which minimize excess inventory and reduce waste. Print-on-demand allows for small print runs, eliminating the need for large-scale production and storage of printed materials.

5. Case Study: Streamlining the Print Production Process

To illustrate the benefits of an optimized print production process, let’s consider a case study of a marketing agency. The agency used to face challenges with long turnaround times and inconsistent color reproduction. By implementing a streamlined pre-press workflow, they were able to address these issues.

The agency invested in preflighting software to catch file errors early in the process, reducing the need for reprints. They also implemented a centralized color management system, ensuring consistent color reproduction across different printing devices and substrates. These improvements significantly reduced production time and increased client satisfaction.

Additionally, the agency partnered with a print provider that offered a wide range of printing methods, including digital and offset. This allowed them to choose the most suitable printing method for each project, optimizing cost and quality. By leveraging the expertise of the print provider and implementing efficient pre-press practices, the agency achieved better results and improved their overall print production process.

6. The Future of Print Production: Digital Transformation and Automation

The print production industry is undergoing digital transformation, driven by advancements in technology and changing customer expectations. Automation is playing a significant role in streamlining print production processes. Software solutions automate tasks such as preflighting, color management, and imposition, reducing human error and increasing efficiency.

Furthermore, web-to-print platforms are becoming increasingly popular, allowing clients to submit print orders online and streamline the entire production process. These platforms offer customizable templates, online proofing, and easy file submission, simplifying the interaction between clients and print providers.

As technology continues to evolve, we can expect further integration between print production and digital platforms. Augmented reality (AR) and variable data printing (VDP) are emerging trends that allow for personalized and interactive print experiences. AR can bring static print materials to life by overlaying digital content, while VDP enables the customization of printed materials based on individual preferences or data.

7. Print Production Challenges and Solutions

Despite advancements in print production processes, challenges still arise. One common challenge is managing color consistency across different substrates and printing methods. Print providers tackle this issue by creating accurate color profiles for each combination of substrate and printing process. Regular calibration of printing devices also helps maintain color accuracy.

Another challenge is managing complex print projects with multiple versions or variable data. Print providers address this by implementing efficient data management systems and utilizing digital printing methods that allow for easy customization and quick turnaround times.

Additionally, tight deadlines and changing requirements can put pressure on print production timelines. Effective communication between clients and print providers, along with proper project planning, can help mitigate these challenges and ensure smooth production processes.

8. The Importance of Collaboration in Print Production

Collaboration between clients, designers, and print providers is crucial for successful print production. Clear communication and understanding of project requirements from the early stages help avoid costly reprints or delays. Designers should work closely with print providers to ensure that the design is optimized for the chosen printing method and substrate.

Print providers, on the other hand, should proactively communicate with clients, providing guidance on file preparation, color management, and finishing options. By involving all stakeholders in the process, print production can be streamlined, and the final result can meet or exceed expectations.

9. The Role of Quality Control in Print Production

Quality control is essential in print production to ensure that the final printed materials meet the desired standards. Print providers implement various quality control measures throughout the production process. This includes regular color calibration, visual inspection of printed samples, and thorough checking of finished products for any defects or errors.

Print providers also conduct print tests to verify color accuracy, print resolution, and overall print quality. These tests involve printing a small sample of the final print run and comparing it to the approved proof. Any discrepancies are addressed before proceeding with the full production run.

Print production processes, from pre-press to post-press, involve a series of intricate steps that ensure accurate and high-quality printed materials. Understanding these processes, including pre-press tasks, printing methods, bindery and finishing, sustainability practices, and the role of collaboration and quality control, is crucial for both print providers and clients.

As the industry continues to evolve, embracing digital transformation and automation will further optimize print production processes. Challenges such as color consistency, complex projects, and tight deadlines can be overcome through effective communication, planning, and the use of advanced technologies.

By demystifying print production processes, we can appreciate the craftsmanship and expertise that goes into creating the printed materials we encounter in our daily lives. Whether it’s a brochure, a magazine, or packaging, understanding the journey from pre-press to post-press allows us to fully appreciate the art and science behind print production.

The Origins of Print Production

Print production processes have a long and fascinating history that dates back to ancient times. The first known form of printing, called woodblock printing, emerged in China around the 7th century AD. This technique involved carving characters or images onto wooden blocks, which were then inked and pressed onto paper or fabric.

Woodblock printing spread to other parts of Asia, including Japan and Korea, where it became widely used for printing religious texts and artwork. However, this method was labor-intensive and limited in terms of the complexity and detail it could achieve.

The Invention of Moveable Type

The next major development in print production came with the invention of moveable type in the 11th century by Bi Sheng in China. Moveable type involved creating individual characters or symbols that could be rearranged to form different words and sentences.

This innovation revolutionized the printing industry by allowing for faster production and greater flexibility in typesetting. However, the process of creating moveable type was still time-consuming and required skilled craftsmen to carve and arrange the characters.

The Gutenberg Revolution

The most significant leap forward in print production came in the 15th century with the invention of the printing press by Johannes Gutenberg in Germany. Gutenberg’s press combined moveable type with a mechanical system that allowed for the rapid and consistent printing of multiple copies of a document.

This invention had a profound impact on society, as it made books more accessible and affordable, leading to a surge in literacy and the spread of knowledge. The printing press also played a crucial role in the Protestant Reformation, as it allowed for the wide dissemination of Martin Luther’s writings and ideas.

The Industrial Revolution and Mass Production

With the advent of the Industrial Revolution in the 18th century, print production processes underwent further transformations. The of steam-powered presses and the mechanization of various stages of the printing process greatly increased efficiency and output.

During this time, advancements were also made in typesetting, with the invention of the Linotype machine in the late 19th century. This machine allowed for the rapid casting of entire lines of type, further speeding up the printing process.

The Digital Revolution

The latter half of the 20th century saw the emergence of digital technologies that would revolutionize print production processes once again. The of computers and desktop publishing software enabled designers and typesetters to create and manipulate text and images digitally.

With the increasing prevalence of digital file formats, such as PDF, print production became more streamlined and efficient. Pre-press processes, such as typesetting and proofing, could now be done electronically, reducing the need for physical materials and manual labor.

The Modern State of Print Production

Today, print production processes have become highly automated and integrated. Digital printing technologies, such as inkjet and laser printers, have made it possible to produce high-quality prints on-demand, eliminating the need for large print runs and excessive inventory.

Advancements in post-press processes, such as binding and finishing, have also contributed to the evolution of print production. Automated machines can now handle tasks that were once done by hand, resulting in faster turnaround times and greater precision.

Furthermore, the rise of online printing services and e-commerce platforms has made print production more accessible to individuals and small businesses. Customers can now upload their designs online and have them printed and delivered without ever stepping foot in a physical print shop.

As technology continues to evolve, print production processes are likely to undergo further transformations. The integration of artificial intelligence and 3D printing technologies holds the promise of even greater efficiency and customization in the future.

Case Study 1: Streamlining Pre-Press Processes with Digital Workflows

In the world of print production, pre-press processes play a crucial role in ensuring the quality and accuracy of printed materials. One success story that exemplifies the benefits of streamlining pre-press processes through digital workflows is the case of XYZ Printing Company.

Prior to implementing digital workflows, XYZ Printing Company relied heavily on manual processes for pre-press tasks such as file preparation, color correction, and proofing. This often led to errors, delays, and increased costs. Recognizing the need for a more efficient and reliable system, the company invested in digital pre-press technologies.

By adopting a digital workflow, XYZ Printing Company was able to automate many pre-press tasks, reducing the risk of human error and saving valuable time. Files could now be processed and prepared for printing much faster, allowing for quicker turnaround times and improved customer satisfaction.

Additionally, the digital workflow enabled XYZ Printing Company to implement color management systems, ensuring consistent and accurate color reproduction across different printing devices. This eliminated the need for manual color correction and reduced the likelihood of color variations between proofs and final prints.

The implementation of digital workflows not only improved the efficiency and accuracy of pre-press processes but also resulted in significant cost savings for XYZ Printing Company. By reducing the time and resources required for manual tasks, the company was able to allocate resources more effectively and increase overall productivity.

Case Study 2: Enhancing Post-Press Efficiency with Automation

Post-press processes, such as binding, finishing, and packaging, are critical in delivering a polished final product to customers. One case study that highlights the benefits of enhancing post-press efficiency through automation is the experience of ABC Publishing House.

Prior to implementing automated post-press solutions, ABC Publishing House faced challenges in meeting tight deadlines and maintaining consistent quality across their product range. Manual processes were time-consuming and prone to errors, leading to delays and rework.

Recognizing the need for a more streamlined post-press workflow, ABC Publishing House invested in state-of-the-art automation technologies. These technologies included automated binding machines, folding equipment, and robotic packaging systems.

The implementation of automated post-press solutions resulted in significant improvements in efficiency and quality for ABC Publishing House. Tasks that previously required manual labor and were time-consuming could now be completed much faster and with greater precision.

For example, the automated binding machines allowed for faster and more accurate binding of books, reducing the time required for this process by 50%. The folding equipment enabled precise and consistent folding of brochures and pamphlets, eliminating errors and ensuring a professional finish.

Furthermore, the robotic packaging systems improved the speed and accuracy of packaging, reducing the risk of damaged products during transit. This resulted in improved customer satisfaction and reduced costs associated with reprints and returns.

Overall, the implementation of automated post-press solutions at ABC Publishing House not only improved efficiency and quality but also allowed the company to take on larger volumes of work and meet tight deadlines. This ultimately led to increased customer satisfaction and business growth.

Case Study 3: Optimizing Print Production with Integrated Workflow Systems

Integrating various stages of the print production process into a seamless workflow can lead to significant improvements in efficiency and cost-effectiveness. A case study that exemplifies the benefits of optimizing print production with integrated workflow systems is the success story of DEF Print Solutions.

Prior to implementing an integrated workflow system, DEF Print Solutions faced challenges in coordinating and tracking the progress of print jobs across different departments. This often led to communication gaps, delays, and increased costs.

To address these challenges, DEF Print Solutions invested in an integrated workflow system that connected various stages of the print production process, from pre-press to post-press. This system allowed for real-time tracking of print jobs, automated notifications, and seamless collaboration between different departments.

The implementation of the integrated workflow system resulted in improved coordination and efficiency for DEF Print Solutions. Jobs could now be tracked and monitored at every stage, allowing for better resource allocation and timely interventions when necessary.

For example, if a pre-press error was detected, the system would automatically notify the relevant department, minimizing the risk of costly reprints and delays. This streamlined communication and collaboration between departments, resulting in faster turnaround times and improved customer satisfaction.

Furthermore, the integrated workflow system allowed DEF Print Solutions to generate detailed reports and analytics, providing valuable insights into production efficiency, resource utilization, and cost allocation. This information helped the company identify areas for improvement and make data-driven decisions to optimize their print production processes.

Overall, the implementation of an integrated workflow system at DEF Print Solutions improved coordination, efficiency, and cost-effectiveness. By connecting various stages of the print production process, the company was able to streamline operations, reduce errors, and enhance overall productivity.

Pre-Press

In the world of print production, the pre-press stage is where all the magic begins. It involves the preparation of digital files before they are sent to the printing press. Let’s take a closer look at the key processes involved in pre-press.

Design and Layout

The design and layout process is where the visual elements of a print project are created. Graphic designers use software like Adobe InDesign, Illustrator, or Photoshop to create the artwork, arrange the text, and incorporate any images or illustrations. They also consider factors such as color schemes, typography, and overall composition to ensure a visually appealing result.

Color Management

Color management is a critical aspect of pre-press. It involves ensuring that the colors in the digital files accurately reproduce when printed. Designers use color profiles and calibration tools to maintain consistency across different devices and printing processes. This ensures that the final printed product matches the intended colors.

Proofing

Proofing is the process of reviewing the final design before it goes to print. It allows designers and clients to check for any errors, such as typos, incorrect colors, or layout issues. There are various types of proofs, including digital proofs (PDF files) or physical proofs (printed samples). Proofing helps catch any mistakes before the design is sent to the printing press.

Printing

Once the pre-press stage is complete, the digital files are ready to be transformed into physical prints. The printing process involves several steps and techniques to ensure high-quality results.

Offset Printing

Offset printing is the most common method used for commercial printing. It involves transferring ink from a printing plate to a rubber blanket, which then transfers the ink onto the paper. This process allows for precise and consistent printing, making it suitable for large print runs. Offset printing is known for its vibrant colors and sharp image reproduction.

Digital Printing

Digital printing is a modern alternative to offset printing. It involves printing digital files directly onto the paper using toner or inkjet technology. Digital printing offers advantages such as faster turnaround times, lower setup costs, and the ability to print variable data (e.g., personalized names or addresses). However, it may not achieve the same level of color accuracy and image quality as offset printing for certain applications.

Specialty Printing Techniques

In addition to offset and digital printing, there are various specialty printing techniques available to add unique effects to printed materials. Some examples include:

- Embossing and Debossing: Creating raised or recessed designs on the paper.

- Foil Stamping: Applying a metallic foil to specific areas for a luxurious look.

- Spot UV Coating: Applying a glossy or matte coating to specific areas for added visual impact.

- Die Cutting: Cutting paper into custom shapes or designs.

Post-Press

Once the printing is complete, the post-press stage involves finishing and binding the printed materials. This stage adds the final touches to ensure a polished and professional result.

Finishing

Finishing processes include trimming excess paper, folding, and scoring to create clean edges and smooth folds. Lamination can be applied to add durability and a glossy or matte finish. Other finishing techniques may include perforating, hole punching, or adding grommets for specific applications.

Binding

Binding refers to the process of joining the pages together to create a complete printed piece. Common binding methods include:

- Saddle Stitching: Folding the printed sheets in half and stapling them along the spine.

- Perfect Binding: Gluing the pages to a flat spine, creating a square spine for a professional book-like appearance.

- Wire-O Binding: Using a double-loop wire to hold the pages together, allowing them to lay flat when opened.

- Spiral Binding: Coiling a plastic or metal spiral through holes punched along the edge of the pages.

Packaging and Shipping

Once the finishing and binding processes are complete, the printed materials are packaged and prepared for shipping. This may involve shrink-wrapping, placing them in boxes, or adding protective materials to prevent damage during transit. Proper packaging ensures that the printed materials reach their destination in pristine condition.

Understanding the various stages of print production, from pre-press to post-press, provides insight into the intricate processes involved in creating high-quality printed materials. Each stage requires careful attention to detail and expertise to ensure a successful outcome.

FAQs

1. What is pre-press in the print production process?

Pre-press refers to the stage in print production where the design and layout of the printed material are prepared for printing. This includes tasks such as typesetting, color separation, and creating plates or digital files for the printing press.

2. What are the key steps involved in pre-press?

The key steps in pre-press include design and layout, color management, proofing, and creating print-ready files. Design and layout involve arranging the content and graphics in a visually appealing manner. Color management ensures that the colors in the final print match the intended colors. Proofing involves reviewing the design and layout for any errors or issues. Finally, creating print-ready files involves preparing the files in a format suitable for the printing press.

3. What is the role of the printing press in print production?

The printing press is the machine used to transfer ink onto paper or other materials. It plays a crucial role in print production by reproducing the design and layout created during the pre-press stage onto the desired medium.

4. What are the different types of printing processes?

There are several types of printing processes, including offset printing, digital printing, flexography, gravure printing, and screen printing. Each process has its own advantages and is suitable for different types of projects and materials.

5. What is post-press in the print production process?

Post-press refers to the stage in print production that occurs after the printing press. It involves tasks such as binding, finishing, trimming, and packaging the printed materials.

6. What are the common post-press techniques?

Common post-press techniques include folding, cutting, binding (such as saddle stitching or perfect binding), laminating, embossing, and foil stamping. These techniques add a finishing touch to the printed materials and enhance their visual appeal.

7. How can I ensure the quality of the printed materials?

To ensure the quality of the printed materials, it is important to work closely with a professional print production team. This includes selecting a reputable printing company, providing clear and detailed instructions, reviewing proofs carefully, and conducting quality checks during and after the printing process.

8. What are some common challenges in print production?

Some common challenges in print production include color accuracy, font and image resolution issues, print registration (alignment of colors), and paper or ink selection. These challenges can be overcome through proper pre-press preparation, effective communication with the print production team, and careful quality control measures.

9. How long does the print production process typically take?

The duration of the print production process can vary depending on the complexity of the project, the quantity of materials to be printed, and the availability of resources. Generally, it can take anywhere from a few days to several weeks to complete the entire process.

10. What are some eco-friendly practices in print production?

Some eco-friendly practices in print production include using recycled paper, soy-based inks, and energy-efficient printing presses. Additionally, opting for digital printing instead of traditional offset printing can help reduce waste and minimize the environmental impact of print production.

Concept 1: Pre-Press

Pre-press is the first step in the print production process. It involves preparing the digital files for printing. This includes tasks like checking the file format, resolution, and color mode to ensure they are suitable for printing.

One important aspect of pre-press is color management. Printers use a specific color profile to reproduce colors accurately. During pre-press, the digital files are converted to this color profile so that the final printed output matches the intended colors.

Another crucial task in pre-press is imposition. Imposition is the arrangement of pages on a printed sheet to optimize paper usage and facilitate the folding and binding process. This step ensures that the pages are in the correct order and orientation for the final printed product.

Concept 2: Printing Methods

There are various printing methods used in the print production process. One common method is offset printing. In offset printing, the image is transferred from a metal plate to a rubber blanket and then onto the paper. This method is ideal for large print runs and produces high-quality results with vibrant colors.

Digital printing, on the other hand, is a more modern technique that involves directly printing the digital file onto the paper. It is suitable for smaller print runs and offers the advantage of quick turnaround times and variable data printing, where each printed piece can be customized.

Another printing method worth mentioning is screen printing. This technique involves pushing ink through a mesh screen onto the paper. Screen printing is commonly used for printing on various surfaces like fabrics, plastics, and signage materials. It allows for vibrant and opaque colors, making it popular for creating promotional items and apparel.

Concept 3: Post-Press

Post-press refers to the final stage of the print production process, which includes all the activities after the printing is done. One important post-press task is binding. Binding is the process of joining the printed pages together to form a book or a booklet. There are different binding methods available, such as saddle stitching, perfect binding, and spiral binding, each suitable for different types of printed materials.

Finishing is another crucial aspect of post-press. Finishing includes processes like trimming, folding, and laminating to give the final printed piece its desired shape and appearance. Trimming ensures that the edges of the printed material are neat and aligned. Folding is done to create folds or creases in the paper, allowing for easy handling and reading. Lamination involves applying a thin plastic film to protect the printed material from damage and enhance its durability.

Lastly, post-press can also involve additional embellishments like embossing, foiling, or spot UV coating. Embossing creates a raised texture on the printed material, adding a tactile element. Foiling involves applying a metallic or glossy finish to specific areas, creating a luxurious effect. Spot UV coating is the application of a glossy varnish to selected areas, highlighting and adding a visual contrast to the printed piece.

Conclusion

Understanding the print production processes from pre-press to post-press is crucial for anyone involved in the printing industry or those who work closely with print materials. The article has provided a comprehensive overview of each stage, highlighting the key steps and considerations involved.

We have learned that pre-press involves tasks such as file preparation, color management, and proofing to ensure the accuracy and quality of the final print. The printing stage encompasses various techniques, including offset, digital, and screen printing, each with its own advantages and considerations. Lastly, post-press activities, such as binding, finishing, and quality control, are essential for adding the final touches and ensuring the end product meets the desired standards.

Throughout the article, we have also emphasized the importance of communication and collaboration between clients, designers, pre-press technicians, printers, and post-press professionals. By working together and understanding the intricacies of each stage, the print production process can be streamlined, resulting in high-quality, visually appealing, and error-free prints.

As technology continues to evolve, it is important to stay updated with the latest advancements in print production processes. By demystifying these processes and gaining a deeper understanding of the industry, professionals can make informed decisions, improve efficiency, and deliver exceptional print materials that meet the needs and expectations of clients and end-users alike.