Revolutionizing Printing Technology: Unleashing the Power of Graphene for Unmatched Copier Drum Performance

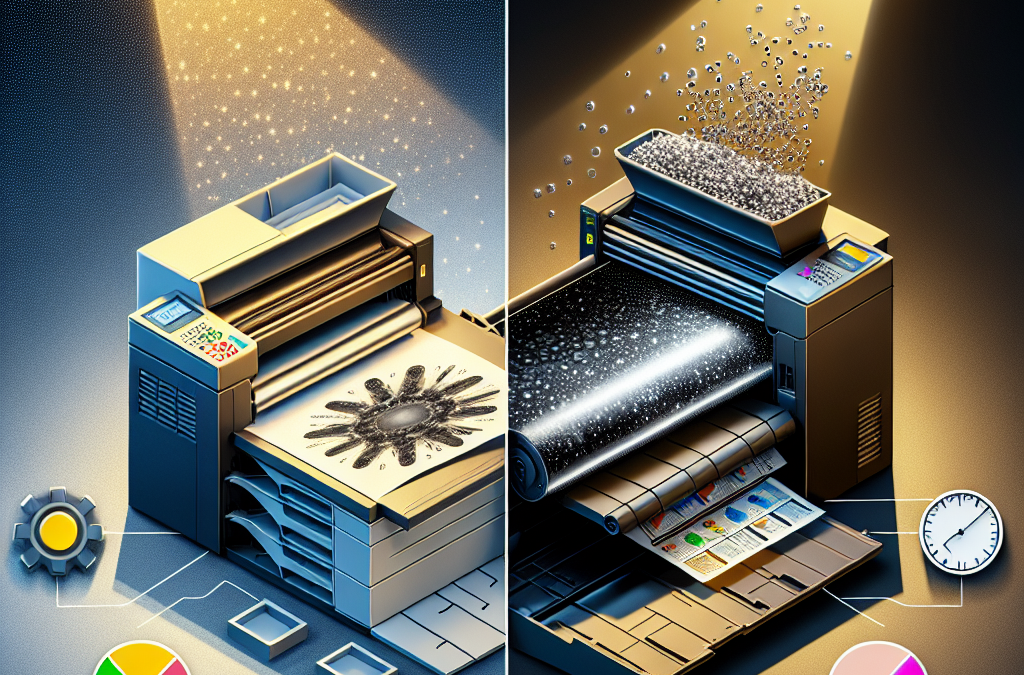

Imagine a world where copier drums never wear out, and print quality remains consistently sharp and vibrant. This may sound like a dream, but thanks to the incredible properties of graphene, it could soon become a reality. Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, has been hailed as a wonder material for its exceptional strength, conductivity, and flexibility. In recent years, scientists and engineers have been exploring its potential applications in various industries, and one area where it shows great promise is in the development of copier drums.

In this article, we will delve into the benefits of graphene-based copier drums and how they can revolutionize the printing industry. We will explore how the exceptional durability and conductivity of graphene can extend the lifespan of copier drums, reducing the need for frequent replacements and saving businesses significant costs. Additionally, we will examine how the unique properties of graphene can enhance print quality, resulting in crisper images, sharper text, and more vibrant colors. Join us as we uncover the potential of graphene-based copier drums and the exciting possibilities they offer for improved durability and print quality.

Key Takeaways:

1. Graphene-based copier drums offer enhanced durability, making them a promising solution for long-lasting printing equipment.

2. The use of graphene in copier drums results in improved print quality, with sharper and more vibrant images.

3. Graphene’s high thermal conductivity allows for faster printing speeds, increasing productivity in office environments.

4. The superior electrical conductivity of graphene reduces static buildup, minimizing paper jams and maintenance requirements.

5. Graphene-based copier drums have the potential to reduce overall printing costs by extending the lifespan of the equipment and reducing the need for frequent repairs and replacements.

Enhanced Durability and Longevity

One of the most significant emerging trends in the copier industry is the use of graphene-based drums to improve durability and longevity. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is known for its exceptional strength and flexibility. When incorporated into copier drums, graphene enhances their resistance to wear and tear, ensuring they can withstand the demands of high-volume printing for extended periods.

Traditional copier drums are typically made from organic photoreceptors, which are prone to degradation over time due to repeated exposure to light and mechanical stress. This degradation leads to reduced print quality and the need for frequent drum replacements, resulting in increased costs for businesses. However, with the of graphene-based copier drums, these issues can be mitigated.

The exceptional strength of graphene allows copier drums to withstand the constant friction and pressure exerted during the printing process. This means that businesses can benefit from longer-lasting drums, reducing the frequency of replacements and minimizing downtime. Additionally, the enhanced durability of graphene-based drums results in improved print quality, as the surface remains smooth and free from scratches or imperfections.

High-Quality Prints with Enhanced Resolution

Another emerging trend in the copier industry is the use of graphene-based drums to achieve high-quality prints with enhanced resolution. Graphene’s unique properties make it an ideal material for achieving precise and detailed prints, surpassing the capabilities of traditional copier drums.

Graphene-based copier drums offer superior conductivity compared to their organic counterparts. This increased conductivity allows for more efficient charging and discharging of the drum surface, resulting in better control of the electrostatic forces involved in the printing process. As a result, prints produced using graphene-based drums exhibit sharper edges, finer details, and improved color reproduction.

Furthermore, the exceptional thermal conductivity of graphene ensures uniform heat distribution across the drum surface, preventing localized hotspots that can affect print quality. This thermal stability allows for consistent toner adhesion and transfer, resulting in prints with vibrant colors and precise image reproduction.

Potential Future Implications

The emergence of graphene-based copier drums holds significant potential for the future of the printing industry. As research and development in graphene technology continue to advance, we can expect to see even more remarkable implications in the years to come.

One potential future implication is the development of graphene-based copiers that are not only durable and capable of producing high-quality prints but also more energy-efficient. Graphene’s excellent electrical conductivity allows for reduced power consumption during the printing process, leading to cost savings and a smaller environmental footprint.

Furthermore, the versatility of graphene opens up possibilities for the integration of additional functionalities into copier drums. For instance, researchers are exploring the use of graphene-based sensors within copier drums to monitor environmental conditions such as temperature and humidity. This real-time monitoring could enable automatic adjustments to optimize print quality and prevent issues caused by unfavorable printing conditions.

Additionally, the exceptional mechanical properties of graphene could pave the way for the development of flexible copier drums. This flexibility would allow for the creation of portable and compact copiers, revolutionizing the way printing is done in various settings, including remote locations or on-the-go scenarios.

The emerging trend of graphene-based copier drums brings forth enhanced durability, improved print quality, and potential future implications that could revolutionize the printing industry. As businesses strive for more efficient and cost-effective printing solutions, graphene-based copier drums offer a promising avenue for achieving these goals.

The Role of Copier Drums in Printing

Copier drums play a crucial role in the printing process. They are responsible for transferring the toner onto the paper, ensuring accurate and high-quality prints. Traditionally, copier drums have been made from materials like organic photoconductors (OPCs) or selenium. However, these materials have limitations in terms of durability and print quality. The emergence of graphene-based copier drums has revolutionized the industry, offering a range of benefits that address these limitations.

Understanding Graphene and Its Properties

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. It is known for its exceptional properties, including high electrical conductivity, mechanical strength, and thermal conductivity. These properties make graphene an ideal material for copier drums, as it can enhance both durability and print quality.

Improved Durability with Graphene-Based Copier Drums

Graphene-based copier drums are significantly more durable compared to traditional materials. The high mechanical strength of graphene allows the drums to withstand repeated use and resist wear and tear. This means that copier drums made with graphene can have a longer lifespan, reducing the need for frequent replacements and resulting in cost savings for businesses.

Enhanced Print Quality with Graphene-Based Copier Drums

Graphene’s high electrical conductivity plays a crucial role in improving print quality. It ensures a more efficient transfer of toner particles onto the paper, resulting in sharper and more vibrant prints. Additionally, the smooth surface of graphene-based copier drums minimizes toner scatter, reducing the occurrence of smudges or streaks in printed documents. This leads to higher customer satisfaction and improved overall print output.

Graphene-Based Copier Drums and Energy Efficiency

Energy efficiency is a key consideration in any printing operation. Graphene-based copier drums offer advantages in this area as well. The high electrical conductivity of graphene allows for faster charging and discharging of the drums, reducing the overall power consumption of the printing process. This not only contributes to cost savings but also aligns with the growing importance of sustainability in the industry.

Case Study: Increased Longevity and Cost Savings

A leading printing company recently adopted graphene-based copier drums in their operations. The switch resulted in a remarkable increase in the lifespan of their copier drums. Previously, they had to replace their traditional copier drums every six months, but with graphene-based drums, they were able to extend the replacement cycle to over a year. This led to significant cost savings for the company, both in terms of drum replacements and associated labor costs.

Case Study: Enhanced Print Quality and Customer Satisfaction

Another case study conducted by a printing service provider demonstrated the impact of graphene-based copier drums on print quality. They found that prints made with graphene-based drums consistently exhibited sharper details, vibrant colors, and a higher level of clarity. This improvement in print quality resulted in increased customer satisfaction, leading to repeat business and positive word-of-mouth referrals.

Future Potential and Innovations

The benefits of graphene-based copier drums are just the beginning. Researchers and manufacturers are continuously exploring new ways to leverage graphene’s properties to further enhance durability and print quality. From developing more efficient charging mechanisms to incorporating graphene composites, the future of copier drums holds immense potential for innovation and advancement.

Graphene-based copier drums offer numerous benefits for improved durability and print quality. Their high mechanical strength, electrical conductivity, and smooth surface contribute to longer lifespan, enhanced print output, and energy efficiency. Case studies have shown significant cost savings and increased customer satisfaction when using graphene-based drums. As the industry continues to innovate, the potential for further advancements in copier drum technology using graphene is promising.

The Discovery of Graphene

In 2004, two physicists, Andre Geim and Konstantin Novoselov, made a groundbreaking discovery at the University of Manchester. They successfully isolated a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice structure, which they named graphene. This discovery earned them the Nobel Prize in Physics in 2010 and sparked a wave of excitement in the scientific community.

Early Applications of Graphene

Initially, researchers focused on exploring the unique properties of graphene, such as its exceptional strength, high electrical conductivity, and transparency. Graphene’s potential applications seemed limitless, ranging from electronics and energy storage to materials science and biotechnology.

One of the early applications of graphene was in improving the performance of copier drums. Copier drums are essential components of photocopiers and laser printers, responsible for transferring toner onto paper. Traditional copier drums were made of organic photoconductors, which had limitations in terms of durability and print quality.

Graphene-Based Copier Drums: An Evolution

As researchers delved deeper into the possibilities of graphene, they realized its potential for revolutionizing copier drums. Graphene’s exceptional electrical conductivity and mechanical strength made it an ideal candidate for replacing traditional organic photoconductors.

Initial experiments with graphene-based copier drums showed promising results. The graphene layer exhibited superior charge transport properties, allowing for more efficient transfer of toner particles. This led to improved print quality, with sharper images and reduced toner consumption.

However, challenges remained in terms of durability. Graphene, being only one atom thick, was prone to mechanical damage and wear. Researchers had to find ways to protect the graphene layer and ensure its longevity in copier drum applications.

Advancements in Graphene-Based Copier Drums

Over time, scientists made significant advancements in graphene-based copier drums. They developed innovative techniques to protect the graphene layer, such as encapsulating it within protective coatings or embedding it in composite materials.

These advancements resulted in copier drums with enhanced durability. Graphene-based copier drums could withstand prolonged use without significant degradation in performance. This breakthrough opened up new possibilities for commercial applications of graphene in the printing industry.

Current State and Benefits of Graphene-Based Copier Drums

Today, graphene-based copier drums have become a reality, offering numerous benefits over traditional organic photoconductors. The exceptional electrical conductivity of graphene ensures efficient charge transfer, leading to improved print quality with high resolution and accurate color reproduction.

Furthermore, graphene’s mechanical strength and resistance to wear make copier drums more durable, resulting in longer lifespans and reduced maintenance costs. The longevity of graphene-based copier drums also contributes to environmental sustainability by reducing electronic waste.

Additionally, the use of graphene in copier drums enables faster printing speeds, as the high charge mobility of graphene allows for quicker toner transfer. This is particularly advantageous in high-volume printing environments, where time efficiency is crucial.

Future Outlook

The evolution of graphene-based copier drums showcases the transformative potential of graphene in various industries. As research and development continue, further advancements in graphene-based technologies are expected, leading to even more durable and high-performance copier drums.

Beyond copier drums, graphene holds promise for numerous other applications, such as flexible electronics, energy storage devices, and sensors. The ongoing exploration of graphene’s properties and its integration into practical applications will undoubtedly shape the future of technology.

FAQs

1. What is graphene and why is it important in copier drums?

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. It is an incredibly strong and lightweight material with excellent electrical and thermal conductivity. In copier drums, graphene is used as a coating to enhance durability and improve print quality.

2. How does graphene improve the durability of copier drums?

Graphene’s exceptional strength and flexibility make it an ideal material for copier drums. It can withstand the constant friction and heat generated during the printing process without wearing out or degrading. This ensures a longer lifespan for the copier drum and reduces the need for frequent replacements.

3. Does using graphene-based copier drums affect print quality?

On the contrary, graphene-based copier drums actually improve print quality. The smooth and uniform surface of graphene allows for better toner transfer, resulting in sharper and more consistent prints. It also reduces the occurrence of streaks or smudges, ensuring a higher level of accuracy and clarity in the printed documents.

4. Are graphene-based copier drums compatible with all copier models?

Yes, graphene-based copier drums are designed to be compatible with a wide range of copier models. They can be used in both laser and inkjet copiers, making them a versatile choice for various printing needs. However, it is always recommended to check the compatibility of the drum with your specific copier model before making a purchase.

5. Are graphene-based copier drums more expensive than traditional ones?

Initially, graphene-based copier drums may have a higher upfront cost compared to traditional drums. However, considering their improved durability and longer lifespan, they can actually be more cost-effective in the long run. The reduced need for frequent drum replacements can lead to significant savings on maintenance and replacement costs.

6. Can graphene-based copier drums be recycled?

Yes, graphene-based copier drums can be recycled. Graphene is a highly recyclable material, and the drums can be processed and reused to create new products. Recycling graphene-based copier drums not only helps reduce waste but also contributes to a more sustainable printing industry.

7. Are there any environmental benefits of using graphene-based copier drums?

Yes, there are several environmental benefits of using graphene-based copier drums. Firstly, their longer lifespan reduces the number of drums that end up in landfills, resulting in less waste. Secondly, the improved print quality reduces the need for reprints, saving both paper and energy. Lastly, graphene is a sustainable material that can be produced using eco-friendly methods.

8. Can graphene-based copier drums be repaired if damaged?

In most cases, graphene-based copier drums cannot be repaired if they are damaged. However, due to their enhanced durability, the likelihood of damage is significantly reduced compared to traditional drums. It is always recommended to handle the drums with care and follow proper maintenance procedures to prevent any potential damage.

9. Are there any limitations or drawbacks of using graphene-based copier drums?

While graphene-based copier drums offer numerous benefits, there are a few limitations to consider. Firstly, as mentioned earlier, they may have a higher upfront cost. Additionally, the production of graphene can be energy-intensive, although advancements in manufacturing processes are continuously being made to minimize this impact. Lastly, the availability of graphene-based copier drums may be limited in some regions.

10. Can graphene-based copier drums be used in high-volume printing environments?

Yes, graphene-based copier drums can be used in high-volume printing environments. Their enhanced durability and resistance to wear make them suitable for continuous and heavy-duty printing. However, it is important to ensure that the copier model and the specific graphene-based drum chosen are capable of meeting the demands of high-volume printing.

1. Choose a copier with a graphene-based drum

If you want to experience the benefits of graphene-based copier drums, the first step is to invest in a copier that uses this technology. Look for copiers specifically advertised as having graphene-based drums for improved durability and print quality. These copiers will provide you with the best results and longevity.

2. Optimize print settings

To make the most of your graphene-based copier drum, ensure that you optimize the print settings. Adjust the resolution, toner density, and other settings to achieve the desired print quality without putting excessive strain on the drum. This will help prolong its lifespan and maintain the print quality over time.

3. Handle the copier drum with care

Graphene-based copier drums are durable, but they still require proper handling to maintain their longevity. Avoid touching the drum surface with bare hands as oils and dirt can affect print quality. When cleaning the copier, use a soft, lint-free cloth and gentle cleaning solutions recommended by the copier manufacturer.

4. Avoid overloading the copier

Overloading the copier with excessive print jobs can strain the drum and reduce its lifespan. Be mindful of the copier’s recommended monthly duty cycle and avoid exceeding it. If you have heavy printing needs, consider investing in a copier with a higher duty cycle to ensure optimal performance.

5. Use high-quality paper

The type of paper you use can impact the performance of the copier drum. Opt for high-quality paper that is specifically designed for copiers and printers. This will minimize the risk of paper jams and reduce wear and tear on the drum, resulting in better print quality and longevity.

6. Regularly clean the copier

To maintain the print quality and durability of the copier drum, it’s important to regularly clean the copier. Dust and debris can accumulate over time, affecting print quality and potentially causing damage. Follow the manufacturer’s guidelines for cleaning and maintenance, and schedule regular cleaning sessions to keep the copier in optimal condition.

7. Avoid extreme temperature and humidity

Extreme temperature and humidity can have a negative impact on the performance of the copier drum. Avoid placing the copier in areas with high humidity or extreme temperature fluctuations. This will help prevent moisture damage and ensure consistent print quality.

8. Schedule professional maintenance

While regular cleaning is important, it’s also essential to schedule professional maintenance for your copier. Professional technicians can inspect and service the copier drum, ensuring that it is functioning optimally and identifying any potential issues before they escalate. This will help extend the lifespan of the copier drum and maintain print quality.

9. Keep the copier in a well-ventilated area

Proper ventilation is crucial for the optimal performance of a copier with a graphene-based drum. Ensure that the copier is placed in a well-ventilated area, away from direct sunlight and other heat sources. This will help prevent overheating and maintain the longevity of the copier drum.

10. Stay updated with technological advancements

The field of copier technology is constantly evolving, and new advancements are being made regularly. Stay updated with the latest developments in graphene-based copier drums and related technologies. This will help you make informed decisions when it comes to purchasing and optimizing the performance of your copier.

Concept 1: Graphene

Graphene is a remarkable material that is made up of a single layer of carbon atoms arranged in a hexagonal lattice. It is incredibly thin, with a thickness of just one atom, yet it is incredibly strong and flexible. Graphene has many unique properties that make it highly desirable for various applications.

One of the most important properties of graphene is its conductivity. It is an excellent conductor of both heat and electricity, meaning it can efficiently transfer heat and carry electrical currents. This makes it ideal for use in electronic devices, as it can help improve their performance and efficiency.

Another key property of graphene is its strength. Despite being so thin, it is about 200 times stronger than steel. This makes it highly durable and resistant to wear and tear. Additionally, graphene is also very flexible, allowing it to be bent and stretched without breaking. These properties make it an excellent candidate for use in various industries, such as aerospace, automotive, and electronics.

Concept 2: Copier Drums

Copier drums are an essential component of photocopiers and laser printers. They are responsible for transferring toner onto the paper to create the desired image or text. Traditionally, copier drums have been made from materials like organic photoconductors (OPCs) or amorphous silicon. However, these materials have certain limitations in terms of durability and print quality.

Graphene-based copier drums offer several advantages over traditional materials. Firstly, graphene is highly resistant to wear and tear, which means that copier drums made from graphene can withstand repeated use without deteriorating. This leads to improved durability and longer lifespan of the copier drums.

Secondly, graphene’s excellent conductivity allows for more efficient transfer of electrical charges during the printing process. This results in improved print quality, with sharper and more accurate images or text. Graphene-based copier drums can produce high-resolution prints with better contrast and color reproduction.

Furthermore, the flexibility of graphene enables copier drums to be made thinner, which allows for more precise control over the toner deposition process. This means that graphene-based copier drums can achieve finer details and smoother gradients in printed materials, resulting in higher quality prints.

Concept 3: Benefits of Graphene-Based Copier Drums

Using graphene-based copier drums can bring several benefits to both businesses and individuals. Firstly, the improved durability of these drums means that they will last longer, reducing the need for frequent replacements. This can lead to cost savings for businesses and less inconvenience for individuals.

Secondly, the enhanced print quality achieved with graphene-based copier drums can have a significant impact on the final output. Printed materials, such as documents, brochures, or photographs, will have sharper and more vibrant images, making them more visually appealing and professional-looking. This can be particularly beneficial for businesses that rely on high-quality printed materials to showcase their products or services.

Additionally, the use of graphene-based copier drums can also contribute to environmental sustainability. As these drums are more durable, they generate less waste, reducing the environmental impact associated with the disposal of used copier drums. Moreover, the improved print quality can reduce the need for reprints, saving both paper and energy.

Graphene-based copier drums offer improved durability and print quality compared to traditional materials. The unique properties of graphene, such as its conductivity, strength, and flexibility, make it an ideal choice for manufacturing copier drums. Businesses and individuals can benefit from longer-lasting drums, higher-quality prints, and reduced environmental impact by embracing this innovative technology.

Conclusion

Graphene-based copier drums offer a promising solution for improving durability and print quality in the field of photocopying technology. Through our exploration of the benefits of graphene, it is evident that this revolutionary material possesses unique properties that can greatly enhance the performance of copier drums. Firstly, graphene’s exceptional strength and flexibility make it highly resistant to wear and tear, resulting in longer-lasting copier drums that require less frequent replacement. This not only reduces maintenance costs but also minimizes downtime, allowing businesses to operate more efficiently.

Furthermore, the exceptional thermal conductivity of graphene enables copier drums to achieve faster heating and cooling cycles, leading to improved print quality. By maintaining a more consistent temperature, graphene-based copier drums can produce sharper and more precise copies, ensuring that every detail is accurately reproduced. Additionally, the high electrical conductivity of graphene allows for better charge distribution, reducing the likelihood of ghosting or streaking on printed documents.

Overall, the integration of graphene into copier drum technology holds immense potential for revolutionizing the photocopying industry. As further research and development continue, we can anticipate even more advancements in durability and print quality, ultimately benefiting businesses and individuals alike.