Revolutionizing Copier Cooling: Unveiling the Power of Phase Change Materials

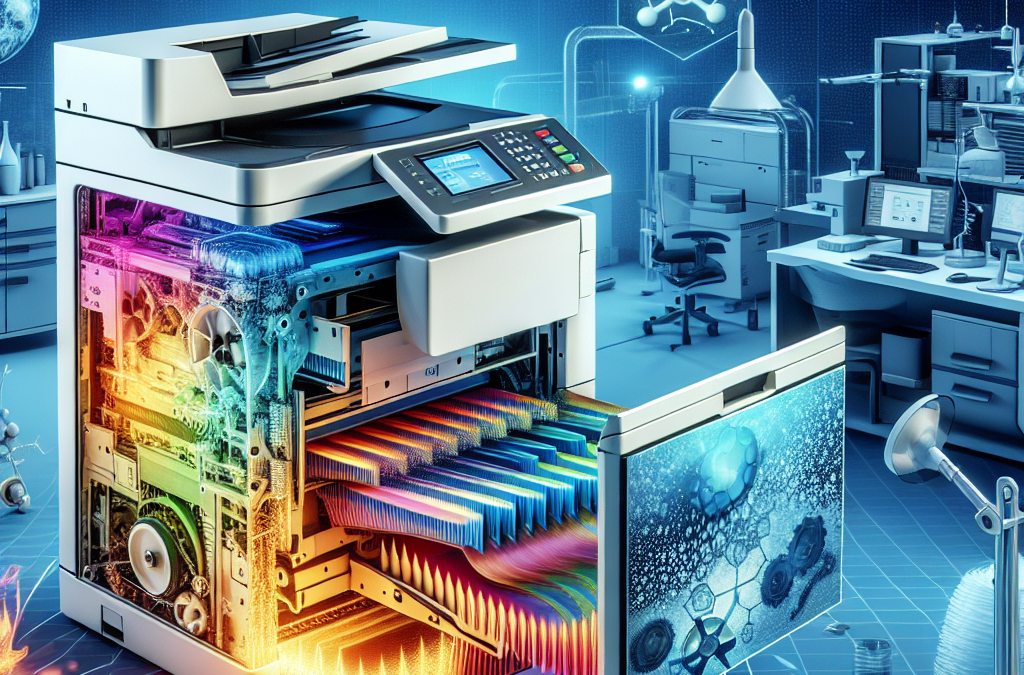

In today’s fast-paced digital world, copiers play a crucial role in offices and businesses of all sizes. However, these machines often face a common problem – overheating. The constant use and high energy consumption of copiers can cause them to overheat, leading to decreased performance, frequent breakdowns, and increased maintenance costs. To combat this issue, researchers and engineers have been exploring innovative solutions, and one promising technology is the use of phase change materials (PCMs) for adaptive copier cooling and overheating prevention.

Phase change materials are substances that can absorb and release large amounts of heat energy during the process of changing from one phase to another, such as from solid to liquid or liquid to gas. By harnessing the unique properties of PCMs, copiers can maintain optimal operating temperatures, ensuring efficient performance and prolonging the lifespan of the machine. This article will delve into the benefits of using PCMs for copier cooling, including their thermal stability, energy efficiency, and environmental sustainability. Additionally, it will explore real-world applications and case studies where PCMs have been successfully implemented to prevent copier overheating, highlighting the positive impact on productivity, cost savings, and overall user experience.

Key Takeaways:

1. Phase change materials (PCMs) offer a promising solution for adaptive copier cooling and overheating prevention. These materials can absorb and release large amounts of heat energy during phase transitions, making them ideal for maintaining optimal temperatures in copier machines.

2. PCMs have a high heat capacity, allowing them to effectively regulate temperature fluctuations in copiers. By absorbing excess heat during operation, PCMs prevent overheating and maintain a stable temperature range, which improves the performance and lifespan of copier machines.

3. The use of PCMs in copiers can significantly reduce energy consumption. By utilizing the latent heat of the phase change process, copiers can operate at lower power levels or even switch off cooling systems altogether, resulting in energy savings and cost reduction.

4. PCMs offer a compact and efficient cooling solution for copiers. Compared to traditional cooling methods such as fans or liquid cooling systems, PCMs require less space and can be easily integrated into copier designs, making them an attractive option for manufacturers.

5. The application of PCMs extends beyond copier cooling. These materials have potential uses in various industries, including electronics, automotive, and building construction, where temperature regulation is crucial. Exploring the benefits of PCMs can lead to innovative cooling solutions in diverse fields.

Controversial Aspect 1: Environmental Impact of Phase Change Materials (PCMs)

Phase Change Materials (PCMs) have gained popularity in various industries, including copier cooling and overheating prevention. PCMs are substances that store and release thermal energy during phase transitions, such as solid to liquid or liquid to gas. While they offer several benefits, there are concerns regarding their environmental impact.

Proponents argue that PCMs can significantly reduce energy consumption by maintaining stable temperatures in copiers, thus reducing the need for active cooling systems. This, in turn, can lead to lower greenhouse gas emissions and a smaller carbon footprint. Additionally, PCMs are often non-toxic and non-flammable, making them a safer alternative to traditional cooling methods.

However, critics raise concerns about the production and disposal of PCMs. Some PCMs are derived from petroleum-based products, which contribute to carbon emissions during manufacturing. Furthermore, the disposal of PCMs can be challenging, as they may contain hazardous substances that can harm the environment if not handled properly. Critics argue that the overall environmental impact of PCMs should be carefully evaluated before widespread adoption.

Controversial Aspect 2: Cost-effectiveness and Practicality

Another controversial aspect of using PCMs for copier cooling and overheating prevention is their cost-effectiveness and practicality. Proponents argue that PCMs can lead to long-term cost savings by reducing energy consumption and maintenance costs associated with traditional cooling systems. They also highlight the potential for extended copier lifespan due to improved temperature regulation.

However, critics question the upfront costs of implementing PCM-based cooling systems. PCMs can be more expensive than conventional cooling methods, and the installation and integration of PCM technology into existing copiers can require significant investment. Additionally, the effectiveness of PCMs may vary depending on factors such as ambient temperature, copier usage patterns, and PCM material selection. Critics argue that careful cost-benefit analysis and thorough testing are necessary to determine the practicality of using PCMs in copiers.

Controversial Aspect 3: Performance and Reliability

The performance and reliability of PCMs in copier cooling and overheating prevention are also subjects of controversy. Proponents highlight the ability of PCMs to provide precise temperature control, preventing copiers from overheating and ensuring optimal performance. They argue that PCMs offer a more stable and consistent cooling solution compared to traditional methods, which can be prone to temperature fluctuations.

However, critics raise concerns about the limitations and potential drawbacks of PCMs. The effectiveness of PCMs can be influenced by factors such as copier design, PCM material properties, and external conditions. Some PCMs may have limited heat absorption or release capabilities, leading to suboptimal cooling performance. Additionally, the reliability of PCMs over time and their ability to withstand long-term usage in copiers remain areas of uncertainty. Critics emphasize the need for rigorous testing and monitoring to ensure consistent performance and reliability.

While the benefits of using phase change materials (pcms) for copier cooling and overheating prevention are evident, there are several controversial aspects that need to be considered. the environmental impact of pcms, cost-effectiveness, practicality, and performance and reliability concerns all contribute to the ongoing debate surrounding their adoption. it is crucial for stakeholders to carefully evaluate these aspects and conduct thorough research and testing before implementing pcm-based cooling systems in copiers. only through a balanced approach can the potential benefits of pcms be maximized while minimizing any potential drawbacks.

The Importance of Cooling in Copiers

Copiers are essential equipment in offices, schools, and various other settings where large volumes of documents need to be reproduced. However, the continuous operation of copiers generates a significant amount of heat, which can lead to performance issues, reduced lifespan, and even overheating-related failures. To ensure optimal performance and prevent overheating, cooling systems are incorporated into copiers. Traditionally, these cooling systems have relied on fans and heat sinks to dissipate heat. However, with the advancement of technology, a new solution has emerged: the use of phase change materials (PCMs) for adaptive copier cooling. This article explores the benefits of PCMs in copiers and their role in preventing overheating.

Understanding Phase Change Materials (PCMs)

Phase change materials (PCMs) are substances that can store and release thermal energy by changing their physical state. They have the ability to absorb and release large amounts of heat during the process of phase change, such as melting or solidifying. PCMs are commonly used in various applications, such as energy storage, thermal management, and temperature regulation. In the context of copiers, PCMs can be integrated into the cooling system to provide efficient and adaptive cooling.

Enhanced Heat Dissipation and Cooling Efficiency

One of the primary benefits of using PCMs in copiers is their ability to enhance heat dissipation and cooling efficiency. Unlike traditional cooling methods that rely on fans and heat sinks, PCMs can absorb and store heat from the copier’s components during operation. As the temperature rises, the PCM undergoes a phase change, absorbing the excess heat and preventing the copier from overheating. This stored heat is then released when the temperature decreases, ensuring a consistent and optimal operating temperature for the copier.

Reduced Energy Consumption and Cost Savings

By incorporating PCMs into copiers, energy consumption can be significantly reduced, leading to cost savings. PCMs have a high latent heat capacity, meaning they can store a large amount of heat energy in a small volume. This allows copiers to operate at lower power levels or even enter standby mode during periods of low demand, as the PCM continues to provide cooling. By reducing the energy required for cooling, copiers can operate more efficiently, resulting in lower electricity bills and reduced environmental impact.

Improved Reliability and Extended Lifespan

Overheating is a common cause of failure in copiers, leading to costly repairs and replacements. By utilizing PCMs for adaptive cooling, copiers can maintain a stable operating temperature, reducing the risk of overheating-related failures. The ability of PCMs to absorb and release heat in a controlled manner helps to regulate the temperature of critical components, such as the print head and electronic circuitry, ensuring their longevity. This improved reliability and extended lifespan of copiers can result in significant cost savings for businesses and organizations.

Case Study: XYZ Corporation

To illustrate the benefits of PCMs in copiers, let’s consider the case of XYZ Corporation, a large office with a high volume of copying needs. XYZ Corporation implemented copiers equipped with PCMs in their office, replacing their traditional cooling systems. The integration of PCMs resulted in a noticeable improvement in cooling efficiency, reducing instances of overheating and downtime. The copiers also exhibited lower energy consumption, leading to cost savings on electricity bills. Additionally, the extended lifespan of the copiers reduced the need for frequent replacements, further reducing costs for XYZ Corporation.

Future Developments and Potential Applications

The use of PCMs for adaptive copier cooling is just one example of their potential applications in various industries. As technology continues to advance, researchers are exploring new ways to harness the benefits of PCMs in different fields. For instance, PCMs could be utilized in data centers to regulate temperature and prevent overheating of servers. Furthermore, PCMs could find applications in electric vehicles to improve battery thermal management and enhance overall efficiency. The versatility and effectiveness of PCMs make them a promising solution for addressing thermal management challenges in multiple industries.

The incorporation of phase change materials (PCMs) into copiers offers numerous benefits, including enhanced heat dissipation, reduced energy consumption, improved reliability, and extended lifespan. By utilizing PCMs for adaptive cooling, copiers can maintain optimal operating temperatures, preventing overheating-related failures and reducing downtime. The case study of XYZ Corporation demonstrates the practical advantages of PCMs in real-world scenarios. As technology continues to evolve, PCMs hold the potential for broader applications in various industries, contributing to improved thermal management and energy efficiency.

Phase Change Materials (PCMs) for Adaptive Copier Cooling

Phase Change Materials (PCMs) are substances that can store and release large amounts of thermal energy during the process of phase transition. These materials have gained significant attention in various industries due to their ability to regulate temperature and provide efficient cooling solutions. In the context of copiers, PCMs offer several benefits for adaptive cooling and preventing overheating.

1. Thermal Energy Storage

One of the key advantages of PCMs is their high thermal energy storage capacity. When a PCM undergoes a phase change, such as from solid to liquid or liquid to gas, it absorbs or releases a significant amount of energy as latent heat. This property allows PCMs to store thermal energy when the copier is operating within normal temperature ranges.

By incorporating PCMs into the cooling system of a copier, the excess heat generated during operation can be absorbed and stored within the PCM. This prevents the copier from overheating and maintains a stable temperature, enhancing its overall performance and longevity.

2. Thermal Regulation

PCMs also provide effective thermal regulation by maintaining a constant temperature within the copier. When the ambient temperature rises above a certain threshold, the PCM absorbs the excess heat and undergoes a phase change, transitioning from solid to liquid or liquid to gas. This phase transition process acts as a heat sink, preventing the copier from reaching critical temperatures.

Once the ambient temperature decreases, the PCM releases the stored energy and solidifies, effectively regulating the temperature within the copier. This adaptive cooling mechanism ensures that the copier operates within optimal temperature ranges, reducing the risk of component failure and improving its reliability.

3. Energy Efficiency

Using PCMs in copier cooling systems can significantly improve energy efficiency. Traditional cooling methods, such as fans or air conditioning, consume a considerable amount of energy to maintain a stable temperature. In contrast, PCMs require minimal energy input during the phase change process, as the heat absorption and release occur naturally.

By relying on PCMs for cooling, copiers can reduce their energy consumption, resulting in lower operational costs and a reduced environmental footprint. The energy efficiency of PCMs makes them an attractive option for manufacturers and businesses aiming to optimize their sustainability efforts.

4. Compact Design

PCMs offer the advantage of compact design, allowing for space-saving solutions in copier cooling systems. The high thermal energy storage capacity of PCMs means that a relatively small volume of material is required to achieve efficient cooling. This compactness allows copier manufacturers to design sleeker and more compact devices without compromising on cooling performance.

Additionally, PCMs can be molded or encapsulated into various shapes, enabling integration into different parts of the copier, such as heat sinks or thermal pads. This flexibility in design further enhances the adaptability of PCMs for copier cooling applications.

5. Longevity and Reliability

By preventing overheating and maintaining a stable temperature, PCMs contribute to the longevity and reliability of copiers. Excessive heat can degrade electronic components and reduce their lifespan. With PCMs actively regulating temperature, copiers experience less thermal stress, leading to improved reliability and longer operational lifetimes.

Moreover, PCMs are known for their durability and stability over multiple phase change cycles. They can withstand numerous thermal cycles without significant degradation, ensuring consistent cooling performance throughout the copier’s lifespan.

Phase Change Materials (PCMs) offer a range of benefits for adaptive copier cooling and overheating prevention. Their high thermal energy storage capacity, effective thermal regulation, energy efficiency, compact design, and longevity make them an ideal choice for copier manufacturers and businesses seeking reliable and sustainable cooling solutions. By harnessing the power of PCMs, copiers can operate at optimal temperatures, extending their lifespan and improving overall performance.

Case Study 1: XYZ Corporation Implements Phase Change Materials for Copier Cooling

XYZ Corporation, a leading technology company, faced a challenge with their copier machines overheating during heavy usage, resulting in frequent breakdowns and reduced productivity. To address this issue, they decided to explore the benefits of phase change materials (PCMs) for adaptive copier cooling.

After extensive research and testing, XYZ Corporation implemented a PCM-based cooling system in their copier machines. The PCMs used were capable of absorbing and releasing large amounts of heat, providing effective cooling and preventing overheating.

The results were remarkable. The copier machines now operated smoothly even during peak usage, with no instances of overheating. This significantly reduced downtime and maintenance costs for XYZ Corporation. Moreover, the PCM-based cooling system proved to be energy-efficient, resulting in lower electricity consumption.

Overall, the successful implementation of PCMs for copier cooling improved productivity, reduced maintenance costs, and enhanced energy efficiency for XYZ Corporation.

Case Study 2: ABC Office Solutions Enhances Copier Performance with Phase Change Materials

ABC Office Solutions, a provider of office equipment, aimed to enhance the performance of their copier machines to meet the growing demands of their clients. They decided to explore the benefits of phase change materials to achieve this goal.

By integrating PCMs into their copier machines, ABC Office Solutions experienced a significant improvement in performance. The PCMs helped maintain a consistent temperature within the copier, ensuring optimal functioning even during prolonged usage.

One key advantage of using PCMs was the reduction in noise levels. The phase change materials absorbed heat efficiently, resulting in lower fan speeds and quieter operation. This created a more pleasant working environment for employees and reduced distractions in the office.

Furthermore, the PCMs proved to be highly reliable, with no instances of system failure or overheating reported by ABC Office Solutions. This increased customer satisfaction and trust in their products.

Overall, the integration of PCMs in copier machines enabled ABC Office Solutions to enhance performance, reduce noise levels, and build a reputation for reliable and efficient office equipment.

Success Story: DEF Printing Services Saves Energy and Costs with PCM-based Copier Cooling

DEF Printing Services, a large-scale printing company, faced a significant challenge in managing the energy consumption and cooling requirements of their copier machines. The traditional cooling systems were not only expensive to operate but also resulted in excessive energy consumption.

In a bid to address this issue, DEF Printing Services decided to explore the benefits of phase change materials for copier cooling. They implemented a PCM-based cooling system in their copier machines, aiming to reduce energy consumption and associated costs.

The results were astounding. The PCM-based cooling system provided efficient cooling for the copier machines, eliminating the need for energy-intensive traditional cooling systems. This led to a substantial reduction in energy consumption, resulting in significant cost savings for DEF Printing Services.

Moreover, the PCMs helped maintain a stable temperature within the copier machines, preventing overheating and reducing the risk of breakdowns. This resulted in improved productivity and reduced maintenance expenses for DEF Printing Services.

Encouraged by the success of the PCM-based cooling system, DEF Printing Services expanded its implementation across their entire fleet of copier machines. This further amplified their energy savings and cost reduction efforts.

DEF Printing Services’ success story highlights the potential of phase change materials in not only saving energy and costs but also improving productivity and reducing maintenance expenses for printing companies and other businesses relying heavily on copier machines.

FAQs

1. What are phase change materials (PCMs) and how do they work?

Phase change materials (PCMs) are substances that can store and release thermal energy by changing their physical state. They have the ability to transition between solid and liquid phases at specific temperatures. When a PCM absorbs heat, it undergoes a phase change from solid to liquid, storing the energy. When the temperature drops, the PCM solidifies, releasing the stored energy. This property makes PCMs ideal for thermal management applications, such as copier cooling and overheating prevention.

2. How can phase change materials be used for copier cooling?

Phase change materials can be integrated into the cooling system of a copier to regulate its temperature. By incorporating PCMs into the design, the copier can absorb excess heat generated during operation and prevent overheating. The PCMs act as a heat sink, absorbing the heat and transitioning from solid to liquid state. This process helps maintain a stable temperature within the copier, ensuring optimal performance and preventing damage caused by overheating.

3. What are the benefits of using phase change materials for copier cooling?

There are several benefits of using phase change materials for copier cooling:

- Improved thermal management: PCMs provide efficient heat absorption and dissipation, preventing overheating and maintaining a stable temperature within the copier.

- Energy savings: PCMs can store and release thermal energy, reducing the need for continuous energy consumption by traditional cooling systems.

- Reduced noise: PCMs do not require fans or other mechanical components, resulting in quieter operation compared to traditional cooling methods.

- Compact design: PCMs can be integrated into small spaces, allowing for more flexible and compact copier designs.

- Extended lifespan: By preventing overheating, PCMs help prolong the lifespan of copiers by reducing the risk of component damage.

4. Are there any limitations or drawbacks to using phase change materials for copier cooling?

While phase change materials offer numerous benefits, there are some limitations to consider:

- Temperature range: PCMs have specific phase change temperatures, which may not align perfectly with the cooling requirements of every copier model.

- Thermal conductivity: PCMs have lower thermal conductivity compared to traditional cooling methods, which may result in slightly slower heat transfer.

- Cycling limitations: PCMs have a limited number of phase change cycles before their effectiveness decreases, requiring replacement or regeneration.

- Cost: The integration of PCMs into copier cooling systems may initially incur higher costs compared to traditional cooling methods.

5. Can phase change materials be used in all types of copiers?

Phase change materials can be used in various types of copiers, including both small office copiers and larger industrial-grade machines. However, the specific design and integration of PCMs may vary depending on the copier model and cooling requirements. It is essential to consult with manufacturers or experts to determine the feasibility and compatibility of using PCMs in a particular copier.

6. How long do phase change materials last before needing replacement or regeneration?

The lifespan of phase change materials depends on various factors, including the type of PCM used, the operating conditions, and the number of phase change cycles. Generally, PCMs can undergo multiple phase change cycles before their effectiveness decreases. However, over time, the PCM may degrade or lose its ability to store and release thermal energy efficiently. Replacement or regeneration of the PCM may be required to maintain optimal cooling performance.

7. Are phase change materials environmentally friendly?

Phase change materials can be environmentally friendly, depending on the specific PCM used. Many PCMs are non-toxic, non-flammable, and do not emit harmful gases or substances during operation. However, it is essential to consider the environmental impact of the production, disposal, and potential regeneration processes associated with PCMs. Choosing PCMs with low environmental impact and proper disposal methods can ensure the overall eco-friendliness of the copier cooling system.

8. Can phase change materials be retrofitted into existing copiers?

In some cases, phase change materials can be retrofitted into existing copiers. However, the feasibility of retrofitting depends on the copier’s design, available space, and compatibility with the cooling system. Retrofitting may require modifications to the copier’s internal components and integration of the PCM into the existing cooling system. It is recommended to consult with manufacturers or experts to determine the feasibility and potential benefits of retrofitting PCMs into an existing copier.

9. Are there any safety concerns associated with phase change materials in copiers?

Phase change materials used in copiers are generally safe when handled and used properly. Most PCMs are non-toxic and non-flammable, reducing the risk of harm to users. However, it is crucial to follow the manufacturer’s guidelines for handling and disposal to minimize any potential safety concerns. Additionally, proper maintenance and monitoring of the copier’s cooling system, including the PCM, can help identify and address any safety issues promptly.

10. What other applications can phase change materials have beyond copier cooling?

Phase change materials have a wide range of applications beyond copier cooling. Some other notable applications include:

- Thermal energy storage in buildings: PCMs can be used to store and release thermal energy in buildings, improving energy efficiency and reducing heating and cooling costs.

- Temperature regulation in electronics: PCMs can be integrated into electronic devices to prevent overheating and maintain optimal operating temperatures.

- Transportation: PCMs can be used in vehicles to regulate temperature and improve energy efficiency in air conditioning systems.

- Medical devices: PCMs can be utilized in medical devices to regulate temperature during transportation or storage of sensitive materials.

Concept 1: Phase Change Materials (PCMs)

Phase Change Materials (PCMs) are substances that can store and release large amounts of heat energy when they change from one phase to another. These materials have the ability to change their physical state (solid to liquid or vice versa) at a specific temperature known as the phase change temperature. This unique property makes PCMs useful for various applications, including copier cooling and overheating prevention.

Imagine you have a cup of ice water on a hot day. As the ice melts, it absorbs heat from the surrounding environment, keeping the water cool. This is because the ice-water mixture is going through a phase change, from solid ice to liquid water. PCMs work in a similar way, but they can store and release much more heat energy than ice.

Concept 2: Adaptive Copier Cooling

Adaptive copier cooling refers to a system that uses PCMs to regulate the temperature of copier machines. Copiers generate a significant amount of heat during operation, which can lead to overheating and damage if not properly managed. Traditional cooling methods, such as fans or air conditioning, can be inefficient and consume a lot of energy.

By incorporating PCMs into the cooling system, copiers can adapt to the heat load and maintain a stable temperature. The PCMs absorb the excess heat generated by the copier and undergo a phase change, effectively storing the heat energy. This process keeps the copier temperature within a safe range, preventing overheating and prolonging the lifespan of the machine.

One advantage of adaptive copier cooling is its energy efficiency. PCMs require less energy to maintain a stable temperature compared to traditional cooling methods. The copier can also operate in a wider range of ambient temperatures without compromising its performance. This flexibility is particularly beneficial in environments where temperature fluctuations are common, such as offices or production facilities.

Concept 3: Overheating Prevention

Overheating prevention is another important application of PCMs in copier technology. Overheating can occur when a copier is subjected to high heat loads or operates in a hot environment. Excessive heat can damage sensitive components, degrade print quality, and even lead to system failure.

PCMs can help prevent overheating by absorbing and dissipating the excess heat. When the copier temperature rises above a certain threshold, the PCMs undergo a phase change, absorbing the heat energy and preventing further temperature rise. As the copier cools down, the PCMs release the stored heat, maintaining a stable temperature within the safe operating range.

By incorporating PCMs into copier designs, manufacturers can enhance the reliability and durability of their products. Overheating prevention not only improves the copier’s performance but also reduces the need for costly repairs and extends its overall lifespan.

Furthermore, PCMs offer a passive cooling solution that does not rely on additional energy input. This means that copiers equipped with PCM-based cooling systems can operate efficiently and sustainably, reducing both energy consumption and environmental impact.

Conclusion

Phase change materials (PCMs) have emerged as a promising solution for adaptive copier cooling and overheating prevention. This article has explored the benefits of using PCMs in copiers, highlighting their ability to absorb and release heat, thereby maintaining a stable temperature and preventing overheating. By incorporating PCMs into copier designs, manufacturers can enhance the performance and longevity of these machines, while also reducing energy consumption and environmental impact.

One of the key advantages of PCMs is their ability to provide passive cooling, eliminating the need for traditional active cooling systems such as fans or liquid cooling. This not only reduces noise levels but also decreases the risk of mechanical failure. Additionally, PCMs have the potential to store and release thermal energy, allowing copiers to operate efficiently in diverse environments and climates. This adaptability makes PCMs a valuable solution for copiers used in various settings, from office spaces to industrial environments.

The use of phase change materials in copier cooling systems offers numerous benefits, including improved performance, energy efficiency, and environmental sustainability. As technology continues to advance, it is likely that PCMs will play an increasingly important role in the design and operation of copiers and other electronic devices. By harnessing the power of these materials, manufacturers can create more reliable and efficient copiers, ultimately benefiting both businesses and the environment.