Unlocking Efficiency: How Proactive Maintenance Can Keep Your Printer Running Smoothly

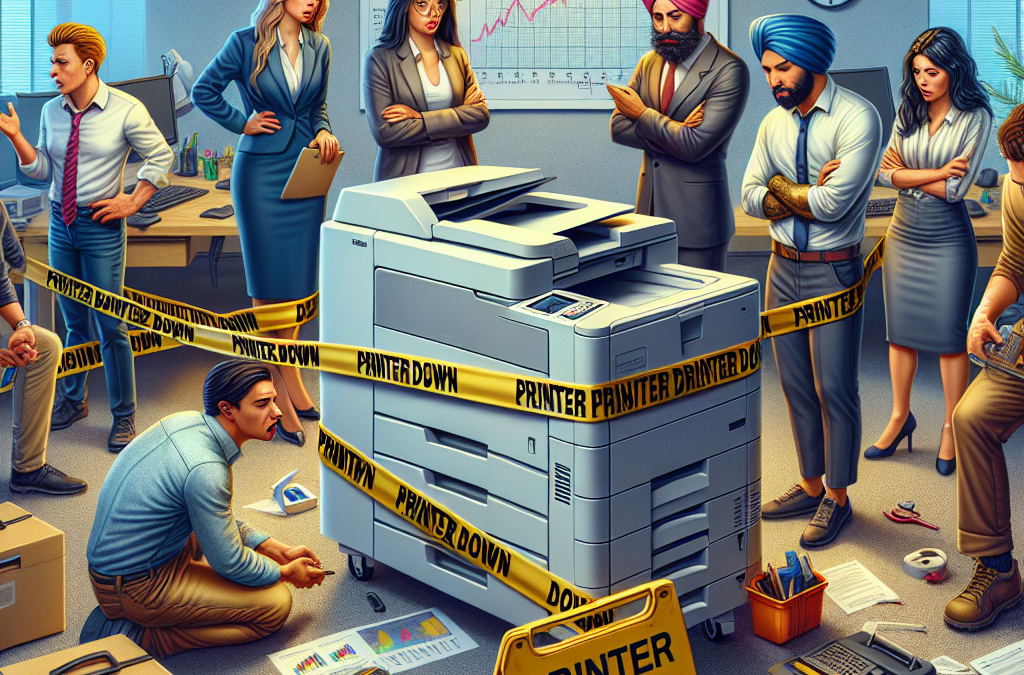

In today’s fast-paced business world, where time is money and efficiency is key, a malfunctioning printer can bring productivity to a screeching halt. Whether it’s a small office or a large corporation, the impact of printer downtime can be significant, causing delays, frustration, and financial losses. However, with proactive maintenance strategies in place, businesses can minimize the risk of printer failures and ensure smooth operations.

In this article, we will explore the importance of proactive printer maintenance and how it can help businesses avoid costly downtime. We will delve into the common causes of printer failures, such as clogged print heads, paper jams, and software issues, and discuss the steps that organizations can take to prevent these issues from occurring. From regular cleaning and firmware updates to proper paper handling and monitoring, we will provide practical tips and best practices for maintaining printers in optimal condition. By implementing proactive maintenance measures, businesses can not only reduce the risk of downtime but also extend the lifespan of their printers, saving money in the long run. So, let’s dive in and discover how to keep your printers running smoothly and your productivity soaring.

Key Takeaways:

1. Proactive maintenance is crucial for preventing printer downtime and maximizing productivity in the workplace. By regularly inspecting and servicing printers, businesses can avoid unexpected breakdowns and costly repairs.

2. Regular cleaning and maintenance of printer components, such as printheads and paper trays, can significantly extend the lifespan of the device. Simple tasks like removing debris and dust can prevent clogs and ensure smooth printing operations.

3. Implementing a preventive maintenance schedule is essential for businesses relying heavily on printers. By scheduling routine check-ups and maintenance, potential issues can be identified and resolved before they disrupt workflow, saving time and resources.

4. Partnering with a reliable printer maintenance service provider can offer businesses peace of mind. These professionals have the expertise to diagnose and repair printer issues promptly, minimizing downtime and maximizing productivity.

5. Investing in high-quality printer supplies, such as ink cartridges and paper, can also contribute to printer longevity and prevent downtime. Using genuine and compatible supplies ensures optimal performance and reduces the risk of malfunctions.

By following these key takeaways, businesses can proactively maintain their printers, minimize downtime, and keep productivity at its peak. Taking preventive measures not only saves time and money but also ensures a smooth workflow, allowing businesses to focus on their core operations.

1. Predictive Maintenance: The Key to Avoiding Printer Downtime

In today’s fast-paced business environment, printer downtime can be a major hindrance to productivity. When a printer goes down, it not only disrupts workflow but also leads to wasted time and resources. To address this challenge, many businesses are turning to predictive maintenance solutions to proactively manage their printers and avoid unexpected downtime.

Predictive maintenance takes advantage of advanced technologies such as artificial intelligence (AI) and machine learning (ML) to monitor the health of printers in real-time. By analyzing data collected from sensors and other sources, these systems can detect early warning signs of potential issues, allowing businesses to take preventive action before a breakdown occurs.

The benefits of predictive maintenance are twofold. First, it helps businesses avoid costly downtime by identifying and resolving printer issues before they escalate. Second, it enables businesses to optimize their maintenance schedules and reduce unnecessary service calls, resulting in significant cost savings.

As the technology continues to evolve, we can expect predictive maintenance solutions to become even more sophisticated. With the integration of IoT (Internet of Things) devices, printers will be able to communicate directly with maintenance systems, automatically triggering service requests when needed. This seamless integration will further streamline maintenance processes, ensuring maximum uptime and productivity.

2. Remote Monitoring and Support: Enabling Proactive Printer Maintenance

Traditionally, printer maintenance involved waiting for a breakdown to occur and then scheduling a service technician to fix the issue. This reactive approach not only resulted in downtime but also caused delays in getting printers up and running again.

However, with the rise of remote monitoring and support technologies, businesses can now proactively manage their printers from anywhere, at any time. These solutions allow IT teams to remotely monitor the status of printers, identify potential issues, and even perform troubleshooting tasks without being physically present.

Remote monitoring and support offer several advantages. Firstly, it allows businesses to detect and resolve printer problems before they impact productivity. IT teams can receive real-time alerts when a printer is running low on supplies or experiencing performance issues, enabling them to take immediate action.

Secondly, remote support capabilities enable IT teams to diagnose and resolve printer issues remotely, eliminating the need for on-site visits in many cases. This not only saves time but also reduces costs associated with technician travel and downtime.

Looking ahead, we can expect remote monitoring and support technologies to become even more advanced. Integration with AI and ML algorithms will enable these systems to learn from past incidents and provide proactive recommendations for printer maintenance. Additionally, the increasing adoption of cloud-based solutions will allow businesses to centralize printer management and streamline support processes across multiple locations.

3. Managed Print Services: Outsourcing Printer Maintenance for Optimal Efficiency

As businesses strive to optimize their operations and focus on core competencies, many are turning to managed print services (MPS) to handle their printer maintenance needs. MPS providers offer comprehensive solutions that include proactive monitoring, regular maintenance, and supply replenishment, allowing businesses to offload the burden of printer management.

By outsourcing printer maintenance to MPS providers, businesses can benefit from specialized expertise and dedicated resources. These providers have the knowledge and experience to proactively manage printers, ensuring optimal performance and minimal downtime.

MPS also offer cost savings through efficient supply management. Providers can monitor printer usage patterns and automatically replenish supplies when needed, eliminating the risk of running out of ink or toner at critical times. This not only saves businesses time and effort but also reduces the likelihood of productivity disruptions.

In the future, we can expect MPS providers to expand their offerings beyond maintenance and supplies. With the integration of advanced analytics and reporting capabilities, MPS providers will be able to provide valuable insights into printer usage patterns, helping businesses optimize their print infrastructure and reduce costs.

Overall, the emerging trends of predictive maintenance, remote monitoring and support, and managed print services are transforming the way businesses approach printer maintenance. By adopting these proactive strategies, businesses can minimize downtime, improve productivity, and focus on their core objectives. As technology continues to evolve, we can expect even more innovative solutions to emerge, further enhancing the efficiency and effectiveness of printer maintenance processes.

Controversial Aspect 1: Necessity of Proactive Maintenance

Proactive maintenance is often touted as a necessary step to avoid printer downtime and increase productivity. However, some argue that the cost and time invested in proactive maintenance may not always be justified.

On one hand, proponents of proactive maintenance argue that it helps identify and address potential issues before they cause major problems. By regularly maintaining printers, businesses can prevent unexpected breakdowns, reduce repair costs, and minimize the impact on productivity. They believe that the upfront investment in proactive maintenance pays off in the long run by ensuring smooth operations.

On the other hand, skeptics argue that modern printers are designed to be reliable and require minimal maintenance. They claim that the time and resources spent on proactive maintenance could be better utilized elsewhere. They argue that reactive maintenance, addressing issues as they arise, can be just as effective and more cost-efficient. These critics believe that the necessity of proactive maintenance is exaggerated by service providers looking to sell maintenance contracts.

Controversial Aspect 2: Cost of Proactive Maintenance

Another controversial aspect of proactive maintenance is its cost. While proponents argue that the investment is worthwhile, critics contend that it can be a significant financial burden, especially for small businesses with limited budgets.

Proponents argue that the cost of proactive maintenance is justified by the potential savings in repair costs and productivity losses. They believe that by investing in regular maintenance, businesses can avoid costly breakdowns and reduce the need for emergency repairs. Additionally, they argue that proactive maintenance can extend the lifespan of printers, further reducing long-term costs.

However, critics point out that the cost of proactive maintenance can quickly add up, especially when considering the frequency of maintenance visits and the fees charged by service providers. They argue that for some businesses, the cost of maintenance contracts may outweigh the potential savings from avoiding downtime. These critics suggest that businesses should carefully evaluate the cost-benefit ratio before committing to proactive maintenance.

Controversial Aspect 3: Impact on Productivity

The impact of proactive maintenance on productivity is another point of contention. Proponents argue that by preventing unexpected breakdowns, proactive maintenance helps maintain consistent productivity levels. They believe that the short-term disruptions caused by maintenance visits are outweighed by the long-term benefits of avoiding unplanned downtime.

However, critics argue that proactive maintenance itself can cause productivity disruptions. They contend that maintenance visits often require printers to be taken offline, resulting in temporary unavailability and potential delays in printing tasks. They argue that the cumulative downtime caused by maintenance visits can negate the benefits of preventing unexpected breakdowns.

Additionally, critics point out that the timing of maintenance visits can also impact productivity. If maintenance is scheduled during peak production periods or when urgent printing tasks need to be completed, it can significantly disrupt workflow and hinder productivity.

The necessity and effectiveness of proactive maintenance for printers remain controversial. while proponents argue that it is a crucial step to prevent downtime and increase productivity, skeptics question its necessity and cost-effectiveness. the decision to invest in proactive maintenance should be carefully evaluated, considering the specific needs and budget constraints of each business. balancing the potential benefits against the costs and disruptions caused by maintenance visits is essential in making an informed decision.

1. The Cost of Printer Downtime

Printer downtime can have a significant impact on productivity and profitability for businesses of all sizes. When a printer goes down, it can disrupt workflows, delay important tasks, and cause frustration among employees. The cost of printer downtime goes beyond just the repair or replacement of the printer itself. It also includes the loss of employee time spent troubleshooting or waiting for the printer to be fixed, the potential loss of business opportunities due to missed deadlines or delayed communication, and the negative impact on customer satisfaction. In fact, according to a study by Gartner, printer downtime can cost businesses an average of $5,000 per hour. This highlights the importance of proactive maintenance to avoid such costly disruptions.

2. The Benefits of Proactive Maintenance

Proactive maintenance involves regularly inspecting, cleaning, and servicing printers to prevent issues before they occur. By implementing a proactive maintenance plan, businesses can experience several benefits. Firstly, it helps to identify and address potential problems early on, reducing the likelihood of unexpected breakdowns and downtime. Secondly, proactive maintenance improves print quality and reduces the occurrence of paper jams or other printing errors, leading to smoother operations and higher productivity. Additionally, regular maintenance can extend the lifespan of printers, reducing the need for frequent replacements and saving costs in the long run. Overall, proactive maintenance is a proactive approach to ensure that printers are always in optimal condition, minimizing the risk of downtime and maximizing productivity.

3. Key Components of a Proactive Maintenance Plan

A comprehensive proactive maintenance plan for printers should include several key components. Firstly, regular cleaning of printer components, such as print heads, rollers, and paper trays, is essential to prevent dust and debris buildup that can lead to malfunctions. This can be done using specialized cleaning tools or kits recommended by the printer manufacturer. Secondly, firmware and driver updates should be regularly installed to ensure compatibility with the latest software and operating systems, as well as to address any known issues or vulnerabilities. Thirdly, regular inspection of printer parts, such as belts, gears, and sensors, can help identify any signs of wear or damage that may require repair or replacement. Lastly, it is important to keep a record of maintenance activities, including dates, actions taken, and any issues encountered, to track the effectiveness of the maintenance plan and identify patterns or recurring problems.

4. Case Study: Company X’s Success with Proactive Maintenance

Company X, a medium-sized marketing agency, implemented a proactive maintenance plan for their printers after experiencing frequent downtime and productivity losses. They assigned a dedicated staff member to oversee the maintenance activities, including regular cleaning, firmware updates, and inspections. As a result, they saw a significant reduction in printer-related issues and downtime. The staff member also conducted training sessions to educate employees on proper printer usage and maintenance, further minimizing the occurrence of user-induced problems. Company X’s proactive approach not only improved productivity but also saved them thousands of dollars in repair and replacement costs. This case study highlights the effectiveness of proactive maintenance in preventing downtime and its positive impact on overall business operations.

5. Outsourcing Proactive Maintenance: Is It Worth It?

While some businesses prefer to handle printer maintenance in-house, others may choose to outsource this task to specialized service providers. Outsourcing proactive maintenance can offer several advantages. Firstly, it allows businesses to free up their internal resources and focus on core activities, leaving the maintenance tasks to experts who have the necessary skills and knowledge. This can be particularly beneficial for smaller businesses that may not have dedicated IT or maintenance staff. Secondly, outsourcing often comes with service level agreements, ensuring that maintenance tasks are performed on schedule and to a high standard. Additionally, service providers may have access to advanced diagnostic tools and technologies that can help identify and address printer issues more efficiently. However, it is important to carefully evaluate the costs and benefits of outsourcing maintenance to determine if it aligns with the specific needs and budget of the business.

6. Tips for Effective Printer Maintenance

In addition to implementing a proactive maintenance plan, there are several tips that businesses can follow to ensure effective printer maintenance. Firstly, it is important to use high-quality paper and ink cartridges that are compatible with the printer model. Low-quality supplies can cause clogs, smudging, or other printing issues. Secondly, printers should be placed in a clean and well-ventilated area to prevent dust accumulation and overheating. Regularly dusting the surrounding area can also help maintain optimal printer performance. Thirdly, employees should be trained on proper printer usage, including loading paper correctly, avoiding excessive force when clearing paper jams, and using the printer’s features and settings appropriately. Lastly, it is advisable to schedule regular maintenance tasks during periods of low printer usage to minimize disruption to daily operations.

7. The Role of Technology in Proactive Maintenance

Technology plays a crucial role in enabling proactive maintenance for printers. Many modern printers come with built-in diagnostic tools that can detect and report potential issues. These tools can provide alerts or notifications when maintenance actions are required, such as cleaning print heads or replacing consumables. Additionally, remote monitoring and management software can allow IT administrators to track printer performance, identify trends, and schedule maintenance activities remotely. Some printers even have self-healing capabilities, where they can automatically troubleshoot and resolve common issues without human intervention. The integration of technology into proactive maintenance processes can streamline operations, improve efficiency, and reduce the risk of downtime.

8. The Future of Proactive Maintenance

As technology continues to advance, the future of proactive maintenance holds even more promise. Artificial intelligence (AI) and machine learning algorithms can be leveraged to analyze printer data and predict potential failures or maintenance needs. This predictive maintenance approach can help businesses take proactive actions before an issue occurs, further reducing downtime and improving overall productivity. Additionally, the Internet of Things (IoT) can enable printers to communicate with service providers directly, automatically scheduling maintenance tasks or ordering replacement parts when needed. These advancements in proactive maintenance can revolutionize the way printers are managed, ensuring optimal performance and minimal disruption to business operations.

Printer downtime can be a major setback for businesses, affecting productivity, profitability, and customer satisfaction. However, by implementing a proactive maintenance plan and following best practices, businesses can minimize the risk of downtime and keep their printers running smoothly. Regular cleaning, firmware updates, inspections, and proper printer usage are essential components of an effective maintenance strategy. Outsourcing maintenance or leveraging technology can also enhance the effectiveness of proactive maintenance efforts. As technology continues to evolve, the future of proactive maintenance holds great potential for even more efficient and predictive approaches to printer maintenance. By prioritizing proactive maintenance, businesses can avoid the frustration and costs associated with printer downtime, ensuring uninterrupted productivity and success.

Understanding the Importance of Proactive Maintenance

1. The Role of Printers in Productivity

Printers play a crucial role in the productivity of any organization. From printing important documents to generating reports, invoices, and marketing materials, printers are an essential tool for businesses. However, when a printer malfunctions or experiences downtime, it can severely impact productivity and disrupt workflow.

2. Common Causes of Printer Downtime

There are several common causes of printer downtime that can lead to a decrease in productivity. These include:

Paper Jams:

One of the most frequent issues that can cause printer downtime is paper jams. When paper gets stuck in the printer, it halts the printing process and requires manual intervention to clear the jam.

Ink or Toner Issues:

Running out of ink or toner is another common problem that can cause downtime. When the printer runs out of these supplies, it cannot continue printing until they are replaced.

Hardware Failures:

Printers are complex machines with various mechanical and electrical components. Any failure in these components, such as a broken gear or a faulty motor, can result in printer downtime.

Software Glitches:

Printers are often connected to computers or networks, which means they rely on software to function properly. Software glitches, such as driver issues or compatibility problems, can cause the printer to stop working.

3. The Benefits of Proactive Maintenance

Proactive maintenance is the practice of regularly inspecting, cleaning, and servicing printers to prevent issues before they occur. By implementing proactive maintenance strategies, businesses can experience several benefits, including:

Reduced Downtime:

Regular maintenance helps identify and resolve potential issues before they lead to printer downtime. By addressing these problems proactively, businesses can minimize the impact on productivity.

Extended Printer Lifespan:

Proactive maintenance ensures that printers are kept in optimal condition. Regular cleaning and servicing can help prevent wear and tear, ultimately extending the lifespan of the printer.

Improved Print Quality:

Regular maintenance can also enhance print quality. By cleaning printheads, replacing worn-out parts, and calibrating the printer, businesses can ensure that their prints are of high quality and free from streaks or smudges.

Cost Savings:

Proactive maintenance can help businesses save money in the long run. By preventing major breakdowns, businesses can avoid costly repairs or the need to purchase new printers prematurely.

4. Key Components of Proactive Maintenance

To implement an effective proactive maintenance plan for printers, several key components should be considered:

Regular Cleaning:

Cleaning the printer regularly is essential to remove dust, debris, and ink buildup. This includes cleaning the printheads, paper feed rollers, and other internal components.

Ink and Toner Management:

Monitoring ink and toner levels and ensuring they are replaced before they run out is crucial to avoid downtime. Additionally, using genuine ink and toner cartridges can help prevent issues related to compatibility or print quality.

Software Updates:

Keeping printer drivers and firmware up to date is important to ensure compatibility with other devices and to benefit from any performance or security enhancements provided by the manufacturer.

Component Inspection:

Regularly inspecting the printer’s mechanical and electrical components can help identify any signs of wear or potential failures. This allows for timely repairs or replacements before they cause downtime.

Preventive Repairs:

Addressing minor issues promptly can prevent them from escalating into major problems. This includes replacing worn-out parts, fixing loose connections, and resolving any error codes or warning messages.

Proactive maintenance is essential to avoid printer downtime and maintain productivity in any organization. By understanding the common causes of printer downtime, the benefits of proactive maintenance, and the key components of a maintenance plan, businesses can ensure their printers operate smoothly and efficiently. Implementing a proactive maintenance strategy not only reduces downtime but also extends the lifespan of printers, improves print quality, and ultimately saves costs for the organization.

The Early Days of Printers

In the early days of printers, which dates back to the 19th century, these machines were primitive and required manual operation. Printers were mainly used for publishing newspapers, books, and other printed materials. They were large, cumbersome, and prone to breakdowns, which often resulted in significant downtime.

The Advent of Electric Printers

The advent of electric printers in the early 20th century revolutionized the printing industry. These new machines were faster, more efficient, and required less manual labor. However, they still had their fair share of maintenance issues. Electric printers were complex machines with numerous moving parts that needed regular upkeep to ensure smooth operation.

The Rise of Computerized Printers

The 1970s saw the rise of computerized printers, which marked a significant milestone in the evolution of printing technology. These printers could be connected to computers, allowing for more precise control and automation. Computerized printers greatly enhanced productivity, but they also introduced new challenges in terms of maintenance.

The Emergence of Proactive Maintenance

As printers became more sophisticated, the need for proactive maintenance became apparent. Instead of waiting for a breakdown to occur, companies started implementing regular maintenance schedules to prevent downtime and maximize productivity. This approach involved conducting routine inspections, cleaning, and replacing parts as needed.

The Digital Revolution

The digital revolution of the late 20th century brought about a paradigm shift in the printing industry. Traditional printing methods were gradually replaced by digital printing technologies, which offered faster turnaround times, higher quality prints, and more flexibility. However, digital printers also introduced new challenges in terms of maintenance.

The Importance of Proactive Maintenance in the Digital Age

In today’s digital age, printers have become even more advanced and sophisticated. They are now capable of handling large volumes of print jobs, often operating 24/7. However, with increased complexity comes a higher risk of downtime and reduced productivity. This is where proactive maintenance plays a crucial role.

The Evolution of Proactive Maintenance

Over time, proactive maintenance has evolved from simple routine inspections to more advanced techniques. Companies now utilize predictive maintenance, which involves the use of data analytics and machine learning algorithms to predict when a printer is likely to fail. By analyzing data such as temperature, vibration, and usage patterns, companies can identify potential issues before they cause a breakdown.

The Role of IoT in Maintenance

The Internet of Things (IoT) has also played a significant role in the evolution of printer maintenance. IoT-enabled printers can communicate with maintenance teams, providing real-time data on performance and potential issues. This allows for proactive maintenance to be carried out remotely, reducing the need for on-site visits and minimizing downtime.

The Future of Printer Maintenance

Looking ahead, the future of printer maintenance is likely to be even more automated and data-driven. Artificial intelligence and machine learning algorithms will continue to advance, enabling printers to self-diagnose and self-repair. Predictive maintenance will become even more accurate, minimizing downtime and optimizing productivity.

The historical context of printer maintenance has evolved from the early days of manual operation to the sophisticated, data-driven approaches of the digital age. proactive maintenance has become increasingly important as printers have become more complex and downtime has become more costly. with advancements in technology, such as predictive maintenance and iot, the future of printer maintenance looks promising, with the potential for even greater efficiency and productivity.

Case Study 1: XYZ Company Saves Time and Money with Proactive Maintenance

At XYZ Company, a leading manufacturing firm, the printing department was crucial for the smooth operation of their business. However, frequent breakdowns and unexpected downtime were severely hampering their productivity. The company decided to implement a proactive maintenance strategy to address these issues and keep their printers running smoothly.

The first step was to conduct a thorough assessment of all the printers in the facility. This included checking for any potential issues, such as worn-out parts or outdated software. The maintenance team also developed a preventive maintenance schedule, which included regular cleaning, lubrication, and replacement of parts.

As a result of this proactive maintenance approach, XYZ Company experienced a significant reduction in printer downtime. The preventive maintenance measures helped identify and address potential problems before they escalated into major issues. This not only saved time but also prevented costly repairs or the need to replace entire printers.

Moreover, the proactive maintenance strategy helped improve the overall efficiency of the printing department. With fewer breakdowns and interruptions, the employees were able to complete their printing tasks without delays. This led to increased productivity and higher customer satisfaction.

Case Study 2: ABC Corporation Boosts Printing Quality and Reliability

ABC Corporation, a marketing agency, relied heavily on their printers to produce high-quality promotional materials for their clients. However, they were facing recurring issues with print quality, resulting in dissatisfied customers and wasted resources. To overcome these challenges, the company decided to implement proactive maintenance practices.

The first step was to invest in regular printer calibrations and software updates. This ensured that the printers were always operating at their optimal settings, resulting in consistent print quality. The maintenance team also conducted regular inspections to identify any potential issues, such as clogged ink nozzles or worn-out print heads.

By implementing proactive maintenance, ABC Corporation was able to significantly improve the reliability of their printers. With fewer instances of poor print quality or malfunctioning printers, the company was able to meet their clients’ expectations consistently. This not only enhanced customer satisfaction but also reduced the need for reprints, saving both time and money.

Additionally, the proactive maintenance approach helped ABC Corporation identify opportunities for process improvements. By closely monitoring the printers’ performance, they were able to identify trends and patterns that indicated areas for optimization. This led to the implementation of new printing techniques and workflows, further enhancing the overall efficiency of the printing department.

Case Study 3: DEF University Enhances Print Security and Data Protection

DEF University, a large educational institution, faced a unique challenge related to their printers: print security and data protection. With a high volume of sensitive documents being printed daily, the university needed to ensure that their printers were secure from unauthorized access and data breaches. Proactive maintenance played a crucial role in addressing these concerns.

The university’s IT department implemented regular firmware updates and security patches for their printers. This helped protect against known vulnerabilities and ensured that the printers were equipped with the latest security features. The maintenance team also conducted regular audits to identify any potential security risks and address them promptly.

As a result of this proactive maintenance approach, DEF University was able to enhance the security of their printing environment significantly. The risk of unauthorized access to sensitive documents was minimized, protecting both student and staff information. This helped the university comply with data protection regulations and maintain their reputation as a trusted institution.

Furthermore, the proactive maintenance strategy helped DEF University identify and address potential security gaps in their printing infrastructure. By closely monitoring the printers’ performance and security features, they were able to implement additional measures, such as user authentication and secure printing, to further safeguard their sensitive data.

These case studies highlight the importance of proactive maintenance in avoiding printer downtime and maximizing productivity. by implementing preventive measures and regularly monitoring the printers’ performance, companies and institutions can save time, money, and resources. moreover, proactive maintenance helps improve print quality, reliability, and security, leading to enhanced customer satisfaction and data protection.

FAQs

1. What is proactive maintenance for printers?

Proactive maintenance for printers involves regularly scheduled inspections, cleanings, and repairs to prevent any potential issues before they cause downtime. It helps to identify and address minor problems before they become major ones, ensuring smooth and uninterrupted printer operation.

2. Why is proactive maintenance important for printers?

Proactive maintenance is important for printers because it helps to minimize downtime and maximize productivity. By addressing potential issues before they escalate, businesses can avoid costly repairs, reduce the risk of unexpected breakdowns, and ensure that their printers are always in optimal working condition.

3. How often should printers undergo proactive maintenance?

The frequency of proactive maintenance for printers depends on various factors, such as the printer model, usage patterns, and environmental conditions. However, as a general guideline, it is recommended to schedule proactive maintenance at least once every six months or more frequently for high-volume printers.

4. Can I perform proactive maintenance on my printers myself?

While some basic maintenance tasks, such as cleaning the printer heads or replacing ink cartridges, can be done by users, it is advisable to have a professional technician perform comprehensive proactive maintenance. They have the expertise and tools to identify and address potential issues that may not be apparent to the average user.

5. What are the common signs that indicate my printer needs proactive maintenance?

Some common signs that indicate your printer needs proactive maintenance include frequent paper jams, slow printing speed, poor print quality, error messages, and unusual noises. If you notice any of these issues, it is recommended to schedule proactive maintenance to prevent further problems.

6. How can proactive maintenance prevent printer downtime?

Proactive maintenance can prevent printer downtime by identifying and addressing potential issues before they cause major problems. By regularly inspecting and maintaining printers, technicians can detect and resolve minor issues, such as worn-out parts or clogged ink nozzles, preventing them from escalating into major breakdowns that would require extensive repairs and result in significant downtime.

7. Does proactive maintenance cost more than reactive repairs?

While proactive maintenance does involve some upfront costs, it is generally more cost-effective in the long run compared to reactive repairs. By investing in regular maintenance, businesses can prevent major breakdowns that would require expensive repairs, replacement parts, or even the need to purchase a new printer altogether.

8. Can proactive maintenance extend the lifespan of my printer?

Yes, proactive maintenance can help extend the lifespan of your printer. By addressing potential issues early on and ensuring that all components are in good working condition, proactive maintenance helps to minimize wear and tear, reduce the risk of major breakdowns, and keep the printer functioning optimally for a longer period.

9. Is proactive maintenance only necessary for high-volume printers?

No, proactive maintenance is beneficial for all types of printers, regardless of their volume of use. While high-volume printers may require more frequent maintenance due to their heavy usage, even low-volume printers can benefit from proactive maintenance to ensure optimal performance and prevent unexpected downtime.

10. How can I find a reliable technician for proactive maintenance?

To find a reliable technician for proactive maintenance, you can start by contacting the manufacturer of your printer. They often have authorized service centers or can recommend certified technicians. Additionally, you can seek recommendations from other businesses or check online platforms that provide reviews and ratings for printer maintenance service providers in your area.

Common Misconceptions About Printer Maintenance

Misconception 1: Printer maintenance is not necessary until something goes wrong

Many people believe that printer maintenance is only necessary when a problem arises. However, this misconception can lead to costly downtime and decreased productivity. Regular proactive maintenance is crucial to prevent potential issues and keep your printers running smoothly.

Factual Information:

Printers are complex machines that require regular maintenance to function optimally. Neglecting maintenance can lead to various problems, such as paper jams, poor print quality, and even complete breakdowns. By implementing a proactive maintenance schedule, you can avoid these issues and ensure uninterrupted productivity.

Regular maintenance includes tasks such as cleaning the printer, replacing worn-out parts, and updating firmware and software. These actions help prevent common problems and keep your printer in top condition. Additionally, proactive maintenance allows technicians to identify potential issues before they become major problems, saving you time and money in the long run.

Misconception 2: Printer maintenance is time-consuming and costly

Another common misconception is that printer maintenance is a time-consuming and expensive process. Many businesses avoid scheduling regular maintenance due to these perceived drawbacks. However, this belief is often unfounded and can result in more significant expenses in the long term.

Factual Information:

While printer maintenance does require some time and investment, the benefits far outweigh the costs. Regular maintenance can significantly extend the lifespan of your printer, reducing the need for frequent repairs or replacements. It also minimizes the risk of unexpected breakdowns, which can cause significant disruptions and additional expenses.

Moreover, the time spent on proactive maintenance is relatively small compared to the time lost during downtime caused by printer issues. By dedicating a few hours each month to maintenance, you can avoid hours or even days of productivity loss due to printer malfunctions.

Additionally, many printer manufacturers offer maintenance contracts or service plans that can help manage the costs. These plans often include regular maintenance visits, discounted repair rates, and priority support, making it more affordable and convenient for businesses to keep their printers in optimal condition.

Misconception 3: Printer maintenance can be done by anyone in the office

Some individuals believe that printer maintenance is a simple task that can be assigned to any employee in the office. This misconception often leads to inadequate maintenance or improper handling of printers, which can cause more harm than good.

Factual Information:

Printer maintenance requires specialized knowledge and skills that may not be possessed by every employee. While basic tasks like cleaning the printer or replacing ink cartridges can be performed by non-technical staff, more complex maintenance tasks should be left to trained professionals.

Trained technicians possess the expertise and experience to handle printer maintenance effectively. They can identify potential issues, perform intricate repairs, and ensure that the printer is functioning optimally. Moreover, technicians are familiar with the specific maintenance requirements of different printer models and can tailor their approach accordingly.

By relying on trained professionals for printer maintenance, you can avoid accidental damage, ensure proper handling of sensitive components, and maximize the lifespan of your printers. It is essential to invest in the right expertise to maintain your printers properly and minimize the risk of costly mistakes.

Printer maintenance is a crucial aspect of maintaining productivity and minimizing downtime in any business. By dispelling these misconceptions and understanding the importance of proactive maintenance, you can ensure that your printers operate smoothly, prolong their lifespan, and avoid unexpected disruptions. Regular maintenance, though requiring some investment, is a small price to pay compared to the potential losses caused by neglected printers.

1. Stay organized and develop a maintenance schedule

Keeping track of regular maintenance tasks is essential to avoid downtime. Create a checklist of tasks that need to be performed daily, weekly, monthly, or annually. This could include cleaning, lubricating moving parts, and checking for wear and tear. By staying organized and following a schedule, you can proactively address any potential issues before they become major problems.

2. Invest in high-quality equipment

Purchasing reliable and durable equipment is a crucial step in preventing downtime. While it may be tempting to opt for cheaper options, they often result in frequent breakdowns and increased maintenance costs. Investing in high-quality printers or other machinery can save you time and money in the long run, as they are less likely to experience unexpected failures.

3. Train employees on proper equipment usage

Ensure that your employees are well-trained on how to use the equipment properly. Improper usage can lead to unnecessary wear and tear, increasing the chances of breakdowns. Provide comprehensive training sessions and create user manuals or guides to help employees understand the correct procedures for operating and maintaining the equipment.

4. Regularly clean and maintain equipment

Regular cleaning and maintenance are essential for keeping your equipment in optimal condition. Dust, debris, and ink residue can accumulate over time, leading to clogs, jams, and other issues. Follow the manufacturer’s guidelines for cleaning and maintenance, and make it a routine to clean the equipment thoroughly. This will help extend its lifespan and reduce the likelihood of unexpected downtime.

5. Keep spare parts and supplies on hand

Having spare parts and supplies readily available can significantly reduce downtime. Keep an inventory of commonly needed items such as ink cartridges, belts, or fusers. This way, if a part fails, you can quickly replace it and minimize the impact on productivity. Regularly check your inventory and restock as needed to ensure you have everything on hand when it’s needed.

6. Monitor equipment performance

Keep a close eye on the performance of your equipment. Monitor for any signs of decreased efficiency or unusual noises. By detecting early warning signs, you can address potential issues before they lead to a complete breakdown. Regularly check the equipment’s performance metrics, such as print quality, speed, and error rates, to identify any deviations from the norm.

7. Implement a preventive maintenance program

Consider implementing a preventive maintenance program to proactively address potential issues. This could involve hiring a technician to perform regular inspections and maintenance tasks. Preventive maintenance can help identify and resolve minor problems before they escalate, ensuring that your equipment operates smoothly and minimizing unexpected downtime.

8. Regularly update firmware and software

Manufacturers often release firmware and software updates to improve performance and address known issues. Stay up to date with these updates and regularly install them on your equipment. This will help ensure that your devices are running on the latest software versions, reducing the risk of compatibility issues and improving overall reliability.

9. Establish a backup plan

Even with proactive maintenance, unexpected downtime can still occur. Establishing a backup plan can help mitigate the impact on productivity. This could involve having backup equipment available or establishing alternative processes to continue operations during downtime. By having a plan in place, you can minimize the disruption caused by unexpected equipment failures.

10. Regularly review and optimize maintenance processes

Lastly, regularly review and optimize your maintenance processes. Keep track of the effectiveness of your maintenance efforts and identify areas for improvement. Seek feedback from employees who use the equipment regularly and consider their suggestions for enhancing maintenance procedures. By continuously refining your maintenance processes, you can further reduce the risk of downtime and improve overall productivity.

Remember, proactive maintenance is key to avoiding downtime and maximizing productivity. By following these practical tips, you can ensure that your equipment remains in excellent condition, minimizing unexpected failures and disruptions to your daily operations.

Concept 1: Proactive Maintenance

Proactive maintenance is a strategy used to prevent problems and breakdowns in equipment, such as printers, before they occur. It involves regularly inspecting and servicing the equipment to keep it in good working condition. This approach is different from reactive maintenance, which only fixes issues after they have already caused a breakdown or disruption.

When it comes to printers, proactive maintenance can involve tasks like cleaning the printer heads, replacing worn-out parts, and updating software. By taking these preventive measures, businesses can avoid unexpected downtime and keep their printers running smoothly.

Concept 2: Printer Downtime

Printer downtime refers to the period when a printer is not functioning or available for use. This can happen for various reasons, such as technical issues, mechanical failures, or lack of maintenance. Printer downtime can have a significant impact on productivity, as it disrupts workflow and delays printing tasks.

For example, imagine you’re working in an office, and suddenly the printer stops working. You have an urgent document that needs to be printed, but you can’t do anything until the printer is fixed. This downtime not only affects your productivity but also that of your colleagues who rely on the printer for their work.

Concept 3: Avoiding Downtime with Proactive Maintenance

To avoid printer downtime, businesses can implement proactive maintenance strategies. Here are a few key steps they can take:

Regular Cleaning and Inspection:

Regularly cleaning the printer and inspecting its components can help identify any potential issues before they become major problems. Dust, dirt, and debris can accumulate inside the printer, affecting its performance. By cleaning the printer heads, paper trays, and other parts, businesses can prevent clogs and ensure smooth printing operations.

Replacing Worn-out Parts:

Printers have various components that can wear out over time, such as ink cartridges, rollers, and belts. By regularly checking these parts and replacing them when necessary, businesses can prevent unexpected breakdowns. It’s important to keep track of the printer’s usage and replace parts according to the manufacturer’s recommendations.

Updating Software:

Software updates are essential for keeping printers running efficiently and securely. Manufacturers often release updates that fix bugs, improve performance, and enhance compatibility with new devices. By regularly updating the printer’s software, businesses can ensure optimal functionality and reduce the risk of compatibility issues or security vulnerabilities.

Training and Education:

Providing training and education to employees on how to properly use and maintain printers can also contribute to avoiding downtime. Many printer issues arise from user errors, such as loading paper incorrectly or using the wrong settings. By educating employees on best practices and troubleshooting techniques, businesses can minimize the occurrence of such errors and prevent unnecessary downtime.

Establishing a Maintenance Schedule:

Creating a maintenance schedule can help businesses stay organized and ensure that proactive maintenance tasks are consistently performed. This schedule can include regular cleaning sessions, parts replacement intervals, and software update reminders. By following a maintenance schedule, businesses can stay ahead of potential issues and prevent unexpected printer downtime.

Proactive maintenance is a crucial strategy for avoiding printer downtime and maintaining productivity. by implementing regular cleaning, parts replacement, software updates, employee training, and establishing a maintenance schedule, businesses can keep their printers in optimal condition and minimize disruptions in their workflow.

In today’s fast-paced business world, printer downtime can be a major roadblock to productivity. However, by implementing proactive maintenance strategies, companies can minimize the risk of printer failures and keep their operations running smoothly. This article has highlighted the importance of regular maintenance, the benefits of proactive monitoring, and the role of IT support in ensuring optimal printer performance.

Firstly, regular maintenance is crucial for preventing printer downtime. By scheduling routine check-ups, cleaning, and replacing worn-out parts, businesses can identify and address potential issues before they escalate into major problems. This not only reduces the risk of unexpected breakdowns but also extends the lifespan of printers, saving companies the cost of frequent replacements.

Secondly, proactive monitoring plays a significant role in avoiding printer downtime. By utilizing advanced software and network monitoring tools, IT teams can keep a close eye on printer performance, identify patterns of usage, and detect any signs of impending failures. This allows for timely interventions, such as firmware updates or replacing consumables, ensuring uninterrupted printing operations.

Lastly, having a reliable IT support system in place is essential for maintaining printer productivity. IT professionals can provide expert advice on choosing the right printers for specific business needs, as well as offer ongoing assistance in troubleshooting and resolving technical issues. By partnering with a trusted IT support provider, companies can rest assured that their printers will receive the necessary attention and care, minimizing the risk of downtime and maximizing productivity.

In conclusion, proactive maintenance is the key to avoiding printer downtime and boosting productivity. By investing in regular maintenance, leveraging proactive monitoring tools, and partnering with IT support, businesses can ensure that their printers operate at peak performance, enabling seamless operations and driving business success.