Revolutionizing Healthcare: The Transformative Power of Specialized 3D Printing

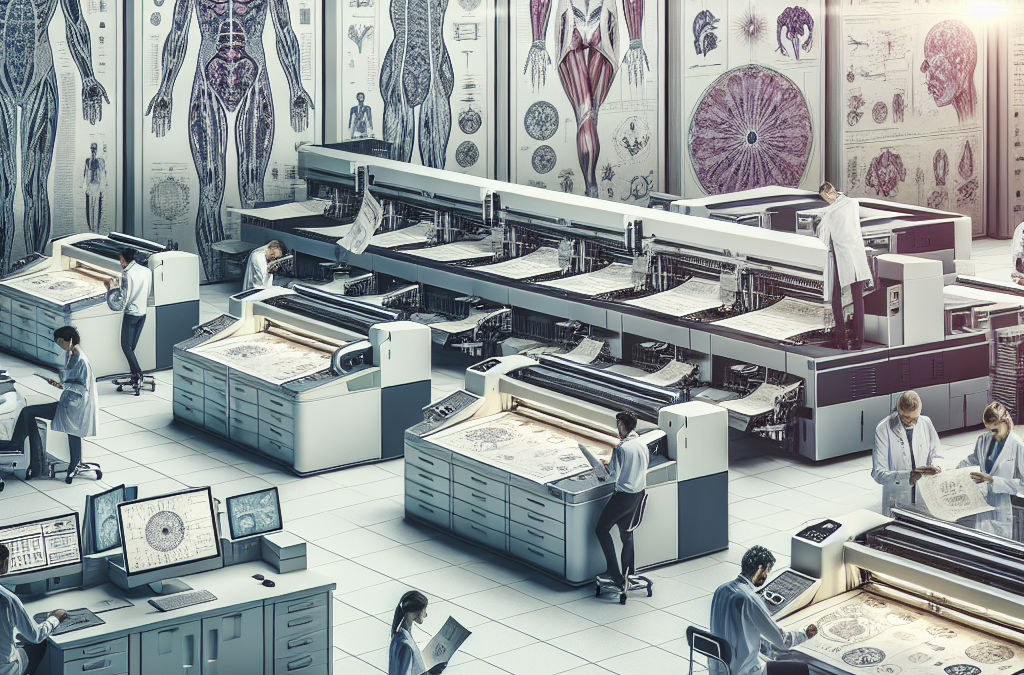

In today’s rapidly advancing world, technology continues to revolutionize various industries, and the healthcare sector is no exception. One area where innovation is making a significant impact is in printing for specialized industries, specifically in healthcare and medical applications. From 3D printing of prosthetics to customized drug dosage forms, the possibilities seem endless. This article explores the diverse applications of printing technology in the healthcare sector, highlighting its potential to improve patient care, enhance medical research, and revolutionize the way healthcare professionals approach treatment.

Printing technology has come a long way from traditional ink on paper. In recent years, it has evolved into a powerful tool for healthcare professionals, enabling them to create personalized medical solutions. From the production of anatomical models for surgical planning to the development of customized implants, 3D printing has revolutionized the field of medical device manufacturing. Additionally, printing technology is being utilized in the creation of drug delivery systems, allowing for precise dosage forms tailored to individual patients’ needs. Furthermore, printing has found its way into the world of regenerative medicine, with the ability to create tissue and organ scaffolds, offering hope for patients in need of transplants. This article delves into the various applications of printing technology in healthcare, shedding light on its potential to transform the industry and improve patient outcomes.

Key Takeaways

1. The use of 3D printing in healthcare and medical applications is revolutionizing the industry by providing customized solutions and improving patient care. From prosthetics to surgical models, 3D printing is enabling personalized healthcare like never before.

2. 3D printing allows for the creation of complex and intricate medical devices that were previously impossible to manufacture. This technology enables the production of lightweight, durable, and patient-specific implants, leading to better outcomes and reduced recovery times.

3. The ability to print pharmaceuticals on-demand has the potential to transform the way medications are produced and distributed. This technology can ensure precise dosages, reduce waste, and provide personalized medicine tailored to individual patients.

4. The integration of 3D printing with other advanced technologies, such as artificial intelligence and bioprinting, holds great promise for the future of healthcare. These advancements have the potential to revolutionize tissue engineering, drug discovery, and even organ transplantation.

5. Despite the numerous benefits, challenges still exist in the widespread adoption of 3D printing in healthcare. Regulatory hurdles, cost considerations, and the need for specialized expertise are some of the barriers that need to be overcome. However, as the technology continues to evolve and become more accessible, its impact on healthcare will only continue to grow.

The Controversial Aspects of

1. Ethics and Privacy Concerns

One of the most controversial aspects of printing for healthcare and medical applications is the ethical and privacy concerns that arise. With the advancement of 3D printing technology, it is now possible to print various medical devices, prosthetics, and even human tissue. While this innovation brings great potential for improving patient care and quality of life, it also raises important questions about patient privacy and the potential misuse of printed medical devices.

Privacy concerns arise when it comes to the storage and handling of patient data used in the printing process. Medical files and imaging data are often required to create personalized medical devices or replicas of body parts. Ensuring the security of this sensitive information becomes crucial to protect patient privacy. There is a risk that unauthorized access or hacking could lead to the misuse of personal health information.

Moreover, the production of medical devices through 3D printing introduces the possibility of counterfeit or substandard products entering the market. While regulations and quality control measures exist, the decentralized nature of 3D printing makes it difficult to monitor and regulate the production of these devices effectively. This raises concerns about the safety and efficacy of printed medical devices, potentially putting patients at risk.

On the other hand, proponents argue that the benefits of 3D printing in healthcare outweigh the potential risks. The ability to create customized medical devices and implants can significantly improve patient outcomes and reduce the need for invasive surgeries. Additionally, 3D printing allows for faster production and lower costs, making healthcare more accessible to underserved populations.

2. Intellectual Property and Patent Issues

Another controversial aspect of printing for specialized industries, particularly in healthcare, is the issue of intellectual property and patents. 3D printing enables the replication of existing products and designs, raising concerns about copyright infringement and the protection of intellectual property rights.

When it comes to medical devices, companies invest significant resources in research and development to create innovative solutions. However, with 3D printing, it becomes easier for individuals or other companies to replicate these devices without proper authorization. This poses a challenge for the protection of intellectual property rights and may discourage companies from investing in new technologies and innovations.

On the other hand, some argue that 3D printing can foster innovation by allowing for the rapid prototyping and customization of medical devices. It can empower healthcare professionals and researchers to create unique solutions tailored to individual patient needs. By sharing designs and collaborating, the medical community can collectively advance healthcare technology and improve patient care.

3. Regulatory Challenges and Standardization

The third controversial aspect of printing for specialized industries, particularly in healthcare, is the regulatory challenges and the lack of standardization in the field. As 3D printing continues to advance, regulatory bodies struggle to keep up with the pace of innovation, leading to potential gaps in oversight and quality control.

Unlike traditional manufacturing processes, 3D printing allows for decentralized production, which makes it challenging to regulate and ensure consistent quality across different facilities. This lack of standardization can lead to variations in the safety and efficacy of printed medical devices, potentially compromising patient health.

Furthermore, the classification and certification of 3D printed medical devices pose challenges for regulatory bodies. Determining the appropriate regulatory pathway for these devices is complex, as they often straddle multiple categories. This can result in delays in market approval and hinder the adoption of innovative technologies.

However, proponents argue that the regulatory challenges should not overshadow the potential benefits of 3D printing in healthcare. They believe that a balance can be struck between innovation and regulation by establishing clear guidelines and standards for the design, production, and testing of 3D printed medical devices.

While printing for specialized industries, particularly in healthcare and medical applications, brings forth great potential, it also raises controversial aspects that need careful consideration. Ethical and privacy concerns, intellectual property issues, and regulatory challenges are all valid points of contention. However, with effective regulation, collaboration between stakeholders, and a focus on patient safety, the benefits of 3D printing in healthcare can be maximized while minimizing the potential risks.

Insight 1: Advancements in 3D printing revolutionize healthcare and medical applications

One key insight into the impact of printing for specialized industries, particularly in healthcare and medical applications, is the significant advancements in 3D printing technology. 3D printing, also known as additive manufacturing, has transformed the way medical devices, prosthetics, and even human tissues are produced.

Traditionally, manufacturing medical devices and prosthetics required complex and time-consuming processes. However, with the advent of 3D printing, healthcare providers can now create customized and patient-specific solutions quickly and efficiently. This technology allows for the production of intricate designs and complex geometries that were previously impossible or extremely challenging to achieve.

For example, 3D printing has revolutionized the production of prosthetic limbs. By scanning a patient’s residual limb and using computer-aided design (CAD) software, healthcare professionals can create personalized prosthetics that perfectly fit the individual’s unique anatomy. This not only improves comfort and functionality but also enhances the overall quality of life for amputees.

Furthermore, 3D printing has also found applications in the production of medical implants. By using biocompatible materials, such as titanium or polymer composites, surgeons can now create patient-specific implants that seamlessly integrate with the recipient’s body. This personalized approach reduces the risk of complications, improves surgical outcomes, and shortens recovery times.

Insight 2: 3D bioprinting opens new possibilities in tissue engineering and regenerative medicine

Another significant impact of printing for specialized industries in healthcare and medical applications is the emergence of 3D bioprinting. This cutting-edge technology allows for the fabrication of living tissues and organs, providing hope for patients in need of transplants and regenerative therapies.

Traditionally, organ transplantation relies on the availability of donor organs, which are often scarce. However, with 3D bioprinting, researchers can now create functional tissues and organs using a patient’s own cells. This eliminates the need for immunosuppressive drugs and reduces the risk of rejection, making transplants safer and more accessible.

3D bioprinting works by depositing bioinks, which are composed of living cells and supportive biomaterials, layer by layer to construct complex 3D structures. These bioinks can be derived from various sources, including stem cells, allowing for the creation of patient-specific tissues and organs.

The potential applications of 3D bioprinting are vast. It can be used to create skin grafts for burn victims, cartilage implants for joint repair, and even functional organs such as kidneys and hearts. While the technology is still in its early stages, ongoing research and development hold promise for a future where organ shortages are no longer a barrier to healthcare.

Insight 3: 3D printing enables the production of personalized pharmaceuticals

Printing for specialized industries has also had a profound impact on the pharmaceutical sector, with the emergence of personalized medicine through 3D printing. This technology allows for the precise fabrication of dosage forms tailored to an individual’s specific needs, revolutionizing drug delivery and patient care.

Traditional pharmaceutical manufacturing relies on mass production of standardized medications. However, this one-size-fits-all approach may not be suitable for all patients, as factors such as age, weight, and metabolism can influence drug efficacy and safety. With 3D printing, pharmaceutical companies can now produce personalized medications with precise dosages and release profiles.

For example, patients who have difficulty swallowing large tablets can benefit from 3D-printed medications in smaller, easier-to-swallow forms. Additionally, pediatric patients may require lower dosages than adults, and 3D printing enables the production of child-friendly formulations with accurate dosing.

Moreover, 3D printing allows for the incorporation of multiple drugs into a single dosage form, creating personalized combination therapies. This can be particularly beneficial for patients with complex medical conditions who require multiple medications, as it simplifies their medication regimen and improves adherence.

Overall, 3D printing in the pharmaceutical industry has the potential to enhance patient outcomes, improve medication adherence, and reduce adverse effects. As the technology continues to evolve, personalized medicine through 3D printing is expected to become more widespread, transforming the way medications are manufactured and administered.

The Role of 3D Printing in Healthcare

3D printing, also known as additive manufacturing, has revolutionized various industries, and healthcare is no exception. The ability to create complex three-dimensional objects layer by layer has opened up new possibilities for personalized medical treatments, surgical planning, and the production of medical devices. One of the key advantages of 3D printing in healthcare is its ability to create patient-specific models, implants, and prosthetics. For example, surgeons can now use 3D-printed models of a patient’s anatomy to plan complex surgeries and practice procedures before operating on the actual patient. This not only enhances surgical precision but also reduces the risk of complications.

Customized Medical Devices and Implants

Printing technology has made it possible to create customized medical devices and implants that perfectly fit an individual patient’s needs. Traditional manufacturing techniques often involve mass production of standardized devices, which may not provide an optimal fit for every patient. 3D printing allows for the production of patient-specific implants and devices, ensuring a better fit and improved patient outcomes. For example, in dentistry, 3D printing enables the creation of custom dental implants that match the exact shape and size of a patient’s missing tooth. This not only improves the aesthetics but also enhances comfort and functionality.

Biofabrication and Tissue Engineering

One of the most exciting applications of 3D printing in healthcare is in the field of biofabrication and tissue engineering. Researchers are exploring the possibility of using 3D printing technology to create functional human tissues and organs. By layering bioinks containing living cells, scientists can create complex structures that mimic the natural architecture of tissues and organs. This has the potential to revolutionize organ transplantation by eliminating the need for donors and reducing the risk of rejection. While the technology is still in its early stages, researchers have already successfully 3D-printed tissues such as skin, cartilage, and blood vessels, bringing us closer to the era of regenerative medicine.

Pharmaceuticals and Drug Delivery Systems

Printing technology is not limited to physical objects but also extends to the production of medications and drug delivery systems. 3D printing allows for the precise formulation of drugs, enabling personalized dosages and combinations. This is particularly beneficial for patients who require customized medications due to factors such as allergies, age, or specific medical conditions. Additionally, 3D printing can be used to create drug delivery systems, such as implants or patches, that release medication in a controlled manner. This technology has the potential to improve patient compliance, reduce side effects, and enhance treatment efficacy.

Challenges and Future Directions

While the applications of 3D printing in healthcare are promising, there are still challenges to overcome before widespread adoption can occur. One of the main challenges is the regulatory framework surrounding 3D-printed medical devices and medications. As the technology evolves, regulatory bodies need to establish guidelines and standards to ensure the safety and efficacy of these products. Another challenge is the cost-effectiveness of 3D printing in healthcare. While the technology has the potential to reduce costs in the long run, the initial investment and materials can be expensive. However, as the technology advances and becomes more widely adopted, the costs are expected to decrease.

Case Study: 3D-Printed Prosthetics

A notable example of 3D printing in healthcare is the production of prosthetic limbs. Traditional prosthetics are often expensive and may not provide the desired functionality or comfort. 3D printing has revolutionized the field by allowing for the production of affordable, customizable prosthetics. Organizations like e-NABLE have developed open-source designs that can be 3D printed and assembled locally, making prosthetics accessible to individuals in need around the world. This technology has not only improved the quality of life for many but has also highlighted the potential of 3D printing in healthcare.

Printing technology has opened up new possibilities in healthcare, from personalized medical treatments to the production of customized devices and implants. 3D printing has the potential to revolutionize surgical planning, tissue engineering, pharmaceuticals, and prosthetics. While there are challenges to overcome, such as regulation and cost, the future of printing in specialized industries like healthcare looks promising. As the technology continues to advance, we can expect more innovative applications and improved patient outcomes.

Case Study 1: 3D Printing Revolutionizes Prosthetics in Pediatric Healthcare

In the field of healthcare, 3D printing has emerged as a game-changer, particularly in the development of prosthetics. One remarkable case study that showcases the power of this technology is the story of a young girl named Emma.

Emma was born with a rare condition called arthrogryposis, which severely affected the development of her arms. Traditional prosthetics were not suitable for her, as they were expensive, uncomfortable, and did not provide the flexibility she needed. However, thanks to 3D printing, Emma’s life took a remarkable turn.

Using a combination of 3D scanning and printing technologies, a team of engineers and doctors were able to create customized prosthetic arms specifically tailored to Emma’s unique needs. The 3D-printed prosthetics were not only lightweight and affordable but also allowed Emma to move her arms with greater freedom and dexterity.

Emma’s case demonstrates how 3D printing has the potential to transform the field of healthcare, particularly in providing personalized solutions for patients with specialized needs. It highlights the ability of this technology to improve the quality of life for individuals, especially in pediatric healthcare.

Case Study 2: 3D-Printed Organs Pave the Way for Advancements in Transplantation

Another groundbreaking application of printing in the healthcare industry is the development of 3D-printed organs. This technology has the potential to revolutionize organ transplantation, addressing the critical shortage of donor organs and saving countless lives.

A notable success story in this field is the case of a patient named Tom, who was suffering from end-stage renal disease and urgently needed a kidney transplant. However, finding a suitable donor was proving to be a significant challenge. Fortunately, Tom’s doctors turned to 3D printing as a solution.

Using Tom’s own cells, a 3D-printed kidney was created, replicating the intricate structure and functionality of a real organ. This personalized approach eliminated the need for a donor and reduced the risk of rejection. The 3D-printed kidney was successfully transplanted into Tom’s body, restoring his kidney function and improving his overall health.

This case study exemplifies how 3D printing can revolutionize organ transplantation by providing a viable alternative to traditional donor organs. It showcases the potential of this technology to address the global organ shortage crisis and offer hope to patients who are in dire need of life-saving transplants.

Case Study 3: Customized Medications with 3D-Printed Pills

Printing technology has also made significant strides in the pharmaceutical industry, particularly in the production of personalized medications. One remarkable success story in this field is the development of 3D-printed pills.

A patient named Sarah suffered from a rare medical condition that required her to take multiple medications in precise dosages. However, the available commercial medications did not meet her specific requirements, leading to suboptimal treatment outcomes. This is where 3D printing stepped in.

Using 3D printing technology, Sarah’s doctors were able to create customized pills tailored to her exact dosage needs. The 3D-printed pills were designed to release the medication at specific intervals, ensuring optimal absorption and effectiveness. This personalized approach significantly improved Sarah’s treatment outcomes and quality of life.

This case study highlights the potential of 3D printing in the pharmaceutical industry, particularly in the production of customized medications. It demonstrates how this technology can enhance patient care by providing tailored solutions that meet individual needs and improve treatment outcomes.

FAQs

1. What are the benefits of printing for healthcare and medical applications?

Printing for healthcare and medical applications offers several benefits, including improved patient care, increased efficiency, and cost savings. It allows for the production of customized medical devices, prosthetics, and implants, as well as personalized medication dosages. Printing also enables the creation of anatomical models for surgical planning and training, reducing the risk and improving the success rate of complex procedures.

2. What types of materials can be used in printing for healthcare and medical applications?

A wide range of materials can be used in printing for healthcare and medical applications, including biocompatible polymers, metals, ceramics, and even living cells. These materials are specifically designed to meet the stringent requirements of medical use, such as biocompatibility, sterilization, and durability.

3. How is 3D printing used in healthcare and medical applications?

3D printing is used in healthcare and medical applications for various purposes. It allows for the creation of patient-specific anatomical models, surgical guides, and implants. It also enables the production of customized medical devices, such as hearing aids and prosthetics. Additionally, 3D printing is used in tissue engineering and regenerative medicine to create living tissues and organs.

4. What are the challenges of printing for healthcare and medical applications?

Printing for healthcare and medical applications faces several challenges, including regulatory compliance, quality control, and scalability. Medical devices and materials must meet strict regulatory standards to ensure patient safety. Quality control is essential to ensure the accuracy and reliability of printed products. Scaling up production to meet the demands of the healthcare industry can also be a challenge.

5. How does printing for healthcare and medical applications impact patient care?

Printing for healthcare and medical applications has a significant impact on patient care. It allows for personalized treatment plans, tailored medical devices, and improved surgical outcomes. The ability to create patient-specific anatomical models and surgical guides enhances surgical precision and reduces the risk of complications. It also enables the development of innovative solutions for complex medical conditions.

6. Can printing for healthcare and medical applications reduce healthcare costs?

Yes, printing for healthcare and medical applications has the potential to reduce healthcare costs in several ways. Customized medical devices and implants can eliminate the need for multiple surgeries or adjustments, resulting in cost savings. Personalized medication dosages can improve treatment efficacy and reduce medication waste. Additionally, 3D printing can streamline the supply chain for medical devices, reducing inventory costs.

7. Is printing for healthcare and medical applications widely adopted?

Printing for healthcare and medical applications is gaining traction but is not yet widely adopted. While the technology has shown great promise, there are still challenges to overcome, including regulatory hurdles, cost considerations, and the need for further research and development. However, the potential benefits are driving increased interest and investment in this field.

8. What are the future prospects of printing for healthcare and medical applications?

The future prospects of printing for healthcare and medical applications are promising. Advancements in technology and materials will continue to expand the possibilities for personalized medicine, regenerative therapies, and surgical interventions. As the technology becomes more accessible and cost-effective, we can expect to see wider adoption and integration of printing in healthcare and medical practices.

9. Are there any ethical considerations associated with printing for healthcare and medical applications?

Yes, there are ethical considerations associated with printing for healthcare and medical applications. These include issues related to patient privacy, informed consent, and the equitable distribution of medical resources. As the technology evolves, it is crucial to address these ethical concerns to ensure that printing in healthcare is used responsibly and for the benefit of all patients.

10. How can healthcare providers and medical professionals incorporate printing into their practices?

Healthcare providers and medical professionals can incorporate printing into their practices by collaborating with experts in the field, investing in the necessary equipment and training, and staying updated on the latest advancements. They can explore partnerships with 3D printing companies, research institutions, and regulatory bodies to ensure compliance and access to cutting-edge technologies. By embracing printing, healthcare providers can enhance patient care and stay at the forefront of medical innovation.

Common Misconceptions about

Misconception 1: 3D printing is not suitable for medical applications

One common misconception about printing for specialized industries, particularly healthcare and medical applications, is that 3D printing is not suitable for these fields. However, this is far from the truth. In fact, 3D printing has revolutionized the healthcare industry in numerous ways.

One of the most significant advantages of 3D printing in healthcare is the ability to create customized medical devices and implants. Traditional manufacturing methods often struggle to meet the unique needs of patients, resulting in generic solutions that may not be the most effective. With 3D printing, healthcare professionals can design and produce patient-specific implants, prosthetics, and surgical instruments that fit perfectly and improve patient outcomes.

Furthermore, 3D printing allows for the rapid prototyping of medical devices, enabling healthcare professionals to test and refine their designs before mass production. This iterative process helps to identify and address any flaws or limitations in the early stages, resulting in safer and more effective medical devices.

Additionally, 3D printing has been instrumental in creating anatomical models for surgical planning and medical education. Surgeons can now have accurate replicas of a patient’s anatomy, allowing them to practice complex procedures and develop personalized surgical strategies. This technology has proven particularly useful in complex cases, such as organ transplants or intricate surgeries.

Misconception 2: 3D printing in healthcare is limited to creating simple objects

Another misconception is that 3D printing in healthcare is limited to creating simple objects. While it is true that 3D printers can produce basic items like surgical instruments or patient-specific models, the capabilities of this technology extend far beyond that.

One area where 3D printing has made significant advancements is in the production of complex medical devices. For example, researchers have successfully 3D printed functional organs and tissues using bioinks and living cells. This breakthrough has the potential to revolutionize organ transplantation and eliminate the need for organ donors.

Furthermore, 3D printing has enabled the creation of intricate drug delivery systems. By precisely controlling the structure and composition of the printed objects, researchers can develop personalized drug delivery systems tailored to an individual’s specific needs. This level of customization and control has the potential to improve medication efficacy and reduce side effects.

Moreover, 3D printing has been used to fabricate microfluidic devices, which are essential in various medical applications, including drug testing and diagnostics. These devices allow for the manipulation of small amounts of fluids and can be customized to perform specific functions, such as analyzing blood samples or detecting diseases.

Misconception 3: 3D printing in healthcare is not cost-effective

A common misconception surrounding 3D printing in healthcare is that it is not cost-effective. While it is true that the initial investment in 3D printing technology can be significant, the long-term benefits outweigh the costs.

One of the primary cost-saving advantages of 3D printing in healthcare is the ability to produce customized medical devices on-demand. Traditional manufacturing methods often require large-scale production runs, resulting in excess inventory and wasted resources. With 3D printing, healthcare facilities can produce medical devices as needed, reducing inventory costs and minimizing waste.

Additionally, 3D printing can significantly reduce the lead time for producing medical devices. In emergency situations or when a patient requires immediate intervention, waiting for a device to be manufactured and shipped can be a matter of life and death. 3D printing allows for rapid production, ensuring that patients receive the necessary treatment without delays.

Moreover, 3D printing can also reduce the costs associated with surgical planning and medical education. Anatomical models created through 3D printing are often more cost-effective than traditional methods, such as cadaveric dissection or using plastic models. These models can be produced quickly and at a fraction of the cost, making them more accessible for medical training and surgical preparation.

It is essential to dispel common misconceptions surrounding printing for specialized industries, particularly healthcare and medical applications. 3D printing has proven to be highly suitable for these fields, enabling the production of customized medical devices, complex objects, and cost-effective solutions. As technology continues to advance, the possibilities for 3D printing in healthcare are only expected to expand, leading to improved patient care and outcomes.

1. Stay informed about the latest advancements in healthcare printing

It is crucial to stay updated on the latest developments and advancements in healthcare printing. Subscribe to industry magazines, follow relevant websites and blogs, and attend conferences and trade shows to keep yourself informed about the latest technologies and applications in healthcare printing.

2. Understand the specific needs of healthcare and medical industries

Healthcare and medical industries have unique requirements when it comes to printing. Understand the specific needs and challenges faced by these industries, such as the need for accurate labeling, patient identification, and medical device manufacturing. This knowledge will help you tailor your printing solutions to meet these specific needs.

3. Choose the right printing technology

There are various printing technologies available for healthcare and medical applications, including inkjet, laser, and 3D printing. Each technology has its strengths and limitations. Research and choose the right printing technology based on your specific application requirements, such as printing medical devices, prosthetics, or pharmaceutical packaging.

4. Ensure compliance with regulatory standards

Healthcare and medical industries are highly regulated, and compliance with regulatory standards is of utmost importance. Familiarize yourself with the relevant regulations, such as FDA guidelines, and ensure that your printing processes and materials comply with these standards. This will help you avoid legal issues and ensure the safety and efficacy of printed healthcare products.

5. Collaborate with healthcare professionals and experts

Collaboration with healthcare professionals and experts is essential to understand their specific needs and challenges. Engage in discussions and seek feedback from doctors, nurses, medical researchers, and other healthcare professionals to gain insights into how your printing solutions can better serve their needs. This collaboration will help you develop innovative and effective printing solutions for the healthcare industry.

6. Invest in quality control and testing

Quality control and testing are critical in healthcare printing to ensure the accuracy, reliability, and safety of printed products. Implement stringent quality control measures and regularly test your printing processes and materials to identify any potential issues or defects. This will help you maintain high-quality standards and build trust with your clients in the healthcare industry.

7. Explore the potential of 3D printing

3D printing has revolutionized healthcare by enabling the production of customized medical devices, implants, and prosthetics. Explore the potential of 3D printing in healthcare and medical applications. Consider investing in 3D printing technology and collaborate with medical professionals to develop innovative solutions that can significantly improve patient care and outcomes.

8. Embrace sustainability in healthcare printing

Sustainability is a growing concern in all industries, including healthcare. Look for ways to minimize waste, reduce energy consumption, and use eco-friendly materials in your printing processes. This will not only help protect the environment but also improve the overall sustainability of the healthcare industry.

9. Develop strong partnerships with suppliers

Building strong partnerships with reliable suppliers is crucial in healthcare printing. Identify suppliers who specialize in providing materials and equipment for healthcare and medical applications. Establish long-term relationships with them to ensure a steady supply of high-quality materials and access to the latest printing technologies.

10. Continuously innovate and adapt

Lastly, healthcare and medical industries are constantly evolving, and so should your printing solutions. Continuously innovate and adapt to stay ahead of the curve. Keep exploring new technologies, materials, and applications to provide cutting-edge printing solutions that meet the changing needs of the healthcare industry.

Conclusion

Printing technology has revolutionized healthcare and medical applications, providing numerous benefits and advancements in the industry. The ability to 3D print medical devices, prosthetics, and implants has significantly improved patient care and treatment options. This technology allows for customization and personalization, ensuring a better fit and function for patients.

Additionally, printing has played a crucial role in pharmaceuticals, enabling the production of personalized medications and drug delivery systems. This has the potential to enhance treatment outcomes and reduce adverse effects. Furthermore, the use of printing in healthcare has facilitated the development of anatomical models and surgical guides, aiding in preoperative planning and improving surgical precision.

Overall, printing for specialized industries in healthcare and medical applications has proven to be a game-changer. It has opened up new possibilities for personalized care, improved treatment options, and enhanced patient outcomes. As technology continues to advance, we can expect even more innovative uses of printing in the medical field, ultimately shaping the future of healthcare.