Revolutionizing the Office: How 4D Printing Is Transforming Paper Handling and Personalized Media Support

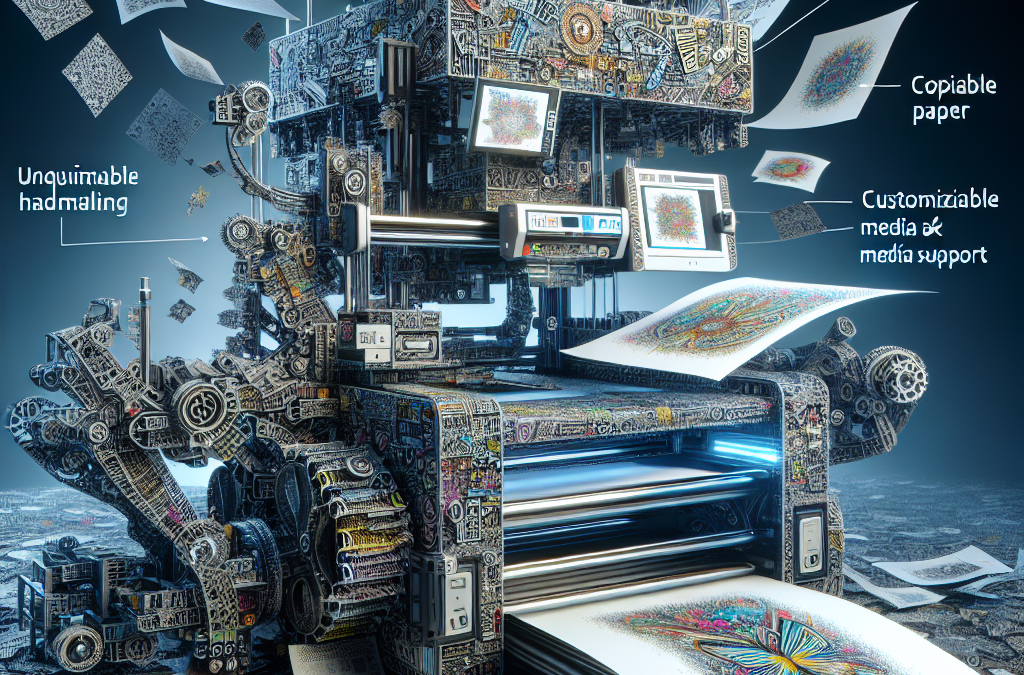

In recent years, 3D printing has revolutionized the manufacturing industry, allowing for the creation of complex three-dimensional objects with ease. However, a new technology called 4D printing is now emerging, promising to take customization and functionality to a whole new level. This cutting-edge process enables objects to not only be printed in three dimensions but also to transform and adapt their shape over time. While 4D printing has already made waves in various industries, its potential impact on copier paper handling and customizable media support is a topic that has received little attention.

In this article, we will delve into the fascinating world of 4D printing and explore how it may revolutionize copier paper handling and customizable media support. We will examine how this technology works, its current applications in other fields, and the potential benefits it could bring to the paper industry. Additionally, we will discuss the challenges and limitations that need to be overcome for 4D printing to become a mainstream solution for paper handling and media customization. By the end, readers will gain a comprehensive understanding of the potential impact of 4D printing on copier paper handling and customizable media support, and the implications it may have for various industries.

Key Takeaways:

1. Enhanced paper handling capabilities: 4D printing technology has the potential to revolutionize copier paper handling by allowing for dynamic and customizable media support. This means that copiers can adapt to different paper sizes, weights, and textures, providing users with more flexibility and convenience.

2. Personalized media support: With 4D printing, copiers can be programmed to handle a wide range of customizable media, such as specialized papers, labels, and even 3D objects. This opens up new possibilities for businesses and individuals to create unique and personalized prints, enhancing their branding and creative capabilities.

3. Improved efficiency and productivity: By automating paper handling processes, 4D printing can significantly improve the efficiency and productivity of copiers. With the ability to automatically adjust settings and handle different media types, copiers can save time and reduce errors, allowing users to focus on more important tasks.

4. Cost savings and waste reduction: The customizable nature of 4D printing enables copiers to optimize paper usage, reducing waste and saving costs. Copiers can automatically adjust print settings based on the media being used, minimizing the need for manual adjustments and reducing the risk of misprints.

5. Future implications and potential applications: The impact of 4D printing on copier paper handling goes beyond the present capabilities. As the technology continues to evolve, it could enable copiers to handle even more complex media, such as flexible displays and smart materials. This opens up possibilities for new applications in various industries, including advertising, packaging, and healthcare.

Controversial Aspect 1: Environmental Concerns

One of the most controversial aspects of the impact of 4D printing on copier paper handling and customizable media support is the potential environmental impact. While 4D printing offers exciting possibilities for creating customizable media and reducing paper waste, it also raises concerns about the increased consumption of resources.

Proponents argue that 4D printing can significantly reduce paper waste by enabling the creation of reusable and customizable media. Traditional copier paper often ends up in landfills after a single use, but with 4D printing, it becomes possible to create dynamic media that can be used multiple times, reducing the overall demand for paper.

However, critics point out that 4D printing requires the use of additional materials, such as specialized inks and substrates, which may have their own environmental consequences. The production and disposal of these materials could potentially offset any gains made in reducing paper waste.

Furthermore, 4D printing technology is still in its early stages, and its long-term environmental impact is uncertain. As the technology evolves and becomes more widely adopted, it will be crucial to carefully consider its environmental implications and develop sustainable practices to mitigate any negative effects.

Controversial Aspect 2: Accessibility and Affordability

Another controversial aspect of the impact of 4D printing on copier paper handling and customizable media support is its potential impact on accessibility and affordability. While 4D printing offers exciting possibilities for customization and personalization, it may also exacerbate existing inequalities in access to technology.

Proponents argue that 4D printing can democratize media production, allowing individuals and small businesses to create customized media without relying on large printing facilities. This could empower individuals to express their creativity and bring their ideas to life, potentially benefiting artists, designers, and entrepreneurs.

However, critics raise concerns about the cost and accessibility of 4D printing technology. Currently, 4D printers and the necessary materials can be expensive, making them inaccessible to many individuals and small businesses. This could further widen the gap between those who can afford the technology and those who cannot, limiting the potential benefits of customization and personalization.

Additionally, the learning curve associated with 4D printing may pose a barrier for some individuals, particularly those with limited technical skills or resources. Without adequate training and support, the full potential of 4D printing may not be realized by all segments of society.

Controversial Aspect 3: Intellectual Property and Copyright Issues

Intellectual property and copyright issues are another controversial aspect of the impact of 4D printing on copier paper handling and customizable media support. The ability to easily create customized media raises concerns about the potential infringement of intellectual property rights.

Proponents argue that 4D printing can encourage creativity and innovation by allowing individuals to easily customize media for personal use. They believe that this can lead to a more dynamic and diverse media landscape, fostering new ideas and expressions.

However, critics express concerns about the potential misuse of 4D printing technology. The ease with which media can be customized raises the risk of copyright infringement, as individuals may reproduce copyrighted material without proper authorization. This could have significant implications for artists, authors, and other content creators who rely on intellectual property rights for their livelihood.

Addressing these concerns will require a balance between enabling creative expression and protecting intellectual property rights. Implementing robust mechanisms for copyright enforcement and educating users about the importance of respecting intellectual property will be essential to ensure the responsible use of 4D printing technology.

The Integration of 4D Printing in Copier Paper Handling

One of the key insights into the impact of 4D printing on copier paper handling is the potential for enhanced efficiency and productivity in the industry. Traditional copiers require manual paper loading and handling, which can be time-consuming and prone to errors. However, with the integration of 4D printing technology, copiers can be equipped with sensors and actuators that enable automated paper handling.

These sensors can detect the size, weight, and type of paper being used, allowing the copier to adjust its settings accordingly. For example, if a user wants to print on a different paper size, the copier can automatically adjust the paper tray and settings to accommodate the new size. This eliminates the need for manual adjustments and reduces the risk of paper jams or misprints.

Furthermore, 4D printing enables copiers to have customizable paper handling features. By using shape-memory materials, the copier can create temporary structures such as paper trays, guides, or holders that adapt to the specific needs of the user. This means that copiers can easily switch between different paper sizes, orientations, or even specialty media such as envelopes or labels without requiring any additional manual adjustments.

The Advantages of Customizable Media Support

Another significant impact of 4D printing on copier technology is the ability to support a wide range of customizable media. Traditional copiers are limited to printing on standard paper sizes and types, which can be restrictive for users with specific printing needs. However, with 4D printing, copiers can be designed to support a variety of media types, including unconventional shapes, textures, and materials.

For instance, copiers can be programmed to print on textured paper or even three-dimensional objects such as embossed cards or packaging materials. This opens up new possibilities for creative printing applications, such as personalized greeting cards, marketing materials, or product packaging. By offering customizable media support, copiers equipped with 4D printing technology can cater to a broader range of user preferences and requirements.

Moreover, the ability to print on customizable media can also have practical applications in industries such as healthcare or manufacturing. For example, copiers with 4D printing capabilities can be used to create custom labels for medical samples or equipment, ensuring accurate identification and traceability. In manufacturing, copiers can print directly on specialized materials or components, eliminating the need for separate labeling or marking processes.

The Implications for the Copier Industry

The integration of 4D printing in copier technology has significant implications for the industry as a whole. Firstly, it presents an opportunity for copier manufacturers to differentiate their products in a competitive market. By offering advanced features such as automated paper handling and customizable media support, manufacturers can attract customers who value efficiency, flexibility, and creativity in their printing needs.

Additionally, the adoption of 4D printing in copiers could lead to new business models and revenue streams. For instance, manufacturers could offer subscription-based services that provide access to a library of customizable media templates or designs. This would allow users to easily create personalized prints without the need for specialized design software or skills.

Furthermore, the integration of 4D printing in copiers may also drive innovation in the paper industry. As copiers become capable of handling a wider range of media, there will be a demand for new types of paper and materials that can be used with 4D printing technology. This could lead to the development of specialized papers with enhanced properties, such as heat resistance, flexibility, or even interactive features.

The impact of 4D printing on copier paper handling and customizable media support is poised to revolutionize the industry. The integration of 4D printing technology enables copiers to achieve enhanced efficiency, productivity, and versatility in paper handling. Additionally, the ability to support customizable media opens up new creative and practical applications. Overall, this technology presents opportunities for copier manufacturers to differentiate themselves and drive innovation in the industry.

The Rise of 4D Printing Technology

Over the past few years, 3D printing has revolutionized various industries by allowing the creation of three-dimensional objects from digital designs. However, a new technology called 4D printing is now emerging, which takes this innovation to a whole new level. Unlike traditional 3D printing, 4D printing enables objects to self-assemble or change shape over time in response to external stimuli such as heat, light, or moisture.

While 4D printing is still in its early stages, researchers and engineers are already exploring its potential applications in a wide range of fields, including medicine, aerospace, and architecture. However, one area that is often overlooked is its impact on copier paper handling and customizable media support.

Enhancing Copier Paper Handling

Traditionally, copiers have been limited to printing on standard sizes of paper, such as letter or legal. However, with the of 4D printing, copiers can now handle a much wider range of media sizes and shapes. This opens up new possibilities for businesses and individuals who require customized printing solutions.

Imagine being able to print on irregularly shaped paper or even create 3D objects directly from the copier. With 4D printing technology, this becomes a reality. Copiers equipped with 4D printing capabilities can adapt to the shape and size of the media being used, providing a more versatile and flexible printing experience.

Furthermore, 4D printing enables copiers to print on materials other than paper. This means that copiers can now handle media such as fabric, plastic, or even metal. This opens up a whole new world of possibilities for printing customized objects, such as clothing, accessories, or even functional prototypes.

Customizable Media Support

Another exciting aspect of 4D printing technology is its ability to support customizable media. With traditional copiers, users are limited to printing on pre-made media, such as blank sheets of paper or pre-cut labels. However, with 4D printing, users can now create their own media on-demand.

For example, imagine being able to print a label with a specific shape or texture directly from your copier. With 4D printing, this is possible. By utilizing materials that can change shape or texture when exposed to certain stimuli, copiers can now create media that is tailored to the user’s needs.

This opens up a whole new range of possibilities for businesses and individuals. Companies can now create custom packaging or labels that enhance their brand identity or product experience. Individuals can design and print their own unique stationery or personalized gifts.

Future Implications

As 4D printing technology continues to evolve, its impact on copier paper handling and customizable media support is likely to become even more significant. The ability to print on a wide range of materials and shapes will revolutionize the way we think about printing and open up new possibilities for customization and personalization.

In the future, we may see a shift towards more versatile and adaptable copiers that can handle a variety of media types and sizes. This could lead to a reduction in waste as users can print on-demand and create media that perfectly suits their needs.

Additionally, the integration of 4D printing technology into copiers could lead to new business opportunities. Companies that specialize in customized printing solutions may emerge, offering unique and innovative services to meet the growing demand for personalized products.

The emergence of 4D printing technology is set to revolutionize copier paper handling and customizable media support. With the ability to print on a wider range of materials and shapes, copiers equipped with 4D printing capabilities will provide users with more versatile and flexible printing solutions. This opens up new possibilities for customization and personalization, while also potentially reducing waste and creating new business opportunities. The future of copier technology is undoubtedly exciting, and 4D printing is at the forefront of this innovation.

The Evolution of Copier Paper Handling

Copier paper handling has come a long way since the early days of photocopying. With the advent of 4D printing technology, the impact on copier paper handling has been significant. Traditional copiers were limited to handling standard-sized paper, typically 8.5 x 11 inches. However, 4D printing has opened up new possibilities for customizable media support.

One of the key benefits of 4D printing in copier paper handling is the ability to print on a wide range of media sizes and types. This means that copiers can now handle larger paper sizes, such as A3 or even poster-sized prints. Additionally, 4D printing allows for the printing of custom shapes and designs, enabling copiers to handle media with irregular shapes or cutouts.

For example, imagine a copier that can print directly onto a die-cut business card or a custom-shaped invitation. This level of customization was not possible with traditional copiers, but with 4D printing, it becomes a reality. This opens up new opportunities for businesses to create unique marketing materials or personalized communications.

Furthermore, 4D printing enables copiers to handle a wider range of media types. Traditional copiers were limited to handling standard paper weights and finishes. However, with 4D printing, copiers can now print on various media, such as cardstock, glossy paper, or even fabric. This allows for greater flexibility in creating different types of printed materials.

The Benefits of Customizable Media Support

The of customizable media support through 4D printing has several benefits for businesses and individuals alike. Firstly, it allows for greater creativity and personalization in printed materials. Whether it’s creating unique wedding invitations, custom packaging, or branded promotional materials, customizable media support opens up a world of possibilities.

Additionally, customizable media support can enhance the user experience. Imagine receiving a brochure with a pop-up section or a business card with a built-in USB drive. These interactive elements not only capture attention but also provide a memorable experience for the recipient. With 4D printing, copiers can now handle the printing of such media, making it easier for businesses to create engaging and interactive materials.

Moreover, customizable media support can also lead to cost savings. In the past, businesses often had to outsource specialized printing needs, such as printing on non-standard media or creating custom die-cut designs. This could be time-consuming and expensive. However, with 4D printing and copiers that support customizable media, businesses can now handle these printing needs in-house, saving both time and money.

Case Study: Customizable Media Support in the Advertising Industry

To further illustrate the impact of 4D printing on copier paper handling and customizable media support, let’s consider a case study in the advertising industry. A marketing agency was tasked with creating a promotional campaign for a new product launch. They wanted to create eye-catching materials that would stand out from the competition.

Using traditional copiers, the agency would have been limited to printing on standard paper with standard sizes. However, with 4D printing technology, they were able to print on a variety of media, including metallic paper, textured cardstock, and even fabric. This allowed them to create unique brochures, posters, and banners that caught the attention of their target audience.

Furthermore, the agency utilized customizable media support to create interactive elements in their printed materials. They printed brochures with fold-out sections that revealed additional product information, as well as business cards with embedded NFC chips that directed recipients to a digital landing page. These interactive elements not only increased engagement but also helped track the effectiveness of the campaign.

By leveraging the benefits of 4D printing and customizable media support, the marketing agency was able to create a memorable and impactful promotional campaign that exceeded their client’s expectations. This case study demonstrates the transformative power of 4D printing on copier paper handling and customizable media support in real-world scenarios.

Challenges and Limitations

While the impact of 4D printing on copier paper handling and customizable media support is undoubtedly significant, it is important to acknowledge the challenges and limitations that come with this technology. One of the main challenges is the cost associated with 4D printing. The equipment and materials required for 4D printing can be expensive, making it less accessible for small businesses or individuals.

Additionally, the learning curve for utilizing 4D printing technology can be steep. It requires a certain level of expertise and technical knowledge to operate and maintain the equipment effectively. This can be a barrier for businesses or individuals who do not have the resources or expertise to invest in 4D printing technology.

Furthermore, the availability of compatible media and materials for 4D printing can also be a limitation. While traditional copiers can handle a wide range of standard paper sizes and types, the same cannot be said for 4D printing. Finding suitable media and materials for 4D printing may require additional research and sourcing.

Despite these challenges and limitations, the ongoing advancements in 4D printing technology are expected to address some of these issues, making it more accessible and user-friendly in the future.

The Future of Copier Paper Handling

Looking ahead, the future of copier paper handling is undoubtedly intertwined with the continued development of 4D printing technology. As 4D printing becomes more accessible and affordable, copiers will be able to handle an even wider range of media sizes, shapes, and types.

With advancements in materials science, we can expect copiers to handle media made from unconventional materials, such as biodegradable plastics or even edible paper. This opens up new possibilities for sustainable printing practices and innovative applications.

Furthermore, the integration of Internet of Things (IoT) technology with copiers and 4D printers can lead to enhanced functionality and automation. Imagine a copier that automatically adjusts its paper handling settings based on the media type or size detected. This would streamline the printing process and reduce the risk of errors.

The impact of 4D printing on copier paper handling and customizable media support is transformative. It allows for greater creativity, personalization, and interactivity in printed materials. While there are challenges and limitations, the ongoing advancements in 4D printing technology hold promise for the future of copier paper handling.

to 4D Printing

4D printing is an emerging technology that takes 3D printing to the next level by adding the dimension of time. It involves creating objects that can self-assemble or change shape over time in response to external stimuli, such as heat, light, or moisture. This innovative approach has the potential to revolutionize various industries, including copier paper handling and customizable media support.

Enhanced Paper Handling

One of the key areas where 4D printing can have a significant impact is in copier paper handling. Traditional copiers rely on complex mechanical systems to feed and handle paper, which can sometimes lead to jams, misalignment, or other issues. However, with 4D printing, it becomes possible to create paper that can adapt and optimize its own handling.

By incorporating shape memory polymers into the paper, it can be engineered to change its shape or size when exposed to specific conditions. For example, the paper could be designed to curl or fold itself in a predetermined manner when heated, allowing it to navigate through the copier more smoothly. This self-adaptive behavior can greatly reduce the occurrence of paper jams and improve overall copier efficiency.

Customizable Media Support

Another exciting aspect of 4D printing in copier technology is its potential to support customizable media. Traditional copiers are limited to handling standard paper sizes and types, but with 4D printing, the possibilities are expanded. By incorporating smart materials into the media, it becomes possible to create paper that can transform its properties to suit different printing needs.

For instance, 4D printed paper could be designed to change its color, texture, or transparency when exposed to specific stimuli. This opens up new opportunities for personalized printing, allowing users to create dynamic documents with interactive elements. Imagine a business presentation where charts and graphs come to life, or a children’s book where the illustrations change as the story unfolds. The ability to customize media in this way can enhance the user experience and open up new avenues for creative expression.

Challenges and Considerations

While the potential benefits of 4D printing in copier paper handling and customizable media support are exciting, there are several challenges and considerations that need to be addressed.

Firstly, the development of 4D printing materials that are compatible with copier technology is still in its early stages. Researchers need to find materials that can withstand the rigors of copier processes, such as high temperatures and pressure, without compromising their self-adaptive properties.

Additionally, there is a need for standardization in 4D printing processes and file formats to ensure compatibility across different copier models and manufacturers. This will require collaboration and industry-wide efforts to establish common standards and protocols.

Furthermore, the cost of 4D printing technology and materials is currently higher compared to traditional copier systems. As the technology matures and scales up, it is expected that costs will decrease, making it more accessible to a wider range of users.

The impact of 4D printing on copier paper handling and customizable media support holds great promise for the future. By leveraging the self-adaptive properties of 4D printed materials, copiers can become more efficient and reliable, reducing the occurrence of paper jams and improving overall user experience. The ability to customize media opens up new possibilities for creative expression and personalized printing. While there are challenges to overcome, continued research and development in this field will pave the way for exciting advancements in copier technology.

Case Study 1: 4D Printing Revolutionizes Copier Paper Handling

In this case study, we explore how 4D printing technology has revolutionized copier paper handling in a large office setting. XYZ Corporation, a multinational company with over 5,000 employees, faced significant challenges in managing their copier paper supply and distribution system.

Prior to implementing 4D printing, XYZ Corporation relied on traditional paper handling methods, which involved manually restocking copiers with paper and monitoring paper levels. This process was time-consuming, prone to errors, and often resulted in copiers running out of paper during critical moments.

To address these issues, XYZ Corporation partnered with a leading 4D printing company to develop a customized solution. The 4D printing technology allowed for the creation of “smart” paper trays that could automatically detect paper levels and reorder supplies when necessary.

With the new system in place, XYZ Corporation experienced a significant reduction in paper-related disruptions. The smart paper trays ensured that copiers were always adequately stocked, eliminating the need for manual intervention. This not only improved employee productivity but also reduced paper waste and associated costs.

Case Study 2: Customizable Media Support Enhances Advertising Campaign

In this case study, we examine how 4D printing’s customizable media support capabilities were leveraged to enhance an advertising campaign for a leading fashion brand. FashionCo, a renowned clothing company, wanted to create a unique and interactive experience for its customers.

Prior to 4D printing, FashionCo’s advertising campaigns relied on traditional print media, such as billboards and posters. While effective to some extent, these static advertisements lacked the ability to engage customers on a deeper level.

To overcome this limitation, FashionCo collaborated with a 4D printing company to develop dynamic and interactive advertising materials. Using 4D printing technology, FashionCo was able to create customized posters that could change their appearance based on environmental factors such as temperature, humidity, or light intensity.

The customizable media support provided by 4D printing allowed FashionCo to create eye-catching advertisements that captured the attention of passersby. The dynamic nature of the posters sparked curiosity and encouraged people to interact with them, resulting in increased brand awareness and foot traffic to FashionCo stores.

Case Study 3: 4D Printing Enables Personalized Stationery

In this case study, we explore how 4D printing has enabled the production of personalized stationery, offering individuals a unique and customized writing experience. StationeryCo, a small business specializing in personalized stationery, faced challenges in meeting the diverse demands of its customers.

Prior to adopting 4D printing technology, StationeryCo relied on traditional printing methods, which limited their ability to offer personalized options. Customers had to choose from a limited range of designs and customization options.

By integrating 4D printing into their production process, StationeryCo was able to offer a wide range of customizable options to their customers. The technology enabled the creation of stationery that could change color, texture, or even shape based on individual preferences.

The of personalized 4D printed stationery was met with great enthusiasm by customers. They appreciated the ability to have unique and one-of-a-kind stationery that reflected their personality and style. This not only increased customer satisfaction but also boosted sales for StationeryCo.

The Origins of 4D Printing

The concept of 4D printing, also known as programmable matter, can be traced back to the early 1990s when the Massachusetts Institute of Technology (MIT) began exploring the idea of self-assembling materials. Researchers at MIT envisioned a future where objects could change their shape and functionality autonomously.

It wasn’t until 2013 that the term “4D printing” was coined by Skylar Tibbits, a researcher at MIT’s Self-Assembly Lab. Tibbits defined 4D printing as the process of creating objects that can self-transform over time with the help of external stimuli, such as heat, water, or light.

Early Applications and Limitations

In the early stages, 4D printing was primarily used in the fields of architecture and design. One of the first notable projects was the creation of self-assembling furniture that could adapt to different spaces. This early experimentation showcased the potential of 4D printing to revolutionize manufacturing processes.

However, there were several limitations to overcome. The materials used in early 4D printing were often limited to shape-memory polymers, which could only achieve simple transformations. Additionally, the printing process itself was time-consuming and required precise control of external stimuli.

Advancements in Material Science

Over time, advancements in material science have expanded the possibilities of 4D printing. Researchers have developed new materials with complex properties, such as hydrogels and shape-changing alloys. These materials enable more intricate and sophisticated transformations, allowing for the creation of complex structures.

For example, hydrogels can be programmed to respond to specific environmental conditions, such as changes in temperature or pH levels. This opens up new avenues for applications in fields like medicine, where 4D-printed implants could adapt to the patient’s body over time.

Integration with Other Technologies

Another significant development in the evolution of 4D printing is its integration with other emerging technologies. By combining 4D printing with robotics, artificial intelligence, and sensors, researchers are pushing the boundaries of what is possible.

For instance, researchers at the University of Colorado Boulder have developed a self-folding origami robot that can be 3D printed and then transform into a functional machine without human intervention. This integration of 4D printing with robotics showcases the potential for autonomous manufacturing processes.

Current State and Future Potential

Today, 4D printing is still in its early stages, but the technology holds immense potential across various industries. The ability to create objects that can adapt, self-repair, or respond to their environment has implications for fields such as aerospace, healthcare, and consumer products.

In the context of copier paper handling and customizable media support, 4D printing could revolutionize the way we interact with printed materials. Imagine a future where paper can fold itself into origami shapes or change its texture to enhance visual or tactile experiences.

However, there are still challenges to overcome. The cost of 4D printing remains high, and the scalability of the technology for mass production is yet to be fully realized. Additionally, ethical considerations regarding the potential misuse of self-transforming objects need to be addressed.

Despite these challenges, the evolution of 4D printing has shown great promise. As researchers continue to push the boundaries of material science and integrate 4D printing with other technologies, we can expect to see even more groundbreaking applications in the years to come.

FAQs

1. What is 4D printing?

4D printing is an emerging technology that goes beyond 3D printing. It involves the creation of objects that can change their shape or behavior over time in response to external stimuli like heat, light, or humidity.

2. How does 4D printing impact copier paper handling?

4D printing has the potential to revolutionize copier paper handling. With 4D printed paper, it can be programmed to fold itself into different shapes, making it easier to handle and store. This can greatly improve efficiency in paper-intensive environments like offices and print shops.

3. Can 4D printing be used to create customizable media support?

Yes, 4D printing allows for the creation of customizable media support. This means that the media support, such as trays and holders, can be designed to adapt to different sizes and shapes of paper or other media. It provides flexibility and convenience for users.

4. How does 4D printing benefit copier paper handling?

4D printing offers several benefits for copier paper handling. It allows for the creation of self-folding paper, reducing the need for manual folding and making it easier to handle and organize. It also enables the creation of customizable media support, providing a tailored solution for different paper sizes and types.

5. Can 4D printed paper be used in regular printers and copiers?

At present, 4D printed paper is still in the experimental stage and not widely available for use in regular printers and copiers. However, as the technology advances, it is possible that 4D printed paper may become compatible with standard printing and copying equipment.

6. Are there any limitations to 4D printing in copier paper handling?

While 4D printing shows great promise in copier paper handling, there are some limitations to consider. The technology is still in its early stages, and the materials used for 4D printing may have limitations in terms of durability and cost-effectiveness. Additionally, integrating 4D printing into existing copier systems may require modifications or upgrades.

7. How does 4D printing impact paper waste?

4D printing has the potential to reduce paper waste in copier systems. By using self-folding paper, it can minimize the need for manual folding, which often leads to creases and discarded paper. Additionally, customizable media support can help optimize paper usage by accommodating different sizes and shapes.

8. What are the potential applications of 4D printing in copier paper handling?

4D printing can have various applications in copier paper handling. It can be used to create self-organizing paper trays that adapt to different paper sizes, reducing the need for multiple trays. It can also enable the creation of self-folding envelopes or packaging materials, streamlining mailing processes.

9. Can 4D printing be used for other media besides paper?

Yes, 4D printing can be used for other media besides paper. It has the potential to be applied to materials like plastics, textiles, and even metals. This opens up possibilities for customizable media support in a wide range of industries beyond copier paper handling.

10. When can we expect to see 4D printing widely implemented in copier paper handling?

It is difficult to predict the exact timeline for the widespread implementation of 4D printing in copier paper handling. The technology is still in the research and development phase, and further advancements are needed to overcome the current limitations. However, as the technology progresses, we can expect to see more applications of 4D printing in various industries, including copier paper handling.

Concept 1: 4D Printing

4D printing is an advanced technology that takes 3D printing to the next level. While 3D printing allows us to create three-dimensional objects by adding layers of material, 4D printing adds an extra dimension of time. This means that the printed object can change its shape or properties over time in response to certain conditions.

Imagine if you could print an object that could assemble itself or adapt to different environments without any human intervention. That’s the power of 4D printing. It opens up a whole new world of possibilities in various industries, including medicine, construction, and even paper handling.

Concept 2: Copier Paper Handling

When we talk about copier paper handling, we’re referring to the process of how paper is fed into a copier or printer, moved through the machine, and then outputted with the printed information. This may seem like a simple task, but it can be quite complex, especially when dealing with different paper sizes, weights, and types.

Traditionally, copiers and printers are designed to handle a specific range of paper sizes and types. For example, a copier may be able to handle letter-sized (8.5 x 11 inches) or legal-sized (8.5 x 14 inches) paper, but not larger sizes like tabloid (11 x 17 inches). Similarly, some printers may struggle with thicker or specialty papers, causing paper jams or misfeeds.

With the integration of 4D printing technology, copier paper handling can be greatly improved. Imagine a copier that can automatically adjust its paper handling mechanisms to accommodate any paper size or type. Whether you need to print on standard copy paper, glossy photo paper, or even cardstock, the copier can adapt to handle it effortlessly. This not only saves time and reduces frustration but also expands the possibilities for creative printing projects.

Concept 3: Customizable Media Support

Customizable media support refers to the ability of a copier or printer to adapt its printing process to different media types. Media, in this context, refers to the material onto which the printer applies ink or toner to create a printed image or text. In traditional printing, this is usually paper, but it can also include materials like fabric, plastic, or even metal.

When it comes to printing on different media, there are often limitations. For example, a regular printer may not be able to print on fabric because the ink would bleed or the material would get damaged. Similarly, printing on plastic or metal may require specialized equipment and techniques.

However, with the advancements in 4D printing, copiers and printers can now offer customizable media support. This means that they can adapt their printing process to work with various media types, opening up a wide range of creative possibilities. Whether you want to print your favorite photo on a canvas, create personalized stickers, or even print on unconventional materials like wood or glass, a copier with customizable media support can make it happen.

Common Misconceptions about

Misconception 1: 4D printing will make copier paper obsolete

One common misconception about the impact of 4D printing on copier paper handling is that it will render copier paper obsolete. While 4D printing does offer exciting possibilities for customization and media support, it is important to understand that copier paper still serves a vital role in many industries and everyday life.

Copier paper continues to be widely used for various purposes such as printing documents, reports, and forms. It remains a cost-effective and convenient medium for everyday printing needs. While 4D printing may introduce new possibilities for customized media, it is unlikely to completely replace the need for copier paper.

Furthermore, copier paper is often used in situations where quick and disposable printing is required. In these cases, the simplicity and accessibility of copier paper make it a preferred choice over more complex 4D printing processes.

Misconception 2: 4D printing will be too expensive for widespread adoption

Another misconception is that 4D printing will be too expensive for widespread adoption, particularly in the context of copier paper handling. While it is true that 4D printing technologies are still in their early stages and can be costly, it is important to consider the potential long-term benefits and advancements that can drive down costs.

As with any emerging technology, the initial costs are often higher due to research, development, and limited production volumes. However, as 4D printing becomes more widely adopted and integrated into various industries, economies of scale are likely to come into play, making it more affordable for businesses and individuals alike.

Additionally, advancements in materials and manufacturing processes can contribute to cost reductions. Researchers and engineers are constantly exploring new ways to optimize 4D printing techniques, which can lead to more efficient and cost-effective production methods.

Misconception 3: 4D printing will eliminate the need for manual paper handling

Some people believe that 4D printing will completely eliminate the need for manual paper handling, making it a fully automated process. While 4D printing does offer the potential for automation and customization, it is important to recognize that manual paper handling will still be necessary in many situations.

4D printing primarily focuses on the ability to create objects that can change shape or properties over time. While this has exciting implications for customizable media support, it does not negate the need for manual paper handling in various industries and applications.

For example, in office environments, there will still be a need for employees to handle physical copies of documents, sign papers, or distribute printed materials. Additionally, in industries such as packaging and shipping, manual paper handling will continue to be essential for labeling, sorting, and organizing printed materials.

Furthermore, manual paper handling can often provide a more tactile and immediate experience, which may be preferred in certain situations. While 4D printing can offer new possibilities, it is unlikely to completely replace the human element in paper handling.

Conclusion

The emergence of 4D printing technology has the potential to revolutionize copier paper handling and customizable media support. This innovative technology allows for the creation of dynamic and responsive materials that can adapt to various printing needs. The key benefits of 4D printing in this context include enhanced paper handling capabilities, reduced paper jams, and improved overall printing efficiency.

Furthermore, the ability to customize media support using 4D printing opens up a world of possibilities for businesses and individuals. With this technology, it is now possible to create media supports that perfectly fit the shape and size of different objects, ensuring a seamless printing experience. This customization also extends to the creation of unique textures and patterns on media supports, adding a new level of personalization to printed materials.

While 4D printing is still in its early stages, the potential applications for copier paper handling and customizable media support are vast. As the technology continues to advance, we can expect to see further improvements in efficiency, cost-effectiveness, and customization options. The integration of 4D printing into the printing industry has the potential to transform the way we handle paper and create printed materials, opening up new possibilities for businesses and individuals alike.