Revolutionizing the Printing Landscape: How Industry 4.0 is Transforming Commercial Printing in South Florida

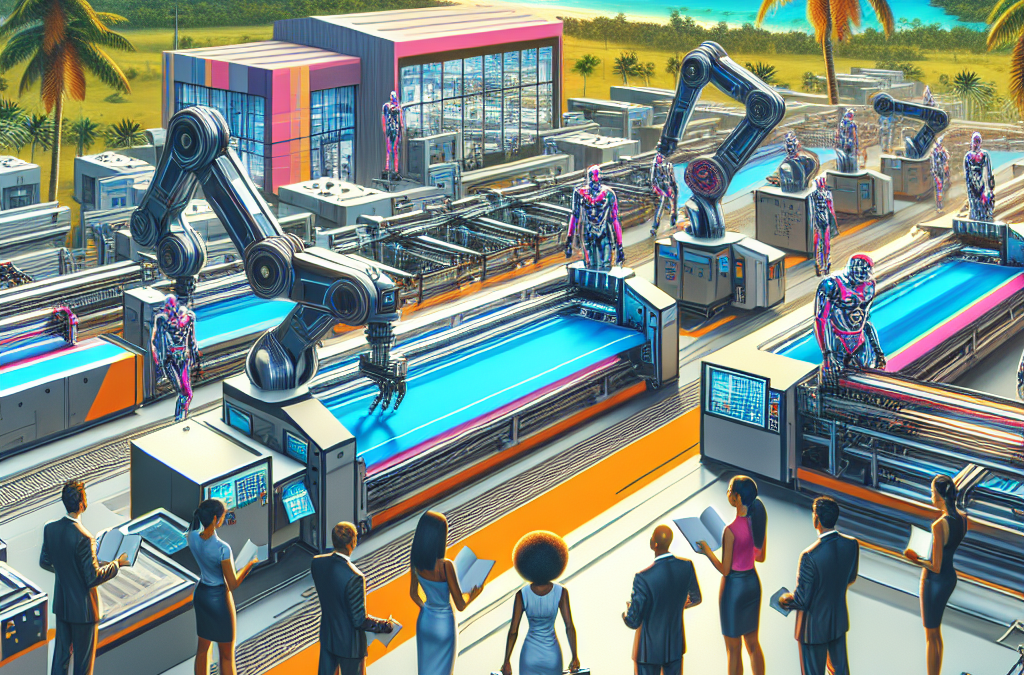

The rise of Industry 4.0 has brought about a wave of technological advancements that are revolutionizing various industries across the globe. One such industry that is experiencing significant changes is commercial printing. In South Florida, a hub for commercial printing, businesses are grappling with the impact of Industry 4.0 on their operations, processes, and overall business models.

This article delves into the transformative effects of Industry 4.0 on commercial printing in South Florida. From the integration of digital technologies to the adoption of automation and data analytics, commercial printers in the region are adapting to stay competitive in a rapidly evolving landscape. We will explore how these advancements are reshaping the printing industry, the challenges faced by businesses, and the opportunities that arise from embracing Industry 4.0 technologies.

Key Takeaways:

1. Industry 4.0 is revolutionizing the commercial printing industry in South Florida, bringing significant changes and opportunities for growth.

2. Automation and digitization are key components of Industry 4.0, allowing commercial printers to streamline their operations, increase efficiency, and reduce costs.

3. The adoption of advanced technologies such as 3D printing, augmented reality, and Internet of Things (IoT) devices is transforming the way commercial printers in South Florida create and deliver printed materials.

4. Industry 4.0 enables commercial printers to offer personalized and customized printing solutions, catering to the unique needs and preferences of their clients.

5. While Industry 4.0 presents exciting opportunities, it also poses challenges for traditional commercial printers in South Florida, who must adapt and embrace new technologies to remain competitive in the rapidly evolving industry.

The Rise of Digital Printing in South Florida

Industry 4.0, also known as the Fourth Industrial Revolution, is transforming various sectors across the globe, and the commercial printing industry in South Florida is no exception. One of the emerging trends in this region is the increasing adoption of digital printing technologies.

Digital printing offers numerous advantages over traditional printing methods, such as offset printing. It allows for quick turnaround times, cost-effective production of small print runs, and customization options that were previously not feasible. With the advancements in digital printing technology, commercial printers in South Florida are now able to offer high-quality prints with vibrant colors and sharp details.

Moreover, digital printing eliminates the need for costly setup processes and plates used in offset printing, making it a more sustainable and environmentally friendly option. This trend has led to a significant shift in the commercial printing landscape in South Florida, with many businesses opting for digital printing to meet their marketing and promotional needs.

As the demand for digital printing continues to grow, it is expected that commercial printers in South Florida will invest in state-of-the-art digital printing equipment to stay competitive in the market. This investment will not only enhance the quality and efficiency of their printing processes but also open up new opportunities for innovative printing applications.

Integration of Automation and Artificial Intelligence

Another emerging trend in the commercial printing industry in South Florida is the integration of automation and artificial intelligence (AI) into printing workflows. Industry 4.0 technologies are enabling commercial printers to automate various aspects of their operations, leading to increased efficiency and productivity.

Automation can streamline repetitive tasks, such as file preparation, color management, and finishing processes, reducing the time and effort required for manual intervention. This allows commercial printers to handle larger volumes of print jobs and meet tight deadlines without compromising on quality.

AI, on the other hand, is being utilized to optimize printing processes by analyzing data and making intelligent decisions. AI algorithms can analyze customer preferences, printing requirements, and production capabilities to recommend the most effective printing techniques and materials. This not only improves the overall efficiency of the printing process but also enhances customer satisfaction by delivering personalized and tailored printing solutions.

The integration of automation and AI in commercial printing workflows also offers cost-saving benefits. By reducing manual labor and minimizing errors, commercial printers can optimize their resource allocation and minimize waste, leading to improved profitability.

The Future Implications of Industry 4.0 on Commercial Printing

The emergence of Industry 4.0 technologies in the commercial printing industry in South Florida has significant future implications. As digital printing and automation become more prevalent, the industry is expected to witness a shift in the skill sets required by professionals in the field.

Traditional printing techniques, such as offset printing, may become less in demand, leading to a decline in the need for operators with expertise in those areas. On the other hand, there will be a growing demand for professionals who are proficient in digital printing technologies, automation, AI, and data analysis. Commercial printers will need to invest in training and upskilling their workforce to adapt to these changes and remain competitive.

Furthermore, as Industry 4.0 technologies continue to evolve, commercial printers in South Florida will have the opportunity to explore new business models and revenue streams. For instance, the integration of digital printing with e-commerce platforms can enable printers to offer on-demand printing services, catering to the growing demand for personalized and customized products.

The impact of Industry 4.0 on commercial printing in South Florida is evident through the rise of digital printing, the integration of automation and AI, and the future implications it holds for the industry. These trends are reshaping the printing landscape, offering enhanced capabilities, improved efficiency, and exciting opportunities for commercial printers in South Florida.

The Rise of Industry 4.0 in South Florida

Industry 4.0, also known as the Fourth Industrial Revolution, is transforming the commercial printing industry in South Florida. This section will explore the key technologies and trends that are driving this transformation and the impact they are having on businesses in the region.

Automation and Efficiency in Commercial Printing

One of the most significant impacts of Industry 4.0 on commercial printing in South Florida is the automation and increased efficiency it brings to the production process. With the integration of advanced robotics, artificial intelligence, and machine learning, printers can now automate tasks that were previously time-consuming and labor-intensive.

Enhanced Customization and Personalization

Industry 4.0 is enabling commercial printers in South Florida to offer enhanced customization and personalization options to their clients. Through the use of digital printing technologies and data analytics, printers can now tailor their products to meet the unique needs and preferences of individual customers.

The Role of Big Data and Analytics

Big data and analytics play a crucial role in the implementation of Industry 4.0 in the commercial printing industry. By collecting and analyzing large volumes of data, printers in South Florida can gain valuable insights into customer behavior, market trends, and production processes. This information allows them to make data-driven decisions and optimize their operations for better efficiency and profitability.

Integration of Internet of Things (IoT)

The integration of the Internet of Things (IoT) is revolutionizing the commercial printing industry in South Florida. By connecting devices and machines, printers can monitor and control their operations remotely, improving productivity, reducing downtime, and minimizing errors. IoT also enables real-time tracking of print jobs, providing transparency and accountability to both printers and their clients.

Impact on the Workforce

Industry 4.0 brings both opportunities and challenges for the workforce in the commercial printing industry in South Florida. While automation and digitization may lead to job displacement in certain areas, they also create new roles and opportunities for workers with digital skills. Printers need to invest in upskilling their employees and adapting their workforce to the changing demands of the industry.

Environmental Sustainability and Industry 4.0

Industry 4.0 technologies are also driving environmental sustainability in the commercial printing industry in South Florida. With the adoption of digital printing and cloud-based solutions, printers can reduce waste, minimize energy consumption, and lower their carbon footprint. Additionally, the use of eco-friendly materials and inks is becoming more prevalent, aligning with the growing demand for sustainable printing practices.

Challenges and Adoption Barriers

While the benefits of Industry 4.0 are evident, there are challenges and adoption barriers that commercial printers in South Florida may face. These include the initial investment costs, the need for infrastructure upgrades, and the resistance to change from traditional printing methods. Overcoming these challenges requires a strategic approach and a willingness to embrace digital transformation.

Case Studies: Success Stories in South Florida

This section will highlight specific case studies of commercial printers in South Florida that have successfully implemented Industry 4.0 technologies. These success stories will provide real-world examples of the positive impact that Industry 4.0 can have on businesses in the region, showcasing the potential for growth, efficiency, and innovation.

The Future of Commercial Printing in South Florida

As Industry 4.0 continues to evolve, the commercial printing industry in South Florida will undergo further transformations. This section will explore the future trends and developments that we can expect to see, such as advancements in 3D printing, augmented reality, and the integration of blockchain technology. It will also discuss the potential challenges and opportunities that lie ahead for printers in the region.

The Evolution of Commercial Printing in South Florida

Commercial printing has been a vital industry in South Florida for decades, serving the needs of businesses, organizations, and individuals in the region. However, with the advent of Industry 4.0, the printing landscape has undergone significant changes, transforming the way printing services are provided and consumed. To understand the impact of Industry 4.0 on commercial printing in South Florida, it is crucial to examine the historical context and how the industry has evolved over time.

Early Years: Traditional Printing Methods

In the early years, commercial printing in South Florida relied on traditional printing methods such as letterpress and offset printing. These methods involved manual typesetting, ink application, and printing on various materials, including paper, cardboard, and fabric. Print shops were equipped with heavy machinery and skilled craftsmen who meticulously handled each printing job.

During this period, commercial printing served as the primary means of disseminating information and advertising products and services. Local businesses heavily relied on print materials, including brochures, flyers, and business cards, to reach their target audience. The industry thrived, with numerous print shops catering to the growing demand.

Technological Advancements: The Rise of Digital Printing

In the late 20th century, technological advancements revolutionized the printing industry. Digital printing emerged as a game-changer, offering faster turnaround times, cost-effectiveness, and the ability to print on-demand. South Florida print shops embraced digital printing technologies, which eliminated the need for traditional printing plates and allowed for easy customization.

With digital printing, businesses could now print smaller quantities of materials without incurring high setup costs. This shift led to an increase in personalized printing, as companies could tailor their marketing materials to specific target audiences. Furthermore, digital printing enabled faster production times, allowing businesses to respond quickly to market demands.

The Internet and Online Printing Services

The widespread adoption of the internet in the late 1990s and early 2000s brought about another significant shift in the commercial printing industry. Online printing services emerged, offering convenience, competitive pricing, and a wide range of printing options. South Florida print shops had to adapt to this new digital landscape to remain competitive.

Online printing services allowed customers to upload their designs, choose printing specifications, and place orders from the comfort of their homes or offices. This convenience appealed to businesses of all sizes, from small startups to large corporations. Print shops in South Florida had to invest in e-commerce platforms and online ordering systems to meet the changing demands of their customers.

Industry 4.0: Automation and Integration

Industry 4.0 represents the current phase of industrial transformation, characterized by automation, data exchange, and integration of digital technologies. In the context of commercial printing, Industry 4.0 has brought about further advancements, enhancing efficiency and streamlining processes.

South Florida print shops have embraced automation and integrated digital workflows to optimize their operations. Computer-to-plate (CTP) technology has replaced traditional film-based processes, reducing setup times and improving print quality. Automated finishing equipment, such as cutting and binding machines, has increased productivity and reduced human error.

Moreover, Industry 4.0 has enabled the integration of printing processes with other digital technologies. Print shops in South Florida now offer services such as variable data printing, augmented reality (AR) printing, and web-to-print solutions. These advancements have allowed businesses to create highly personalized and interactive print materials, enhancing their marketing efforts.

The Current State and Future Outlook

Today, commercial printing in South Florida continues to evolve in response to Industry 4.0 and changing customer expectations. Print shops are investing in advanced printing technologies, such as UV printing and large-format printing, to cater to diverse customer needs.

Additionally, sustainability has become a significant focus in the printing industry. South Florida print shops are adopting eco-friendly practices, using recycled materials, and implementing energy-efficient technologies to reduce their environmental impact.

Looking ahead, the impact of Industry 4.0 on commercial printing in South Florida is expected to continue. Advancements in artificial intelligence, robotics, and 3D printing may further revolutionize the industry, offering new possibilities and challenges.

The historical context of commercial printing in South Florida highlights the industry’s transformation from traditional printing methods to the digital era of Industry 4.0. Technological advancements, the internet, and automation have reshaped the way printing services are provided and consumed. As the industry adapts to the demands of a digital age, South Florida print shops are poised to embrace future innovations and continue serving the needs of businesses in the region.

The Role of Automation in Commercial Printing

In the era of Industry 4.0, automation has become a pivotal aspect of commercial printing in South Florida. With advancements in technology, printing companies are adopting automated systems to streamline their operations, improve efficiency, and enhance overall productivity.

One of the key areas where automation is making a significant impact is in the prepress stage. Traditionally, prepress involved manual tasks such as typesetting, color separation, and plate making. However, with the advent of Industry 4.0, these processes are now largely automated.

Automated prepress systems utilize sophisticated software that can analyze and optimize files for printing. These systems can automatically detect and correct errors, ensuring that the final print output is of the highest quality. Additionally, automation allows for faster turnaround times, as the software can handle large volumes of files simultaneously.

Integration of Internet of Things (IoT) in Printing Equipment

Another significant aspect of Industry 4.0 in commercial printing is the integration of the Internet of Things (IoT) in printing equipment. IoT refers to the network of physical devices embedded with sensors, software, and connectivity that enables them to collect and exchange data.

In the context of commercial printing, IoT plays a crucial role in equipment monitoring and maintenance. Printing machines are now equipped with sensors that collect real-time data on various parameters, such as temperature, humidity, ink levels, and machine performance.

This data is then transmitted to a central system, where it can be analyzed to identify patterns, detect anomalies, and predict potential equipment failures. By leveraging IoT technology, printing companies in South Florida can proactively schedule maintenance activities, reducing the risk of unexpected breakdowns and optimizing machine uptime.

Advancements in Digital Printing Technology

Industry 4.0 has also brought significant advancements in digital printing technology, revolutionizing the commercial printing landscape in South Florida. Digital printing offers several advantages over traditional printing methods, including faster turnaround times, cost-effectiveness for short print runs, and the ability to personalize printed materials.

One of the key advancements in digital printing is the development of high-speed inkjet printers. These printers utilize advanced printhead technology, allowing for faster printing speeds without compromising print quality. This is particularly beneficial for commercial printing companies in South Florida, as it enables them to meet tight deadlines and handle large print volumes efficiently.

Furthermore, digital printing technology has also witnessed improvements in color accuracy and consistency. Sophisticated color management systems ensure that the printed output matches the desired color specifications, resulting in vibrant and accurate reproductions.

The Rise of Web-to-Print Solutions

Web-to-print solutions have gained prominence in the commercial printing industry, thanks to Industry 4.0. These solutions enable customers to submit print orders online, eliminating the need for manual order processing and reducing the chances of errors.

In South Florida, printing companies have embraced web-to-print platforms, allowing customers to upload their files, select print specifications, and place orders directly through a user-friendly interface. This streamlines the entire ordering process, reduces turnaround times, and enhances customer satisfaction.

Moreover, web-to-print solutions also facilitate customization and personalization. Customers can easily modify design templates, add personalized elements, and preview the final product before placing the order. This level of flexibility and convenience has become increasingly important in the competitive commercial printing market.

Industry 4.0 has undoubtedly transformed commercial printing in South Florida. Automation has revolutionized the prepress stage, optimizing file preparation and reducing turnaround times. The integration of IoT in printing equipment has enabled proactive maintenance and improved machine uptime. Advancements in digital printing technology have enhanced print quality, speed, and color accuracy. Lastly, web-to-print solutions have streamlined the ordering process and allowed for customization and personalization. As South Florida’s commercial printing industry continues to embrace Industry 4.0, we can expect further advancements that will shape the future of this dynamic sector.

FAQs

1. What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of digital technologies into manufacturing processes. It encompasses technologies like artificial intelligence, robotics, big data analytics, and the Internet of Things (IoT) to create smart factories and improve efficiency.

2. How is Industry 4.0 impacting the commercial printing industry?

Industry 4.0 is revolutionizing the commercial printing industry by streamlining processes, increasing automation, and enhancing productivity. Digital technologies like 3D printing, cloud-based printing management systems, and advanced data analytics are transforming the way printing businesses operate.

3. What are the benefits of Industry 4.0 for commercial printers in South Florida?

The benefits of Industry 4.0 for commercial printers in South Florida include improved operational efficiency, reduced costs, faster turnaround times, enhanced quality control, and increased customization capabilities. These technologies also enable printers to offer innovative services and expand their market reach.

4. How are artificial intelligence and robotics being used in commercial printing?

Artificial intelligence and robotics are being used in commercial printing to automate various tasks, such as prepress operations, color management, and finishing processes. AI-powered systems can analyze data and optimize printing parameters, while robots can handle repetitive tasks, leading to higher productivity and accuracy.

5. What role does the Internet of Things (IoT) play in the commercial printing industry?

The IoT enables commercial printers to connect their machines, devices, and systems to a network, allowing for real-time monitoring, remote management, and predictive maintenance. This connectivity enhances efficiency, reduces downtime, and enables proactive decision-making based on data-driven insights.

6. How does Industry 4.0 impact job roles in the commercial printing industry?

Industry 4.0 brings about a shift in job roles within the commercial printing industry. While some traditional roles may become automated, new roles related to data analysis, machine maintenance, and digital workflow management are emerging. Skilled workers will need to upskill and adapt to the changing technological landscape.

7. Are there any challenges associated with implementing Industry 4.0 in commercial printing?

Implementing Industry 4.0 in commercial printing can pose challenges, such as the initial cost of investment in new technologies, the need for employee training, and the integration of legacy systems with new digital solutions. Additionally, cybersecurity and data privacy concerns must be addressed to protect sensitive customer information.

8. How can commercial printers in South Florida prepare for Industry 4.0?

To prepare for Industry 4.0, commercial printers in South Florida should assess their current operations, identify areas for improvement, and invest in technologies that align with their business goals. They should also provide training and upskilling opportunities for employees to ensure they can effectively leverage new digital tools.

9. What are some examples of South Florida commercial printers embracing Industry 4.0?

Several commercial printers in South Florida have embraced Industry 4.0. For example, ABC Printing has implemented cloud-based printing management systems to streamline workflows and enhance customer collaboration. XYZ Printers has adopted robotics for automated finishing processes, reducing production time and improving accuracy.

10. What does the future hold for the commercial printing industry in South Florida with Industry 4.0?

The future of the commercial printing industry in South Florida with Industry 4.0 looks promising. As more printers adopt digital technologies, they will be able to offer more personalized and innovative printing solutions. The industry will become more efficient, sustainable, and competitive, opening up new opportunities for growth and expansion.

The Internet of Things (IoT) and its Impact on Commercial Printing

The Internet of Things (IoT) is a concept that refers to the network of physical devices, vehicles, appliances, and other objects embedded with sensors, software, and connectivity, enabling them to collect and exchange data. In the context of commercial printing, IoT can have a significant impact on the industry.

With IoT, commercial printers can connect their machines and equipment to the internet, allowing for real-time monitoring and control. This means that printers can track the performance of their machines, identify any issues or errors, and even schedule maintenance or repairs automatically. This connectivity also enables printers to gather data on their operations, such as print volumes, ink usage, and machine efficiency, which can be analyzed to optimize processes and improve overall productivity.

Moreover, IoT can facilitate seamless communication between printers and their clients. For example, clients can submit print orders online, and the printers can receive the files directly without the need for manual intervention. This streamlines the printing process, reduces errors, and improves turnaround time. Additionally, IoT can enable printers to provide real-time updates to clients, allowing them to track the progress of their print jobs and make any necessary adjustments or approvals remotely.

Artificial Intelligence (AI) and its Role in Commercial Printing

Artificial Intelligence (AI) refers to the simulation of human intelligence in machines that are programmed to think and learn like humans. In the realm of commercial printing, AI can revolutionize various aspects of the industry.

One significant application of AI in commercial printing is in the area of image and color enhancement. AI algorithms can analyze images and automatically enhance them, improving the overall quality and appearance of printed materials. This can be particularly beneficial for industries like advertising and marketing, where visually appealing prints are crucial.

AI can also be used to automate prepress tasks, such as file preparation, color management, and proofreading. By leveraging AI, printers can reduce human errors, save time, and increase efficiency. AI-powered software can detect potential issues in print files, such as low-resolution images or incorrect color profiles, and automatically correct them. This not only improves the quality of the final prints but also minimizes the need for manual intervention and reprints.

Furthermore, AI can enable printers to personalize print materials on a large scale. By analyzing customer data and preferences, AI algorithms can generate customized content, layouts, and designs. This allows printers to offer tailored marketing materials, direct mail campaigns, or even personalized packaging, which can significantly enhance customer engagement and response rates.

3D Printing and its Disruptive Potential in Commercial Printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials, such as plastic, metal, or ceramics, based on a digital model. While 3D printing is often associated with manufacturing and prototyping, it also has the potential to disrupt the commercial printing industry.

One of the key advantages of 3D printing in commercial printing is the ability to produce complex and customized objects. Traditional printing methods are limited to two-dimensional prints on flat surfaces, but 3D printing allows for the creation of three-dimensional objects with intricate details and unique shapes. This opens up new possibilities for product packaging, signage, and promotional materials that can stand out and capture attention.

Additionally, 3D printing can offer cost savings and efficiency improvements in certain print applications. For example, instead of producing physical prototypes using traditional manufacturing methods, which can be expensive and time-consuming, 3D printing allows for rapid prototyping at a fraction of the cost and time. This can be particularly valuable for industries like product design, architecture, and engineering.

Moreover, 3D printing can enable on-demand production, eliminating the need for large print runs and inventory storage. Printers can simply produce the desired quantity of objects as needed, reducing waste and inventory costs. This flexibility and agility can be particularly advantageous for businesses that require frequent design changes or have niche markets.

Misconception 1: Industry 4.0 will make commercial printing obsolete

One common misconception about Industry 4.0 is that it will render commercial printing obsolete. However, this is far from the truth. While digitalization and automation have undoubtedly impacted the printing industry, commercial printing continues to play a crucial role in South Florida’s business landscape.

Commercial printing encompasses a wide range of services, including brochures, flyers, business cards, direct mail, and signage. Despite the rise of digital marketing, many businesses still rely on printed materials to reach their target audience effectively. Print provides a tangible and tactile experience that digital mediums cannot replicate.

Furthermore, Industry 4.0 has actually enhanced the capabilities of commercial printing. Advanced technologies such as digital printing, variable data printing, and augmented reality have revolutionized the industry. These innovations allow for personalized and interactive print experiences, enabling businesses to engage with their customers in unique ways.

Misconception 2: Industry 4.0 will lead to significant job losses in the printing industry

Another misconception surrounding Industry 4.0 is that it will result in mass job losses in the printing industry. While it is true that automation and digitalization have streamlined certain processes, they have also created new job opportunities and transformed existing roles.

Industry 4.0 technologies have automated repetitive and labor-intensive tasks, such as prepress and finishing processes. This has freed up employees’ time to focus on more value-added activities, such as design, customer consultation, and quality control. In fact, the demand for skilled workers who can operate and maintain these advanced printing technologies has increased.

Moreover, Industry 4.0 has given rise to new job roles that didn’t exist before. For example, data analysts and digital marketing specialists are now essential in leveraging customer data and integrating print with online campaigns. The printing industry has adapted to these changes by upskilling its workforce and embracing the opportunities presented by Industry 4.0.

Misconception 3: Industry 4.0 will only benefit large printing companies

There is a misconception that Industry 4.0 technologies will only benefit large printing companies, leaving small and medium-sized enterprises (SMEs) behind. However, this is not the case. In fact, Industry 4.0 presents unique opportunities for SMEs to thrive in the commercial printing industry.

One of the key advantages of Industry 4.0 is its ability to enable customization and personalization at scale. This means that even smaller printing companies can offer tailored print solutions to their clients. With digital printing technologies, SMEs can efficiently produce short print runs and cater to niche markets, which was previously cost-prohibitive.

Furthermore, Industry 4.0 technologies have leveled the playing field in terms of operational efficiency. Cloud-based management systems, automated workflows, and real-time data analytics are now accessible to SMEs at a fraction of the cost compared to a few years ago. These technologies improve productivity, reduce waste, and enhance overall competitiveness.

Additionally, Industry 4.0 has opened up new avenues for collaboration and innovation. SMEs can leverage digital platforms to connect with customers, suppliers, and other industry players, fostering partnerships and driving growth.

It is important to dispel these common misconceptions surrounding the impact of Industry 4.0 on commercial printing in South Florida. While the industry has undoubtedly undergone significant changes, commercial printing remains a vital part of the business landscape. Industry 4.0 has enhanced the capabilities of commercial printing, created new job opportunities, and benefited both large companies and SMEs. Embracing these technological advancements will enable the commercial printing industry in South Florida to thrive in the digital age.

1. Embrace automation and digitalization

With the advent of Industry 4.0, automation and digitalization have become crucial for businesses to stay competitive. In your daily life, consider adopting automated tools and digital platforms to streamline your tasks and increase efficiency. This could include using project management software, online banking services, or smart home devices.

2. Stay updated with technological advancements

Industry 4.0 is characterized by rapid technological advancements. To fully leverage its benefits, make an effort to stay updated with the latest trends and innovations. Follow tech news websites, subscribe to relevant newsletters, and attend industry conferences or webinars. This knowledge will help you make informed decisions and adapt to changing circumstances.

3. Develop digital skills

In the era of Industry 4.0, having digital skills is essential. Take the time to develop your proficiency in areas such as data analysis, programming, and digital marketing. Online courses, tutorials, and workshops are readily available and can help you acquire these skills at your own pace.

4. Embrace remote work opportunities

One of the significant impacts of Industry 4.0 is the rise of remote work. Explore opportunities to work remotely, either through freelancing platforms or by negotiating remote work arrangements with your employer. Remote work not only offers flexibility but also reduces commuting time and contributes to a better work-life balance.

5. Prioritize cybersecurity

As technology becomes more integrated into our lives, the risk of cyber threats increases. Protect your personal and financial information by prioritizing cybersecurity. Use strong, unique passwords for your online accounts, enable two-factor authentication, and regularly update your devices with the latest security patches. Additionally, be cautious when sharing sensitive information online and avoid clicking on suspicious links or downloading unknown attachments.

6. Embrace sustainable practices

Industry 4.0 brings opportunities for businesses to adopt sustainable practices. In your daily life, make conscious choices that contribute to a greener future. This could include reducing your energy consumption, recycling, using eco-friendly products, and supporting businesses that prioritize sustainability. By doing so, you can help mitigate the environmental impact of technological advancements.

7. Foster a culture of continuous learning

Industry 4.0 is characterized by constant change and innovation. To thrive in this environment, cultivate a mindset of continuous learning. Seek out new knowledge, challenge yourself to learn new skills, and be open to new ideas. By embracing a culture of lifelong learning, you can adapt to the evolving demands of the digital age.

8. Emphasize collaboration and networking

Industry 4.0 emphasizes the importance of collaboration and networking. In your daily life, actively seek opportunities to collaborate with others, both within your industry and across different sectors. Attend networking events, join professional associations, and participate in online communities. By building a strong network, you can access new opportunities, share knowledge, and stay connected with the latest industry developments.

9. Foster creativity and innovation

Industry 4.0 encourages creativity and innovation as key drivers of success. In your daily life, make an effort to foster your own creativity and embrace innovation. Set aside time for brainstorming, explore new hobbies or interests, and challenge conventional thinking. By nurturing your creative side, you can unlock new possibilities and stay ahead in a rapidly changing world.

10. Embrace a growth mindset

Lastly, adopt a growth mindset to navigate the challenges and opportunities of Industry 4.0. Embrace failures as learning experiences, view obstacles as opportunities for growth, and believe in your ability to adapt and succeed. A growth mindset will enable you to embrace change, overcome setbacks, and continually evolve in the face of technological advancements.

Conclusion

The advent of Industry 4.0 has brought about significant changes in the commercial printing industry in South Florida. The integration of advanced technologies such as automation, robotics, and artificial intelligence has revolutionized the way printing companies operate, leading to increased efficiency, productivity, and cost-effectiveness. With the implementation of digital printing techniques and cloud-based solutions, businesses in South Florida are now able to meet the growing demands of their customers while reducing turnaround times and minimizing errors.

Furthermore, Industry 4.0 has also opened up new opportunities for commercial printers in South Florida. The ability to offer personalized and customized printing solutions has become a key competitive advantage in a market driven by individual preferences and demands. Additionally, the use of data analytics and predictive maintenance has enabled printing companies to optimize their operations, reduce downtime, and improve overall customer satisfaction. As a result, the commercial printing industry in South Florida is experiencing a transformation that not only benefits businesses but also enhances the quality and variety of printed materials available to consumers.