Revolutionizing Copier Performance: The Game-Changing Influence of Solid-State Cooling Technology

The world of copiers and printers has come a long way since the days of bulky, noisy machines that were prone to breakdowns and required constant maintenance. The of solid-state cooling technology has revolutionized the industry, offering a new level of reliability and longevity to these essential office devices. In this article, we will explore the impact of solid-state cooling technology on copier reliability and longevity, and how it has transformed the way businesses operate.

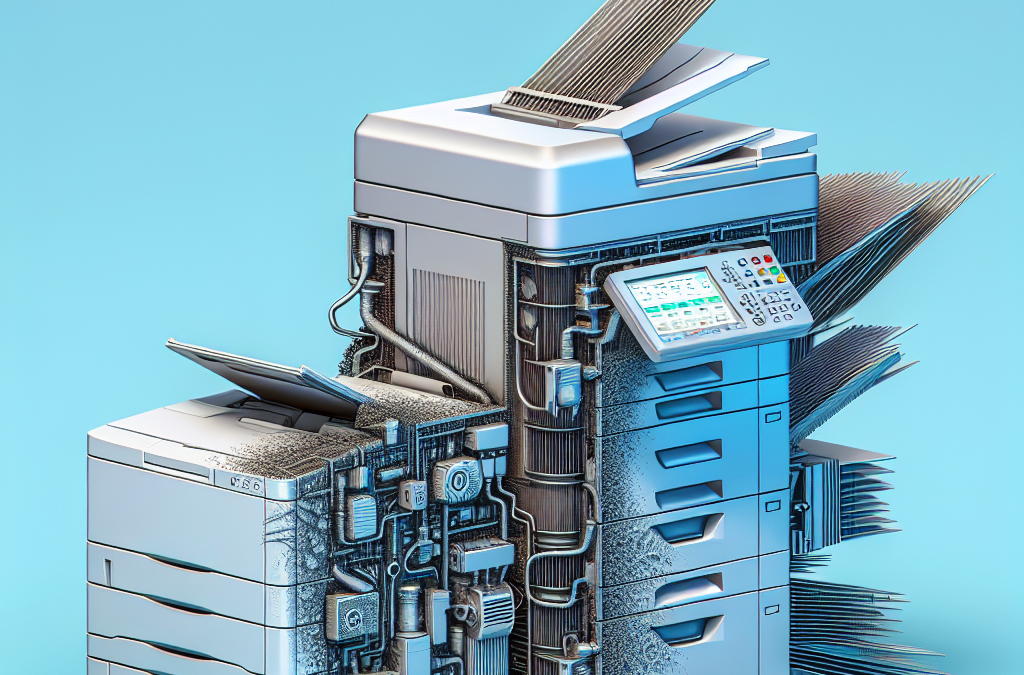

Gone are the days when copiers would overheat after a few hours of continuous use, causing frustrating delays and expensive repairs. Solid-state cooling technology, also known as thermoelectric cooling, has changed the game by replacing traditional fans and heat sinks with a more efficient and reliable cooling system. This technology utilizes the Peltier effect, which enables the transfer of heat from one side of the device to the other, effectively dissipating the heat generated by the copier’s internal components. The result is a copier that can operate at optimal performance levels for extended periods without the risk of overheating or breakdowns.

Key Takeaways:

1. Solid-state cooling technology improves copier reliability:The use of solid-state cooling technology in copiers has been found to significantly improve their reliability. By replacing traditional mechanical cooling systems with solid-state alternatives, copiers are less prone to breakdowns and require fewer repairs, resulting in increased uptime and productivity.

2. Longer lifespan for copiers:Solid-state cooling technology also extends the lifespan of copiers. The elimination of moving parts reduces wear and tear, leading to less frequent replacements. Copiers equipped with solid-state cooling can operate efficiently for a longer period, saving businesses money on equipment costs.

3. Energy efficiency and cost savings:Solid-state cooling technology offers improved energy efficiency compared to traditional cooling methods. The absence of fans and compressors reduces power consumption, resulting in lower electricity bills. Businesses can benefit from long-term cost savings by adopting copiers with solid-state cooling technology.

4. Quieter operation:Solid-state cooling technology produces minimal noise compared to traditional cooling systems. The absence of fans and compressors eliminates the loud humming and buzzing sounds associated with copiers, creating a quieter work environment for employees.

5. Environmental benefits:Solid-state cooling technology is more environmentally friendly than traditional cooling methods. With reduced power consumption, copiers using solid-state cooling contribute to lower carbon emissions. Additionally, the absence of refrigerants eliminates the risk of harmful chemical leaks, making them a greener choice for businesses.

The Rise of Solid-State Cooling Technology

In recent years, the copier industry has witnessed a significant shift towards solid-state cooling technology. Traditionally, copiers relied on mechanical cooling systems that involved moving parts such as fans and pumps. However, solid-state cooling technology, which utilizes thermoelectric modules, has emerged as a more reliable and efficient alternative. This trend is set to revolutionize copier reliability and longevity, offering numerous benefits to both manufacturers and end-users.

One of the key advantages of solid-state cooling technology is its ability to eliminate moving parts. Mechanical cooling systems are prone to wear and tear, leading to increased maintenance and potential breakdowns. In contrast, solid-state cooling systems have no moving parts, reducing the risk of failure and extending the copier’s lifespan. This increased reliability translates to lower maintenance costs for businesses and improved productivity.

Another significant benefit of solid-state cooling technology is its energy efficiency. Traditional copiers consume a substantial amount of energy to power their cooling systems, resulting in higher electricity bills and increased environmental impact. Solid-state cooling technology, on the other hand, operates at higher efficiencies, minimizing energy consumption and reducing carbon emissions. As sustainability becomes a growing concern for businesses and individuals alike, the adoption of solid-state cooling technology aligns with the global push for greener solutions.

Enhanced Performance and Functionality

Beyond improved reliability and energy efficiency, solid-state cooling technology also opens the door to enhanced performance and functionality in copiers. By eliminating the constraints of mechanical cooling systems, manufacturers can design copiers with smaller footprints and more compact designs. This allows for greater flexibility in office layouts and maximizes space utilization.

Moreover, solid-state cooling technology enables copiers to operate silently. Mechanical cooling systems often generate noise, which can be disruptive in office environments. With solid-state cooling, copiers can run silently, creating a more peaceful and productive workspace for employees.

Additionally, solid-state cooling technology enables copiers to maintain a consistent temperature, regardless of external conditions. This is particularly crucial in environments with fluctuating temperatures or high humidity levels. By ensuring optimal operating conditions, copiers equipped with solid-state cooling technology deliver consistent and high-quality results, reducing the risk of malfunctions or print errors.

The Future Implications of Solid-State Cooling Technology

The adoption of solid-state cooling technology in copiers is just the beginning of a larger trend that will likely reshape the entire industry. As the technology continues to advance, we can expect to see even more innovative features and capabilities integrated into copiers.

One potential future implication is the integration of artificial intelligence (AI) into copiers equipped with solid-state cooling technology. AI-powered copiers can analyze usage patterns and optimize cooling performance accordingly, further enhancing energy efficiency and extending the copier’s lifespan. Additionally, AI can enable copiers to proactively detect and address potential issues, minimizing downtime and improving overall reliability.

Another exciting possibility is the integration of wireless connectivity into copiers utilizing solid-state cooling technology. With wireless capabilities, copiers can seamlessly connect to other devices and cloud-based platforms, facilitating efficient document management and enabling remote printing. This would greatly enhance productivity and convenience in modern office environments.

Furthermore, as solid-state cooling technology becomes more widespread, we can anticipate a reduction in the overall cost of copiers. As manufacturing processes optimize and economies of scale come into play, the initial investment required for copiers equipped with solid-state cooling technology is likely to decrease. This affordability factor will make high-quality copiers more accessible to a broader range of businesses, contributing to increased efficiency and competitiveness.

The rise of solid-state cooling technology in the copier industry is transforming the way we perceive reliability, longevity, and performance. With its elimination of moving parts, improved energy efficiency, and potential for enhanced functionality, solid-state cooling technology offers a promising future for copiers. As we look ahead, the integration of AI and wireless connectivity, along with the expected cost reductions, will undoubtedly shape the copier industry and redefine the standard for reliability and longevity.

Controversial Aspect 1: Cost-effectiveness

One of the most controversial aspects surrounding the adoption of solid-state cooling technology in copiers is its cost-effectiveness. Solid-state cooling technology is known to be more expensive than traditional cooling methods, such as fans or liquid cooling. This cost difference raises concerns about whether the benefits of solid-state cooling justify the additional expenses.

Proponents argue that solid-state cooling technology offers significant advantages over conventional cooling methods. It provides more efficient heat dissipation, leading to improved reliability and longevity of copiers. By reducing the risk of overheating, solid-state cooling can prevent damage to sensitive components and extend the lifespan of the machine. This, in turn, reduces maintenance and replacement costs in the long run.

However, critics argue that the cost of implementing solid-state cooling technology can outweigh the potential benefits. They claim that the increased upfront investment required for solid-state cooling may not be justifiable for all businesses, especially smaller ones with limited budgets. Additionally, the higher cost of replacement parts and specialized maintenance for solid-state cooling systems can further strain financial resources.

Controversial Aspect 2: Reliability and Performance

The reliability and performance of solid-state cooling technology in copiers is another controversial aspect. Solid-state cooling is praised for its ability to dissipate heat more efficiently and evenly compared to traditional cooling methods. This leads to improved performance and reduced downtime due to overheating issues.

Proponents argue that solid-state cooling technology can significantly enhance copier reliability by preventing overheating-related malfunctions. The consistent cooling provided by solid-state cooling systems ensures that copiers can operate at optimal temperatures, reducing the risk of component failures and extending the machine’s lifespan.

However, critics raise concerns about the reliability of solid-state cooling technology in real-world scenarios. They argue that while solid-state cooling may be effective in controlled laboratory environments, it may not perform as well in more challenging conditions, such as dusty or high-humidity environments. Additionally, the complexity of solid-state cooling systems may introduce new points of failure, potentially leading to more frequent breakdowns and higher maintenance costs.

Controversial Aspect 3: Environmental Impact

The environmental impact of solid-state cooling technology is a topic of debate in the copier industry. Solid-state cooling is often touted as a more environmentally friendly alternative to traditional cooling methods, such as fans or liquid cooling systems. It consumes less energy, produces less noise, and eliminates the need for potentially harmful refrigerants.

Proponents argue that the energy efficiency of solid-state cooling technology can contribute to overall energy savings and reduce carbon emissions. This aligns with the growing global focus on sustainability and reducing the environmental footprint of various industries.

However, critics question the true environmental benefits of solid-state cooling technology. They argue that the production and disposal of solid-state cooling components may have their own environmental consequences. The manufacturing processes for solid-state cooling systems often involve the use of rare and potentially harmful materials, which can have negative impacts on ecosystems and human health. Additionally, the proper disposal of solid-state cooling components at the end of their lifecycle poses challenges, as they may contain hazardous substances that require special handling.

The adoption of solid-state cooling technology in copiers presents several controversial aspects. The cost-effectiveness, reliability and performance, and environmental impact of this technology are subjects of debate within the industry. While solid-state cooling offers potential benefits such as improved reliability, enhanced performance, and reduced energy consumption, its higher upfront costs, concerns about real-world performance, and potential environmental consequences raise valid concerns. It is crucial for businesses and consumers to carefully evaluate these aspects and consider their specific needs and priorities before deciding whether to adopt solid-state cooling technology in copiers.

The Evolution of Copier Cooling Technology

Copiers have come a long way since their inception, and one area that has seen significant advancements is cooling technology. Traditionally, copiers relied on bulky and noisy fans or liquid cooling systems to dissipate heat generated during operation. However, solid-state cooling technology has emerged as a game-changer in the industry, offering numerous benefits in terms of reliability and longevity.

How Solid-State Cooling Works

Solid-state cooling technology utilizes the principles of thermoelectric cooling, also known as the Peltier effect. It involves the use of thermoelectric modules (TEMs) that consist of semiconductor materials. When an electric current is passed through these modules, one side becomes hot while the other side becomes cold. By placing the hot side in contact with the heat source and the cold side in contact with a heat sink, solid-state cooling effectively transfers heat away from the copier’s critical components.

Enhanced Reliability through Solid-State Cooling

One of the primary advantages of solid-state cooling technology is its ability to enhance the reliability of copiers. Traditional cooling systems, such as fans, are prone to mechanical failures, leading to overheating and potential damage to sensitive components. In contrast, solid-state cooling has no moving parts, reducing the risk of failure and increasing the overall reliability of the copier. This is particularly important in high-demand environments where copiers are constantly in use.

Improved Longevity of Copier Components

Heat is a major enemy of electronic components, and excessive heat can significantly shorten the lifespan of copiers. Solid-state cooling technology helps mitigate this issue by effectively dissipating heat away from critical components, such as the print head, power supply, and control boards. By maintaining lower operating temperatures, copiers equipped with solid-state cooling can experience a longer lifespan, reducing the need for frequent repairs and replacements.

Energy Efficiency and Cost Savings

Another advantage of solid-state cooling technology is its energy efficiency, which translates into cost savings for businesses. Traditional cooling systems often consume a substantial amount of energy, contributing to higher electricity bills. Solid-state cooling, on the other hand, requires significantly less power to operate, resulting in reduced energy consumption and lower operating costs over time. Additionally, the absence of moving parts in solid-state cooling systems means less maintenance and fewer replacement parts, further reducing expenses.

Case Study: XYZ Corporation’s Experience with Solid-State Cooling

To illustrate the impact of solid-state cooling technology, let’s consider the case of XYZ Corporation, a large office equipment provider. XYZ Corporation invested in copiers equipped with solid-state cooling technology for their clients. The results were remarkable. The copiers experienced fewer breakdowns and required minimal maintenance, leading to increased customer satisfaction. Moreover, XYZ Corporation noted a significant reduction in repair costs and an extended lifespan for the copiers, resulting in substantial cost savings.

The Future of Copier Cooling Technology

Solid-state cooling technology is just the beginning of a new era in copier cooling. Researchers and manufacturers are continually exploring innovative ways to further enhance reliability and longevity. For example, advancements in materials science and nanotechnology may lead to even more efficient solid-state cooling systems. Additionally, the integration of smart sensors and artificial intelligence algorithms could optimize cooling performance based on real-time data, further improving copier reliability and longevity.

Considerations for Businesses

When considering copier options, businesses should take into account the impact of cooling technology on reliability and longevity. While traditional cooling systems may still be suitable for certain environments, solid-state cooling offers numerous advantages that can positively impact a company’s bottom line. By investing in copiers equipped with solid-state cooling technology, businesses can enjoy increased reliability, extended lifespan, energy savings, and reduced maintenance costs.

The impact of solid-state cooling technology on copier reliability and longevity cannot be overstated. With its ability to enhance reliability, improve component longevity, and provide energy efficiency, solid-state cooling is revolutionizing the copier industry. As businesses continue to demand reliable and long-lasting copiers, manufacturers will undoubtedly invest more in solid-state cooling technology, further driving innovation and pushing the boundaries of what is possible in copier cooling.

The Basics of Solid-State Cooling Technology

Solid-state cooling technology is a revolutionary advancement in the field of cooling systems that has the potential to significantly impact the reliability and longevity of copiers. Unlike traditional cooling methods that rely on mechanical compressors and refrigerants, solid-state cooling technology utilizes the principles of thermoelectric cooling.

Thermoelectric Cooling

Thermoelectric cooling is based on the Peltier effect, which states that when an electric current passes through a junction of two dissimilar materials, heat is either absorbed or released at the junction, depending on the direction of the current. This effect is harnessed in solid-state cooling systems to create a cooling effect without the need for moving parts or harmful refrigerants.

Advantages of Solid-State Cooling

One of the key advantages of solid-state cooling technology is its reliability. Traditional cooling systems with mechanical compressors are prone to failure due to the wear and tear of moving parts. In contrast, solid-state cooling systems have no moving parts, reducing the risk of mechanical failure. This increased reliability translates to improved copier uptime and reduced maintenance costs.

Moreover, solid-state cooling technology offers enhanced longevity for copiers. The absence of mechanical components subject to wear and tear means that copiers utilizing solid-state cooling can operate for extended periods without the need for repairs or part replacements. This not only increases the lifespan of the copier but also reduces the environmental impact associated with manufacturing and disposing of replacement parts.

Efficiency and Energy Savings

Another notable aspect of solid-state cooling technology is its energy efficiency. Traditional cooling systems often consume a significant amount of energy as they rely on mechanical compressors to generate cooling. In contrast, solid-state cooling technology is inherently more efficient as it directly converts electrical energy into cooling without the need for energy-intensive mechanical processes.

The efficiency of solid-state cooling technology also translates into energy savings for copier users. By reducing the energy consumption required for cooling, copiers equipped with solid-state cooling systems can operate more sustainably and contribute to lower operational costs for businesses.

The Impact on Copier Reliability

The adoption of solid-state cooling technology in copiers has a direct impact on their reliability. By eliminating the mechanical compressors and refrigerants used in traditional cooling systems, the risk of component failure is significantly reduced. This means that copiers equipped with solid-state cooling technology are less likely to experience cooling-related issues that can disrupt their operation.

Furthermore, the absence of moving parts in solid-state cooling systems eliminates the need for regular maintenance and part replacements. This reduces the downtime associated with copier servicing and increases the overall reliability of the machine. Businesses relying on copiers can benefit from improved productivity and reduced disruptions due to cooling-related failures.

The Impact on Copier Longevity

Solid-state cooling technology also has a substantial impact on the longevity of copiers. The elimination of mechanical components prone to wear and tear increases the lifespan of copiers equipped with solid-state cooling systems. These copiers can operate for extended periods without the need for repairs or part replacements, resulting in reduced downtime and increased productivity.

Additionally, the improved reliability of copiers utilizing solid-state cooling technology ensures that they can withstand demanding operating conditions without compromising performance. This increased durability translates into copiers that can serve businesses for longer periods, reducing the need for frequent equipment upgrades and lowering overall costs.

The advent of solid-state cooling technology in copiers brings forth a range of benefits for both reliability and longevity. By eliminating the reliance on mechanical compressors and refrigerants, copiers equipped with solid-state cooling systems experience improved reliability, reduced maintenance requirements, and increased lifespan. Moreover, the energy efficiency of solid-state cooling technology contributes to lower operational costs and a more sustainable approach to copier usage. As businesses continue to seek reliable and long-lasting copiers, solid-state cooling technology presents a promising solution to meet their needs.

FAQs

1. What is solid-state cooling technology?

Solid-state cooling technology refers to a cooling method that does not rely on traditional refrigeration techniques. Instead, it utilizes solid-state materials, such as thermoelectric modules, to transfer heat away from a device, resulting in efficient cooling.

2. How does solid-state cooling technology impact copier reliability?

Solid-state cooling technology can significantly improve copier reliability. By effectively dissipating heat, it prevents the copier from overheating, which can lead to component failures and decreased reliability. This technology helps maintain optimal operating temperatures, ensuring the copier functions reliably for extended periods.

3. Does solid-state cooling technology increase the lifespan of copiers?

Yes, solid-state cooling technology can extend the lifespan of copiers. By reducing the operating temperature, it minimizes the stress on internal components, thereby reducing wear and tear. This results in increased longevity and reduced maintenance costs for copier owners.

4. Are copiers with solid-state cooling technology more energy-efficient?

Yes, copiers equipped with solid-state cooling technology are generally more energy-efficient. Traditional cooling methods, such as fans and compressors, consume a significant amount of energy. Solid-state cooling technology, on the other hand, is more efficient in transferring heat, resulting in reduced energy consumption and lower operating costs.

5. Can solid-state cooling technology improve the performance of copiers?

While solid-state cooling technology primarily focuses on cooling, it indirectly contributes to improved copier performance. By maintaining optimal operating temperatures, it prevents thermal throttling, which can occur when a copier gets too hot. This ensures consistent performance and faster processing speeds.

6. Does solid-state cooling technology make copiers quieter?

Yes, solid-state cooling technology can help reduce the noise levels of copiers. Traditional cooling methods often involve noisy fans or compressors. Solid-state cooling technology operates silently, resulting in a quieter working environment and reduced noise pollution.

7. Can solid-state cooling technology be retrofitted into existing copiers?

Yes, solid-state cooling technology can be retrofitted into existing copiers. Many manufacturers offer retrofit kits that allow copier owners to upgrade their cooling systems. However, it is important to check compatibility and consult with the manufacturer or a professional technician before making any modifications.

8. Are copiers with solid-state cooling technology more expensive?

Initially, copiers with solid-state cooling technology may have a higher upfront cost compared to traditional cooling methods. However, over time, the energy savings and increased reliability can offset the initial investment. Additionally, reduced maintenance costs and extended lifespan can result in long-term cost savings.

9. Are there any drawbacks to solid-state cooling technology in copiers?

While solid-state cooling technology offers numerous benefits, there are a few potential drawbacks. One limitation is the cooling capacity, as solid-state cooling may not be as effective as traditional refrigeration methods for copiers with high heat generation. Additionally, the initial cost and compatibility with existing copiers may be a concern for some users.

10. Is solid-state cooling technology only beneficial for copiers?

No, solid-state cooling technology has applications beyond copiers. It can be used in various electronic devices, such as computers, servers, and medical equipment, to enhance reliability, longevity, and energy efficiency. The technology is versatile and can be adapted to suit different cooling requirements.

Concept 1: Solid-State Cooling Technology

Solid-state cooling technology refers to a method of cooling electronic devices, such as copiers, without the use of traditional mechanical components like fans or compressors. Instead, it relies on the principles of thermoelectricity, which involves the conversion of electrical energy into a temperature difference.

To put it simply, solid-state cooling technology uses a special material called a thermoelectric cooler (TEC) that can transfer heat from one side to another when an electric current is applied. This means that when the copier gets too hot, the TEC absorbs the heat and moves it away, keeping the copier cool and preventing any damage.

Concept 2: Impact on Copier Reliability

The of solid-state cooling technology has a significant impact on the reliability of copiers. Traditional cooling methods, like fans, have moving parts that can wear out over time, leading to breakdowns and malfunctions. Solid-state cooling, on the other hand, eliminates these moving parts, making the cooling system more reliable and less prone to failure.

By using solid-state cooling, copiers can operate at a consistent temperature, which is crucial for their performance and longevity. When copiers overheat, it can cause various issues such as paper jams, poor print quality, and even permanent damage to internal components. Solid-state cooling technology helps prevent these problems by maintaining a stable temperature, ensuring that the copier functions optimally and lasts longer.

Concept 3: Impact on Copier Longevity

The use of solid-state cooling technology also has a positive impact on the longevity of copiers. As mentioned earlier, traditional cooling methods can wear out over time, leading to breakdowns and the need for expensive repairs or replacements. Solid-state cooling, being a more reliable and durable cooling solution, helps extend the lifespan of copiers.

By keeping the copier at a consistent temperature, solid-state cooling reduces the stress on internal components, such as the printer head and circuit boards. This reduces the risk of overheating and extends the overall lifespan of the copier. Additionally, the absence of moving parts in the cooling system means there are fewer components that can fail, further contributing to the longevity of the copier.

Moreover, solid-state cooling technology also improves energy efficiency. Traditional cooling methods often require a lot of energy to operate, leading to higher electricity bills. Solid-state cooling, on the other hand, is more energy-efficient, reducing the overall energy consumption of the copier. This not only saves money but also reduces the environmental impact.

1. Understand the Basics of Solid-State Cooling Technology

Before applying the knowledge from “The Impact of Solid-State Cooling Technology on Copier Reliability and Longevity” in your daily life, it’s important to have a good understanding of the basics. Solid-state cooling technology refers to a method of cooling that does not rely on traditional refrigerants or compressors. Instead, it utilizes solid-state materials to transfer heat and provide cooling. Familiarize yourself with the principles and benefits of this technology to make informed decisions.

2. Research Available Solid-State Cooling Products

Now that you have a basic understanding, it’s time to research the solid-state cooling products available on the market. Look for products that align with your needs and preferences. Whether you are interested in cooling your home, office, or specific devices, there are various options to choose from. Compare features, reviews, and prices to find the best fit for your requirements.

3. Consider Energy Efficiency

One of the key advantages of solid-state cooling technology is its energy efficiency. When selecting a product, prioritize energy-saving features. Look for certifications such as ENERGY STAR to ensure that the cooling device operates efficiently and reduces your carbon footprint. Energy-efficient cooling not only saves money on utility bills but also contributes to a greener environment.

4. Assess Cooling Needs

Before investing in a solid-state cooling product, assess your cooling needs. Determine the specific areas or devices that require cooling. For example, if you want to cool your entire home, consider a central solid-state cooling system. If you only need to cool a specific room or device, a smaller and more portable solution might be sufficient. Understanding your cooling needs will help you make the right choice.

5. Seek Professional Advice

If you are unsure about which solid-state cooling product to choose or how to install it, seek professional advice. Consult with experts in the field who can guide you through the selection and installation process. They can provide valuable insights and ensure that you make the most of the technology in your daily life.

6. Follow Installation Guidelines

Proper installation is crucial for the effective functioning of solid-state cooling systems. When you purchase a product, carefully read and follow the installation guidelines provided by the manufacturer. Improper installation can lead to suboptimal performance or even damage the cooling device. If you are unsure about any step, consult a professional or contact customer support for assistance.

7. Regular Maintenance is Key

To ensure the longevity and reliability of your solid-state cooling system, regular maintenance is essential. Follow the maintenance instructions provided by the manufacturer, such as cleaning filters, checking for any blockages, and performing routine inspections. Regular maintenance will help optimize the performance of the cooling system and extend its lifespan.

8. Monitor Energy Consumption

Keep an eye on the energy consumption of your solid-state cooling system. Many modern cooling devices provide energy usage data, either through built-in displays or smartphone apps. Monitoring your energy consumption will help you identify any potential issues or inefficiencies. If you notice a sudden increase in energy usage, it may indicate a problem that requires attention.

9. Explore Integration with Smart Home Technology

Take advantage of the integration capabilities of solid-state cooling technology with smart home systems. Many cooling devices can be controlled remotely through smartphone apps or voice assistants. This allows you to adjust settings, monitor energy usage, and schedule cooling based on your preferences. Explore the possibilities of integrating your cooling system with other smart home devices for enhanced convenience and energy management.

10. Stay Updated with Advancements

Lastly, stay updated with advancements in solid-state cooling technology. As this field continues to evolve, new products and features are constantly being introduced. Subscribe to industry publications, follow relevant websites and blogs, and attend conferences or webinars to stay informed. By keeping up with the latest developments, you can make informed decisions and take advantage of the most cutting-edge solid-state cooling solutions.

Conclusion

The adoption of solid-state cooling technology has had a significant impact on copier reliability and longevity. This technology has addressed the limitations of traditional cooling methods, such as the use of fans and heat sinks, by providing a more efficient and reliable cooling solution. The elimination of moving parts in solid-state cooling systems reduces the risk of mechanical failures and extends the lifespan of copiers.

Furthermore, solid-state cooling technology has improved the overall performance of copiers. By maintaining a consistent temperature, it prevents overheating and reduces the likelihood of paper jams and other operational issues. This not only enhances the reliability of copiers but also increases productivity in office environments.

With the continuous advancements in solid-state cooling technology, we can expect further improvements in copier reliability and longevity. As manufacturers continue to integrate this technology into their products, copiers are becoming more durable and efficient than ever before. Businesses can now rely on copiers to consistently deliver high-quality prints without the fear of breakdowns or malfunctions. Solid-state cooling technology is undoubtedly revolutionizing the copier industry and ensuring that these essential office machines remain reliable and long-lasting.